Maintaining a robust and reliable vehicle requires a thorough understanding of its components and systems. Whether you are an enthusiast or a casual driver, having access to detailed information can make all the difference in ensuring optimal performance and longevity. This resource aims to equip you with the necessary knowledge to tackle common issues and routine upkeep effectively.

Within this guide, you will discover essential insights into troubleshooting and enhancing your vehicle’s functionality. From addressing minor inconveniences to undertaking significant enhancements, every section is crafted to assist you in navigating the complexities of automotive care. By familiarizing yourself with various aspects of your machine, you can take proactive steps toward maintaining its condition.

Understanding the intricacies of your vehicle not only empowers you but also fosters a deeper appreciation for its engineering. As you explore the forthcoming topics, you will gain valuable skills that will aid you in preserving the reliability and safety of your cherished ride. Prepare to delve into a world of automotive expertise that will transform your approach to vehicle maintenance.

Understanding the Jeep Commander 2006

This section delves into the key aspects of a robust sport utility vehicle that has garnered attention for its blend of ruggedness and comfort. Designed to accommodate both off-road adventures and city driving, it represents a versatile choice for various lifestyles.

Key Features

- Spacious interior that comfortably seats multiple passengers.

- Advanced safety systems for enhanced protection on the road.

- Powerful engine options to tackle diverse terrains.

- Modern infotainment systems for connectivity and entertainment.

Performance Overview

- Impressive towing capacity, making it suitable for hauling trailers and other equipment.

- All-wheel drive capabilities for improved traction in challenging conditions.

- Fuel efficiency ratings that balance power and economy.

- Suspension designed for a smooth ride, whether on highways or off-road trails.

Understanding these aspects allows owners to maximize their experience with this versatile vehicle, ensuring both functionality and enjoyment in various driving scenarios.

Common Issues Faced by Owners

Many owners of this SUV encounter a range of challenges that can impact performance and comfort. Understanding these common problems can help in maintaining the vehicle and ensuring a smooth driving experience.

Electrical System Problems

One frequent issue involves the electrical system, where owners report malfunctions in lighting, battery drainage, and dashboard warning lights. These electrical failures can lead to unexpected behavior, making it essential to regularly check the battery and wiring connections.

Transmission and Drivetrain Concerns

Another area of concern is the transmission and drivetrain. Many drivers experience hard shifting, slipping, or unusual noises while driving. Regular fluid checks and timely maintenance are crucial to prevent significant repairs down the line.

Essential Tools for Repair Tasks

Having the right set of instruments is crucial for any maintenance or troubleshooting endeavor. A well-equipped workspace not only enhances efficiency but also ensures safety during the process. Below are some fundamental tools that every technician should consider when preparing for various tasks.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types, are essential for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips options in multiple sizes will cover most needs.

- Pliers: Needle-nose and standard pliers are vital for gripping and manipulating small components.

- Hammers: A ball-peen or rubber mallet can be helpful for driving or adjusting parts without causing damage.

Power Tools

- Drill: An electric or cordless drill is invaluable for creating holes or driving screws.

- Impact Wrench: This tool simplifies the process of removing stubborn bolts and nuts.

- Angle Grinder: Useful for cutting, grinding, and polishing metal surfaces.

- Rotary Tool: Versatile for detailed work such as sanding, engraving, or cutting.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your vehicle remains in optimal condition through regular upkeep. Following a systematic process can help extend the lifespan of your automobile and enhance its performance.

Here’s a structured outline for routine care:

-

Engine Oil Change

- Gather necessary tools and materials, including oil, filter, and wrench.

- Warm up the engine slightly to allow old oil to drain easily.

- Remove the oil drain plug and let the old oil flow out completely.

- Replace the oil filter and reattach the drain plug.

- Pour in new oil through the designated opening.

- Check the oil level with the dipstick.

-

Tire Inspection

- Examine tire pressure and inflate to recommended levels.

- Check for uneven wear and damage, including cuts or punctures.

- Rotate tires according to the manufacturer’s schedule.

-

Brake System Check

- Inspect brake pads for thickness; replace if worn.

- Examine brake fluid level and top off if necessary.

- Listen for unusual sounds while braking; investigate any abnormalities.

-

Battery Maintenance

- Inspect terminals for corrosion and clean as needed.

- Check the battery charge and replace if weak.

- Ensure all connections are secure to prevent issues.

-

Fluid Levels Check

- Regularly examine coolant, transmission fluid, and power steering fluid levels.

- Top off any fluids that are below the recommended levels.

Adhering to this guide will help maintain your vehicle’s reliability and safety. Regular inspections and timely interventions can save you from more significant issues down the line.

Engine Troubleshooting Techniques

Diagnosing issues within an automobile’s power unit can be a challenging yet essential task for maintaining optimal performance. Understanding the common signs of malfunction and employing systematic approaches can significantly enhance the troubleshooting process. This section outlines various techniques to identify and resolve engine-related problems efficiently.

Visual Inspection: Begin with a thorough visual examination of the engine compartment. Look for signs of leaks, loose connections, or worn components. This step can often reveal obvious problems that require immediate attention.

Listen for Unusual Noises: Engage the engine and pay attention to any irregular sounds such as knocking, hissing, or grinding. These noises can indicate specific issues like internal wear or exhaust leaks, guiding further investigation.

Monitor Engine Performance: Keep track of the vehicle’s performance, noting any unusual vibrations, reduced power, or stalling. A decline in performance may point to underlying mechanical issues or fuel system problems that need addressing.

Check Diagnostic Codes: Utilize an onboard diagnostic tool to retrieve trouble codes from the engine’s control unit. These codes provide valuable insights into potential faults and help pinpoint areas that require further examination.

Assess Fluid Levels: Regularly check oil, coolant, and other vital fluids. Low or contaminated fluids can lead to overheating or inadequate lubrication, which may contribute to engine failure if not corrected promptly.

Conduct Compression Tests: Performing compression tests on individual cylinders can help evaluate the internal condition of the engine. Low compression in one or more cylinders may indicate issues such as worn piston rings or valve problems.

Inspect the Fuel System: Examine fuel filters, injectors, and pumps for clogs or malfunctions. An improperly functioning fuel system can lead to poor engine performance and should be a focus during troubleshooting.

By employing these techniques, individuals can effectively diagnose and address issues within the engine, ensuring longevity and reliability. Regular maintenance and timely intervention are key to preventing more significant problems down the road.

Electrical System Diagnostics Explained

Understanding the intricacies of an automobile’s electrical framework is essential for ensuring optimal performance and safety. This section delves into the procedures and tools necessary for identifying and resolving issues within the electrical components of a vehicle.

Effective diagnosis relies on a systematic approach, which includes the following key steps:

- Visual Inspection: Begin with a thorough examination of wiring, connectors, and battery terminals. Look for signs of wear, corrosion, or loose connections.

- Utilizing Diagnostic Tools: Employ multimeters, scan tools, and oscilloscopes to measure voltage, current, and resistance. These instruments help pinpoint anomalies in the system.

- Checking Fuses and Relays: Inspect fuses and relays for continuity. Replace any that are blown or malfunctioning, as they can disrupt electrical flow.

- Testing Components: Methodically test individual components such as sensors, switches, and motors. This step is crucial in determining their functionality.

- Analyzing Codes: If equipped with an onboard diagnostic system, retrieve and analyze error codes. This information can provide insight into specific issues.

By following these steps, technicians can effectively troubleshoot and restore the integrity of the electrical system, ensuring the vehicle operates as intended. A proactive approach to diagnostics not only enhances performance but also extends the lifespan of the vehicle’s components.

Transmission Problems and Solutions

When dealing with transmission issues in vehicles, it’s essential to identify common symptoms and understand potential remedies. This section aims to highlight frequent complications that may arise, along with effective approaches for resolution.

Here are some typical transmission problems and their corresponding solutions:

- Slipping Gears:

- Check fluid levels and quality; low or contaminated fluid can cause slipping.

- Inspect for worn-out bands or clutches that may need adjustment or replacement.

- Delayed Engagement:

- Examine the transmission fluid for contamination or improper levels.

- Consider a thorough inspection of the valve body for blockages.

- Overheating:

- Ensure the cooling system is functioning correctly, as overheating can damage components.

- Replace the transmission cooler if it is clogged or malfunctioning.

- Unusual Noises:

- Listen for grinding or whining sounds, which may indicate low fluid or worn parts.

- Investigate the torque converter for potential faults.

- Warning Lights:

- Check the dashboard for warning indicators related to the transmission.

- Use a diagnostic tool to read trouble codes and determine specific issues.

Addressing these issues promptly can help maintain the vehicle’s performance and longevity. Regular maintenance checks can also prevent many of these complications from occurring.

Suspension System Overview and Care

The suspension system is a crucial component of any vehicle, designed to provide stability, comfort, and control while navigating various terrains. It plays a vital role in absorbing shocks from the road, enhancing ride quality, and ensuring proper tire contact with the surface. Understanding its mechanics and maintenance requirements is essential for prolonging its lifespan and optimizing performance.

Key Components of the Suspension System

| Component | Function |

|---|---|

| Shock Absorbers | Minimize bounce and stabilize the ride by controlling the movement of the springs. |

| Springs | Support the weight of the vehicle and absorb road shocks. |

| Control Arms | Connect the suspension to the vehicle’s frame and allow for up-and-down movement. |

| Ball Joints | Facilitate movement between the control arms and the wheel assembly. |

Maintenance Tips

- Inspect shock absorbers for leaks or wear regularly.

- Check for unusual noises while driving, which may indicate a problem.

- Keep an eye on tire wear patterns, as they can signal suspension issues.

- Schedule alignment checks periodically, especially after significant impacts.

By maintaining the suspension system, drivers can enhance their vehicle’s handling and comfort, leading to a safer and more enjoyable driving experience.

Brake System Repair Essentials

The braking mechanism is a critical component of any vehicle, ensuring safety and control during operation. Proper maintenance and timely intervention can prevent more significant issues and enhance overall performance.

Diagnosis is the first step in addressing braking issues. Listen for unusual noises and observe any changes in pedal feel or responsiveness. If you notice squeaking, grinding, or a spongy pedal, it may indicate that the system requires attention.

Next, inspecting the components is essential. Check the brake pads for wear, as they are subject to significant friction. Rotors should also be evaluated for signs of warping or scoring. Additionally, examine the brake lines for leaks or cracks, as hydraulic integrity is crucial for effective braking.

Replacing worn components is a vital part of maintenance. When installing new pads, ensure they are compatible with your system. Similarly, if rotors need to be changed, consider upgrading to performance variants for improved handling. Always follow manufacturer specifications during the installation process.

Finally, bleeding the system is necessary after any work involving brake fluid. This procedure eliminates air pockets, which can compromise braking efficiency. Ensure to use the correct fluid type as specified by the manufacturer.

Cooling System Maintenance Tips

Ensuring optimal performance of the cooling apparatus is crucial for the longevity and efficiency of any vehicle. Regular upkeep not only helps prevent overheating but also promotes the overall health of the engine. Here are some essential tips to maintain the cooling system effectively.

Regular Inspections

Frequent checks of the cooling components can help identify potential issues before they escalate. Inspect hoses for signs of wear or leaks, and ensure that connections are secure. Pay attention to the radiator for any corrosion or damage, as these can lead to significant cooling failures.

Fluid Levels and Quality

Maintaining the appropriate level of coolant is vital. Always use the recommended type of coolant for your vehicle, as using the wrong mixture can lead to corrosion and reduced efficiency. Check the fluid levels regularly, and top off as necessary. Additionally, consider flushing the system periodically to remove any build-up of debris and contaminants, ensuring optimal heat exchange.

Upgrading Parts: What to Consider

Enhancing your vehicle’s components can significantly improve performance and reliability. However, it is crucial to approach upgrades thoughtfully, ensuring that modifications align with your specific needs and driving conditions. This guide outlines key factors to consider when selecting parts for enhancement.

| Factor | Considerations |

|---|---|

| Compatibility | Ensure that new parts are suitable for your model. Check specifications and fitment guidelines to avoid issues. |

| Quality | Opt for high-quality materials and reputable brands. Investing in durable components can save costs on future repairs. |

| Performance Goals | Define what you want to achieve with upgrades. Whether it’s better handling, increased power, or improved efficiency, choose parts that align with these goals. |

| Budget | Set a clear budget before purchasing. Consider both the cost of parts and potential installation expenses to avoid overspending. |

| Installation | Determine if upgrades require professional installation or if you can manage the task yourself. Assess your skills and tools before proceeding. |

| Warranty | Check if the new components come with a warranty. This can provide peace of mind and protection against defects. |

By taking these factors into account, you can make informed decisions that enhance your vehicle’s performance while ensuring safety and reliability on the road.

Resources for DIY Enthusiasts

For those who enjoy tackling automotive projects on their own, a wealth of resources is available to enhance knowledge and skills. Whether you’re a novice or a seasoned expert, these tools and information can empower you to successfully maintain and upgrade your vehicle.

- Online Forums: Engaging with fellow enthusiasts can provide valuable insights. Many forums offer a platform for sharing experiences, troubleshooting, and advice.

- Video Tutorials: Platforms like YouTube host numerous instructional videos that demonstrate various tasks, from basic maintenance to advanced modifications.

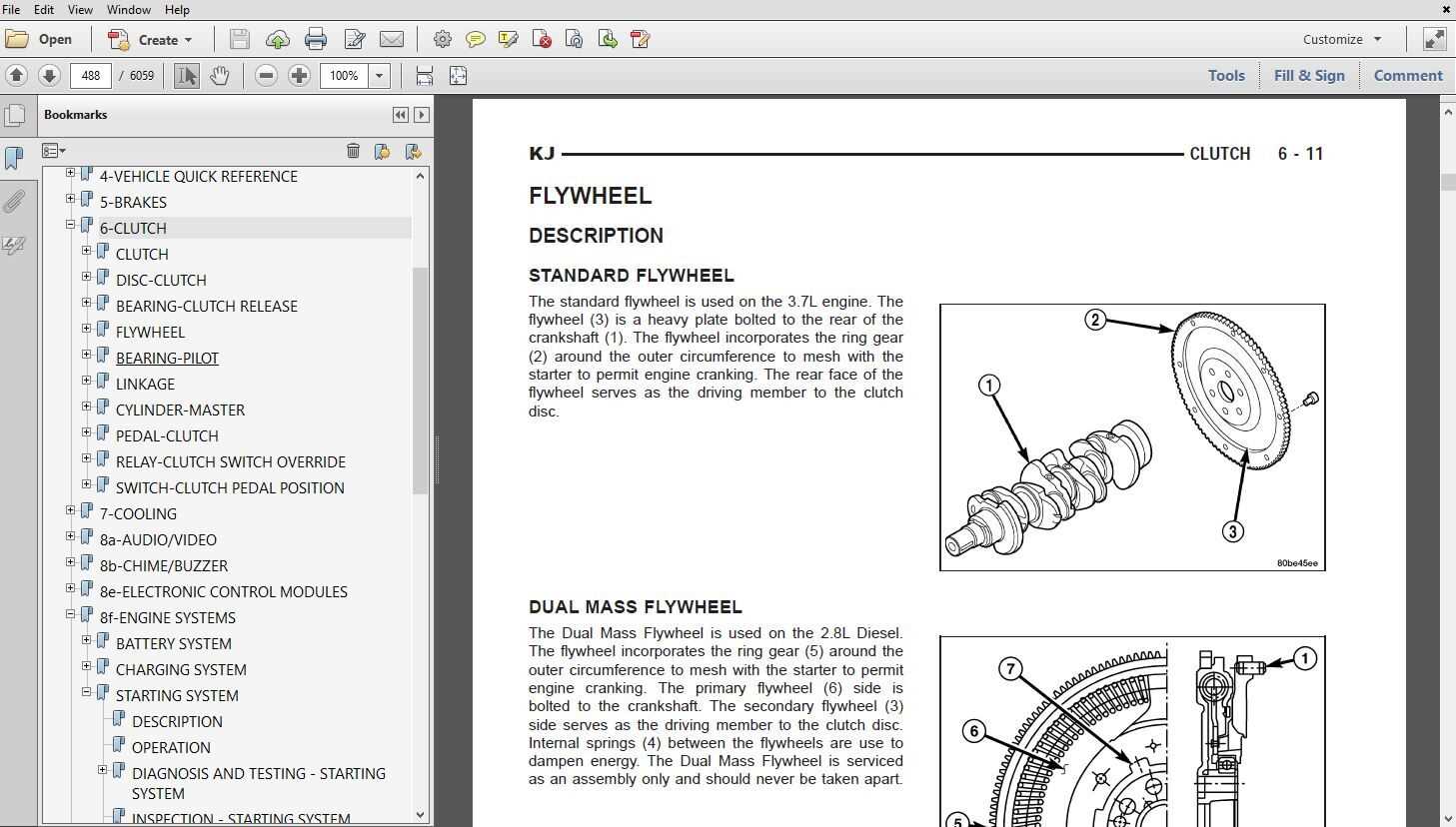

- Books and Guides: Comprehensive guides covering different models can serve as excellent references for understanding systems and procedures.

- Parts Suppliers: Websites dedicated to auto parts often include detailed descriptions, compatibility information, and user reviews to assist in selecting the right components.

By leveraging these resources, enthusiasts can develop their skills, troubleshoot issues, and successfully execute projects, fostering a deeper connection with their vehicles.