In the world of photography, ensuring the functionality of your equipment is essential for achieving outstanding results. This section provides insight into maintaining and troubleshooting essential photographic tools. By understanding how to care for your devices, you can prolong their lifespan and enhance performance.

Proper handling and regular checks are vital practices that every photographer should adopt. This guide outlines effective strategies for addressing common issues that may arise, enabling you to keep your gear in optimal condition. Whether you are an amateur or a seasoned professional, being equipped with knowledge about upkeep will enhance your photographic journey.

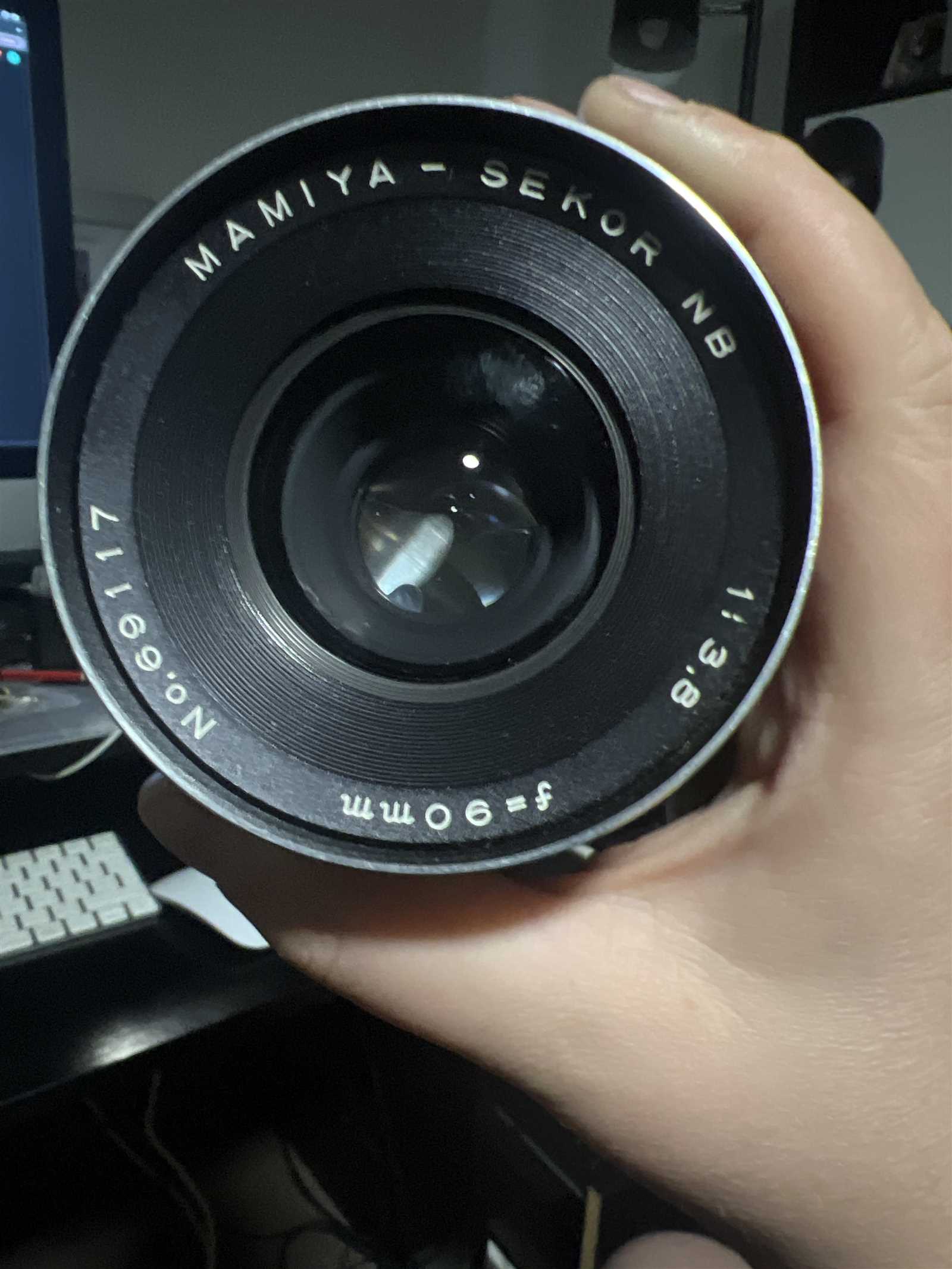

Lens Maintenance Guide

This section provides an overview of essential procedures for the upkeep of photographic optics, ensuring optimal performance and longevity. Understanding common issues and how to address them can significantly enhance the user experience and maintain the quality of your equipment.

Common Issues and Solutions

- Focusing Problems: Check for misalignment and debris that may interfere with smooth operation.

- Optical Distortions: Evaluate the glass elements for scratches or fogging that could impact image quality.

- Mounting Issues: Ensure that the attachment points are free of obstructions and properly lubricated.

Basic Tools Required

- Precision screwdriver set

- Lens cleaning solution and microfiber cloth

- Tweezers for delicate adjustments

- Torque wrench for reassembly

Step-by-Step Maintenance Process

Following a structured approach can make the process more efficient:

- Disassemble the unit carefully, noting the order of components.

- Clean all optical surfaces with appropriate solutions.

- Inspect each element for damage, replacing any defective parts.

- Reassemble the unit, ensuring all parts are secure and functioning correctly.

Understanding Common Lens Issues

Many photographers encounter various challenges with their optical devices that can affect image quality and overall performance. Recognizing these frequent problems is essential for maintaining optimal functionality and ensuring clarity in every shot.

Focus Misalignment: One prevalent issue arises when the focus is not accurately aligned, leading to blurred images. This can occur due to physical impacts or internal component shifts, requiring careful assessment.

Dust and Debris: Accumulation of particles inside the structure can obstruct light pathways, resulting in hazy visuals. Regular cleaning and maintenance can help mitigate this problem and enhance image sharpness.

Fungus Growth: Humid conditions may encourage the growth of mold within the assembly, which can damage coatings and glass surfaces. Proper storage and humidity control are vital in preventing such deterioration.

Mechanical Failures: Components such as apertures and focus rings can wear out over time, leading to sluggish operation. Understanding the signs of wear can prompt timely intervention to preserve the device’s integrity.

Tools Needed for Lens Repairs

To effectively address issues related to optical equipment, having the right set of tools is essential. These instruments not only facilitate the disassembly and assembly processes but also ensure precision and care during the handling of delicate components.

Here are some key instruments that are typically required:

- Screwdrivers: Various sizes are necessary to fit different screws used in the assembly.

- Spanners: Adjustable spanners help in loosening or tightening circular parts without causing damage.

- Tweezers: Fine-point tweezers allow for the careful manipulation of small parts.

- Cleansing materials: Lint-free cloths and appropriate solvents are vital for maintaining clarity and cleanliness.

- Magnifying glass: A magnifier helps in examining intricate details and identifying potential issues.

- Calipers: Precision calipers assist in measuring components accurately for fitting.

By equipping yourself with these essential tools, you can enhance the likelihood of successful maintenance and prolong the lifespan of your optical devices.

Step-by-Step Disassembly Process

Disassembling optical devices requires a careful approach to ensure all components are preserved and reassembled correctly. This section provides a comprehensive guide to systematically taking apart the unit, focusing on maintaining the integrity of each piece throughout the process.

Initial Preparation

Before starting, gather the necessary tools and ensure a clean workspace. Proper lighting and a magnifying glass can help identify small parts. Organizing screws and components in labeled containers will streamline reassembly.

Component Removal

Begin by loosening any exterior fasteners. Gently pry open the casing using a plastic tool to avoid damaging the surface. As you progress, document each step, noting the arrangement of parts. This meticulous attention will facilitate easier reassembly later.

Cleaning Optical Elements Effectively

Maintaining the clarity of visual components is crucial for optimal performance. Regular cleaning helps in preserving the integrity of the surfaces, enhancing image quality, and prolonging the lifespan of your equipment.

Choosing the Right Materials

Utilizing appropriate tools is essential for avoiding damage. Opt for microfiber cloths and specialized solutions designed for optical surfaces. Avoid using paper products or household cleaners, as they may leave scratches or residues.

Cleaning Technique

Start by gently removing any loose dust or debris with a blower. Then, apply a few drops of the cleaning solution to the microfiber cloth, never directly onto the surface. Use circular motions, applying minimal pressure to avoid harming the coatings.

Drying and Final Touches

After cleaning, ensure that the surfaces are completely dry before reassembling your equipment. Inspect for any streaks or remaining spots, repeating the process if necessary to achieve optimal clarity.

Replacing Damaged Lens Components

In the process of maintaining optical equipment, there are instances when certain elements may become compromised. Addressing these issues promptly can significantly enhance performance and prolong the lifespan of the apparatus. This section outlines essential steps for the replacement of damaged parts, ensuring optimal functionality.

Identifying Faulty Parts

Before proceeding with any replacements, it is crucial to accurately diagnose the components that require attention. Inspecting the elements for signs of wear or damage will help in determining which parts need to be substituted. Common indicators include scratches, cracks, or misalignment that can affect overall image quality.

Step-by-Step Replacement Process

Once the faulty components have been identified, carefully disassembling the unit is the next step. Utilize appropriate tools to avoid causing further damage. After removing the defective parts, install the new components, ensuring they are securely fitted. Finally, reassemble the unit and conduct tests to verify that the replacement has restored proper functionality.

Reassembly Techniques for Precision

Achieving optimal performance in optical devices requires meticulous attention during the reassembly process. This section explores effective strategies to ensure that every component is aligned and functions seamlessly, enhancing the overall quality of the instrument.

- Preparation: Before starting, gather all necessary tools and ensure a clean workspace to avoid contamination.

- Organization: Keep parts sorted and labeled to prevent confusion during the reassembly process.

- Use of Guides: Refer to detailed schematics or guides to understand the correct positioning of components.

- Gentle Handling: Handle delicate parts with care to avoid damage and maintain their integrity.

- Alignment Techniques: Utilize visual aids or jigs to assist in precise alignment of elements during assembly.

By implementing these techniques, one can achieve a reliable and accurate reassembly, ensuring that the optical device performs to its fullest potential.

Calibration and Testing After Repairs

Ensuring optimal performance following maintenance is crucial for any optical device. This section outlines the essential procedures to verify that adjustments have been successfully implemented and that the system operates as intended. Proper evaluation not only enhances functionality but also extends the lifespan of the equipment.

Verification of Adjustments

Initially, it is important to confirm that all modifications have been executed accurately. This can be achieved through a series of tests that check alignment and precision. Utilizing specialized tools can aid in assessing the integrity of the adjustments, allowing for any necessary fine-tuning.

Performance Testing

Once adjustments have been verified, conducting performance tests is the next step. This involves assessing the output quality under various conditions to ensure consistency. By analyzing the results, one can determine if further modifications are required or if the system meets the desired specifications.

Troubleshooting Post-Repair Problems

After servicing optical equipment, it is not uncommon to encounter issues that may arise despite the intended fixes. Understanding the common challenges can aid in identifying the root causes and ensuring the equipment functions optimally.

Here are some frequent complications and their possible solutions:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Unfocused Images | Misalignment of components, dust on surfaces | Realign elements, clean optical surfaces |

| Light Leakage | Improper sealing, damaged gaskets | Inspect seals, replace gaskets as needed |

| Mechanical Resistance | Obstruction in moving parts, inadequate lubrication | Check for blockages, apply appropriate lubricant |

| Color Distortion | Improper assembly, incorrect glass elements | Disassemble and verify the correct configuration |

Addressing these problems requires careful inspection and a methodical approach to restore functionality. Regular maintenance can prevent many issues from occurring in the first place.

Preventive Maintenance Tips for Longevity

To ensure the durability and optimal performance of your optical equipment, regular upkeep is essential. By incorporating simple maintenance practices into your routine, you can significantly extend the lifespan of your devices and enhance their functionality.

Regular Cleaning and Care

Dust and debris can accumulate over time, affecting clarity and performance. Use a soft, lint-free cloth to gently wipe the exterior surfaces. For delicate components, consider using a blower to remove particles without scratching the surfaces. Regular cleaning prevents buildup that can lead to more significant issues later.

Proper Storage Techniques

When not in use, store your equipment in a controlled environment. Avoid exposure to extreme temperatures and humidity, which can cause damage. Utilize padded cases or protective covers to shield your gear from impacts and environmental factors. This proactive approach will help maintain optimal conditions for your tools.

Resources for Further Assistance

For individuals seeking additional help with their optical equipment, various resources are available to enhance understanding and troubleshooting capabilities. These platforms offer insights, expert guidance, and community support for enthusiasts and professionals alike.

- Online Forums: Engaging in discussions with fellow enthusiasts can provide valuable tips and solutions. Websites like photography forums and dedicated repair communities are great starting points.

- Instructional Videos: Numerous platforms host video tutorials that visually demonstrate various techniques and common fixes. Searching for specific issues can yield helpful results.

- Workshops and Classes: Local photography shops or community colleges often offer workshops on equipment maintenance, providing hands-on experience and expert instruction.

- Books and Guides: Literature focused on optical devices and maintenance can serve as comprehensive resources, often including diagrams and step-by-step instructions.

- Manufacturer Support: Contacting the manufacturer directly can provide access to professional advice and possibly recommended service centers.