Maintaining the functionality and performance of your sewing device is essential for achieving seamless results in your projects. Over time, even the most reliable models may experience minor issues that require attention. Understanding how to effectively troubleshoot and service your equipment can significantly enhance its longevity and your overall sewing experience.

In this section, we will explore various techniques and strategies for ensuring your sewing apparatus operates smoothly. From basic cleaning procedures to more complex adjustments, we will provide insights that empower you to take charge of your machine’s upkeep. Emphasizing the importance of regular maintenance, this guide will assist you in identifying common problems and implementing solutions that restore your device to optimal performance.

With the right knowledge and tools at your disposal, you can foster a productive and enjoyable sewing journey. By committing to regular care and learning to address potential issues proactively, you will not only preserve your equipment but also enhance your skills as a sewist.

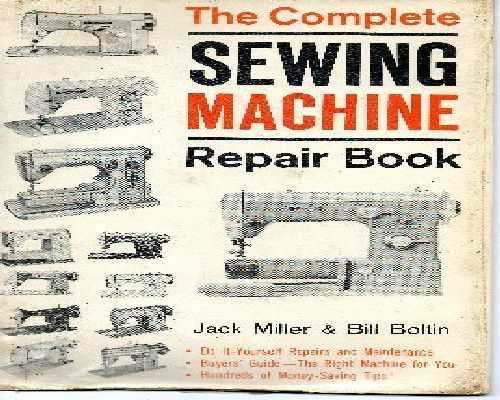

Overview of the Sewing Machine Service Guide

This section provides a comprehensive overview of the service guide for a classic sewing device known for its reliability and performance. Understanding the essential aspects of this guide helps users effectively maintain their equipment, troubleshoot common issues, and ensure optimal functioning over time. By following the outlined steps, owners can enhance their sewing experience and prolong the life of their machine.

Key Features of the Guide

The service document includes detailed information on various components and their functions. It highlights maintenance procedures, adjustment techniques, and safety precautions to consider when operating the machine. Each section is crafted to empower users with the knowledge needed to handle their equipment with confidence.

Contents Overview

| Section | Description |

|---|---|

| Introduction | Basic information about the device and its capabilities. |

| Maintenance Tips | Guidelines for regular upkeep and care procedures. |

| Troubleshooting | Solutions for common problems and how to address them. |

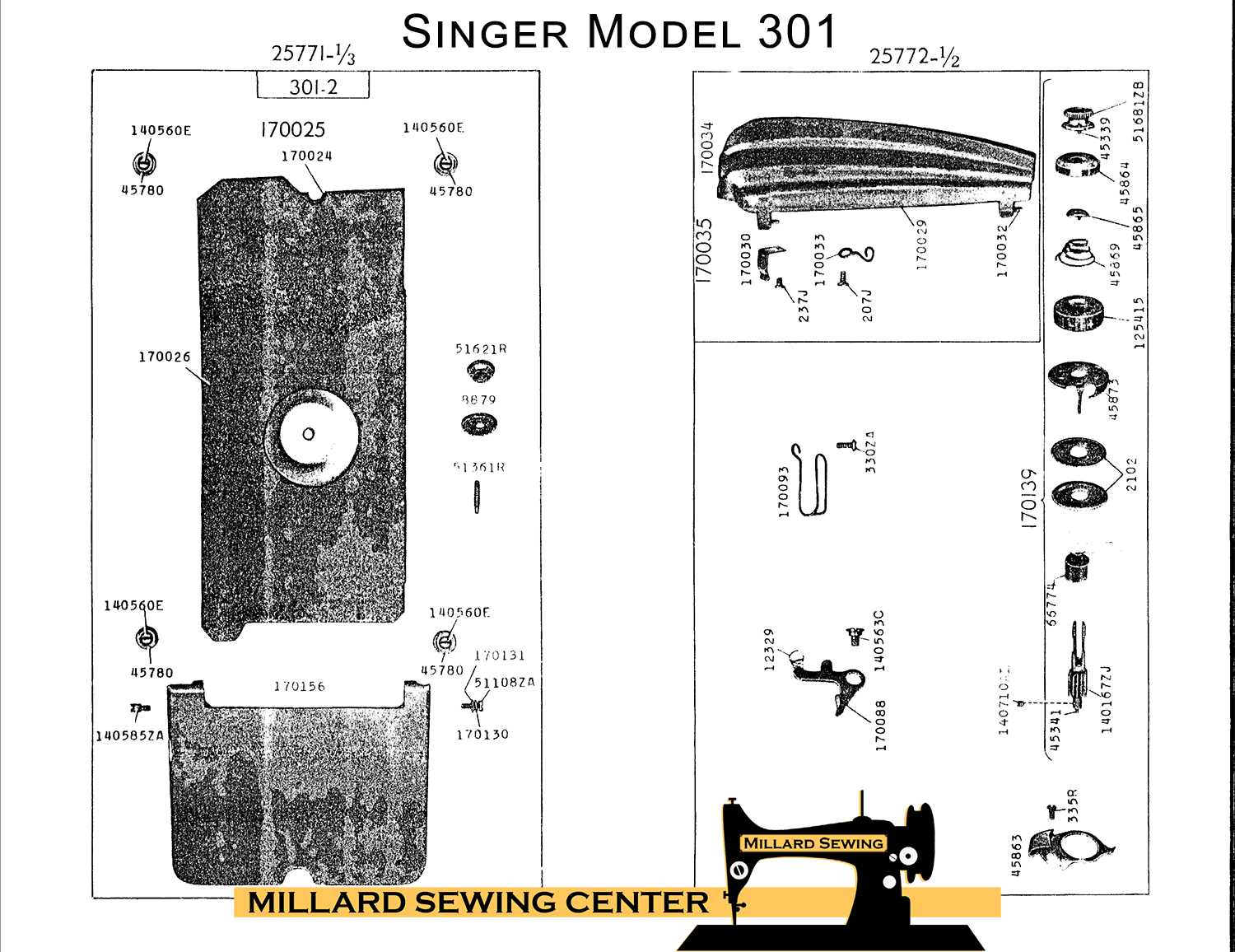

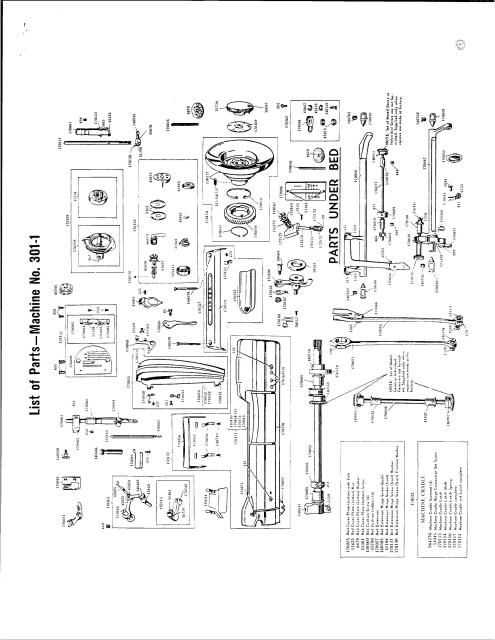

| Parts List | Inventory of essential components and their specifications. |

Common Issues with Singer 301

The machine often encounters a variety of challenges that can hinder its performance. Understanding these common problems can help users maintain functionality and enhance the sewing experience. Addressing these issues promptly ensures optimal operation and longevity.

Frequent Problems

- Thread Bunching: This issue arises when the thread tangles, causing irregular stitches. It may be due to improper threading or a tangled bobbin.

- Skipping Stitches: Missing stitches can occur for various reasons, including a dull needle, incorrect tension, or incompatible fabric.

- Needle Breakage: If the needle frequently breaks, it may indicate incorrect installation or the use of an inappropriate needle type for the fabric.

- Uneven Stitching: Irregular stitching patterns can stem from various factors such as tension settings, feed dog issues, or fabric handling.

Troubleshooting Tips

- Always ensure the thread is correctly threaded through all guides and tension discs.

- Regularly replace the needle to avoid issues related to wear and tear.

- Adjust the tension settings based on the type of fabric being used for better stitch quality.

- Perform routine maintenance to keep all moving parts functioning smoothly.

Troubleshooting Sewing Machine Problems

Identifying and resolving issues with stitching devices can significantly enhance the sewing experience. Common malfunctions may arise from various factors, including improper threading, worn parts, or incorrect settings. Understanding how to systematically approach these problems can save time and frustration.

Common Issues and Solutions

Below are frequent challenges encountered during sewing, along with possible solutions to restore functionality:

| Problem | Possible Cause | Solution |

|---|---|---|

| Skipped Stitches | Incorrect needle or tension settings | Change the needle and adjust tension |

| Thread Bunching | Improper threading or lint buildup | Re-thread the machine and clean the area |

| Machine Not Sewing | Power supply issue or disengaged feed dogs | Check power connection and engage feed dogs |

Preventive Measures

Regular maintenance is crucial for optimal performance. Routine cleaning, lubrication, and timely replacement of worn components can help prevent common malfunctions. Following the manufacturer’s guidelines for care can extend the life of the stitching device.

Essential Tools for Repairs

When embarking on any maintenance task, having the right equipment at your disposal is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures the longevity of your devices. Understanding the essential instruments for these tasks can make the process smoother and more effective.

Here are the key instruments you should consider having:

- Screwdrivers: A set of various sizes, including flathead and Phillips, is vital for loosening and tightening screws.

- Pliers: These come in handy for gripping, twisting, and cutting wires or small components.

- Scissors: Sharp scissors are essential for cutting fabric or thread during adjustments.

- Measuring Tape: Accurate measurements are necessary for ensuring proper fit and alignment.

- Lint-Free Cloths: These are ideal for cleaning surfaces without leaving residue.

- Lubricants: Appropriate oils or greases can help maintain moving parts and prevent wear.

- Needles: A variety of sizes can accommodate different tasks, especially for sewing or stitching.

By assembling a comprehensive collection of these essential tools, you can effectively address various challenges that may arise during your maintenance endeavors.

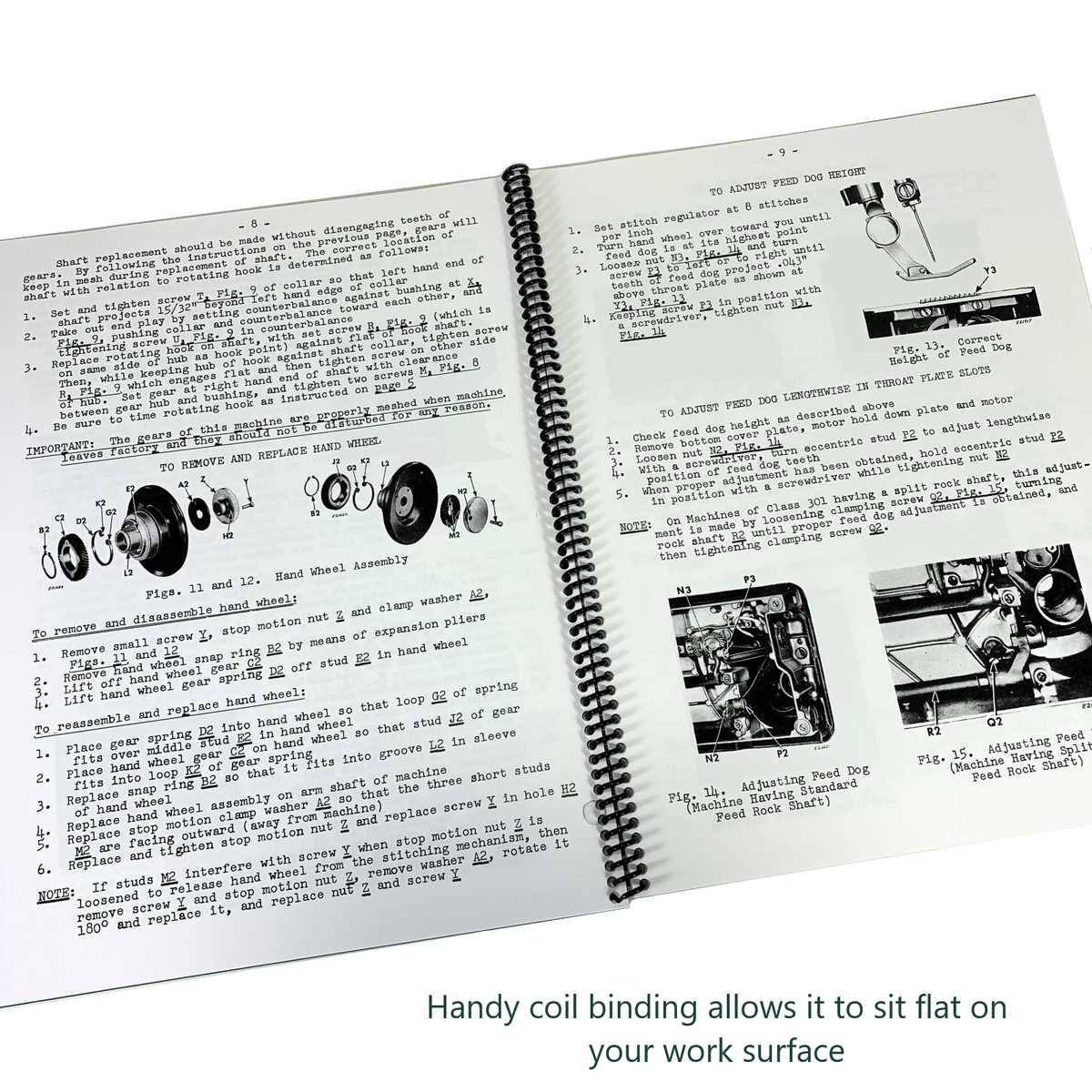

Step-by-Step Maintenance Guide

Ensuring the longevity and optimal performance of your sewing device involves a systematic approach to upkeep. Regular care not only enhances functionality but also prevents potential issues from arising. This section provides a clear and concise roadmap to help you effectively maintain your machine, ensuring it remains in excellent working condition.

Begin by cleaning the machine. Dust and debris can accumulate in various parts, so it is crucial to remove these particles regularly. Use a soft brush and a lint-free cloth to gently wipe down the exterior and interior components. Pay special attention to the bobbin case and feed dogs, as these areas are prone to collecting lint.

Next, check the threading. Proper threading is essential for smooth operation. Refer to your device’s diagram to ensure the thread path is correct. Incorrect threading can lead to tension problems and thread breakage.

Lubricate moving parts. Over time, lubrication can diminish, leading to wear and tear. Apply a few drops of oil to the designated areas as outlined in your user guide. This will help maintain smooth movement and prevent any grinding noises.

Inspect the needles. Dull or damaged needles can result in poor stitching quality. Replace them regularly, and choose the correct size and type for your projects to achieve the best results.

Finally, perform routine checks. Regularly inspect belts, cords, and other mechanical parts for signs of wear. Addressing small issues promptly can prevent larger, more costly repairs down the line.

Replacing the Needle and Thread

Maintaining optimal performance of your sewing device involves the essential task of changing the needle and thread regularly. This ensures that your projects are executed smoothly and with precision. Properly replacing these components can significantly improve the quality of your stitching and prevent potential issues during operation.

To effectively substitute the needle and thread, follow these simple steps:

| Step | Instructions |

|---|---|

| 1 | Turn off the machine and unplug it for safety. |

| 2 | Raise the needle to its highest position using the handwheel. |

| 3 | Loosen the needle clamp screw and carefully remove the old needle. |

| 4 | Insert a new needle with the flat side facing the back and tighten the clamp screw. |

| 5 | Cut a length of thread suitable for your project and thread it through the needle eye. |

| 6 | Follow the threading path as indicated in the device’s guidelines to ensure proper tension. |

| 7 | Test the stitch on a scrap piece of fabric to verify the setup. |

By following these steps, you can ensure that your equipment is always ready to deliver excellent results, enhancing your overall sewing experience.

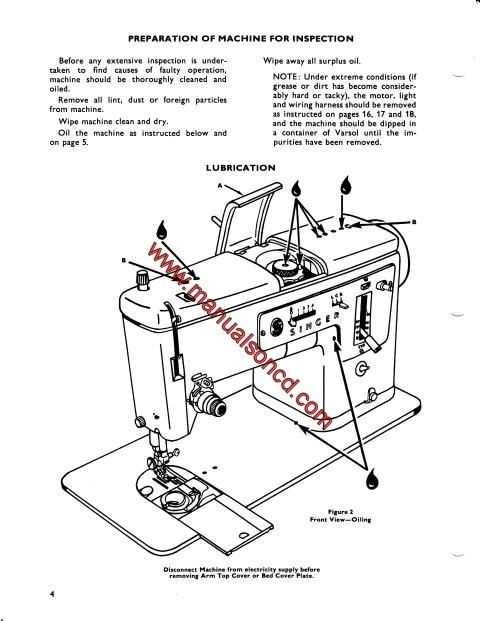

Cleaning and Oiling the Machine

Maintaining your sewing device in optimal condition is essential for ensuring its longevity and performance. Regular cleaning and lubrication are crucial tasks that enhance the functionality and smooth operation of your equipment.

Here are some steps to follow for effective cleaning and oiling:

- Begin by unplugging the machine to ensure safety during maintenance.

- Remove the needle and presser foot to access the machine’s interior.

- Utilize a soft brush or cloth to remove lint and debris from the feed dogs and surrounding areas.

- Check the bobbin case and clean it thoroughly to prevent any buildup of thread and dust.

Once the cleaning process is complete, it’s time to lubricate the necessary components:

- Identify the oiling points as indicated in the device’s guidelines.

- Apply a few drops of sewing machine oil to each point to ensure proper lubrication.

- Wipe away any excess oil to prevent it from accumulating and attracting dust.

By following these simple yet effective steps, you can help maintain the performance and reliability of your sewing machine, ensuring that it operates smoothly for years to come.

Adjusting Tension for Perfect Stitches

Achieving flawless stitches is essential for any sewing project, and one of the critical factors that influence stitch quality is tension. Properly balanced tension ensures that threads interlock correctly, resulting in strong, neat seams. Understanding how to adjust this setting can significantly enhance your sewing experience, allowing for professional-looking results on various fabrics.

To achieve optimal tension, you may need to experiment with different settings. Below is a guide outlining the effects of tension adjustments on stitch appearance:

| Tension Setting | Stitch Appearance | Recommended Fabric Type |

|---|---|---|

| Too Tight | Gathered or puckered fabric, visible thread tension | Lightweight materials |

| Balanced | Smooth, even stitches, good thread interlocking | Most fabric types |

| Too Loose | Loose stitches, potential unraveling, weak seams | Heavyweight materials |

To adjust the tension, refer to the machine’s settings. Turn the tension dial slowly and test on scrap fabric to find the perfect balance for your specific project. Regular maintenance and checks will help maintain optimal performance and improve your overall sewing results.

Repairing the Feed Mechanism

The feed system is crucial for the smooth operation of your stitching device. This section focuses on diagnosing and resolving issues that may affect the functionality of this component. A well-functioning feed mechanism ensures that the fabric moves consistently through the machine, facilitating accurate stitching. Below are steps and considerations to guide you in addressing common concerns related to this system.

Identifying Common Issues

- Inconsistent Stitching: When the fabric does not advance evenly, it can result in uneven stitches.

- Skipped Stitches: This occurs when the fabric does not move correctly during stitching.

- Noise: Unusual sounds may indicate that parts are misaligned or worn.

Steps to Address Issues

- Begin by unplugging the device to ensure safety.

- Remove the needle plate and inspect the feed dogs for any debris or damage.

- Check the feed dog height; it should be flush with the needle plate during operation.

- Examine the tension settings, as incorrect adjustments can impact fabric movement.

- Lubricate moving parts as needed, using appropriate oil to minimize friction.

- Reassemble the components and test the device with scrap fabric to ensure proper functioning.

Replacing the Bobbin Case

Maintaining the functionality of your sewing machine involves periodic updates to its components. One crucial part is the bobbin case, which plays a vital role in the stitching process. When this part becomes damaged or worn, replacing it can significantly improve the performance of your machine.

Identifying the Need for Replacement

Signs that indicate a new bobbin case is necessary include inconsistent stitching, thread jamming, or unusual noise during operation. Addressing these issues promptly can prevent further complications and ensure seamless sewing.

Steps to Replace the Bobbin Case

Follow these simple steps to efficiently replace the bobbin case:

| Step | Action |

|---|---|

| 1 | Power off the machine and unplug it for safety. |

| 2 | Open the access panel to the bobbin area. |

| 3 | Carefully remove the old bobbin case. |

| 4 | Insert the new bobbin case, ensuring it fits snugly. |

| 5 | Close the access panel and check the alignment. |

| 6 | Power on the machine and conduct a test run. |

By following these steps, you can ensure that your sewing device operates smoothly and effectively, enhancing your overall crafting experience.

Fixing Electrical Issues in Singer 301

When dealing with electrical malfunctions in your sewing machine, it is essential to understand the underlying problems that may arise. Addressing these issues promptly ensures the device operates efficiently and enhances the overall sewing experience.

Here are common electrical problems and solutions:

- Power Source Issues: Check the power cord for any signs of damage. Ensure that the outlet is functioning correctly by testing it with another device.

- Foot Pedal Malfunction: Inspect the foot control for any visible wear or obstructions. Cleaning the pedal and checking the connections can often resolve this issue.

- Fuses and Circuit Breakers: If the machine does not turn on, a blown fuse or tripped circuit breaker may be the culprit. Replace the fuse or reset the breaker as needed.

- Internal Wiring Problems: If there are intermittent power issues, internal wiring may be loose or damaged. Open the machine carefully and inspect the wiring connections.

For more complex issues, consulting a professional technician may be advisable to avoid further damage. Regular maintenance and timely attention to these electrical concerns will prolong the lifespan of your sewing equipment.

Upgrading Accessories for Better Performance

Enhancing the functionality of your sewing machine can significantly improve its efficiency and the quality of your projects. By selecting compatible tools and attachments, users can unlock new capabilities and streamline their sewing processes. These upgrades not only increase productivity but also expand creative possibilities, making every sewing experience more enjoyable.

One of the most effective ways to boost performance is by incorporating specialized presser feet. Each foot serves a unique purpose, allowing for precise stitching techniques that can transform ordinary seams into professional-quality finishes. For instance, using a walking foot can ensure even feeding of multiple layers of fabric, which is essential for quilting and other thick materials.

In addition to presser feet, consider enhancing the needle selection. Different fabrics and techniques require specific needle types for optimal results. Choosing the right needle can prevent issues such as skipped stitches and fabric damage, leading to a smoother sewing experience. Furthermore, upgrading to high-quality threads can also make a noticeable difference in the final appearance of the stitched fabric.

Lastly, organizing and maintaining accessories is vital for efficient sewing. A dedicated storage solution for tools and attachments not only keeps everything easily accessible but also promotes a more organized workspace. Regularly reviewing and updating accessories ensures that your setup remains current and fully equipped to handle various projects, ultimately enhancing overall performance.

Resources for Singer 301 Owners

For those who own this classic sewing machine, a wealth of materials and support is available to enhance the experience of using and maintaining your device. These resources cover everything from troubleshooting to sewing tips, ensuring that users can maximize their enjoyment and functionality.

Here are some valuable options to consider:

- Online forums: Connect with other enthusiasts and experts to share experiences, seek advice, and find solutions to common issues.

- Video tutorials: Platforms like YouTube offer a variety of instructional videos that guide users through different aspects of machine operation and care.

- Social media groups: Joining dedicated groups on platforms like Facebook allows for community support and sharing of insights related to usage and maintenance.

- Books and guides: Numerous publications provide in-depth knowledge on techniques and repairs, helping users deepen their understanding.

- Local workshops: Many craft stores and sewing centers offer classes focused on machine usage, providing hands-on experience.

By exploring these resources, owners can gain confidence in their skills and ensure their machines remain in excellent condition for years to come.