Understanding the intricacies of advanced equipment is essential for ensuring optimal performance and longevity. This section aims to provide detailed insights into various aspects of maintaining and troubleshooting specific devices. With a focus on practical advice and essential information, users can effectively manage their tools and enhance their operational efficiency.

In-depth knowledge of functionality and common issues allows users to approach challenges with confidence. By following structured procedures and utilizing available resources, one can navigate through complexities with ease. Whether it involves routine checks or addressing unexpected anomalies, having a reliable reference can significantly streamline the process.

Ultimately, the goal is to empower users with the skills and understanding necessary to handle their equipment proficiently. Through this guide, individuals will gain the expertise needed to optimize their experience and ensure the seamless operation of their devices.

KX 155 Repair Manual Overview

This section provides a comprehensive introduction to the documentation related to maintenance and troubleshooting of the KX 155 model. It outlines the essential features and functionalities that are crucial for ensuring optimal performance.

The resource includes detailed descriptions of components, guidelines for diagnostics, and step-by-step procedures for various servicing tasks. Users will find valuable information to assist in addressing common issues and ensuring longevity in operation.

Additionally, it emphasizes the importance of adhering to manufacturer recommendations to maintain efficiency and reliability. With this guidance, users can navigate through the complexities of maintenance with confidence.

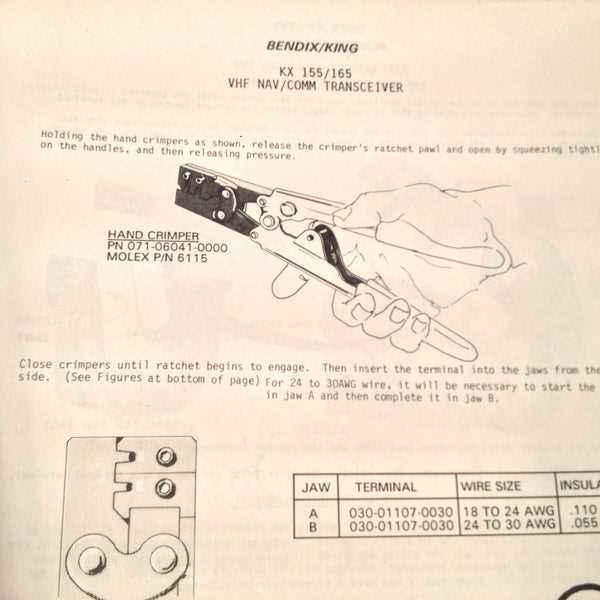

Essential Tools for KX 155 Maintenance

Proper upkeep of equipment requires a set of specific instruments designed to ensure optimal performance and longevity. Having the right tools not only simplifies maintenance tasks but also enhances safety and efficiency during the process.

Wrenches and socket sets are fundamental for tightening and loosening bolts, enabling access to various components. A torque wrench is essential for achieving the correct tightness, preventing damage from over-torquing.

Screwdrivers in various sizes and types are vital for adjusting and securing parts, while pliers assist in gripping and manipulating components that are hard to reach. Additionally, a multimeter is indispensable for diagnosing electrical issues, ensuring that all systems function as intended.

Cleaning supplies, including brushes and cloths, help maintain surfaces, removing debris that may hinder operation. Finally, a well-organized toolbox ensures that all instruments are readily available, contributing to an efficient workflow during maintenance tasks.

Common Issues and Troubleshooting Tips

This section aims to address frequent challenges encountered by users and provide effective solutions to enhance the overall experience. Understanding typical malfunctions and their respective remedies can significantly streamline the troubleshooting process and ensure optimal functionality.

Below are some of the most prevalent concerns along with practical advice for resolving them:

| Issue | Description | Solution |

|---|---|---|

| Poor Signal Reception | Users may experience weak or intermittent signals. | Check antenna connections and reposition the unit for better alignment. |

| Display Malfunctions | The screen may freeze or show incorrect information. | Restart the device and ensure all connections are secure. |

| Audio Distortion | Sound may be unclear or distorted during communication. | Inspect audio connections and adjust volume settings. |

| Power Issues | The unit may not power on or experience unexpected shutdowns. | Check power supply and ensure the battery is charged. |

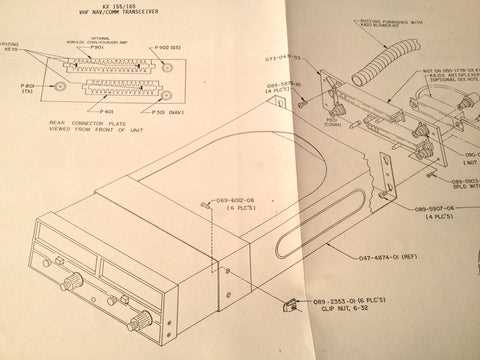

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to dismantling the device effectively and safely. Following a systematic method ensures that all components are handled with care, minimizing the risk of damage and facilitating reassembly.

Before beginning the process, ensure that you have the necessary tools at hand. Here is a list of essential items:

- Screwdriver set

- Pliers

- Plastic prying tool

- Container for screws

- Work surface or mat

Follow these steps to disassemble the unit:

- Power off the device and disconnect it from any power sources.

- Remove the outer casing by unscrewing the screws located at the back and sides.

- Carefully detach any connected wires or cables, noting their positions for later reconnection.

- Use the plastic prying tool to gently separate the front panel from the main body.

- Take out internal components, starting with the larger parts before addressing smaller pieces.

- Organize the removed parts systematically to ensure easy reassembly.

By adhering to these steps, the disassembly process can be conducted smoothly, laying the groundwork for any subsequent modifications or assessments needed.

Reassembly Techniques for KX 155

The process of reassembling complex systems requires precision and attention to detail. Effective techniques not only ensure that all components fit together seamlessly but also enhance the overall performance of the unit. Understanding the best practices during reassembly can significantly impact the longevity and reliability of the equipment.

Prior to commencing reassembly, it is essential to organize all components methodically. Categorizing parts by function and ensuring that each piece is clean and free from debris will facilitate a smoother assembly process. Employing appropriate tools designed for specific tasks can also minimize the risk of damage during reinstallation.

When reassembling, following the original sequence of disassembly is crucial. This approach helps maintain the structural integrity of the unit. Additionally, using torque specifications when tightening screws and fasteners guarantees that parts are secured without over-torquing, which can lead to component failure.

Incorporating lubricants where applicable can further enhance the functionality of moving parts. It is important to apply lubricants sparingly to avoid attracting dirt and debris. Finally, conducting a thorough inspection after reassembly ensures that all parts are correctly aligned and functioning as intended, ultimately contributing to the device’s optimal performance.

Recommended Replacement Parts and Brands

Ensuring optimal functionality of aviation equipment often necessitates the use of high-quality components. Selecting reliable replacement items is crucial for maintaining performance and safety. This section outlines essential alternatives and reputable manufacturers that contribute to the longevity and effectiveness of your device.

When considering replacements, prioritize components that meet industry standards. Renowned brands frequently provide parts that offer both reliability and compatibility. Investing in original equipment manufacturer (OEM) items is often advisable, as they are specifically designed for your system. Additionally, aftermarket options can also deliver excellent performance if sourced from trustworthy suppliers.

Consulting with fellow enthusiasts and industry professionals can provide valuable insights into the best choices available. Utilizing forums and specialized communities helps in identifying dependable brands that have garnered positive feedback from users. Remember that the right components not only enhance functionality but also ensure safety and compliance with regulations.

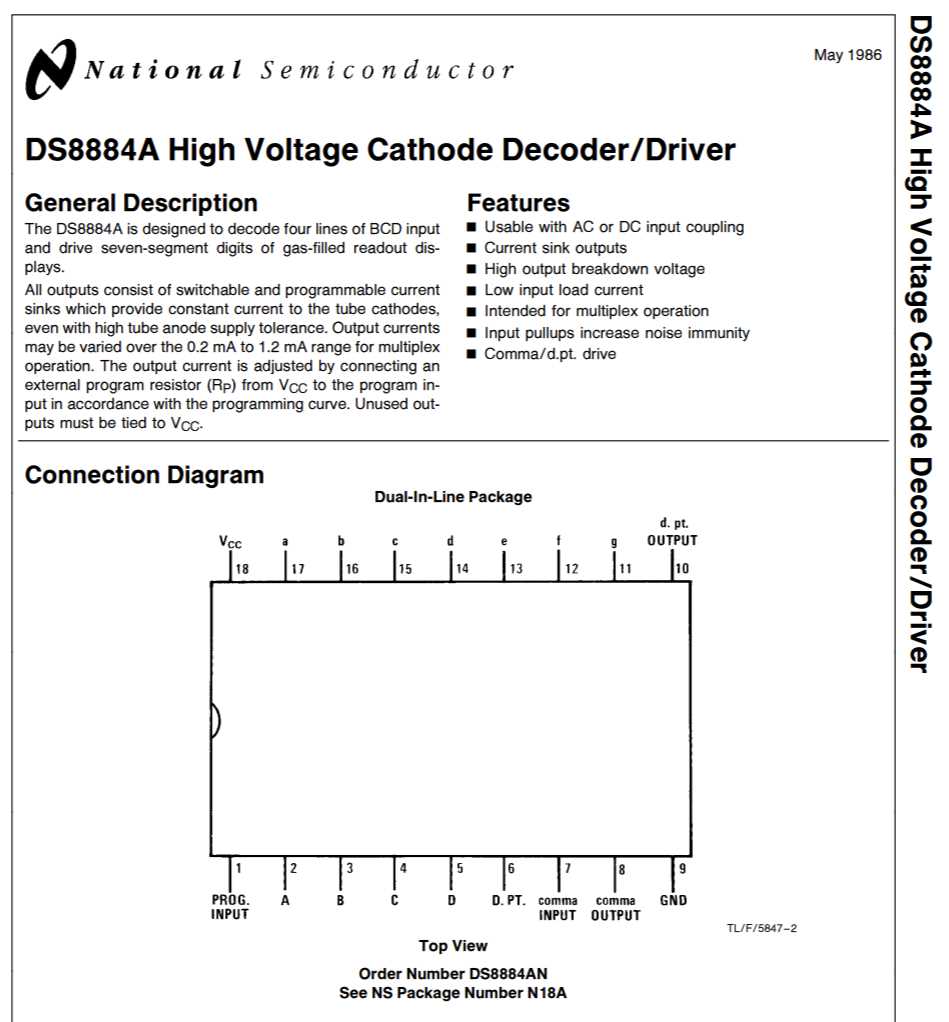

Electrical System Diagnostics and Repairs

Effective troubleshooting and maintenance of the electrical components in aviation equipment are essential for ensuring optimal performance and safety. This section outlines essential procedures for identifying issues and implementing corrective measures to restore functionality.

Identifying Electrical Issues

The first step in addressing electrical malfunctions is accurate diagnosis. Begin by examining the wiring for any visible signs of damage or wear. Utilize diagnostic tools to assess voltage levels, continuity, and signal integrity. Understanding the typical symptoms of electrical problems can significantly expedite the identification process.

Implementing Solutions

Once the issues are diagnosed, appropriate actions must be taken to rectify them. This may include replacing faulty components, repairing damaged wiring, or recalibrating systems. It is crucial to adhere to industry standards and safety protocols during these procedures to ensure reliability and prevent future complications. Thorough documentation of all modifications is recommended to maintain accurate records for future reference.

Fluid Replacement Procedures Explained

Proper maintenance of fluids is essential for ensuring optimal performance and longevity of equipment. Regularly scheduled fluid changes help to prevent contamination and degradation, ultimately enhancing the efficiency of the system. Understanding the procedures involved in fluid replacement can significantly impact operational reliability.

Identifying the Correct Fluids: It is crucial to use the right types of fluids specified for the system. This includes engine oil, hydraulic fluids, and cooling agents, each serving distinct functions. Using the appropriate fluids not only promotes effective operation but also minimizes the risk of damage.

Draining Old Fluids: Before introducing new fluids, it is important to thoroughly drain the old ones. This process often involves locating the drain plugs, removing them, and allowing sufficient time for all fluid to exit. Ensuring that all residues are cleared is vital for optimal performance.

Introducing New Fluids: Once the old fluids have been removed, carefully refill the system with fresh fluids. It is advisable to follow manufacturer specifications regarding the quantity and type. Monitoring the levels after filling is important to ensure they remain within the recommended ranges.

Disposing of Old Fluids: Responsible disposal of used fluids is necessary to adhere to environmental regulations. Many locations offer recycling services specifically for hazardous materials, making it easy to dispose of old fluids safely and responsibly.

Engine Tune-Up Best Practices

Regular maintenance is essential for ensuring optimal performance and longevity of your aircraft’s powerplant. Proper tuning not only enhances efficiency but also helps identify potential issues before they escalate. This section outlines effective strategies for keeping your engine in peak condition.

Routine Inspection

Conducting regular inspections is crucial for maintaining engine health. Here are key aspects to focus on:

- Check for leaks in fuel and oil lines.

- Examine hoses and belts for signs of wear.

- Inspect the condition of spark plugs and ignition components.

Fuel System Maintenance

Ensuring the fuel system operates efficiently can significantly impact engine performance. Consider the following practices:

- Replace fuel filters according to the manufacturer’s recommendations.

- Regularly clean fuel injectors to prevent clogging.

- Monitor fuel quality and address any contamination promptly.

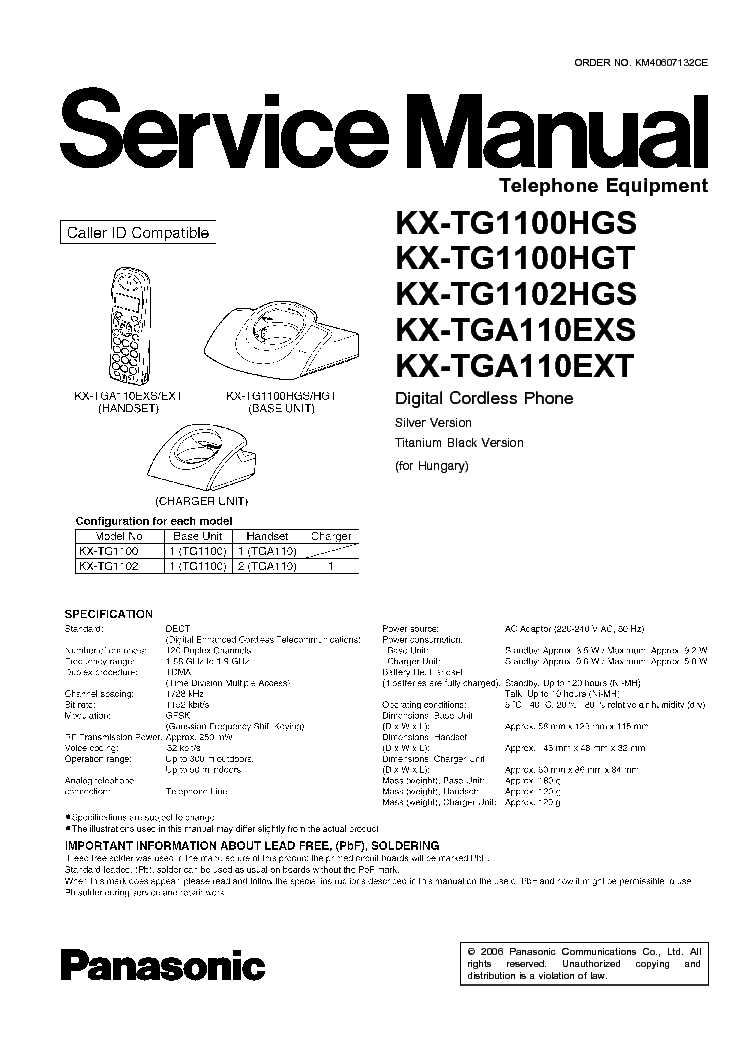

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety is of paramount importance. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Proper preparation and awareness of the environment contribute to a safer workspace, allowing for efficient and effective task completion.

Preparation and Awareness

Before beginning any maintenance activity, it is essential to familiarize oneself with the equipment and the surrounding area. Taking the time to assess potential hazards can prevent unforeseen incidents. Here are some critical points to consider:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, goggles, and masks to protect against harmful substances. |

| Tool Inspection | Ensure all tools are in good working condition and free from defects before use. |

| Work Area Organization | Keep the workspace clean and clutter-free to avoid tripping hazards and facilitate efficient workflow. |

Emergency Procedures

Having a clear plan in case of emergencies is crucial. Familiarize yourself with the location of first aid kits, fire extinguishers, and emergency exits. Additionally, understanding the procedures for reporting incidents can help ensure a swift response if an accident occurs.

Performance Enhancements for KX 155

Optimizing the functionality of aviation equipment can lead to significant improvements in efficiency and reliability. By implementing specific enhancements, users can experience better performance, increased durability, and enhanced user experience. This section delves into various strategies that can be employed to achieve these goals.

One of the primary methods for enhancing performance is through regular maintenance and timely upgrades of critical components. Ensuring that all parts are functioning optimally not only prolongs the lifespan of the equipment but also improves its overall responsiveness. Additionally, integrating advanced technology can provide users with better data analysis and operational feedback.

Furthermore, user education plays a crucial role in maximizing performance. Familiarizing oneself with the capabilities and settings of the equipment can lead to more efficient usage. Participating in training programs or workshops can equip users with the knowledge needed to exploit all features effectively.

Lastly, consulting with professionals for tailored modifications can yield customized solutions that cater specifically to individual needs. By focusing on these aspects, users can significantly enhance the overall functionality and experience of their aviation systems.

Maintenance Schedule for Optimal Performance

To ensure longevity and efficiency, a structured upkeep plan is essential for any equipment. Regular attention to key aspects of operation will enhance reliability and prevent unexpected failures. Adopting a proactive approach not only maintains functionality but also optimizes performance over time.

- Daily Checks:

- Inspect external components for any visible damage.

- Verify that all indicators and displays are functioning correctly.

- Ensure all connections are secure and free from corrosion.

- Weekly Maintenance:

- Clean filters and ventilation areas to prevent blockages.

- Check fluid levels and top up if necessary.

- Test functionality of operational controls.

- Monthly Inspections:

- Conduct a thorough examination of internal systems.

- Replace worn or outdated components as needed.

- Review operational logs for any anomalies.

- Annual Overhaul:

- Perform a comprehensive evaluation of all systems.

- Update software and firmware to the latest versions.

- Engage professional services for in-depth analysis and repairs.

By adhering to this comprehensive schedule, users can significantly enhance the efficiency and lifespan of their equipment, ensuring peak performance throughout its operational life.

Frequently Asked Questions on Repairs

This section aims to address common inquiries related to maintenance and troubleshooting procedures. Understanding these queries can enhance the overall efficiency and longevity of your device, ensuring that users are well-informed about potential issues and solutions.

One of the most frequent concerns revolves around identifying the symptoms of malfunctions. Users often wonder what indicators signal that service is needed. It is crucial to recognize early warning signs to prevent further complications.

Another popular question relates to the availability of parts and whether they can be sourced easily. Knowing where to find high-quality components can save time and enhance the performance of the device.

Additionally, many seek guidance on the best practices for conducting routine checks. Regular maintenance is essential for optimal functionality, and understanding how to perform these tasks can be invaluable for users.

Lastly, users frequently ask about the most effective troubleshooting methods. Having a clear approach to diagnose issues can significantly reduce downtime and improve overall satisfaction with the equipment.