Understanding the inner workings and keeping the vehicle’s transmission in optimal condition is essential for maintaining smooth and efficient driving performance. Regular attention to this complex component can prevent costly issues and extend the life of the vehicle. In this guide, we’ll cover practical insights and technical nuances that support a well-functioning transmission system.

Each transmission system requires unique care based on its specific design and operating mechanisms. This guide offers structured advice on identifying early signs of issues, interpreting key signals, and performing targeted maintenance procedures. By following these recommendations, vehicle owners can gain confidence in addressing common challenges that arise with prolonged use.

For those looking to go beyond basic troubleshooting, this resource provides in-depth strategies for maintaining transmission health. From preventative measures to technical adjustments, the information here aims to support both novices and those familiar with automotive systems in achieving reliable performance and smooth operation.

TF 80SC Transmission Repair Guide

This section provides a comprehensive overview of essential procedures for maintaining and enhancing the performance of the TF transmission. By following these steps, one can address common functionality challenges, improve durability, and ensure optimal operational quality over time.

Key Maintenance Steps

- Fluid Inspection: Regularly monitor fluid levels and condition to detect any contaminants or wear-related issues early.

- Filter Replacement: Replace the filter periodically to prevent debris build-up, which can affect component performance and longevity.

- System Clean-Up: Conduct a thorough cleaning of transmission parts to remove any particles or residues that may impair function.

Common Issues and Solutions

- Delayed Shifting: Adjust fluid levels and inspect for leaks. This may help alleviate delays in shifting and improve response times.

- Unexpected Noises: Address unusual sounds by checking the gears and inspecting for worn parts. Replacing faulty components can often resolve noise-related concerns.

- Ove

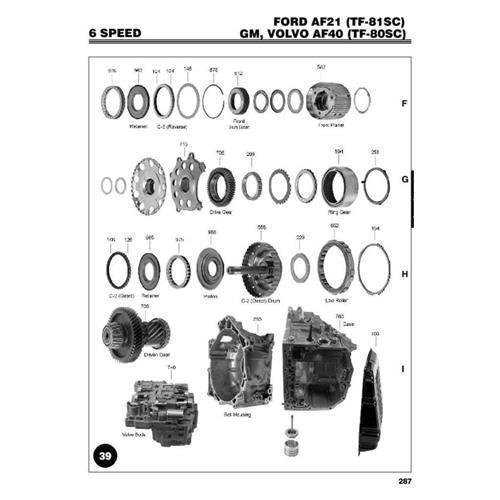

Understanding the TF Transmission Design

This section provides a thorough overview of the TF transmission’s structural layout and functionality, highlighting its core components and how they work in harmony to support efficient and reliable performance. By understanding its composition, users can gain insight into the engineering principles that allow it to perform smoothly under diverse conditions.

Key Structural Elements

The TF transmission design comprises several critical elements that contribute to its operational effectiveness. Each component plays a distinct role, which, together, creates a balanced and responsive driving experience.

- Torque Converter: Acts as a bridge between the engine and transmission, allowing smooth power transfer and torque multiplication.

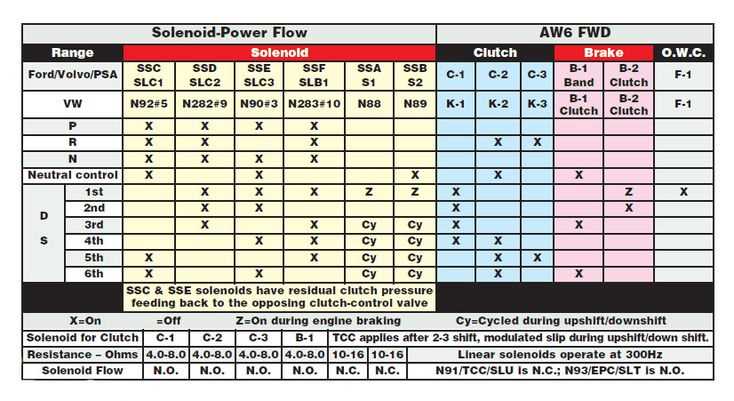

- Valve Body: Serves as the central control hub, directing hydraulic fluid to various clutches and gears based on driving demands.

- Planetary Gear Sets: Enable diff

Common TF 80SC Transmission Issues

This section outlines frequent challenges faced by vehicle owners with this transmission model, including symptoms and potential causes that may affect driving performance and reliability. Understanding these common issues can help in identifying early signs and taking preventive measures.

1. Symptoms of Shifting Problems

- Delayed or rough gear shifts

- Unexpected downshifts during acceleration

- Transmission slipping when changing gears

These symptoms often indicate wear in specific components or the need for recalibration. They may arise from fluid degradation, sensor misalignment, or internal part deterioration.

2. Fluid Leaks and Overheating

- Fluid pooling under the vehicle

- Burning odor while driving

- Increased transmission temperature warning

Leaks and overheating are often due to seal

Essential Tools for TF 80SC Repairs

When working on transmission systems, having the right equipment is crucial to achieve precision and efficiency. Properly chosen instruments not only streamline the task but also ensure safe and thorough handling of every component.

Socket and Wrench Set is indispensable for working with a range of fasteners found in transmission assemblies. A set with varied sizes allows for flexibility across different parts and components.

Another critical tool is a Torque Wrench, used to apply specific torque to bolts and fasteners, ensuring secure and consistent fitting without risking overtightening.

Diagnostic Scanner plays a vital role in identifying underlying issues within the system. It offers detailed insights, helping to locate problems accurately and swiftly.

Additionally, Hydraulic Jacks are required to safely lift the assembly for inspection and repairs. They provide stability, making it easier to wor

Diagnosing TF Transmission Problems

Understanding common transmission issues is essential for identifying symptoms that indicate malfunctions. Recognizing early signs can prevent more extensive damage and costly repairs, ensuring the transmission continues to function smoothly.

- Shifting Delays: If gear changes feel delayed or sluggish, this may point to underlying issues affecting response times.

- Unexpected Noises: Whining, clunking, or humming sounds often signal internal problems, possibly linked to worn-out parts.

- Fluid Leaks: Fluid spots under the vehicle or a noticeable drop in fluid levels can indicate leaks, which can affect overall performance.

- Warning Lights: Dashboard indicators related to the transmission are important to address promptly, as they often high

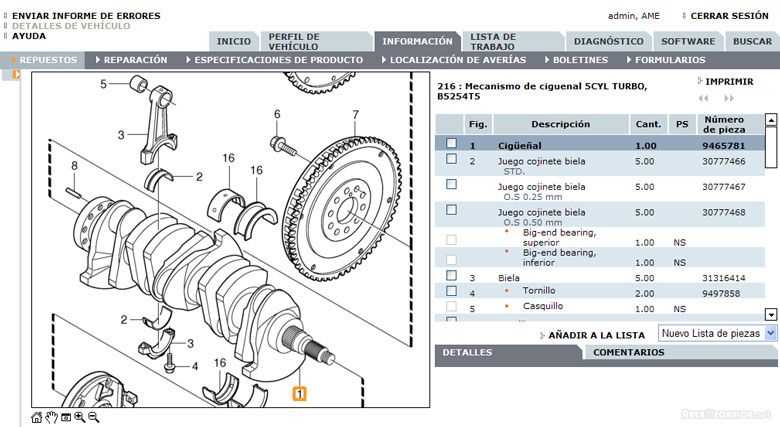

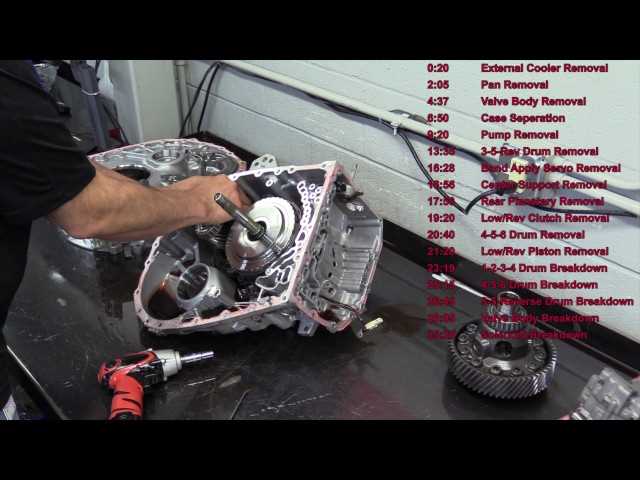

Step-by-Step Transmission Disassembly Process

This section provides a comprehensive overview of the procedure for carefully taking apart a transmission unit. By following each step systematically, you can ensure that all components are handled with care, allowing for effective troubleshooting and maintenance.

Preparation for Disassembly

Before starting the disassembly, it is crucial to gather all necessary tools and materials. This includes a socket set, screwdrivers, and a clean workspace. Ensure that you have adequate lighting and that the area is organized to prevent losing any small parts. Safety precautions should also be observed, such as wearing gloves and eye protection to safeguard against potential hazards.

Disassembly Steps

Begin by removing any external attachments, such as cables and mounts, to provide access to the transmission housing. Once exposed, carefully unscrew the housing cover and gently lift it off, ensuring not to damage any sealing surfaces. Continue by removing internal components in a systematic order, noting their arrangement for reassembly. Take special care with fragile elements and store them in labeled containers for easy identification later. Documentation of each step can also aid in a smooth reassembly process.

Replacing Worn Parts in TF 80SC

Maintaining optimal performance in machinery often requires the timely substitution of components that exhibit signs of wear. This process is crucial for ensuring longevity and functionality, as well as preventing further damage to the system. Understanding which elements need attention and how to effectively replace them is essential for successful upkeep.

Identifying Worn Components: Regular inspections can help detect parts that may have deteriorated over time. Look for signs such as unusual noises, vibrations, or decreased efficiency, which can indicate that specific components are no longer functioning as intended.

Replacement Procedure: Once worn parts are identified, follow the manufacturer’s guidelines for removal and installation. Ensure that the appropriate tools are used and that safety measures are observed. It is important to handle each component carefully to avoid damaging surrounding areas.

Choosing Quality Parts: When selecting replacement components, opt for high-quality alternatives that meet or exceed the original specifications. This decision will significantly contribute to the overall reliability and performance of the machinery.

By adhering to these practices, you can effectively maintain your system, ensuring it operates smoothly and efficiently over time.

Tips for Reassembling the Transmission

Reassembling a transmission can be a complex task that requires attention to detail and a methodical approach. Proper preparation and organization are essential for ensuring all components fit together seamlessly and function as intended. Here are some valuable suggestions to keep in mind during the reassembly process.

Tip Description 1. Organize Parts Keep all components sorted and labeled to avoid confusion during reassembly. 2. Follow the Order Adhere to the correct assembly sequence as outlined in reference materials to ensure proper alignment. 3. Use Quality Tools Utilize the right tools for the job to prevent damage to components and ensure a secure fit. 4. Inspect Seals Check all seals and gaskets for wear and replace them as needed to prevent leaks. 5. Torque Specifications Pay attention to torque specifications for fasteners to ensure all parts are securely attached. Fluid Types and Maintenance Tips

Understanding the various fluid types and their proper maintenance is crucial for optimal vehicle performance. Regular checks and timely replacements can significantly enhance the lifespan of essential components, ensuring a smoother driving experience.

Engine oil, transmission fluid, and coolant are among the primary fluids that require attention. Each type serves a specific purpose, such as lubricating moving parts, facilitating gear shifts, or regulating engine temperature. Selecting the correct fluids according to manufacturer specifications is essential to maintain efficiency.

Regular maintenance practices, such as checking fluid levels, looking for leaks, and adhering to replacement schedules, play a vital role in vehicle upkeep. Keeping an eye on fluid quality can help identify potential issues early, preventing more significant problems down the line. Always consult your vehicle’s guidelines to ensure you are using the right products and following the appropriate maintenance routines.

Testing and Adjusting the Transmission

This section focuses on evaluating and fine-tuning the functionality of the gearbox to ensure optimal performance. Proper examination is crucial to identify any inconsistencies or areas that require correction. The following guidelines outline the necessary steps to effectively assess and modify the transmission system.

- Initial Inspection: Begin with a visual assessment of the transmission components. Check for any signs of wear, leaks, or damage.

- Fluid Level Check: Ensure that the transmission fluid is at the recommended level. Low fluid can lead to inadequate lubrication and overheating.

- Fluid Condition: Examine the fluid quality. It should be clean and free from contaminants. Discolored or burnt fluid may indicate internal issues.

- Shift Points Adjustment: Test the shifting points during acceleration. If shifts occur too early or late, adjustments may be necessary for smoother transitions.

- Diagnostic Testing: Utilize diagnostic tools to read any error codes from the transmission control unit. This can reveal specific problems requiring attention.

Following these steps will help ensure that the transmission operates efficiently, prolonging its lifespan and enhancing the overall driving experience.

Preventing Future Transmission Failures

Ensuring the longevity and reliability of a vehicle’s transmission system is crucial for maintaining optimal performance. By following preventive measures, owners can significantly reduce the likelihood of encountering serious issues. Regular maintenance and attentive driving habits play vital roles in extending the life of these intricate mechanisms.

Regular Maintenance Checks

Conducting routine inspections and servicing is essential for identifying potential problems before they escalate. Fluid levels, including transmission fluid, should be monitored and changed according to the manufacturer’s recommendations. Additionally, filters must be replaced periodically to ensure that contaminants do not interfere with the system’s functionality.

Driving Habits

Adopting careful driving practices can also mitigate wear and tear on the transmission. Avoiding abrupt acceleration and hard braking helps in maintaining smooth transitions and reducing stress on the components. Furthermore, utilizing the appropriate gear for various driving conditions can prevent unnecessary strain, ensuring a more efficient operation.