When it comes to maintaining essential equipment, having access to comprehensive guidance is crucial. This section focuses on providing detailed insights and steps to ensure optimal functionality of your devices. With the right knowledge, users can effectively troubleshoot common issues and enhance performance.

Understanding the various components and their functions is key to successful upkeep. Whether you are experiencing mechanical problems or routine wear and tear, knowing how to approach repairs can save time and resources. This resource aims to equip users with the necessary skills to confidently tackle challenges.

By following the suggested procedures and utilizing practical tips, individuals can foster a deeper connection with their tools. A proactive approach to maintenance not only prolongs the lifespan of your equipment but also ensures safety during operation. Dive into the details and empower yourself with the ability to manage your tools effectively.

Craftsman T110 Overview

This section provides an essential understanding of a popular lawn care machine designed for efficiency and durability. Users appreciate its reliable performance, making it a favored choice for maintaining outdoor spaces.

| Feature | Description |

|---|---|

| Engine | Powerful engine for optimal performance. |

| Cutting Width | Generous cutting width for efficient mowing. |

| Transmission | Easy-to-use transmission system for smooth operation. |

| Comfort | Ergonomic design for user-friendly experience. |

Common Issues with Craftsman T110

Every mechanical device can face challenges over time, and certain models often exhibit specific recurring problems. Understanding these typical malfunctions can help users maintain optimal performance and longevity.

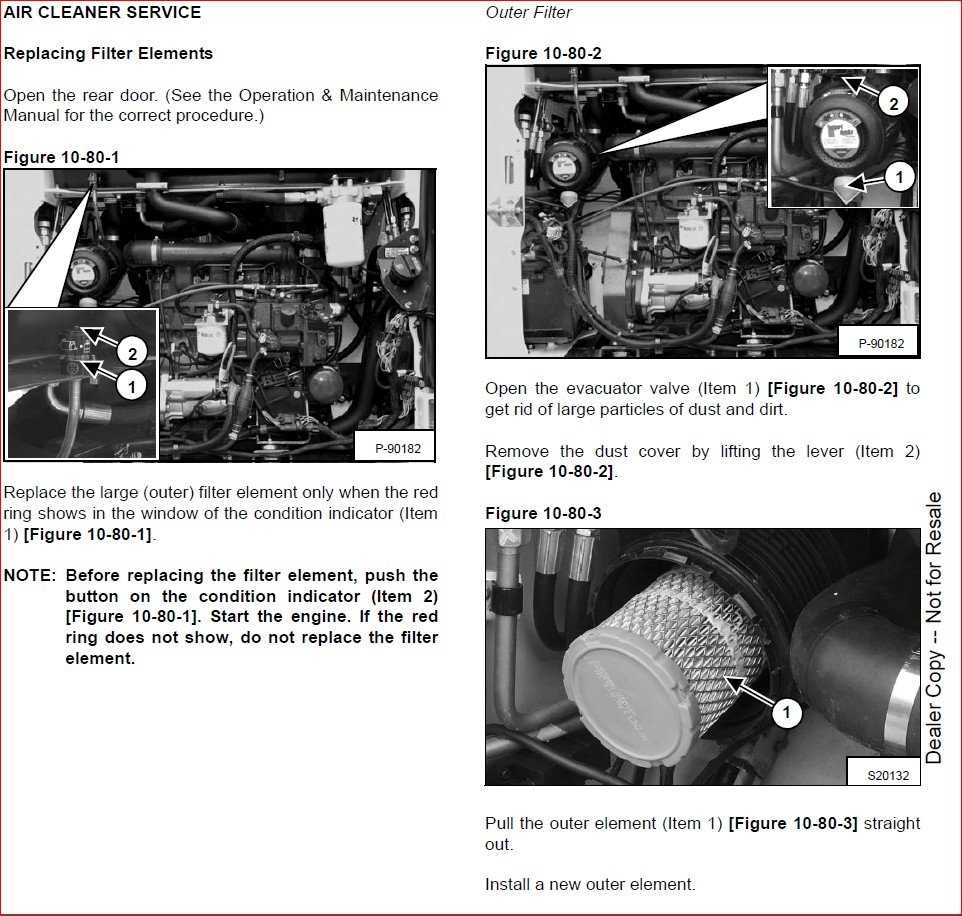

One frequent concern is related to engine performance. Users may notice issues such as difficulty starting or a decrease in power during operation. This could stem from factors like fuel quality or air filter blockage.

Another common area of frustration involves the transmission system. Problems may arise with shifting gears, which can affect maneuverability. Checking for proper lubrication and ensuring there are no leaks can be essential steps in troubleshooting.

Lastly, the cutting mechanism often requires attention. Dull blades or uneven cutting can lead to unsatisfactory results. Regular maintenance, including sharpening or replacing blades, is crucial for achieving the best outcomes.

Basic Maintenance Tips

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. Simple maintenance tasks can prevent costly repairs and extend the lifespan of your tools. Here are some key practices to follow for effective care.

Routine Checks

- Inspect for any visible wear or damage regularly.

- Ensure that all moving parts are properly lubricated.

- Check electrical components for any signs of fraying or corrosion.

Cleaning Procedures

- Clean the exterior to remove dirt and debris after each use.

- Use appropriate cleaning solutions for different materials.

- Keep air filters and vents clear to ensure proper airflow.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for ensuring effective and efficient work. A well-equipped workspace not only facilitates the repair process but also enhances the overall experience. The selection of tools may vary based on the specific tasks at hand, but certain essentials are universally beneficial.

Essential Hand Tools

Basic hand tools form the backbone of any repair job. These typically include screwdrivers, wrenches, and pliers. Each of these tools plays a unique role in disassembling components, adjusting fittings, and securing parts in place. A good set of these hand tools is indispensable, as they allow for precision and control during the maintenance process.

Power Tools for Efficiency

In addition to hand tools, power tools can significantly speed up tasks that require more force or intricate work. Tools like drills and saws are ideal for cutting through materials or driving fasteners quickly. Utilizing power tools not only saves time but also reduces physical strain, making them a valuable addition to any repair toolkit.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with equipment. By following the outlined steps, you can effectively troubleshoot and resolve problems, ensuring optimal performance. This guide emphasizes practical techniques and essential tools required for efficient servicing.

Start by assessing the condition of the machine. Inspect all components for visible signs of wear or damage. It is crucial to document any irregularities, as this will help in diagnosing the underlying causes of malfunction.

Next, gather the necessary tools and replacement parts. A well-equipped workspace will facilitate the repair process and minimize downtime. Ensure that all items are organized and easily accessible.

Begin the disassembly process by carefully removing the outer casing. Take note of how components are arranged, as this will aid in reassembly later. Be cautious to avoid damaging any internal parts during this stage.

Once disassembled, clean all components thoroughly to remove debris and buildup. This will enhance the functionality of the equipment and prolong its lifespan. After cleaning, inspect each part for further damage or required replacements.

After addressing any issues, reassemble the equipment by reversing the disassembly steps. Ensure that all connections are secure and that components fit snugly in place. Double-check the arrangement against your earlier documentation.

Finally, perform a test run to verify that everything operates smoothly. Monitor for any unusual sounds or behaviors, which may indicate that further adjustments are needed. By following this systematic approach, you can effectively maintain and enhance the longevity of your equipment.

Identifying Engine Problems

Understanding how to recognize issues within an engine is crucial for effective maintenance and troubleshooting. By being aware of common symptoms, users can take proactive steps to address potential failures before they escalate into more significant problems.

Various signs may indicate underlying engine troubles, and recognizing these early can save time and resources. Here are some typical indicators:

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Loose components or worn parts |

| Difficulty starting | Fuel delivery issues or battery problems |

| Excessive smoke | Oil leaks or combustion problems |

| Decreased performance | Clogged filters or ignition system failures |

| Warning lights | Sensor malfunctions or critical failures |

Monitoring these signs can facilitate timely interventions and maintain optimal functionality, ensuring longevity and efficiency of the equipment.

Electrical System Troubleshooting

Troubleshooting the electrical system of your equipment is essential for ensuring optimal performance and longevity. Identifying issues early can prevent more significant problems and costly repairs. This section provides guidance on common electrical problems, potential causes, and systematic approaches to diagnosing and resolving these issues.

Begin by checking the power source to ensure it is functioning correctly. Verify that all connections are secure and free from corrosion. Inspect the wiring for any signs of wear, fraying, or damage, which can lead to interruptions in power delivery. Multimeters can be invaluable tools for measuring voltage and continuity, helping to pinpoint faulty components.

If the system fails to start, consider the state of the battery and its connections. A weak or dead battery may prevent the unit from operating. Ensure terminals are clean and securely attached. Additionally, check any fuses or circuit breakers that may have tripped, as these can interrupt the electrical flow.

When diagnosing issues related to lights or indicators, inspect the bulbs and connections. Replacing burnt-out bulbs is often a simple fix, while loose connections may require tightening or resealing. For more complex problems, consult the component diagrams to trace the electrical pathways and identify any potential disruptions.

Regular maintenance and inspections can help mitigate electrical issues before they escalate. Keeping connections clean and secure, along with monitoring battery health, will enhance the reliability and efficiency of the system.

Replacing Key Components

Maintenance and servicing of tools often involve the replacement of essential parts to ensure optimal performance and longevity. Identifying when these components need attention is crucial for effective upkeep. This section discusses the process and considerations involved in substituting critical elements within equipment.

Before starting, it is important to gather the necessary tools and replacement parts. Proper preparation facilitates a smoother transition and minimizes potential complications. Ensuring that the new components are compatible with the existing setup is vital for seamless functionality.

During the replacement process, take care to follow specific procedures for each part. This may involve removing covers, disconnecting power sources, and handling delicate components with caution. Always refer to guidance for any particular nuances associated with the task at hand.

After the replacement, thorough testing is essential. Verifying that the new components function correctly ensures that the equipment operates as intended. Regular inspections following the replacement will help maintain performance and catch any issues early.

Seasonal Maintenance Checklist

Regular upkeep of your equipment ensures optimal performance and longevity. By adhering to a systematic seasonal maintenance routine, you can prevent potential issues and enhance efficiency. This checklist serves as a guide for essential tasks to be conducted at the change of each season.

Spring Maintenance Tasks

As the weather warms, it’s crucial to prepare your equipment for increased usage. Focus on cleaning, inspecting, and making necessary adjustments.

| Task | Description |

|---|---|

| Inspect Blades | Check for wear and sharpen as needed. |

| Clean Air Filter | Remove debris and ensure proper airflow. |

| Change Oil | Replace old oil with fresh lubricant. |

Fall Maintenance Tasks

As temperatures drop, preparation for storage is essential. Perform these checks to protect your equipment during the colder months.

| Task | Description |

|---|---|

| Drain Fuel | Empty the fuel tank to prevent degradation. |

| Inspect Battery | Check connections and clean terminals. |

| Cover Equipment | Use protective covers to shield from elements. |

Safety Precautions During Repair

Ensuring a safe working environment is essential when performing maintenance or fixing equipment. Adhering to safety guidelines minimizes risks and protects individuals from potential hazards associated with mechanical work. It is crucial to prepare adequately and follow recommended practices to prevent accidents and injuries.

Essential Safety Guidelines

Before starting any maintenance tasks, it is important to be aware of the following safety measures:

| Guideline | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and sturdy footwear to protect yourself from injuries. |

| Work Area Organization | Keep your workspace clean and organized to avoid accidents caused by clutter or misplaced tools. |

| Proper Tool Usage | Use tools as intended and ensure they are in good condition to prevent malfunctions or accidents. |

| Electrical Safety | Disconnect power sources before beginning any work on electrically operated equipment to avoid shock hazards. |

Emergency Procedures

Familiarize yourself with emergency procedures, including the location of first aid kits and emergency exits. Knowing how to respond in case of an accident can significantly reduce injury severity.

Where to Find Replacement Parts

Locating suitable components for your equipment can be crucial for maintaining its functionality. Whether you’re looking for specific items or general supplies, there are various avenues to explore to ensure you find what you need.

Online Retailers

One of the most convenient ways to search for parts is through online retailers. Many websites specialize in providing a wide range of components for various types of machinery. Here are some benefits:

- Extensive selection of parts

- Competitive pricing

- Convenience of home delivery

Local Hardware Stores

Your neighborhood hardware store can be an excellent resource for finding the necessary components. Many stores carry commonly needed parts and have knowledgeable staff who can assist you in locating specific items. Consider the following:

- Personalized assistance from staff

- Immediate access to parts

- Possibility of checking compatibility on-site