In the world of vehicle maintenance, addressing the functionality of various mechanisms is crucial for ensuring optimal performance. When certain elements fail to operate smoothly, it can lead to inconvenience and discomfort for the user. Understanding the essentials of these components can aid in restoring them to their original state, enhancing the overall driving experience.

Various approaches exist for addressing issues related to these essential mechanisms. These methods encompass not only the identification of problems but also the implementation of effective solutions. Utilizing specialized tools and components can facilitate the re-establishment of functionality, making it a rewarding endeavor for enthusiasts and professionals alike.

Furthermore, engaging in the process of component revitalization allows individuals to deepen their knowledge of automotive systems. This hands-on experience can foster a greater appreciation for the intricacies of vehicle design and engineering, ultimately leading to more informed decisions in future maintenance tasks.

When undertaking the task of fixing a lifting mechanism, it is crucial to prioritize safety to prevent accidents and ensure effective outcomes. Proper precautions can help mitigate risks associated with the process, allowing for a smoother and more secure experience.

Before beginning the work, familiarize yourself with the tools and components involved. Make sure to wear appropriate protective gear, such as gloves and safety glasses, to safeguard against injuries. Additionally, ensure that the working environment is well-illuminated and free of clutter.

| Precaution | Description |

|---|---|

| Protective Gear | Always wear gloves and goggles to protect against sharp edges and debris. |

| Work Area | Keep the workspace organized and well-lit to avoid accidents. |

| Tool Inspection | Check all tools for damage or wear before use to prevent malfunctions. |

| Power Supply | Ensure the power source is disconnected to avoid electrical hazards. |

| Instructions | Follow guidelines carefully to ensure proper assembly and avoid injuries. |

Troubleshooting After Repair

After completing the maintenance task, it’s essential to ensure everything operates smoothly. Various issues may arise that require attention, and identifying them early can save time and resources. This section will guide you through the common problems and solutions to enhance the functionality of your system.

Common Issues

- Inconsistent movement: The mechanism may not operate smoothly, causing uneven functionality.

- Unusual noises: Listen for any sounds that indicate friction or misalignment during operation.

- Partial closure: The component might not close fully, leaving gaps that could lead to further complications.

Diagnostic Steps

- Inspect the installation: Ensure all components are securely attached and aligned correctly.

- Check for obstructions: Look for any debris or foreign objects that could hinder operation.

- Test the functionality: Operate the mechanism multiple times to assess performance and consistency.

- Review adjustments: If necessary, make fine-tuning adjustments to improve operation.

By following these guidelines, you can effectively address any complications and ensure optimal performance of your system.

Maintaining Your Window Regulators

Proper care of your vehicle’s lifting mechanisms is essential for ensuring their longevity and optimal performance. Regular maintenance can help prevent common issues that may arise due to wear and tear, ultimately saving time and money on future repairs.

Regular Inspections: Check the components periodically for any signs of damage or excessive wear. Look for rust, corrosion, or misalignment that could affect functionality.

Lubrication: Apply a suitable lubricant to moving parts to reduce friction and wear. This practice can help maintain smooth operation and prolong the lifespan of the mechanisms.

Cleaning: Keep the surrounding areas free from debris and dirt. A clean environment reduces the risk of obstructions that can interfere with the performance of the lifting systems.

Timely Repairs: Address any issues promptly. If you notice unusual sounds or irregular movements, investigate the cause and carry out necessary adjustments or replacements to avoid further complications.

Signs Your Regulator Needs Replacement

Recognizing when your vehicle’s lifting mechanism is failing is crucial for maintaining functionality and safety. Several indicators can signal that a replacement is necessary to ensure smooth operation.

| Signs | Description |

|---|---|

| Unresponsive Movement | If the component does not respond when engaged, it may indicate a malfunction. |

| Strange Noises | Unusual sounds, such as grinding or popping, can suggest internal damage. |

| Slow Operation | Sluggish movement when raising or lowering could mean wear and tear. |

| Visible Damage | Cracks or bends in the structure may signal the need for a replacement. |

| Inconsistent Performance | Fluctuating functionality, such as intermittent operation, often points to deeper issues. |

Cost Analysis of Repairs vs. Replacement

When faced with the choice of restoring or substituting a component in a vehicle, understanding the financial implications is crucial. This decision often involves evaluating the long-term benefits of each option, factoring in not only the immediate expenses but also potential future costs. A thorough analysis can help vehicle owners make informed choices that best suit their budgets and needs.

Initial Expenses

The initial outlay for restoration typically appears lower than that for complete replacement. However, this option may require multiple repairs over time, leading to cumulative costs that could surpass the price of a new component. Evaluating the initial costs alongside the frequency and potential expense of future interventions is essential for an accurate comparison.

Longevity and Reliability

While restoration may seem economical, it’s vital to consider the longevity and dependability of the restored part. New components generally offer improved performance and reduced risk of failure. In contrast, frequently repaired elements may result in ongoing issues, ultimately incurring higher expenses and inconveniences. Assessing these factors can provide a clearer picture of the overall financial impact.

DIY vs. Professional Repair Services

When faced with the need to fix a malfunctioning component, individuals often weigh the benefits of tackling the task themselves against seeking assistance from a skilled technician. Both options present unique advantages and challenges that can significantly impact the outcome of the project.

Advantages of DIY Approaches

Taking on a project independently allows for a deeper understanding of the system at hand. It fosters a sense of accomplishment and can save costs associated with hiring external help. Moreover, many resources are available online, offering guidance and tutorials to assist enthusiasts in completing the task effectively.

Benefits of Professional Assistance

On the other hand, enlisting the help of a qualified expert can ensure a higher level of proficiency and speed. Professionals come equipped with the necessary tools and experience, reducing the risk of mistakes that could lead to further issues. This option also often includes warranties on the work performed, providing peace of mind for the owner.

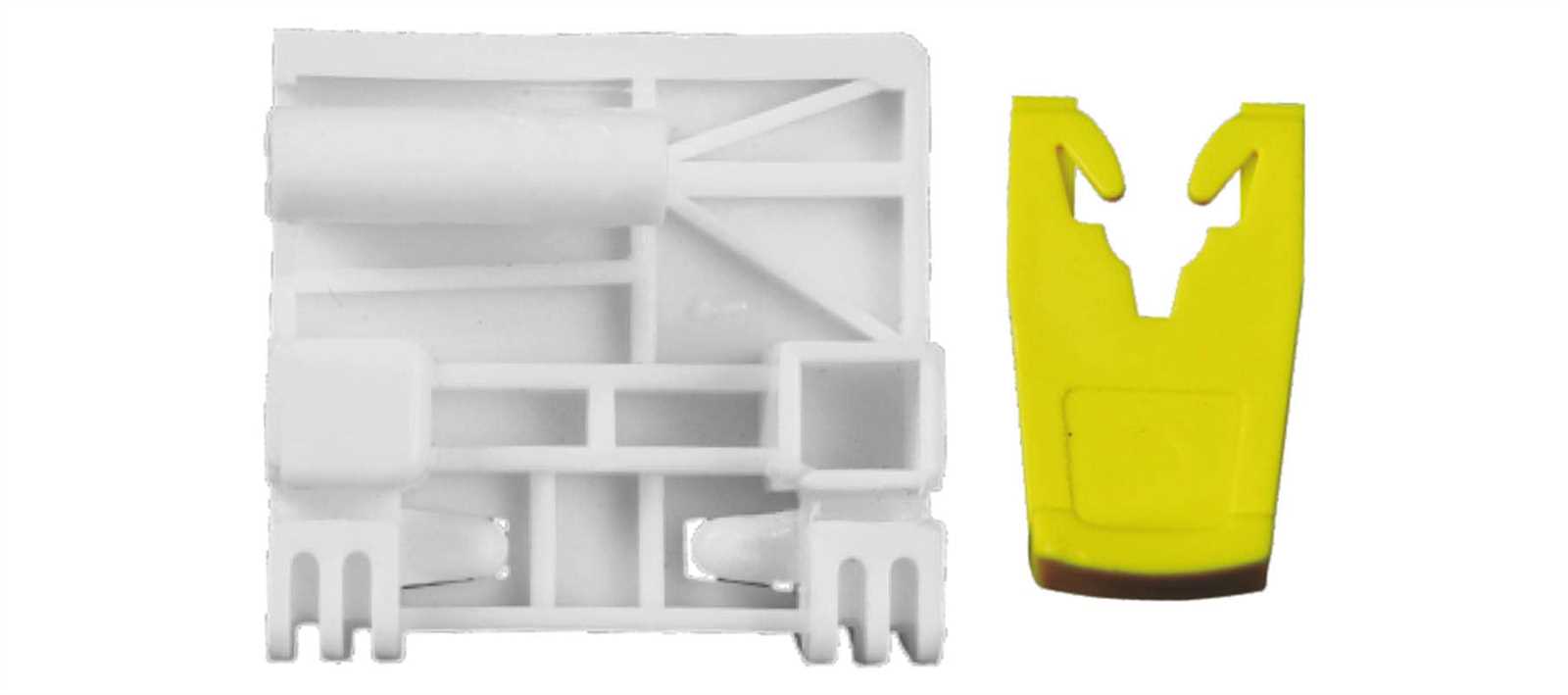

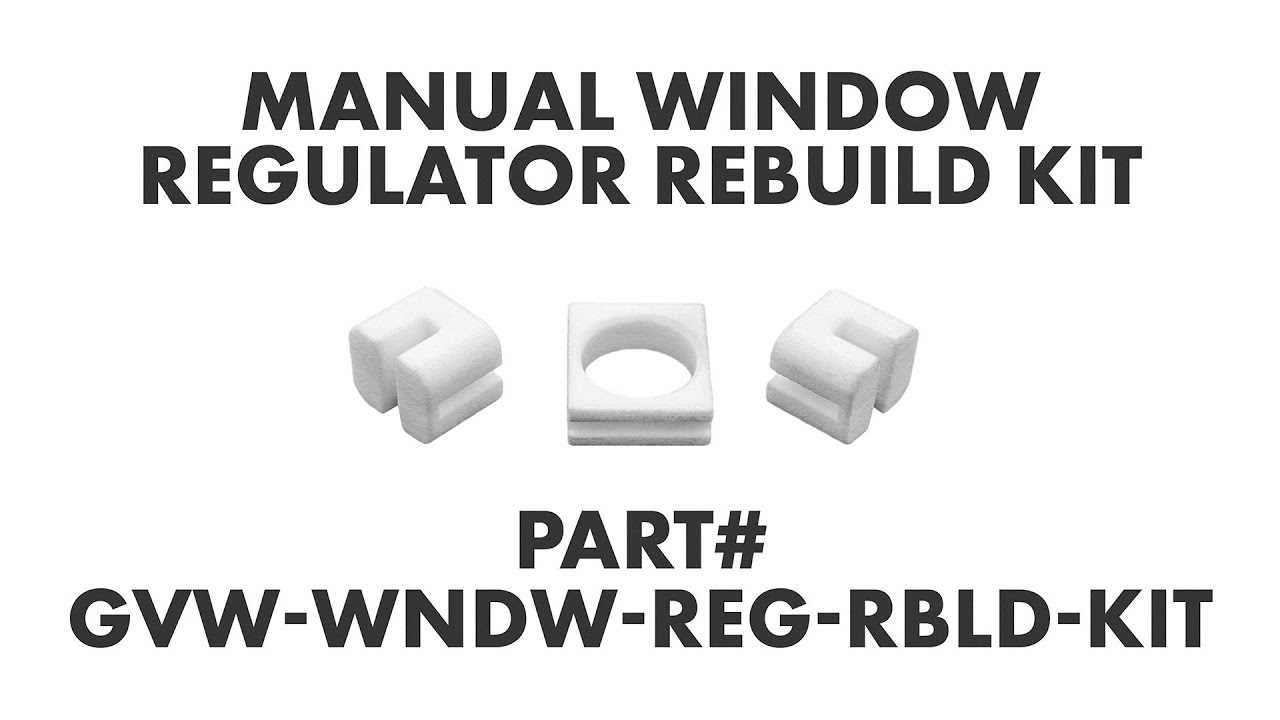

FAQs About Window Regulator Kits

This section addresses common inquiries regarding components designed for restoring the functionality of vehicle openings. These parts play a crucial role in ensuring smooth operation and enhancing user experience.

| Question | Answer |

|---|---|

| What are the signs of a malfunctioning component? | Common indicators include sluggish movement, unusual noises during operation, or complete failure to move. |

| Can I install these parts myself? | Yes, many individuals can successfully complete the installation with basic tools and a little guidance. |

| What tools are needed for installation? | Basic hand tools such as screwdrivers, pliers, and wrenches are typically required for the installation process. |

| How long does the installation take? | Installation time can vary, but most users complete it within 1 to 3 hours, depending on experience. |

| Are these components compatible with all vehicle types? | No, it is essential to check compatibility with your specific vehicle model before purchasing. |

Benefits of Using Quality Parts

Opting for high-grade components in vehicle repairs offers numerous advantages that significantly enhance the overall performance and longevity of the automobile. Quality elements not only improve functionality but also contribute to safety and reliability, ensuring a smooth driving experience.

Durability and Reliability

Investing in superior parts guarantees extended durability, reducing the likelihood of frequent replacements. This reliability translates to fewer breakdowns, allowing for peace of mind while on the road.

Cost-Effectiveness

Though quality components may require a higher initial investment, they often lead to long-term savings. By minimizing repair frequency and enhancing efficiency, these parts can ultimately lower overall maintenance costs.

| Feature | Quality Parts | Standard Parts |

|---|---|---|

| Longevity | High durability and extended lifespan | Shorter lifespan, requiring frequent replacements |

| Performance | Enhanced functionality and efficiency | Variable performance, potential inefficiencies |

| Safety | Improved safety standards | Possible compromises in safety |