In the realm of agricultural machinery, understanding the intricacies of upkeep and troubleshooting is vital for optimal performance. Proper guidance not only enhances the lifespan of these robust machines but also ensures they operate efficiently, minimizing downtime in critical farming operations. With the right resources, operators can navigate common issues and routine maintenance tasks with confidence.

Expertly crafted resources provide detailed insights into the workings of various models, empowering users to tackle challenges effectively. These guides cover a spectrum of topics, from basic adjustments to advanced technical solutions, making them invaluable tools for both seasoned professionals and novice users alike. By equipping oneself with comprehensive knowledge, the user can greatly enhance productivity and reliability in their daily agricultural tasks.

Moreover, having access to step-by-step instructions and troubleshooting tips allows for quick resolutions to unexpected problems. This proactive approach not only saves time but also significantly reduces the costs associated with professional repairs. In an industry where every moment counts, being well-informed translates to better decision-making and improved overall results in the field.

Massey Ferguson Repair Manuals Overview

This section provides a comprehensive insight into the guides essential for the maintenance and troubleshooting of agricultural machinery. Such resources are invaluable for both professionals and enthusiasts, ensuring that equipment operates efficiently and reliably.

These resources typically include:

- Detailed instructions for assembly and disassembly

- Step-by-step troubleshooting procedures

- Specifications for parts and tools

- Maintenance schedules to enhance longevity

- Diagrams and illustrations for clarity

Accessing these documents empowers users to conduct repairs and maintenance with confidence, reducing downtime and ensuring optimal performance. Whether for routine servicing or complex issues, having the right reference material is crucial.

When selecting such resources, consider the following:

- Compatibility with specific equipment models

- Availability of updated information

- User reviews and recommendations

- Format (digital vs. printed)

By utilizing these valuable tools, operators can ensure their machinery remains in peak condition, ultimately leading to improved productivity and reduced operational costs.

Understanding Massey Ferguson Models

This section aims to provide insights into the various types of agricultural machinery produced by a renowned manufacturer. Each variant is designed to cater to specific needs, ensuring efficiency and productivity in farming operations.

Different models come with unique features and specifications that make them suitable for various tasks:

- Tractors: Known for their versatility, these vehicles are essential for numerous agricultural tasks, from plowing to hauling.

- Harvesters: Designed to streamline the collection process, these machines are crucial during harvest season.

- Implement Attachments: Enhancing the functionality of base machines, these tools allow for specialized tasks such as seeding and tilling.

To better understand these machines, consider the following factors:

- Model Types: Familiarize yourself with the various categories available, including compact, mid-sized, and large machines.

- Specifications: Pay attention to engine power, weight, and operational capabilities to match the equipment with specific tasks.

- Technological Features: Many modern models incorporate advanced technology for improved efficiency and ease of use.

By exploring these aspects, users can make informed decisions when selecting machinery that aligns with their agricultural needs.

Importance of Accurate Repair Manuals

Having precise and detailed documentation for maintenance tasks is crucial for ensuring the longevity and efficiency of machinery. Such resources provide essential guidance, enabling operators to perform troubleshooting, servicing, and parts replacement with confidence.

Benefits of Detailed Documentation

- Enhanced Understanding: Clear instructions help users comprehend the mechanics of their equipment, leading to better handling and operation.

- Time Efficiency: Well-organized guidelines reduce the time spent on diagnostics and repairs, allowing for quicker turnaround on machinery uptime.

- Cost-Effectiveness: Accurate information minimizes the risk of errors that could result in expensive repairs or part replacements.

- Safety Assurance: Following reliable procedures reduces the likelihood of accidents, ensuring the safety of operators and bystanders.

Impact on Maintenance Practices

- Consistency in Procedures: Standardized guidelines foster uniformity in maintenance practices, leading to predictable outcomes.

- Improved Problem Solving: Access to correct troubleshooting steps enhances the ability to identify and rectify issues efficiently.

- Informed Decision-Making: Users can make better decisions regarding repairs and upgrades when equipped with accurate information.

How to Access Repair Documentation

Accessing technical documentation is crucial for effective maintenance and troubleshooting of agricultural machinery. This information not only aids in understanding the equipment but also enhances the efficiency of any necessary adjustments or fixes. Here’s how you can obtain this valuable knowledge.

Online Resources

Many manufacturers provide comprehensive resources through their official websites. By navigating to the support or downloads section, you can often find digital copies of technical documents. Additionally, online forums and user communities are excellent places to discover shared experiences and tips from other operators.

Physical Locations

Local dealerships and service centers frequently offer printed materials. Visiting these locations can provide access to hard copies of necessary documents. Furthermore, consulting with trained technicians can yield insights and recommendations tailored to your specific needs.

For ongoing maintenance and effective troubleshooting, utilizing these avenues to access detailed documentation is essential. Understanding the intricacies of your machinery will lead to improved performance and longevity.

Common Repairs for Massey Ferguson

This section discusses frequent maintenance tasks and troubleshooting procedures associated with agricultural machinery. Understanding these essential operations can enhance the longevity and performance of your equipment.

-

Engine Issues:

- Overheating: Check the cooling system, including coolant levels and radiator condition.

- Starting Problems: Inspect the battery, starter motor, and fuel supply.

-

Hydraulic System:

- Fluid Leaks: Examine hoses and fittings for any signs of wear or damage.

- Pump Failure: Regularly test hydraulic pressure to ensure optimal performance.

-

Transmission Troubles:

- Shifting Issues: Adjust the clutch and check the fluid levels.

- Gear Slippage: Inspect for worn components or low fluid levels.

-

Electrical Problems:

- Faulty Lights: Test fuses and bulbs for proper function.

- Wiring Issues: Look for frayed wires or loose connections.

-

General Maintenance:

- Oil Changes: Follow a regular schedule for oil replacement.

- Filter Replacements: Regularly change air and fuel filters to maintain efficiency.

Staying proactive with these common issues can help minimize downtime and keep equipment running smoothly. Regular inspections and timely interventions are key to ensuring optimal functionality.

Tools Required for Effective Repairs

Having the right instruments at your disposal is crucial for achieving successful maintenance tasks. Properly selected tools not only streamline the process but also enhance the quality of the work performed. Understanding which implements are essential can significantly impact the efficiency and effectiveness of your endeavors.

Essential Hand Tools: A good set of wrenches, pliers, and screwdrivers is fundamental. These items allow for quick adjustments and repairs, ensuring that every component can be accessed easily.

Power Tools: Utilizing drills and impact wrenches can expedite tasks that would otherwise be time-consuming. These devices can help you delve deeper into complex issues, making the job easier and quicker.

Diagnostic Equipment: Investing in diagnostic tools can be the ultimate way to identify problems swiftly. These devices provide valuable insights into the operational status of various systems, allowing for precise interventions.

Safety Gear: Don’t overlook the importance of protective equipment. Gloves, goggles, and ear protection are vital to ensure safety while working, creating a secure environment for both you and your machinery.

Tips for Reading Repair Manuals

Understanding technical documents can significantly enhance your maintenance skills and troubleshooting abilities. Here are some strategies to help you navigate these essential resources more effectively.

- Familiarize Yourself with the Structure: Before diving in, take a moment to review the table of contents. This will give you a clear idea of where to find specific information.

- Highlight Key Sections: Use a highlighter or take notes on crucial parts. This practice will help you quickly locate important details when needed.

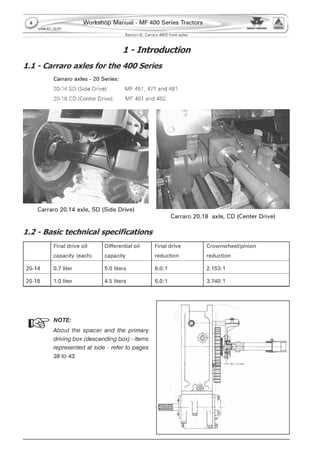

- Utilize Diagrams and Illustrations: Visual aids are often included to clarify complex concepts. Refer to these images to enhance your understanding.

- Follow Step-by-Step Instructions: Adhere to the provided procedures closely. Each step is designed to build upon the previous one for optimal results.

By applying these techniques, you can streamline your approach to technical documentation, making the process of learning and executing tasks more efficient and enjoyable.

- Practice Patience: Take your time to read thoroughly. Rushing can lead to misunderstandings.

- Seek Additional Resources: If something is unclear, don’t hesitate to consult supplementary materials or online forums for clarification.

- Regular Review: Periodically revisit important sections to reinforce your knowledge and skills.

Maintenance Best Practices for Tractors

Ensuring optimal performance and longevity of agricultural machinery requires regular upkeep and attention to detail. By adhering to best practices in maintenance, operators can significantly reduce the risk of breakdowns and enhance efficiency during operation. This section outlines key strategies that can be implemented for effective care of tractors.

Regular Inspections

Conducting frequent checks is essential for identifying potential issues before they escalate. Here are some critical areas to focus on:

- Fluid levels (engine oil, coolant, hydraulic fluid)

- Belts and hoses for signs of wear

- Tires for proper inflation and tread condition

- Battery terminals and connections

Scheduled Maintenance Tasks

Establishing a routine maintenance schedule can help keep machinery in peak condition. Consider the following tasks:

- Change engine oil and filters regularly.

- Clean or replace air filters as needed.

- Grease fittings and lubricate moving parts.

- Inspect and adjust brakes and steering mechanisms.

By implementing these best practices, operators can ensure their tractors remain reliable and efficient, ultimately enhancing productivity on the field.

Repair Manual Resources Online

Accessing reliable resources for maintenance and troubleshooting is essential for anyone working with agricultural machinery. The internet provides a wealth of information that can assist in understanding the intricacies of these machines. Here are some valuable online platforms that can help you find the guidance you need.

Popular Online Platforms

- Manufacturer Websites: Many manufacturers offer digital resources that include comprehensive guides and troubleshooting tips.

- Online Forums: Communities of enthusiasts and professionals often share experiences, advice, and downloadable resources.

- YouTube Channels: Video tutorials can provide visual guidance on repairs and maintenance procedures.

- PDF Archives: Several websites host a collection of documents, making it easy to find specific guides in PDF format.

Tips for Effective Searching

- Use specific keywords related to your machine’s model and the issue you are facing.

- Look for resources that include diagrams and step-by-step instructions for better understanding.

- Check for reviews or recommendations to ensure the credibility of the source.

- Join online groups where you can ask questions and share insights with other users.

Frequently Asked Questions About Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting processes. Understanding these key points can enhance the efficiency and effectiveness of handling various issues that may arise.

| Question | Answer |

|---|---|

| What should I do if my equipment won’t start? | Check the battery, fuel levels, and ensure all safety switches are engaged. If issues persist, consult a specialist. |

| How often should I perform maintenance checks? | Regular inspections are recommended every 100 hours of operation or as specified in the guidelines. |

| What are common signs of wear and tear? | Look for unusual noises, leaks, and decreased performance, which can indicate the need for attention. |

| Can I perform repairs myself? | Many minor adjustments can be done at home, but complex issues should be handled by qualified professionals. |

| Where can I find parts for my machine? | Authorized dealers and online marketplaces often provide a range of components for various models. |

Finding Professional Repair Assistance

When dealing with complex machinery, having access to skilled support is essential. Many owners seek out expertise to ensure that their equipment operates smoothly and efficiently. Professional technicians can provide the necessary knowledge and tools to address various issues, ultimately prolonging the lifespan of the equipment.

Where to Look for Experts

- Local Dealerships: Many dealerships offer specialized services and can connect you with certified technicians.

- Authorized Service Centers: These facilities often have trained staff familiar with specific brands and models.

- Online Directories: Websites and platforms dedicated to service providers can help you find qualified professionals in your area.

Evaluating Potential Technicians

- Check Qualifications: Look for certifications and relevant training that demonstrate expertise in machinery maintenance.

- Read Reviews: Customer feedback can provide insight into the quality of service and reliability of the technician.

- Ask for Recommendations: Consult with fellow equipment owners or local farming communities for trusted referrals.