Understanding the intricacies of your gardening machinery is essential for optimal performance and longevity. Proper upkeep not only enhances efficiency but also prevents costly breakdowns that can disrupt your landscaping projects. This guide aims to provide valuable insights and step-by-step assistance for tackling common issues.

In this resource, you will discover various troubleshooting techniques and preventive measures tailored to your specific model. From routine checks to in-depth fixes, the information is designed to empower users with the knowledge needed to handle their equipment with confidence.

Whether you are a seasoned user or new to lawn care tools, grasping the fundamental principles of maintenance will greatly benefit your gardening experience. This comprehensive approach ensures that your machinery remains in peak condition, ready to tackle any task you throw its way.

Essential Tools for LT1000 Repairs

Having the right instruments on hand can make all the difference when it comes to maintaining and fixing outdoor equipment. This section highlights the fundamental implements you will need to tackle various tasks efficiently and effectively.

Here’s a list of must-have tools:

- Wrenches: Adjustable and socket types are crucial for loosening and tightening various fasteners.

- Screwdrivers: A variety of flathead and Phillips head screwdrivers will cover most screws you encounter.

- Pliers: Needle-nose and standard pliers are versatile for gripping, twisting, and cutting.

- Multimeter: This tool is essential for troubleshooting electrical issues and testing components.

- Oil Filter Wrench: Specifically designed for removing oil filters with ease.

- Jack Stands: For safely elevating the unit while you work underneath.

- Clean Rags: Keeping everything tidy and managing spills is important for safety and efficiency.

Additionally, consider the following items to enhance your toolkit:

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Safety Gear: Gloves, goggles, and masks protect you during maintenance tasks.

- Grease Gun: For applying lubricant to moving parts, helping to extend the life of the machinery.

Equipping yourself with these essential tools will enable you to perform tasks confidently and maintain optimal functionality of your equipment.

Common Issues with Craftsman LT1000

When maintaining a riding mower, users often encounter a variety of challenges that can impact performance and longevity. Understanding these common problems is essential for effective troubleshooting and ensuring a smooth operation.

- Starting Difficulties: Many operators report issues with ignition, which can stem from:

- Worn spark plugs

- Faulty battery connections

- Clogged fuel lines

- Engine Performance: Suboptimal engine performance can be attributed to:

- Dirty air filters

- Incorrect fuel mixtures

- Old or contaminated oil

- Cutting Problems: An uneven cut can result from:

- Dull mower blades

- Improper deck height adjustment

- Obstructions in the cutting path

- Transmission Issues: Operators may experience difficulties with gear shifting due to:

- Low transmission fluid

- Worn belts

- Improperly adjusted cables

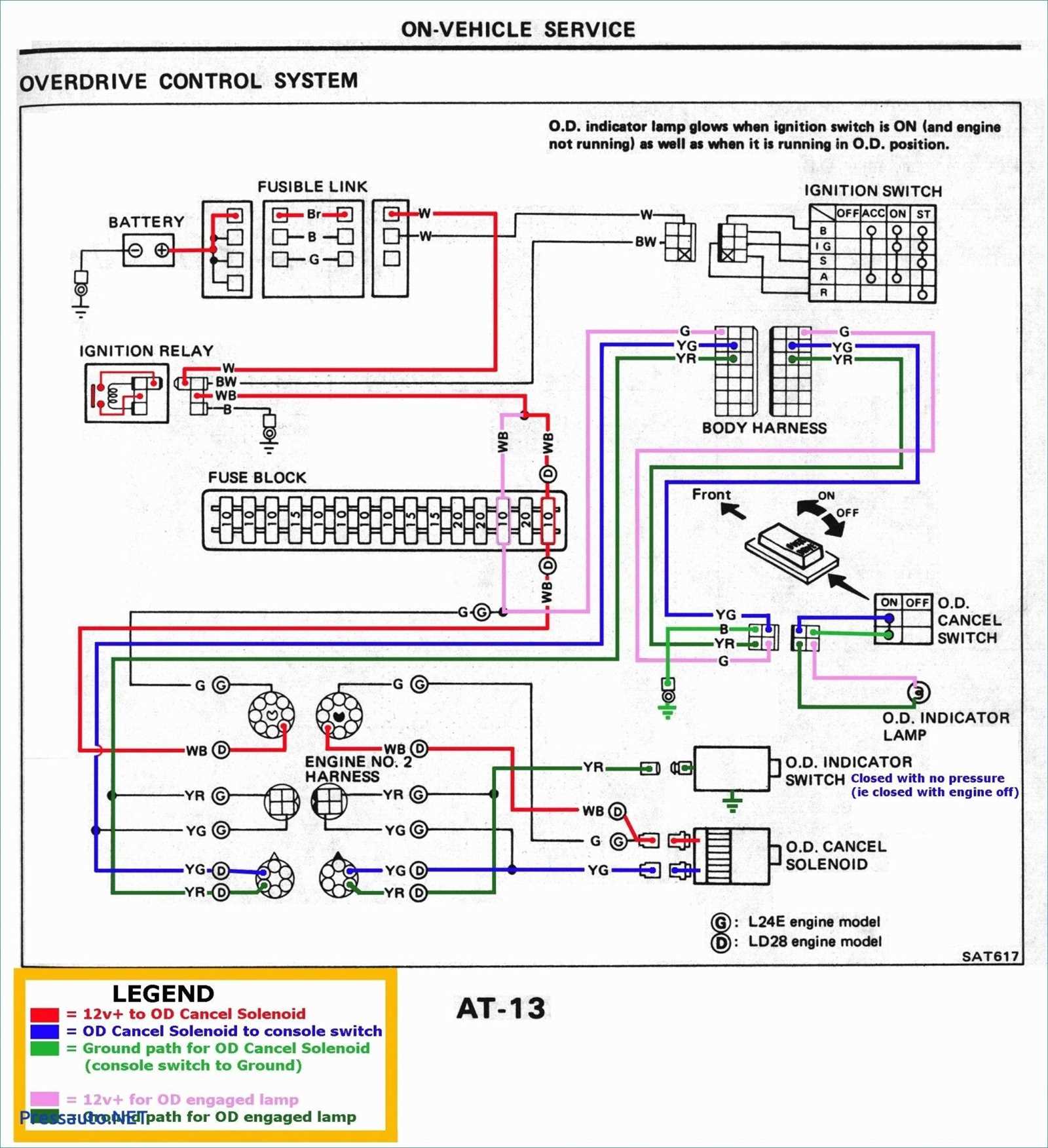

- Electrical Failures: Electrical system malfunctions can arise from:

- Faulty fuses

- Worn wiring

- Defective switches

lessCopy code

Addressing these frequent issues promptly can enhance the overall functionality and lifespan of the mower, ensuring that it remains a reliable tool for lawn care.

Step-by-Step Maintenance Guide

Proper upkeep of your machinery is essential to ensure optimal performance and longevity. This guide provides a structured approach to maintaining your equipment, focusing on key tasks that should be regularly performed. By following these steps, you can enhance the reliability and efficiency of your tools.

Begin with a thorough inspection of the machine. Check for any signs of wear or damage, paying special attention to belts, blades, and other moving parts. Regularly cleaning these components will prevent the buildup of dirt and debris, which can lead to malfunctions.

Next, focus on the lubrication of moving parts. Applying the appropriate lubricants will minimize friction and wear, contributing to smoother operation. Refer to your equipment specifications for the correct type of lubricant and recommended intervals for application.

It’s also crucial to change filters and fluids as specified in the guidelines. Regularly replacing these items helps maintain optimal performance and prevents potential issues caused by contaminants.

Lastly, ensure that all safety features are functioning correctly. This includes checking emergency stops, guards, and any other safety mechanisms in place. Regular maintenance not only prolongs the life of your machine but also enhances safety during operation.

Troubleshooting Engine Problems

Addressing issues with the power unit can often be a straightforward process if you follow a systematic approach. Identifying the symptoms is the first step toward resolution, allowing you to narrow down potential causes and implement effective solutions. This guide will help you diagnose common complications related to engine performance.

Common Symptoms and Causes

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Engine won’t start | Faulty spark plug | Inspect and replace the spark plug if necessary. |

| Rough running | Dirty air filter | Clean or replace the air filter to improve airflow. |

| Overheating | Low oil level | Check oil level and add oil as needed. |

| Excessive smoke | Worn piston rings | Inspect the engine for wear and consider professional assistance. |

Steps to Diagnose

Begin by observing the engine during operation. Note any unusual sounds, vibrations, or behaviors. Conduct a visual inspection for leaks or loose components. Following this, consult the table above to match observed symptoms with potential causes, allowing you to systematically address each issue until the problem is resolved.

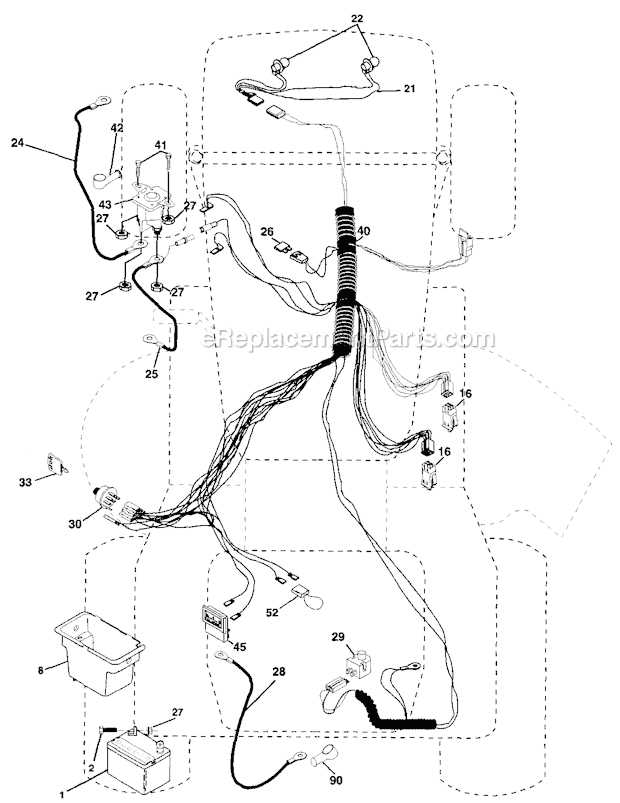

Replacing the Deck Belt

Maintaining the functionality of your outdoor equipment is essential for optimal performance. One critical component that often requires attention is the belt that connects the engine to the cutting deck. Over time, this part can wear out, leading to decreased efficiency or operational issues. This section will guide you through the process of replacing this vital component, ensuring your machinery runs smoothly.

Step 1: Begin by disconnecting the power source to prevent any accidental starts. For safety, remove the spark plug wire and ensure the machine is completely powered down.

Step 2: Next, elevate the machine to access the underside where the deck belt resides. This may involve using a jack or suitable lifting equipment. Always ensure the machine is stable before proceeding.

Step 3: Locate the old belt and take note of its routing around the pulleys. This step is crucial, as improper installation of the new belt can lead to functionality issues.

Step 4: Carefully remove the worn belt from the pulleys. It may require loosening certain components to free the belt completely. Keep all hardware in a secure place for reinstallation.

Step 5: Install the new belt by following the routing pattern observed earlier. Ensure it sits correctly in the grooves of each pulley to avoid slippage during operation.

Step 6: Once the new belt is in place, reassemble any parts that were removed during the process. Double-check that all hardware is tightened securely.

Step 7: Finally, reconnect the power source and start the machine to test the new belt’s functionality. Monitor for any unusual sounds or performance issues during operation.

Replacing the deck belt is a straightforward yet essential task that can enhance the lifespan and efficiency of your equipment. Regular maintenance will help ensure reliable performance season after season.

Adjusting the Carburetor Settings

Properly tuning the fuel-air mixture is essential for optimal engine performance. Adjusting the carburetor settings ensures that the engine runs smoothly, efficiently, and with reduced emissions. This process involves fine-tuning various components to achieve the desired balance for different operating conditions.

Follow these steps to adjust the carburetor settings effectively:

- Prepare the Engine:

- Ensure the engine is off and cool.

- Gather necessary tools, including a screwdriver and a tachometer.

- Locate the Adjustment Screws:

- Identify the idle mixture and speed screws on the carburetor.

- Refer to your equipment’s documentation for exact locations.

- Adjust the Idle Mixture:

- Start the engine and let it warm up.

- Slowly turn the idle mixture screw clockwise until the engine starts to sputter.

- Then, turn it counterclockwise until you reach the optimal idle speed.

- Set the Idle Speed:

- Use the idle speed screw to adjust the RPM to the manufacturer’s specifications.

- Ensure the engine runs steadily without stalling.

- Test the Engine:

- Take the equipment for a short test run.

- Monitor performance and listen for any unusual sounds.

Regular adjustments may be necessary based on environmental changes or fuel variations. Maintaining the correct settings not only prolongs the life of the engine but also enhances overall functionality.

Battery Replacement Process

Replacing the power source is an essential task for maintaining optimal performance in your equipment. A fresh battery ensures reliable operation and extends the lifespan of your machinery. This section outlines the steps needed to safely and effectively swap out the old battery for a new one.

Step 1: Begin by gathering the necessary tools, including a wrench and safety gloves. It’s crucial to prioritize safety throughout this process.

Step 2: Disconnect the device from any power source to prevent accidental activation. Locate the battery compartment, which is usually accessible from the rear or underneath the unit.

Step 3: Carefully remove the old battery by unscrewing any fasteners or clips that hold it in place. Take note of the orientation and connections, as this will be important for the installation of the new unit.

Step 4: Insert the new battery, ensuring that it aligns correctly with the terminals. Secure it in place using the same fasteners or clips that held the previous battery.

Step 5: Reconnect any wires or connectors, paying close attention to the positive and negative terminals to avoid any potential damage.

Step 6: Finally, close the battery compartment and double-check all connections. Reconnect the power source and test the equipment to ensure it functions correctly with the new battery.

Cleaning the Air Filter Effectively

Maintaining the air filter is crucial for ensuring optimal performance and longevity of your equipment. A clean air filter allows for proper airflow, enhancing efficiency and preventing potential damage. Regular maintenance can help you avoid costly repairs and ensure smooth operation.

Follow these steps to effectively clean the air filter:

- Gather Your Tools: Collect necessary items such as a soft brush, a vacuum cleaner, and a mild detergent.

- Remove the Filter: Carefully detach the air filter from its housing, ensuring not to damage any components.

- Inspect the Filter: Examine the filter for signs of wear or excessive dirt buildup. If it’s heavily damaged, consider replacing it.

- Brush Off Debris: Use a soft brush to gently remove dirt and debris from the surface of the filter.

- Vacuum the Filter: For thorough cleaning, use a vacuum cleaner with a brush attachment to remove finer particles.

- Wash the Filter (if applicable): If the filter is washable, rinse it with water and a mild detergent. Avoid using strong chemicals.

- Dry Completely: Allow the filter to dry completely before reinstallation. Moisture can cause mold growth.

- Reinstall the Filter: Once dry, carefully place the air filter back into its housing, ensuring a secure fit.

Regularly checking and cleaning the air filter will not only improve performance but also extend the life of your machinery. Make this task a part of your routine maintenance schedule for best results.

Safety Tips for Lawn Mower Repairs

Performing maintenance on your lawn care equipment requires a focus on safety to prevent accidents and injuries. It is essential to adopt best practices to ensure a safe working environment while addressing any issues that may arise.

Before starting any work, disconnect the spark plug wire to prevent accidental starts. Always ensure the mower is on a flat surface to avoid unexpected movement. Wear appropriate protective gear, including gloves and safety goggles, to shield against flying debris and sharp components.

Keep your workspace organized and free of clutter. This reduces the risk of tripping or misplacing tools. Ensure proper ventilation when working with fuel or lubricants, and always handle these substances with care to prevent spills or fires.

Familiarize yourself with the equipment and its components before attempting any task. Use the right tools for each job, and never force tools or parts into place. If you encounter resistance, reassess the situation rather than risking damage or injury.

Finally, consult documentation or guides when in doubt about procedures. Following recommended guidelines can significantly enhance safety and effectiveness during maintenance tasks.

Finding Replacement Parts Easily

Locating the right components for your equipment can be a straightforward process if you know where to look. Understanding the sources for high-quality parts ensures that your machinery remains in optimal condition without unnecessary hassle.

Online Retailers: A plethora of online platforms specialize in spare parts, providing detailed catalogs that allow you to search by model number or component type. This can save you time and effort, as many sites offer user reviews and comparisons to help you make informed decisions.

Local Hardware Stores: Don’t overlook your neighborhood stores. Many of them stock essential parts or can order specific items for you. Speaking directly with knowledgeable staff can lead to valuable advice and recommendations tailored to your needs.

Manufacturer Websites: Often, the most reliable source for components is directly from the producer. Their official sites typically have a dedicated section for parts, ensuring compatibility and quality assurance.

Forums and Community Groups: Engaging with fellow enthusiasts through online forums or local clubs can provide insights into where to find hard-to-get parts. Community members often share tips and resources, making it easier to locate what you need.

In summary, by utilizing a mix of online resources, local stores, and community networks, you can efficiently track down the necessary components to keep your equipment running smoothly.