Maintaining your automobile in peak condition is crucial for ensuring optimal performance and longevity. A well-structured guide can provide invaluable insights into troubleshooting common issues, performing essential services, and understanding the intricacies of your vehicle’s systems.

In this section, we delve into a detailed resource that covers a wide range of topics related to upkeep and enhancement of your car. Whether you’re a seasoned enthusiast or a novice, this guide offers step-by-step instructions that make the process accessible and straightforward.

From routine checks to more complex repairs, the information contained herein is designed to empower you with the knowledge needed to tackle various challenges. With a focus on practical advice and clear explanations, you’ll find yourself equipped to handle everything from minor adjustments to significant overhauls with confidence.

Additionally, the emphasis on safety and efficiency ensures that each procedure is not only effective but also minimizes risks associated with DIY projects. Embrace the opportunity to take control of your vehicle’s health and enjoy the satisfaction that comes with successful maintenance.

Understanding the Peugeot 406 Model

This section provides a comprehensive overview of a particular vehicle known for its blend of comfort, performance, and practicality. It explores the design philosophy, engineering innovations, and key features that make this automobile a standout choice for various drivers.

The vehicle is celebrated for its sleek aesthetics and well-thought-out interior, offering an inviting atmosphere for both driver and passengers. The thoughtful layout maximizes space while ensuring easy access to controls and essential functions. Moreover, its ergonomic design contributes to an overall pleasant driving experience.

Under the hood, this model is equipped with a range of powertrains that cater to different preferences and requirements. From efficient diesel engines to responsive petrol options, each variant delivers a balance of power and economy, making it suitable for both city commutes and long-distance travel.

Safety features are also a priority in this design, with numerous technologies aimed at protecting occupants. Advanced systems are integrated to enhance stability and control, instilling confidence in a variety of driving conditions.

Overall, this vehicle exemplifies a harmonious combination of style, performance, and practicality, appealing to a diverse audience of automotive enthusiasts and everyday drivers alike.

Common Issues with Peugeot 406

Vehicles of this model often present a range of typical problems that owners should be aware of. Understanding these common complications can help in maintaining optimal performance and ensuring longevity. From electrical glitches to mechanical wear, being informed allows for timely interventions and smoother operation.

Electrical System Failures

One prevalent concern involves the electrical components, including issues with the battery and alternator. Owners may experience difficulties starting the engine or notice warning lights illuminating on the dashboard. Regular checks and maintenance of the electrical system can mitigate these problems.

Suspension and Steering Issues

Another frequent challenge is related to the suspension and steering systems. Drivers often report unusual noises or a lack of responsiveness while turning. These symptoms can indicate worn-out components or misalignment, necessitating immediate inspection to ensure safety and stability on the road.

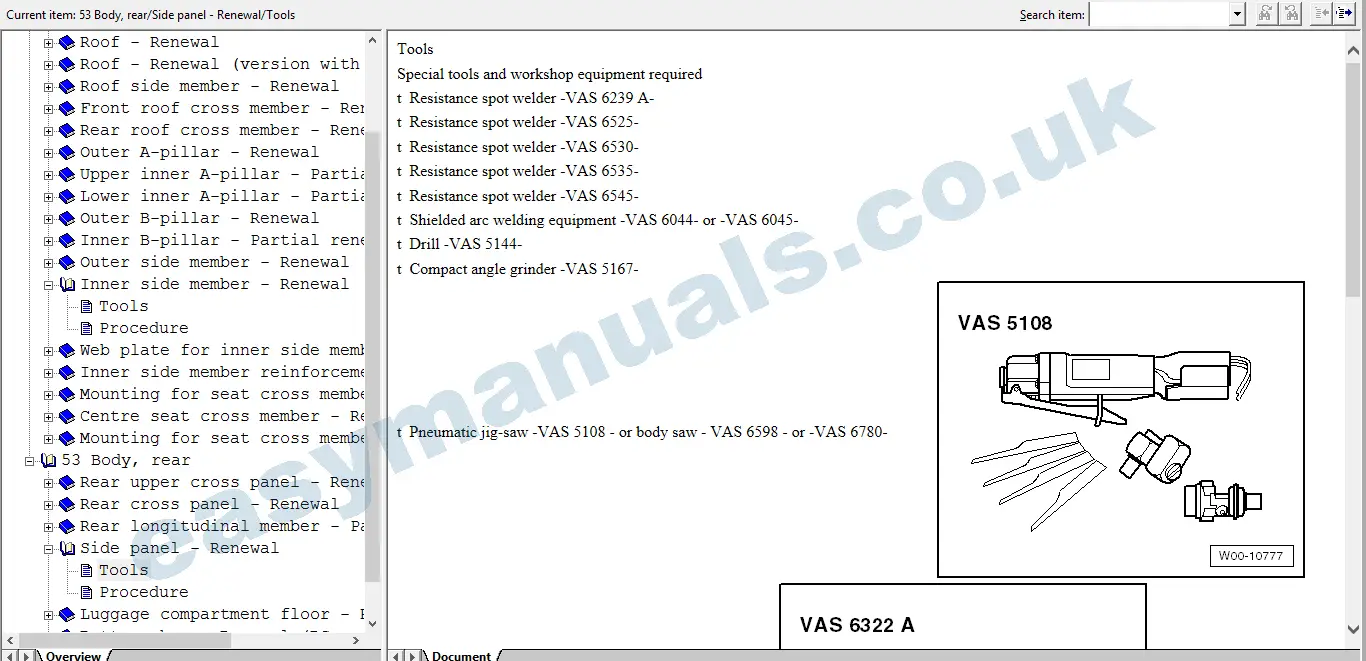

Essential Tools for DIY Repairs

For anyone looking to tackle automotive maintenance and enhancement on their own, having the right equipment is crucial. A well-equipped workspace not only simplifies the process but also enhances safety and efficiency. Understanding which implements are necessary can significantly improve the outcome of your tasks.

Basic Hand Tools are the foundation of any workshop. This includes wrenches, screwdrivers, and pliers. A good set of both metric and imperial sizes ensures you’re prepared for a variety of tasks. Having high-quality tools can prevent damage to components and make the job much smoother.

Power Tools can also be beneficial, especially for larger projects. An electric drill, impact wrench, and angle grinder can save time and effort. These tools allow for more complex jobs to be completed with precision and ease.

Safety gear is equally important. Gloves, safety goggles, and a dust mask protect against injuries and keep you safe from hazardous materials. Investing in protective equipment is a small price to pay for ensuring your well-being during maintenance activities.

Lastly, consider diagnostic equipment. An OBD-II scanner, for instance, can provide vital insights into your vehicle’s performance, helping you identify issues before they escalate. This technology not only aids in troubleshooting but also empowers you to make informed decisions about repairs and upgrades.

Step-by-Step Guide to Oil Change

Regularly replacing engine lubricant is essential for maintaining optimal performance and longevity of your vehicle. This process helps to ensure that all moving parts are properly lubricated, reducing wear and tear while enhancing overall efficiency. Below is a clear and concise guide to performing this important task yourself.

Step 1: Gather Necessary Supplies

Before you begin, ensure you have all required materials on hand. You will need fresh lubricant, an oil filter, a wrench, a drain pan, a funnel, and a pair of gloves to keep your hands clean.

Step 2: Prepare the Vehicle

Park the vehicle on a flat surface and engage the parking brake. It’s advisable to run the engine for a few minutes to warm up the oil, as this allows for better drainage. Turn off the engine and allow it to cool slightly.

Step 3: Locate the Drain Plug

Using the wrench, locate the drain plug underneath the engine. Position the drain pan beneath it to catch the used lubricant that will flow out.

Step 4: Drain the Old Oil

Carefully remove the drain plug and let the old lubricant drain completely into the pan. This may take a few minutes. Once fully drained, replace the drain plug and tighten it securely.

Step 5: Replace the Oil Filter

Next, locate the oil filter, which is usually positioned near the engine. Using the wrench, carefully unscrew the old filter. Before installing the new one, apply a small amount of fresh lubricant to the rubber gasket of the new filter. This helps ensure a proper seal.

Step 6: Add New Oil

Using a funnel, pour the fresh lubricant into the engine through the designated filler cap. Refer to your owner’s guidelines for the correct type and quantity of oil needed.

Step 7: Check Oil Level

After adding the new lubricant, wait a moment and then check the oil level using the dipstick. Pull it out, wipe it clean, and reinsert it to confirm that the level is within the recommended range.

Step 8: Clean Up

Dispose of the used lubricant and oil filter properly, following local regulations. Make sure to clean any spills and store your tools and supplies.

Performing this maintenance task regularly can significantly enhance your vehicle’s performance and extend its lifespan. Always refer to your vehicle’s specific guidelines for further details.

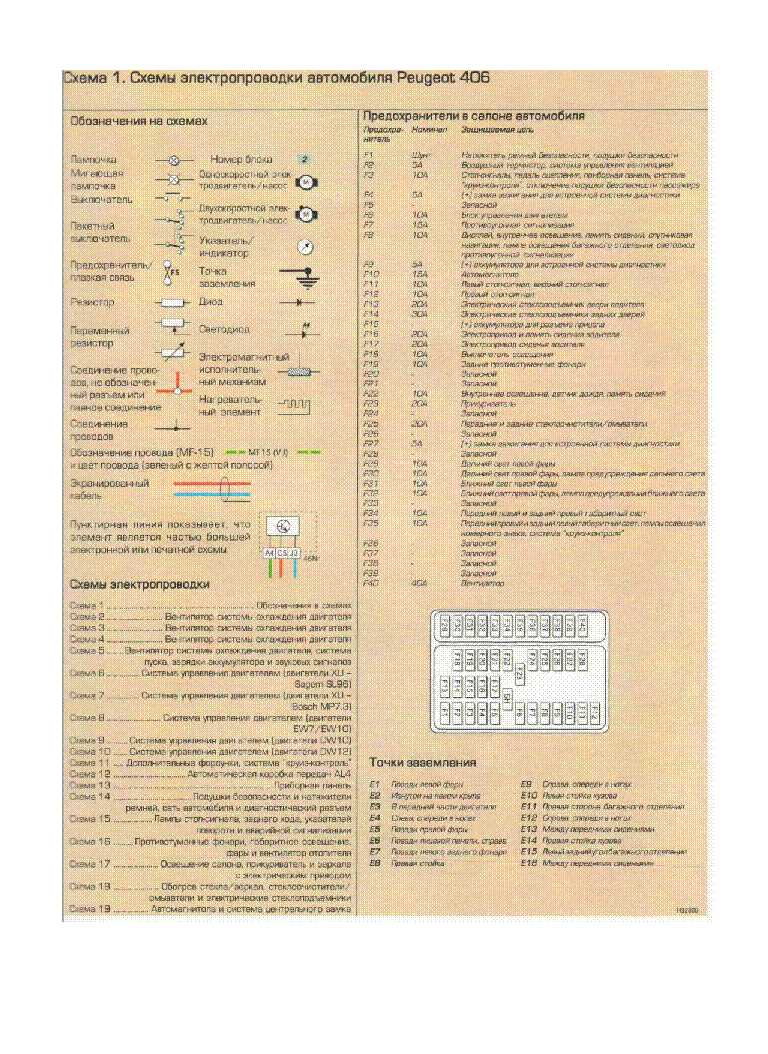

Troubleshooting Electrical Problems

Addressing issues related to the electrical system of a vehicle requires a systematic approach. Identifying the source of a malfunction can prevent further complications and ensure optimal performance. This section outlines key steps to diagnose and resolve common electrical faults.

Follow these steps to effectively troubleshoot:

- Inspect the Battery:

- Check for corrosion on terminals.

- Ensure the battery is fully charged.

- Look for any physical damage or leaks.

- Examine Fuses:

- Locate the fuse box and inspect all fuses.

- Replace any blown fuses with ones of the correct rating.

- Identify any patterns in blown fuses, which may indicate a deeper issue.

- Test the Alternator:

- Check voltage output while the engine is running.

- Listen for unusual noises that might indicate failure.

- Inspect wiring and connections for wear or damage.

- Check Wiring and Connectors:

- Look for frayed or damaged wires.

- Ensure all connections are secure and free from corrosion.

- Use a multimeter to test for continuity where necessary.

- Evaluate Electrical Components:

- Test individual components like relays and sensors.

- Replace faulty parts as needed.

- Refer to specific component guidelines for testing procedures.

By following these outlined steps, one can systematically address and resolve electrical issues, leading to a more reliable and safe driving experience.

Brakes: Maintenance and Repair Tips

Ensuring optimal performance of the braking system is crucial for vehicle safety and reliability. Regular upkeep can help identify issues early and extend the lifespan of components. Here are some essential suggestions for maintaining and addressing problems with your stopping mechanism.

- Regular Inspection: Check the brake pads, rotors, and fluid levels periodically. Look for signs of wear, such as thinning pads or uneven rotor surfaces.

- Brake Fluid Quality: Change the brake fluid according to the manufacturer’s schedule, typically every 2 years. Contaminated fluid can lead to reduced performance.

- Noise Monitoring: Listen for unusual sounds when braking. Squeaking or grinding may indicate that the pads need replacing or that there’s an issue with the rotors.

When it comes to addressing issues, consider the following:

- Replace Worn Components: Always use high-quality replacement parts that meet industry standards to ensure safety and compatibility.

- Proper Installation: Follow guidelines for installing new pads and rotors, ensuring they are fitted correctly to prevent premature wear.

- Brake System Bleeding: After replacing components, it’s important to bleed the system to remove air pockets, ensuring efficient braking response.

By adhering to these practices, you can maintain a reliable braking system that ensures safety on the road.

Replacing the Timing Belt Explained

Replacing the timing belt is a crucial maintenance task that ensures the engine operates smoothly and efficiently. This component plays a vital role in synchronizing the rotation of the crankshaft and camshaft, which is essential for maintaining the proper timing of engine valves. A worn or damaged belt can lead to severe engine damage, making timely replacement a necessity for vehicle longevity.

Before beginning the process, it is important to gather the necessary tools and materials. This will facilitate a smoother workflow and reduce the risk of mistakes. Here’s a list of essential items you may need:

| Tool/Material | Purpose |

|---|---|

| Socket set | To remove bolts and fasteners |

| Torque wrench | To ensure proper bolt tension |

| Timing belt kit | Includes the new belt and tensioners |

| Pulley tools | For adjusting or removing pulleys |

| Engine oil | For lubrication and maintenance |

Follow these general steps to successfully replace the timing belt:

1. Disconnect the battery to ensure safety.

2. Remove any components obstructing access to the timing cover, such as the engine plastic covers or accessories.

3. Align the engine to the correct timing position, usually indicated by markers on the crankshaft and camshaft.

4. Carefully remove the old timing belt, noting the routing and tension adjustments.

5. Install the new timing belt, ensuring it is properly tensioned according to manufacturer specifications.

6. Reassemble all removed components, reconnect the battery, and perform a final check before starting the engine.

Regular inspection and timely replacement of this critical component can prevent costly repairs and ensure the vehicle operates efficiently.

Suspension System: Common Repairs

The suspension system plays a crucial role in providing comfort and stability while driving. Over time, various components may wear out or become damaged, leading to a decline in performance. Understanding common issues and their solutions can help maintain optimal vehicle handling and ride quality.

Regular inspections can identify problems early, allowing for timely interventions. Here are some frequent repairs associated with the suspension system:

| Issue | Description | Common Symptoms | Possible Solutions |

|---|---|---|---|

| Worn Shock Absorbers | Shock absorbers dampen the movement of the springs. | Excessive bouncing, leaking fluid. | Replacement of shock absorbers. |

| Broken Springs | Springs support the vehicle’s weight and absorb impacts. | Unusual noises, uneven ride height. | Spring replacement or repair. |

| Damaged Bushings | These components reduce friction between moving parts. | Vibrations, noise during turns. | Replacing worn bushings. |

| Alignment Issues | Misalignment can lead to uneven tire wear and handling problems. | Pulling to one side, steering wheel off-center. | Wheel alignment adjustment. |

Addressing these common concerns promptly ensures a smoother and safer driving experience. Regular maintenance and checks can significantly extend the lifespan of suspension components.

Engine Overheating: Causes and Fixes

Overheating in automotive engines is a critical issue that can lead to severe damage if not addressed promptly. Understanding the underlying factors contributing to excessive heat is essential for maintaining optimal performance and longevity of the vehicle. This section outlines common causes of overheating and offers effective solutions to mitigate these problems.

Common Causes of Overheating

Several factors can lead to an engine’s temperature rising beyond safe limits. One prevalent cause is a faulty cooling system, which may include leaks in hoses, a malfunctioning radiator, or a broken thermostat. Insufficient coolant levels can also result from evaporation or leaks, preventing effective heat dissipation. Additionally, engine blockages due to debris can restrict coolant flow, further exacerbating the situation. Lastly, mechanical failures such as worn water pumps or damaged fan belts can significantly impair cooling efficiency.

Effective Solutions

To resolve overheating issues, it is crucial to conduct a thorough inspection of the cooling system. Start by checking coolant levels and topping off as necessary. Inspect hoses and connections for any signs of wear or leaks, replacing damaged components promptly. Flushing the radiator can eliminate blockages, ensuring better coolant flow. In cases of mechanical failures, it may be necessary to replace malfunctioning parts to restore proper function. Regular maintenance and monitoring of engine temperature can help prevent future overheating incidents.

Transmission Fluid: Importance and Change

The fluid within the transmission system plays a crucial role in ensuring smooth operation and longevity of the vehicle. It acts as a lubricant, a coolant, and a hydraulic medium, facilitating seamless gear shifts and protecting internal components from wear and tear.

Importance of Transmission Fluid

Maintaining optimal fluid levels is vital for the overall health of the transmission. Over time, the fluid can degrade due to heat, friction, and contamination, leading to decreased performance. Regular checks can prevent issues such as slipping gears, overheating, and potential damage, which can result in costly repairs.

Changing Transmission Fluid

Changing the transmission fluid is a necessary maintenance task that should not be overlooked. It is recommended to follow the manufacturer’s guidelines regarding intervals for fluid replacement. Typically, this process involves draining the old fluid, replacing the filter, and refilling with fresh fluid to ensure the system functions efficiently. When performed regularly, this simple procedure can enhance the vehicle’s performance and extend its lifespan.

In conclusion, understanding the significance of transmission fluid and adhering to a regular maintenance schedule is essential for the optimal functioning of any vehicle.