Maintaining the efficiency and longevity of your two-wheeled vehicle requires a deep understanding of its components and systems. A thorough guide is essential for any enthusiast or owner looking to enhance their knowledge and ensure optimal performance. This resource will provide invaluable insights into troubleshooting, upkeep, and restoration of these machines.

From engine diagnostics to electrical systems, each aspect plays a crucial role in the overall functionality of your ride. By exploring various techniques and methods, you can empower yourself to tackle common issues and prevent potential breakdowns. Knowledge is your best tool when it comes to keeping your vehicle in peak condition.

This guide not only covers the technical details but also emphasizes the importance of regular checks and maintenance practices. Whether you’re a novice or a seasoned rider, the information contained herein will aid you in navigating the complexities of your vehicle’s mechanics and help you achieve a smoother, safer journey.

Understanding GY6 150cc Engines

This section aims to provide insights into a popular type of small engine commonly used in scooters and other lightweight vehicles. These powerplants are recognized for their efficiency, compact design, and ability to deliver reliable performance. Understanding their components and functionality is essential for effective maintenance and troubleshooting.

Key Components

These engines consist of several critical parts that work in harmony to ensure optimal operation. The main components include the cylinder, piston, crankshaft, and ignition system. Each element plays a significant role in the overall performance and longevity of the engine.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates the combustion process. |

| Piston | Moves up and down within the cylinder, converting combustion into mechanical energy. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Ignition System | Ignites the air-fuel mixture for combustion, enabling engine operation. |

Performance Characteristics

These engines are designed to provide a balanced mix of power and fuel efficiency. They typically feature an automatic transmission system, which enhances user convenience by eliminating the need for manual shifting. Additionally, their lightweight design contributes to overall vehicle agility and ease of handling.

Common Issues in GY6 150cc Models

When dealing with scooters and similar vehicles, understanding frequent problems can greatly enhance maintenance and longevity. Many operators encounter similar challenges, which can stem from various factors such as design flaws, component wear, and environmental influences.

Electrical Problems

Electrical issues are among the most reported concerns. Symptoms may include:

- Battery failure

- Inconsistent lighting

- Starting difficulties

These problems often arise from poor connections, corroded terminals, or a drained battery. Regular inspections can help mitigate these issues.

Performance Deterioration

Another common area of concern is performance decline, which can manifest as:

- Reduced acceleration

- Increased fuel consumption

- Unusual noises from the engine

This may result from issues like clogged filters, worn spark plugs, or incorrect tuning. Maintaining a clean fuel system and timely part replacements can significantly improve performance.

Essential Tools for GY6 Repairs

When working on small engines, having the right equipment is crucial for efficient maintenance and troubleshooting. A well-equipped workspace not only facilitates the repair process but also ensures safety and accuracy in every task. Familiarizing yourself with essential instruments will enhance your skills and confidence in handling various issues that may arise.

First and foremost, a quality set of wrenches and sockets is indispensable. These tools allow you to tackle a variety of bolts and nuts, ensuring a secure fit. Additionally, screwdrivers of different sizes and types will help you address various components, making disassembly and reassembly smoother.

A torque wrench is another vital item, enabling you to apply the correct force to fasteners, preventing damage from overtightening. Moreover, a multimeter can be incredibly useful for diagnosing electrical problems, allowing you to measure voltage, current, and resistance effectively.

Other important tools include pliers, a wire cutter, and an assortment of specialty tools tailored for specific tasks. Keeping your workspace organized with a tool chest or pegboard will streamline your workflow and minimize the risk of losing small items. Investing in these essentials will not only aid in current projects but also prepare you for future endeavors in engine maintenance.

Step-by-Step Maintenance Procedures

Proper upkeep of your vehicle is essential for ensuring its longevity and optimal performance. Following systematic procedures allows you to identify potential issues before they escalate and maintain a smooth riding experience. This section outlines essential tasks that can be performed regularly to keep your machine in peak condition.

Start by checking the engine oil level. Warm up the engine for a few minutes, then turn it off and let it sit for a moment. Remove the dipstick, wipe it clean, and reinsert it to check the oil level. Add oil if necessary, ensuring it meets the specified standards.

Next, inspect the air filter. A clean air filter is crucial for efficient engine operation. Remove the filter, and if it appears dirty, clean it with compressed air or replace it as recommended. Make sure it is properly seated when reinstalled.

Examine the fuel system. Look for any leaks or signs of wear in fuel lines and connections. Replace any damaged parts promptly. Additionally, consider using a fuel additive to keep the system clean and functioning efficiently.

Check the brake system to ensure safety. Inspect brake pads for wear and replace them if they are thin. Also, verify the brake fluid level and top it off as needed, using the recommended type of fluid.

Finally, don’t forget to assess the tire pressure and tread depth. Properly inflated tires improve handling and fuel efficiency. Adjust tire pressure to the recommended levels and replace tires that show signs of excessive wear.

Identifying Engine Performance Problems

Engine performance issues can manifest in various ways, often leading to a frustrating experience for the rider. Recognizing the symptoms early can help prevent further damage and ensure a smoother operation. Below are key indicators and potential causes to consider when diagnosing engine troubles.

- Loss of Power:

A noticeable decrease in acceleration or difficulty maintaining speed may suggest internal problems. Common causes include:

- Clogged air filters

- Fuel system blockages

- Worn spark plugs

- Unusual Noises:

Sounds such as knocking, rattling, or hissing can indicate various issues. Possible sources include:

- Loose components

- Low oil levels

- Exhaust leaks

- Overheating:

If the engine runs hotter than usual, it may lead to serious damage. Check for:

- Low coolant levels

- Faulty thermostats

- Blocked cooling fins

- Excessive Smoke:

Different colors of smoke can indicate various issues:

- Blue smoke may signify oil burning

- Black smoke typically indicates a rich fuel mixture

- White smoke often points to coolant entering the combustion chamber

- Inefficient Fuel Consumption:

A sudden drop in fuel efficiency can be a sign of mechanical problems. Factors to inspect include:

- Dirty fuel injectors

- Improperly adjusted carburetors

- Exhaust blockages

lessCopy code

By systematically assessing these symptoms, you can identify potential engine performance problems and take appropriate action to address them. Regular maintenance is key to preventing these issues from arising in the first place.

How to Change the Oil Correctly

Changing the lubricating fluid is essential for maintaining optimal performance and longevity of your engine. This process ensures that moving parts are adequately protected and operate smoothly, preventing unnecessary wear and tear.

Required Tools and Materials

- New oil

- Oil filter

- Wrench set

- Oil pan

- Funnel

- Rags for cleanup

Step-by-Step Guide

- Warm up the engine for a few minutes to thin the oil, making it easier to drain.

- Turn off the engine and allow it to cool slightly.

- Place the oil pan under the drain plug and remove the plug with the appropriate wrench.

- Let the old fluid drain completely.

- Replace the drain plug securely once drained.

- Remove the old oil filter and install the new one, ensuring a proper seal.

- Using a funnel, pour the new lubricating fluid into the engine.

- Check the oil level using the dipstick, adding more if necessary.

- Run the engine for a few minutes and check for leaks.

- Dispose of the old oil and filter responsibly.

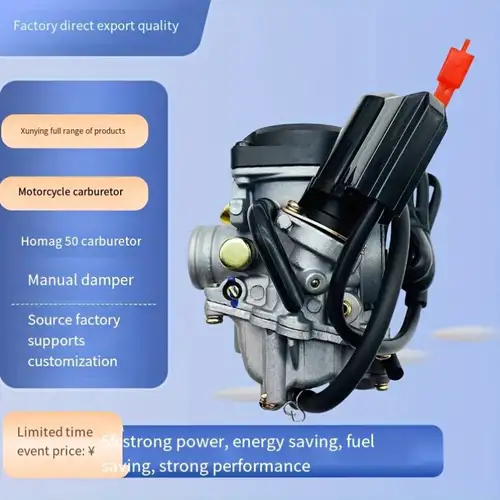

Adjusting the Carburetor Settings

Proper tuning of the fuel delivery system is essential for optimal engine performance. Adjusting the settings can help improve efficiency, enhance throttle response, and reduce emissions. This process involves fine-tuning various components to achieve the right air-fuel mixture, which is crucial for smooth operation.

Before making adjustments, it’s important to have a basic understanding of the carburetor’s components and their functions. The primary elements to focus on include the idle speed screw, mixture screw, and float height. Each of these settings plays a significant role in the overall performance and should be adjusted carefully.

| Component | Adjustment Purpose | Recommended Setting |

|---|---|---|

| Idle Speed Screw | Controls engine idle speed | Set to manufacturer specifications |

| Mixture Screw | Adjusts air-fuel mixture at idle | Turn clockwise for richer, counterclockwise for leaner |

| Float Height | Regulates fuel level in the bowl | Check with a caliper for accuracy |

After adjustments, it’s advisable to test the vehicle to ensure smooth operation. Pay attention to any changes in performance, and make further tweaks as necessary for optimal results. Regular maintenance and tuning will contribute to the longevity and efficiency of the engine.

Tuning the Ignition System

Tuning the ignition system is essential for optimizing engine performance and efficiency. By making precise adjustments, you can enhance power output and fuel economy, ensuring a smoother ride. This process involves evaluating and modifying various components to achieve the ideal timing and spark intensity.

Adjusting the Timing: One of the first steps is to check the ignition timing. Proper timing ensures that the spark plug fires at the right moment, maximizing combustion efficiency. Use a timing light to align the marks on the flywheel and stator, adjusting as necessary for peak performance.

Upgrading Spark Plugs: Consider replacing the standard spark plugs with high-performance alternatives. Premium plugs can improve ignition reliability and fuel combustion. Ensure that the gap is set according to the manufacturer’s specifications for optimal results.

Inspecting the Coil: The ignition coil plays a crucial role in generating the high voltage needed for spark production. Inspect it for any signs of wear or damage, and test its output with a multimeter. A faulty coil can lead to misfires and reduced power.

Wiring and Connections: Examine all wiring and connections associated with the ignition system. Corroded or loose connections can impede performance. Ensure that all wires are intact and securely connected to prevent electrical issues.

Performance Enhancements: For those seeking additional power, consider installing an aftermarket ignition module. These modules can provide advanced timing curves and improved spark energy, resulting in better throttle response and acceleration.

By meticulously tuning the ignition system, you can achieve a significant boost in performance, ensuring that your engine runs smoothly and efficiently under various conditions.

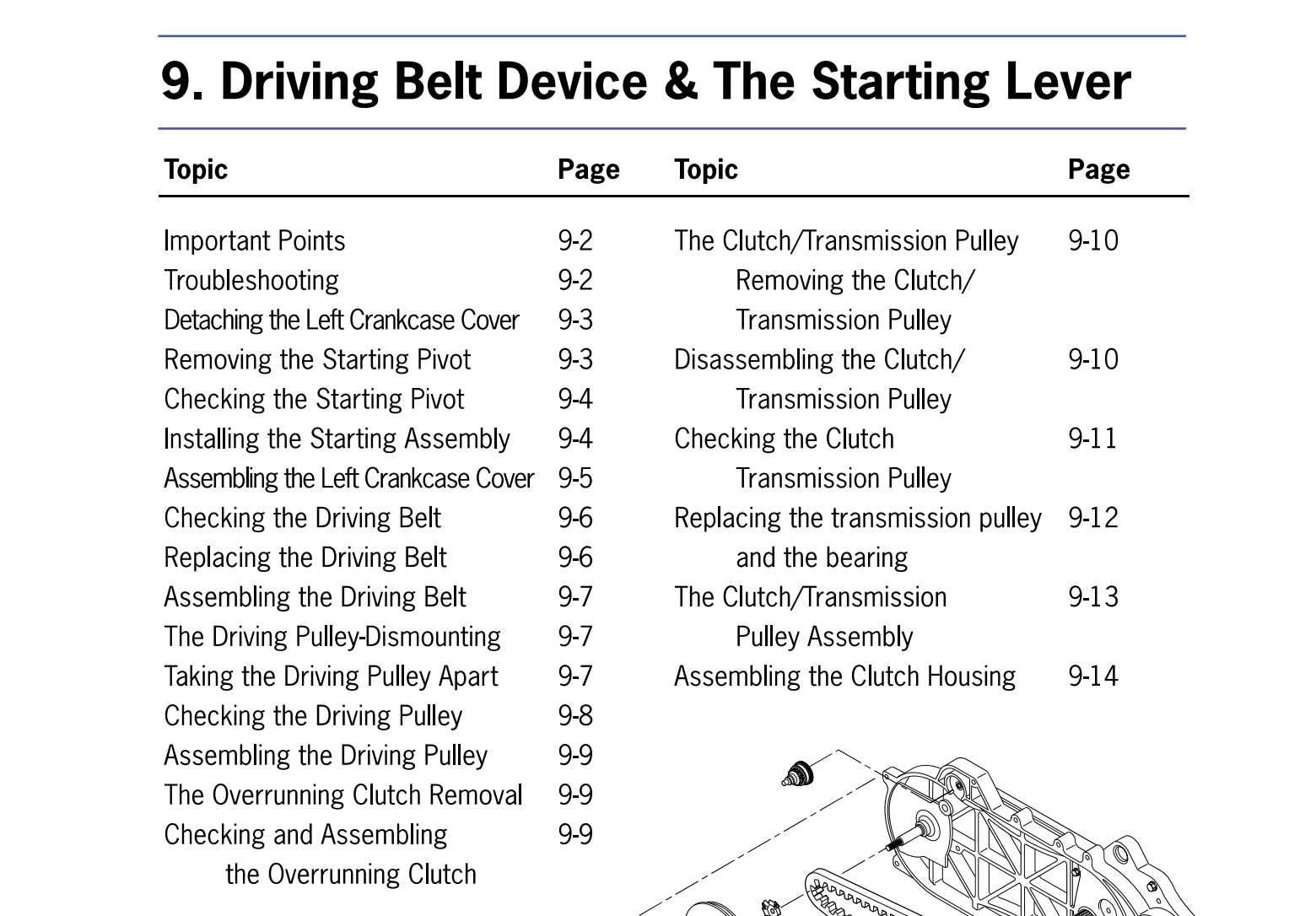

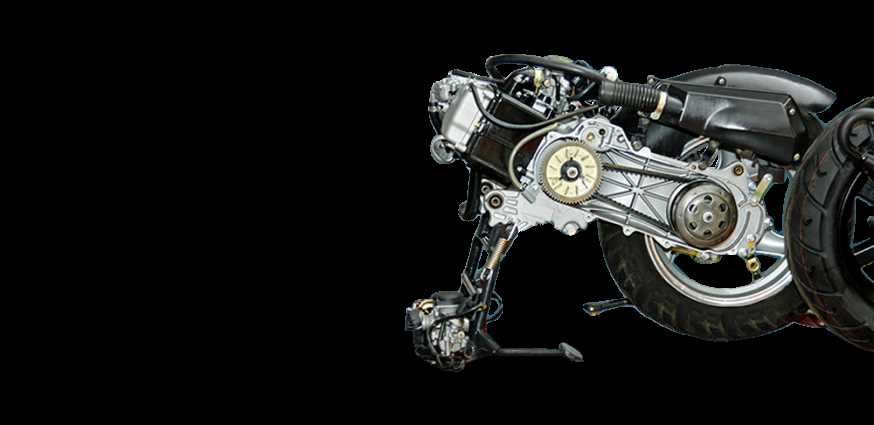

Replacing the Drive Belt Safely

Changing the transmission belt is a crucial maintenance task that ensures optimal performance and longevity of your vehicle. This procedure, while straightforward, requires careful attention to detail to avoid potential hazards and ensure everything is properly fitted.

Follow these essential steps to safely replace the drive belt:

- Gather Necessary Tools:

- Socket set

- Torque wrench

- Replacement belt

- Safety gloves and goggles

- Prepare the Vehicle:

- Ensure the vehicle is on a flat surface.

- Use a center stand or lift for stability.

- Disconnect the battery to prevent electrical hazards.

- Remove the Cover:

- Unscrew and take off the protective casing.

- Keep screws in a safe place for reinstallation.

- Inspect the Components:

- Check for any wear or damage on pulleys.

- Clean any debris or dirt from the area.

- Install the New Belt:

- Position the new belt correctly on the pulleys.

- Ensure it is seated properly without twists or kinks.

- Reassemble the Cover:

- Replace the protective cover and secure it with screws.

- Double-check that everything is tightened to the manufacturer’s specifications.

- Reconnect the Battery:

- Ensure all tools are removed from the work area.

- Reconnect the battery to restore power.

By following these steps diligently, you can replace the transmission belt safely and effectively, contributing to the overall health of your vehicle.

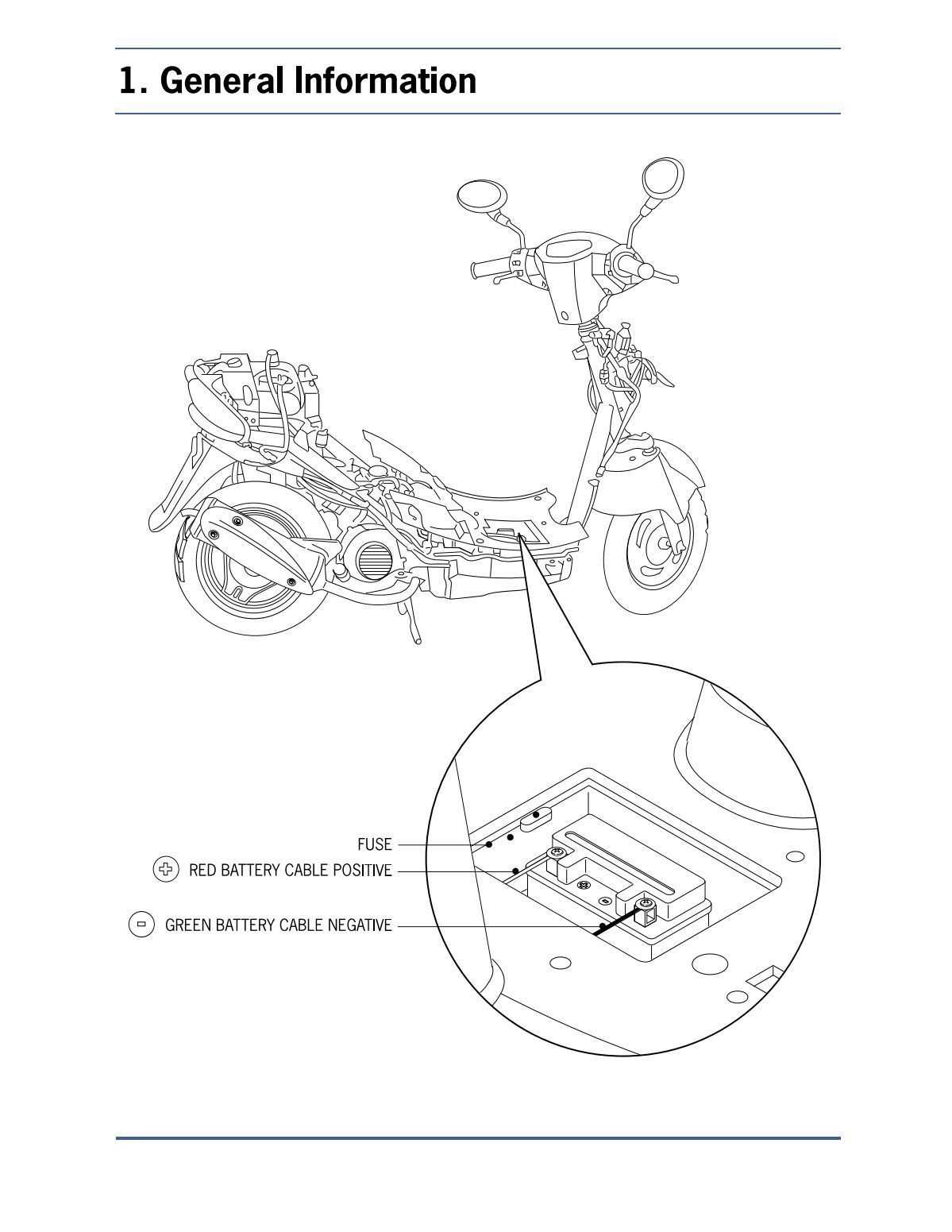

Inspecting Electrical Components Effectively

Ensuring the reliability and functionality of electrical parts is essential for optimal performance. A thorough examination can prevent potential issues and enhance the longevity of your vehicle. This section will guide you through the process of evaluating various electrical elements, ensuring that each component operates as intended.

Begin with Visual Inspection: Start by visually assessing the wiring and connectors for signs of wear, corrosion, or damage. Look for frayed wires, loose connections, and any physical deformities that could compromise functionality. A keen eye can often identify problems before they escalate.

Utilize a Multimeter: Employing a multimeter is crucial for measuring voltage, resistance, and continuity. This tool helps diagnose faults within the circuit. Check each component against its specified values to determine if it is functioning correctly. Pay attention to any irregular readings that might indicate a failing part.

Test Switches and Relays: Switches and relays play vital roles in controlling electrical flow. Test these components by toggling them while monitoring the circuit. A faulty switch may not engage or disengage properly, leading to malfunctioning systems. Ensure that relays click audibly when activated, indicating they are operational.

Examine Grounds and Connections: Ground connections are critical for the safe operation of electrical systems. Inspect ground points for cleanliness and tightness. Corrosion can hinder performance, so clean and secure all connections. A solid ground is essential for reducing electrical resistance and ensuring efficient operation.

Consult Wiring Diagrams: When troubleshooting, refer to wiring diagrams to understand the layout and function of each component. This knowledge can guide you in pinpointing issues and ensuring all connections are correct. Accurate diagrams simplify the identification of faulty wiring or components.

By following these steps, you can effectively inspect and maintain the electrical systems of your vehicle, contributing to its reliability and performance over time.

Understanding Cooling System Maintenance

The cooling system plays a crucial role in maintaining optimal operating temperatures for your vehicle’s engine. Proper maintenance is essential to ensure efficiency and prevent overheating, which can lead to significant damage. Regular checks and care of the cooling components can help prolong the life of your engine and improve overall performance.

Key components of the cooling system include the radiator, water pump, hoses, and thermostat. Each part works in harmony to circulate coolant and dissipate heat effectively. Neglecting any part can result in malfunctions and overheating issues. Therefore, it is vital to stay on top of maintenance tasks.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Coolant Level | Monthly | Ensure the coolant reservoir is filled to the recommended level. |

| Inspect Hoses | Every 3 Months | Look for cracks, leaks, or signs of wear in all hoses. |

| Flush Cooling System | Yearly | Remove old coolant and debris to maintain efficient flow. |

| Check Thermostat Function | Annually | Test the thermostat to ensure it opens and closes properly. |

| Inspect Radiator | Every 6 Months | Check for leaks and ensure the fins are clean and unobstructed. |

By following these maintenance tasks, you can help prevent potential issues and ensure the cooling system operates efficiently. Consistent attention to these details will ultimately enhance the reliability and longevity of your vehicle.

Upgrading Parts for Better Performance

Enhancing the capabilities of your two-wheeled vehicle involves a strategic approach to modifying key components. Upgrading specific parts can lead to significant improvements in speed, acceleration, and overall handling. This section will explore various components that can be upgraded for optimal performance.

Here are some essential parts to consider when looking to enhance your ride:

- Exhaust System: Replacing the stock exhaust with a high-performance system can reduce back pressure, allowing the engine to breathe better and increase horsepower.

- Carburetor: Upgrading to a larger carburetor can improve fuel delivery and enhance throttle response, contributing to a smoother ride.

- Variator: A high-quality variator can improve acceleration and top speed by optimizing the engine’s power delivery through the transmission.

- Cylinder Kit: Installing a performance cylinder kit can significantly increase displacement, leading to more power and torque.

- Ignition System: A performance ignition coil and spark plug can enhance spark efficiency, resulting in better combustion and improved performance.

When considering upgrades, it is essential to maintain a balance between performance and reliability. Each component should be chosen based on compatibility and the desired outcome. Regular maintenance and careful tuning will ensure that modifications yield the best possible results.

When to Seek Professional Help

Knowing when to consult an expert is crucial for maintaining the longevity and performance of your vehicle. While some issues can be tackled with basic knowledge and tools, others may require specialized skills and equipment. Recognizing your limits can save you time, money, and potential damage.

Identifying Complex Problems

If you encounter symptoms that are unfamiliar or beyond your expertise, it’s wise to seek assistance. For example, persistent engine noises, unusual vibrations, or electrical malfunctions often indicate underlying issues that necessitate a professional diagnosis. Ignoring these signs can lead to more severe complications down the line.

Safety Concerns

When it comes to safety, err on the side of caution. If you’re unsure about performing repairs or if an issue affects your ability to operate the vehicle safely, contacting a specialist is the best course of action. Ensuring your safety and that of others on the road should always be a priority.