Maintaining outdoor machinery is essential for optimal performance and longevity. This guide provides valuable insights into the upkeep of various types of gardening equipment, ensuring that users can keep their tools in top condition. Understanding the fundamentals of care and troubleshooting is crucial for any operator.

Effective maintenance not only enhances the functionality of tools but also contributes to safety during use. Users can benefit from learning about common issues, preventive measures, and best practices for handling machinery. By following the advice outlined here, individuals can achieve a higher level of efficiency and reliability from their equipment.

This section aims to provide a comprehensive overview of essential machinery components, focusing on their functions and significance. Gaining familiarity with these elements can enhance operational efficiency and maintenance procedures.

Key Components Overview

Understanding the main parts of the device is crucial for effective usage. Below are some of the fundamental components:

| Component | Function |

|---|---|

| Engine | Drives the entire system, providing the necessary power. |

| Transmission | Transfers power from the engine to the wheels, controlling speed and torque. |

| Chassis | Supports all major components, ensuring structural integrity and stability. |

| Controls | Allows the operator to manage speed, direction, and other functionalities. |

Importance of Regular Maintenance

Regular upkeep of the equipment is vital for longevity and performance. Familiarity with the basics aids in identifying potential issues early, allowing for timely interventions and reducing the risk of more significant problems.

Common Issues and Their Solutions

Maintaining outdoor equipment often involves encountering a range of typical challenges. Identifying these issues promptly can enhance the longevity and efficiency of the machinery. Below are some frequent problems and suggested remedies.

- Engine Not Starting:

This can stem from various factors, such as insufficient fuel, a dead battery, or a faulty ignition system. Checking fuel levels, charging or replacing the battery, and inspecting the ignition components are crucial first steps.

- Excessive Vibration:

Vibration can indicate unbalanced blades or worn-out components. Ensure blades are sharpened and balanced, and check for any loose parts that may require tightening.

- Loss of Power:

Power loss may occur due to clogged air filters or fuel lines. Regular cleaning or replacement of filters, along with ensuring proper fuel flow, can help restore optimal performance.

- Overheating:

Overheating might be caused by low oil levels or blocked cooling vents. Regularly check and maintain oil levels, and keep vents free from debris to promote efficient cooling.

- Difficulty Steering:

If steering becomes stiff or unresponsive, it may be a sign of worn-out components or low hydraulic fluid. Inspect the steering system and replenish fluids as needed.

By addressing these common issues proactively, users can ensure better functionality and reduce the likelihood of more severe problems arising in the future.

Tools Required for Repairs

Having the right tools is essential for effective maintenance and troubleshooting of outdoor equipment. A well-equipped toolkit not only facilitates smoother operations but also ensures safety and efficiency during the process.

Below is a list of essential instruments that are commonly needed:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening various fasteners. |

| Screwdriver Set | For driving screws in and out of components. |

| Pliers | For gripping, bending, and cutting wires or small parts. |

| Socket Set | For efficient removal of bolts and nuts. |

| Torque Wrench | To apply specific torque settings to fasteners. |

| Multimeter | For measuring electrical properties. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This section outlines a systematic approach to maintenance tasks, helping to prevent common issues and enhance efficiency.

- Inspect the Equipment:

- Check for any visible wear or damage.

- Ensure all components are securely fastened.

- Clean the Exterior:

- Remove dirt and debris from surfaces.

- Use appropriate cleaning agents for different materials.

- Change the Filters:

- Locate the air and fuel filters.

- Replace old filters with new ones according to specifications.

- Check Fluid Levels:

- Examine oil, fuel, and coolant levels.

- Top up fluids as necessary to maintain optimal levels.

- Sharpen and Adjust Blades:

- Remove blades safely following manufacturer guidelines.

- Sharpen blades to ensure effective cutting.

- Reattach and adjust blades for proper alignment.

- Test the Equipment:

- Run the equipment briefly to ensure smooth operation.

- Listen for unusual sounds that may indicate issues.

By adhering to these procedures, you can maintain your equipment’s performance and extend its lifespan effectively.

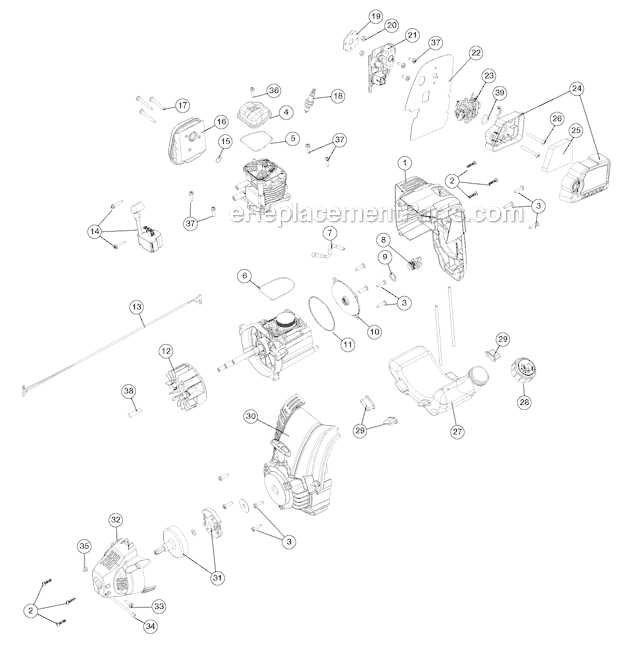

Engine Troubleshooting Tips

Addressing engine issues can often seem daunting, but understanding common symptoms and solutions can simplify the process. This section provides guidance on identifying potential problems and offers strategies to resolve them effectively.

Common Symptoms

Various indicators can signal engine trouble. Recognizing these signs early can prevent further complications.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Engine won’t start | Battery issues or fuel blockage | Check battery connections and fuel supply |

| Unusual noises | Worn parts or insufficient lubrication | Inspect components and add oil if necessary |

| Overheating | Coolant leak or blocked airflow | Examine cooling system and clean vents |

Basic Solutions

Once symptoms are identified, implementing basic solutions can often resolve issues quickly. Regular maintenance and timely interventions are key to ensuring optimal engine performance.

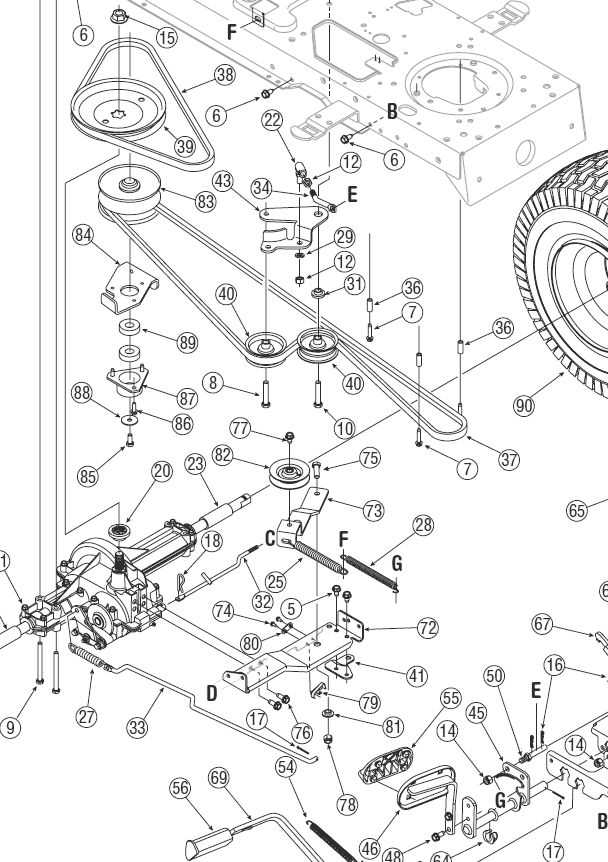

Transmissions and Drive Systems

Understanding the mechanisms behind power transfer is essential for maintaining optimal performance in garden equipment. This section focuses on the various types of transmission and drive systems commonly found in these machines, highlighting their functionality and importance.

Different types of drive systems play a crucial role in how the equipment operates. Below are some common types:

- Gear Drive: Utilizes a set of gears to provide torque and speed adjustments, ensuring efficient operation across varying terrains.

- Belt Drive: Involves the use of belts to transfer power from the engine to the wheels, allowing for smoother operation and easier maintenance.

- Hydrostatic Drive: Employs hydraulic fluid to transmit power, offering seamless speed control and enhanced maneuverability.

Each of these systems has distinct advantages and considerations:

- Durability: Gear-driven systems are often more robust and less prone to wear.

- Ease of Use: Belt drives typically allow for simpler engagement and disengagement.

- Precision: Hydrostatic systems provide precise control, ideal for tasks requiring fine adjustments.

Regular maintenance of these systems is vital to ensure longevity and optimal performance. Inspecting belts for wear, checking fluid levels in hydrostatic drives, and ensuring gears are properly lubricated can prevent costly repairs down the line.

Electrical System Diagnostics

Diagnosing issues within an electrical framework is essential for maintaining optimal performance. This process involves systematic checks to identify any malfunctioning components, ensuring the system operates smoothly.

Begin with a thorough examination of the wiring and connections, as loose or damaged links can lead to significant problems. Utilize appropriate diagnostic tools to measure voltage levels, resistance, and continuity throughout the circuit.

| Component | Testing Method | Common Issues |

|---|---|---|

| Batteries | Check voltage with a multimeter | Low charge, corrosion |

| Fuses | Visual inspection or continuity test | Blown fuse, loose connections |

| Switches | Test for continuity when activated | Faulty switch, intermittent operation |

| Motors | Measure resistance and operational voltage | Stalling, overheating |

Addressing these issues promptly can prevent further complications and ensure reliable operation. Regular diagnostics are recommended to maintain the integrity of the electrical system.

Cleaning and Care Techniques

Maintaining equipment in optimal condition is essential for ensuring its longevity and performance. Regular cleaning and proper care help to prevent wear and tear, enhancing functionality and efficiency. This section outlines effective practices for keeping your machine in top shape.

General Cleaning Practices

- Always disconnect the power source before starting any cleaning procedures.

- Use a soft brush or cloth to remove dirt and debris from the exterior surfaces.

- For stubborn grime, a mild detergent mixed with water can be applied with a sponge.

- Ensure all parts are thoroughly dried after cleaning to prevent rust and corrosion.

Maintenance Tips

- Regularly check and clean the air filters to maintain proper airflow.

- Inspect and tighten any loose screws or bolts to prevent further damage.

- Lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

- Store the equipment in a dry, protected area to avoid exposure to harsh elements.

Parts Replacement Guidelines

Replacing components in machinery is essential for maintaining optimal performance and prolonging the lifespan of the equipment. Following specific procedures ensures that each part is correctly installed and functions as intended.

Before proceeding with any replacements, it’s important to consult a detailed overview of the necessary components. This helps in identifying the correct items required for the task.

| Component | Replacement Procedure | Notes |

|---|---|---|

| Air Filter | Remove the old filter, clean the housing, and install the new filter securely. | Ensure the filter is the correct size and type. |

| Spark Plug | Unscrew the old plug, check for carbon buildup, and install a new plug with the recommended gap. | Use a torque wrench for proper tightness. |

| Belt | Loosen the tensioner, remove the old belt, and route the new belt according to the diagram. | Check for wear on pulleys and adjust tension as necessary. |

Following these guidelines will ensure that the equipment operates efficiently and reliably after component changes. Regular maintenance checks are also advised to prevent premature wear and failure.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance tasks on any equipment. Proper precautions can prevent accidents and injuries, allowing for a more efficient and effective process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves to protect your hands from sharp objects, safety goggles to shield your eyes from debris, and sturdy footwear to minimize the risk of foot injuries. Additionally, ear protection may be necessary when working with noisy machinery.

Work Area Safety

Maintaining a clean and organized workspace is vital. Remove any unnecessary tools and materials that may cause tripping hazards. Ensure that the area is well-lit and free from clutter to facilitate safe handling of parts and equipment. Always keep a first aid kit readily accessible in case of emergencies.

FAQs About the Repair Process

This section addresses common inquiries related to the maintenance and troubleshooting of outdoor equipment. Understanding these aspects can greatly enhance the user experience and ensure optimal performance.

What should I do if my equipment won’t start? Check the fuel level, inspect the spark plug, and ensure that the ignition switch is in the correct position. Additionally, examining the battery connections is essential.

How often should I perform maintenance? Regular upkeep is recommended at least once a season. This includes cleaning filters, checking oil levels, and inspecting belts for wear and tear.

What are some signs that my equipment needs attention? Unusual noises, smoke, or decreased performance are indicators that something may require inspection or servicing.

Can I perform maintenance myself? Many users can handle basic tasks such as changing oil or cleaning filters. However, for complex issues, it is advisable to consult a professional.

Where can I find parts for my equipment? Replacement components can typically be sourced from authorized dealers or online retailers specializing in outdoor machinery.