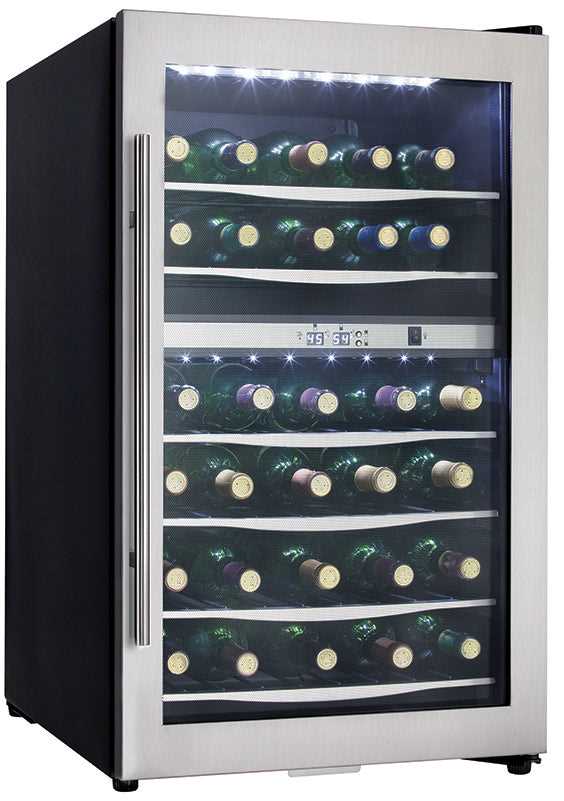

Proper maintenance of your beverage preservation appliance is essential for optimal performance and longevity. Understanding the common challenges that these units may face empowers users to address issues effectively, ensuring a consistent environment for your treasured collections. Knowledge of the fundamental components and their functions is the first step towards effective troubleshooting.

In this section, we will explore various aspects of maintaining your storage device. From temperature regulation to efficient energy usage, a well-informed approach can enhance your experience and extend the life of your appliance. Recognizing signs of malfunction and learning basic interventions can save both time and resources.

Whether you are encountering cooling inconsistencies or unusual noises, having access to comprehensive information will guide you through the necessary steps to restore functionality. By following a structured approach, you can confidently manage issues that may arise with your unit.

Monitoring variations in ambient conditions is crucial for maintaining the integrity of stored beverages. These shifts can lead to undesirable consequences, affecting flavor profiles and overall quality. Understanding how to detect these inconsistencies is essential for effective management.

Common Signs of Temperature Changes:

- Inconsistent readings: Frequent discrepancies in thermometer measurements indicate instability.

- Condensation: Excess moisture on surfaces may signal improper temperature regulation.

- Unusual sounds: Noticeable noises from the unit may suggest malfunctioning components impacting temperature control.

Regularly assessing these indicators can help in early detection of issues, ensuring optimal preservation of contents.

Inspecting the Power Supply

Ensuring a consistent energy source is essential for optimal functioning. A thorough examination of the power system can help identify any potential issues that may hinder performance. This process includes checking connections, voltage levels, and overall integrity of the power supply components.

Begin by disconnecting the unit from the outlet to ensure safety. Afterward, visually inspect the power cord for any signs of damage, such as fraying or cuts. It’s also important to assess the outlet itself to confirm it is providing adequate voltage.

| Component | Check for |

|---|---|

| Power Cord | Frays, cuts, or loose connections |

| Outlet | Voltage output and stability |

| Fuse | Burnt or damaged fuse |

| Internal Wiring | Loose connections or wear |

After completing the visual inspection, use a multimeter to measure voltage output from the outlet and check continuity within the power cord. These steps can help pinpoint whether the issue lies within the power supply or if it is an external problem.

Troubleshooting Cooling System Failures

When a refrigeration unit fails to maintain the desired temperature, it can lead to various issues. Understanding common problems within the cooling mechanism is essential for effective diagnosis and resolution. This section aims to outline typical failures and the steps necessary for troubleshooting.

Common Symptoms of Malfunction

- Insufficient cooling performance

- Unusual noises coming from the unit

- Frequent cycling on and off

- Visible frost buildup on the evaporator coils

Steps for Diagnosis

- Check the power supply to ensure the unit is receiving adequate voltage.

- Inspect the condenser coils for dirt or obstructions that may impede airflow.

- Examine the evaporator coils for frost accumulation, which may indicate airflow issues.

- Assess the thermostat settings and functionality for accurate temperature regulation.

- Look for leaks in the refrigerant lines, which can drastically affect cooling efficiency.

By systematically examining these areas, users can identify the root cause of cooling failures and take appropriate corrective actions.

Understanding Compressor Operations

The operation of a cooling unit is pivotal for maintaining optimal temperatures in various environments. At the heart of this system lies the compressor, a critical component responsible for circulating refrigerant and ensuring effective heat exchange. Understanding its function can provide valuable insights into troubleshooting and enhancing performance.

Functionality of the Compressor

The primary role of the compressor is to compress low-pressure refrigerant gas and convert it into high-pressure gas. This transformation enables the refrigerant to flow through the cooling system, absorbing heat from the surrounding area and facilitating the cooling process. The efficiency of this operation is essential for maintaining desired temperature levels.

Common Issues and Solutions

Several problems can affect the performance of a compressor, leading to inefficient cooling. Recognizing these issues is vital for effective maintenance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Excessive heat can cause compressor failure. | Ensure proper ventilation and check for blocked air intake. |

| Noisy Operation | Unusual sounds may indicate internal damage. | Inspect for loose components and replace damaged parts. |

| Inconsistent Cooling | Failure to maintain set temperatures. | Check refrigerant levels and ensure the thermostat is functioning correctly. |

Evaluating Door Seal Integrity

Ensuring the effectiveness of the door seal is crucial for maintaining optimal internal conditions. A compromised seal can lead to energy inefficiency and fluctuating temperatures, ultimately affecting the performance of the unit. Regular assessment of the sealing mechanism is essential for prolonged functionality.

Visual Inspection

Start by examining the door gasket for any visible signs of wear, tears, or deformation. Look for areas where the seal may not make full contact with the frame. A thorough visual inspection can reveal potential issues before they escalate.

Test for Air Leaks

To confirm the integrity of the seal, perform a simple air leak test. Close the door on a piece of paper; if you can easily pull it out, the seal may need adjustment or replacement. This straightforward method can help identify problematic areas that require attention.

Cleaning and Maintenance Procedures

Regular upkeep and thorough cleaning are essential for ensuring the longevity and optimal performance of your cooling appliance. Implementing a systematic approach to maintenance will not only enhance its functionality but also contribute to a more pleasant environment.

Essential Cleaning Steps

Adhering to these cleaning procedures will help maintain the efficiency of your unit:

- Unplug the device before starting any cleaning activities to ensure safety.

- Use a soft, damp cloth to wipe the exterior surfaces, removing dust and smudges.

- For the interior, use a mixture of mild soap and water. Avoid harsh chemicals that may damage the components.

- Clean the shelves and interior with a gentle scrubber to eliminate any spills or stains.

- Rinse and dry all surfaces thoroughly before reassembling.

Regular Maintenance Tips

In addition to cleaning, regular maintenance will help prolong the life of your appliance:

- Check the door seals for wear and tear. Replace them if necessary to maintain energy efficiency.

- Inspect the condenser coils periodically to remove dust and debris that can affect cooling performance.

- Monitor the temperature settings regularly to ensure they are within the optimal range.

- Schedule professional servicing annually to address any underlying issues and perform comprehensive checks.

Replacing Faulty Components

When dealing with malfunctioning cooling appliances, identifying and substituting defective parts is essential for restoring functionality. This process often requires a systematic approach to ensure all components work harmoniously.

Initial Assessment: Begin by conducting a thorough examination of the unit to pinpoint the problematic areas. Listen for unusual noises and check for any visible damage or irregularities.

Component Identification: Common culprits include the compressor, thermostat, and fan. Utilize the device’s documentation to locate these elements and understand their functions.

Replacement Procedure: After identifying the faulty part, carefully detach it following safety protocols. Ensure the power is disconnected before proceeding. Install the new component, securing it properly to avoid future issues.

Testing: Once replacements are made, restore power and monitor the appliance to confirm that it operates efficiently. Regular checks will help maintain optimal performance.

Utilizing Diagnostic Tools

Effective troubleshooting often hinges on the appropriate use of diagnostic instruments. These tools enable users to identify issues and assess performance accurately, ensuring efficient resolution of problems. By leveraging these resources, one can streamline the assessment process and enhance the longevity of the appliance.

Among the essential tools are multimeters, which measure electrical parameters such as voltage, current, and resistance. Utilizing a multimeter allows for quick evaluations of the power supply and circuit integrity, helping pinpoint electrical faults. Additionally, temperature sensors can be employed to verify cooling performance, ensuring that optimal conditions are maintained.

Incorporating software diagnostics can also be beneficial. Many modern devices feature built-in diagnostic capabilities, providing error codes that facilitate understanding of specific malfunctions. Familiarizing oneself with these codes can greatly expedite the troubleshooting process, allowing for targeted repairs.

Ultimately, understanding how to effectively utilize these diagnostic tools empowers users to tackle issues with confidence, ensuring the appliance operates smoothly and efficiently.

Guidelines for Proper Ventilation

Ensuring adequate airflow around your storage unit is essential for optimal performance and longevity. Proper ventilation not only helps maintain the ideal environment but also prevents overheating and minimizes energy consumption. Here are key considerations to enhance airflow and efficiency.

Airflow Management

Effective airflow is crucial for maintaining the desired temperature within the unit. Avoid placing the appliance in enclosed spaces or against walls that restrict air movement. Ensure that vents are unobstructed to facilitate smooth circulation.

Placement Considerations

When positioning your storage unit, consider its proximity to heat sources and direct sunlight. The ideal location is a cool, shaded area that allows for sufficient breathing space around all sides of the appliance.

| Placement Tips | Effect on Performance |

|---|---|

| Avoid closed cabinets | Prevents overheating |

| Keep away from ovens | Maintains stable temperatures |

| Allow space above and beside | Enhances airflow |

Addressing Noise and Vibration Problems

Excessive noise and unwanted vibrations can detract from the overall experience of using a beverage preservation unit. Identifying the source of these disturbances is crucial for maintaining optimal performance and enhancing user satisfaction. In this section, we will explore common causes and effective solutions to mitigate these issues.

Common Causes of Noise and Vibration

Several factors can contribute to noise and vibrations in a storage appliance. Understanding these sources can help in diagnosing and resolving the problems efficiently. The following table summarizes the typical causes and their descriptions:

| Cause | Description |

|---|---|

| Compressor Operation | The compressor is the primary component responsible for temperature regulation and may generate noise during its operation. |

| Fan Issues | Fans that are misaligned or obstructed can produce excessive sound and vibrations. |

| Improper Leveling | Units that are not level can experience vibrations, leading to noise as components shift during operation. |

| Loose Parts | Worn or loose components can rattle and contribute to increased sound levels. |

Effective Solutions

Once the sources of noise and vibration have been identified, appropriate measures can be implemented. Here are some recommended solutions:

- Ensure the unit is placed on a flat, stable surface to minimize vibrations.

- Check and tighten any loose components to prevent rattling.

- Regularly clean and maintain fans to ensure smooth operation.

- Consider using vibration-dampening pads to absorb excess noise.

Safety Precautions During Repairs

When undertaking maintenance on refrigeration units, it is essential to prioritize safety to prevent accidents and ensure efficient functioning. Proper precautions help mitigate risks associated with electrical components and mechanical systems.

Disconnect Power: Before initiating any service, always unplug the device or turn off the circuit breaker. This step is crucial to avoid electric shock.

Use Personal Protective Equipment: Wearing appropriate gear, such as gloves and safety goggles, can protect against injuries from sharp edges or hazardous materials.

Ventilation: Ensure that the workspace is well-ventilated, especially when handling refrigerants or other chemicals. Adequate airflow minimizes exposure to harmful fumes.

Follow Manufacturer Guidelines: Adhering to the guidelines provided by the manufacturer can prevent improper handling and potential damage to the appliance.

Keep Tools Organized: Maintain a tidy workspace by keeping tools organized. This practice reduces the likelihood of accidents and enhances efficiency.

Be Aware of Surroundings: Always be conscious of your environment and potential hazards, such as slippery surfaces or obstacles that may cause trips and falls.