Ensuring the longevity and performance of your vehicle is essential for any owner. This section provides an in-depth exploration of essential upkeep and problem-solving strategies, aimed at enhancing your driving experience.

Knowledge is power when it comes to understanding the intricacies of your automobile. By diving into the details, you can uncover ultimate techniques for addressing common issues, optimizing performance, and extending the lifespan of your machine.

Whether you’re a seasoned enthusiast or a novice, having access to practical information empowers you to tackle challenges with confidence. Let’s delve into the various aspects that will aid you in mastering the art of vehicle maintenance.

Overview of the 2007 Hummer H3

The vehicle in question is a compact SUV that embodies ruggedness and distinctive styling. Designed for both on-road comfort and off-road capability, it caters to adventurous spirits while providing modern amenities for everyday use. With a powerful engine and a robust chassis, this model is built to navigate challenging terrains while offering a confident driving experience.

Design and Features

This model showcases a bold exterior characterized by its angular lines and prominent grille, giving it a commanding presence. Inside, the cabin combines functionality with comfort, featuring durable materials and intuitive controls. Ample cargo space and versatile seating configurations enhance its practicality, making it suitable for various lifestyles.

Performance and Capability

Common Issues with H3

Vehicles in this category often encounter a range of challenges that can affect performance and reliability. Understanding these frequent problems can aid owners in maintaining their vehicle’s longevity and functionality.

Electrical System Faults: Many owners report issues with the electrical components, including problems with the battery, alternator, and wiring. Symptoms may include dimming lights and difficulty starting.

Transmission Troubles: Some models experience shifting difficulties or unresponsiveness in the transmission. Regular fluid checks and changes can help mitigate these concerns.

Suspension Wear: Over time, the suspension system may degrade, leading to a rough ride and decreased handling. Owners should monitor for unusual noises or vibrations while driving.

Cooling System Problems: Engine overheating can occur due to coolant leaks or radiator malfunctions. Regular inspections can help prevent serious engine damage.

Fuel System Issues: Fuel pump failures or clogged filters can lead to poor engine performance. Keeping the fuel system clean is essential for optimal operation.

By being aware of these common issues, owners can take proactive steps to ensure their vehicle remains in good condition and continues to perform well on the road.

Essential Tools for DIY Repairs

When tackling vehicle maintenance tasks on your own, having the right equipment is crucial for efficiency and effectiveness. A well-equipped workspace can significantly enhance your ability to troubleshoot and resolve issues without the need for professional assistance. Below is a guide to the fundamental tools that every automotive enthusiast should consider having on hand.

Basic Toolset

A solid foundational toolkit is essential for handling a variety of tasks. This includes tools that allow for both assembly and disassembly of various components.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening nuts and bolts. |

| Screwdrivers | Essential for removing or securing screws in various applications. |

| Pliers | Useful for gripping, twisting, and cutting wire or small components. |

| Socket Set | Allows for easier access to bolts in tight spaces. |

Specialized Equipment

In addition to basic tools, certain specialized equipment can make complex tasks more manageable. Investing in these items can save time and improve the quality of your work.

| Tool | Purpose |

|---|---|

| Jack | For lifting the vehicle safely to access the underside. |

| Multimeter | For diagnosing electrical systems and ensuring proper functionality. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Oil Filter Wrench | Makes removing and installing oil filters easier. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your vehicle. Regular upkeep is essential not only for safety but also for preserving the value of your automobile. Following a structured maintenance routine can prevent costly repairs down the line and enhance your driving experience.

Essential Maintenance Tasks

- Check and change engine oil regularly.

- Inspect and replace air filters as needed.

- Examine the braking system for wear.

- Rotate tires to promote even wear.

- Assess and maintain fluid levels (coolant, transmission fluid, etc.).

Seasonal Maintenance Tips

- Before winter:

- Test the battery’s health and charge.

- Ensure wiper blades are in good condition.

- Check antifreeze levels.

- Before summer:

- Inspect air conditioning system functionality.

- Evaluate tire pressure and tread depth.

- Clean and wax the exterior for protection against UV rays.

By adhering to these guidelines, you can significantly extend the life of your vehicle while enhancing safety and reliability on the road.

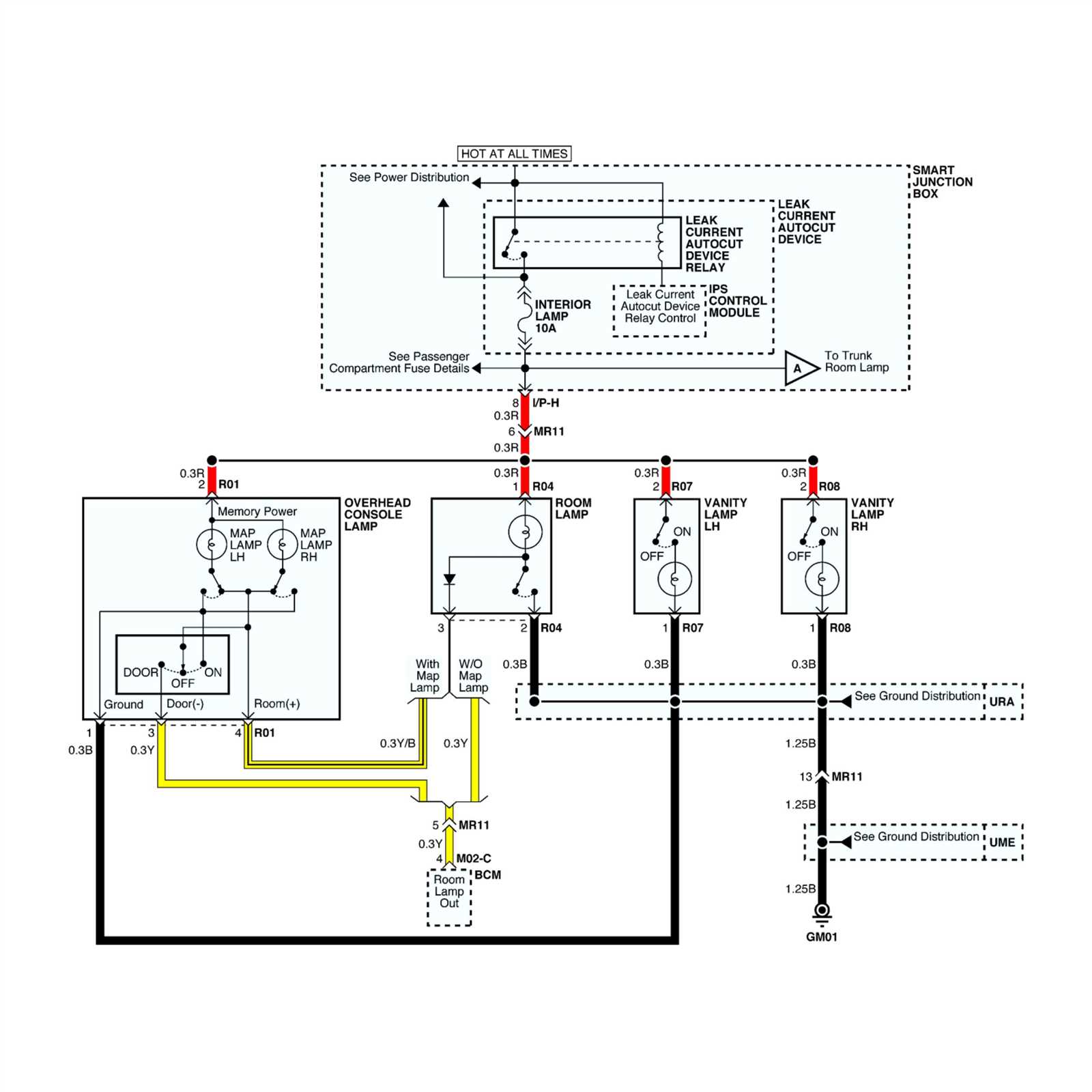

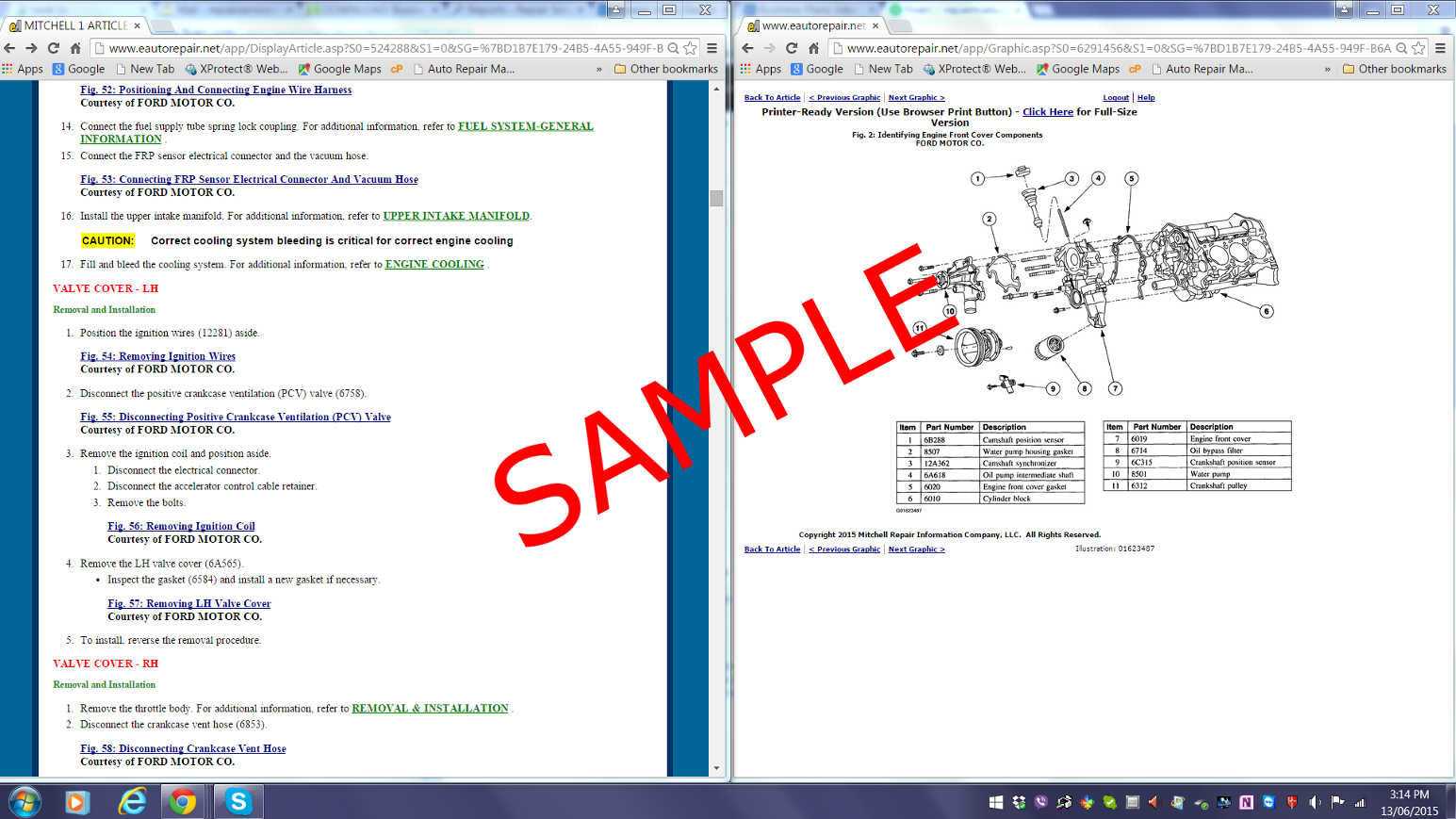

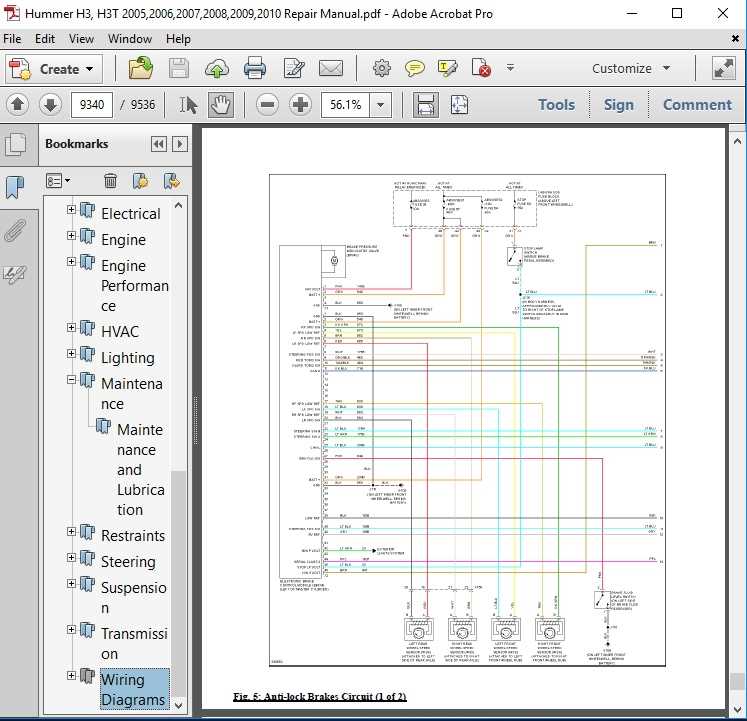

Understanding H3 Electrical Systems

The electrical systems of the H3 vehicle play a crucial role in its overall functionality, ensuring that various components operate smoothly and efficiently. These systems encompass everything from the battery and wiring harness to the numerous electronic modules that control vital functions. A solid understanding of these systems is essential for diagnosing issues and maintaining optimal performance.

Power Distribution is a key aspect, as it involves the management of electrical flow throughout the vehicle. This includes the battery, alternator, and fuses, which work together to ensure that all electrical components receive the necessary power. Regular checks on these elements can prevent unexpected failures.

Wiring and Connectors are integral to the reliability of the electrical system. Corrosion, wear, or damage to wires can lead to shorts or open circuits, causing malfunctions in systems such as lighting and climate control. Inspecting connectors for secure fit and cleanliness is vital for maintaining electrical integrity.

Additionally, understanding the Electronic Control Units (ECUs) is essential. These modules manage everything from engine performance to safety features. Familiarity with how these units communicate and function can aid in troubleshooting and enhance the overall driving experience.

Finally, being aware of the diagnostic tools available can significantly streamline the process of identifying and resolving electrical issues. Utilizing advanced scanning devices allows for efficient monitoring of system performance and quick detection of anomalies, leading to more effective repairs and maintenance.

Engine Troubleshooting Tips

Identifying and resolving engine issues is crucial for maintaining optimal vehicle performance. A systematic approach can help you diagnose problems effectively and ensure your engine runs smoothly. Below are several strategies to assist you in troubleshooting common engine concerns.

1. Check the Warning Lights: Always begin by observing the dashboard for any warning indicators. A check engine light can signal a variety of issues, from minor to serious. Utilizing an OBD-II scanner can provide specific codes to guide your troubleshooting process.

2. Listen for Unusual Noises: Pay attention to any strange sounds coming from the engine. Knocking, ticking, or grinding noises may indicate underlying problems, such as a lack of lubrication or worn components. Documenting these sounds can help mechanics diagnose the issue more efficiently.

3. Inspect Fluid Levels: Regularly checking oil, coolant, and other fluid levels is essential. Low levels can lead to overheating or inadequate lubrication, potentially causing significant damage. Ensure all fluids are at appropriate levels and look for signs of leaks.

4. Monitor Performance: Notice any changes in acceleration, idling, or fuel efficiency. A decline in performance can hint at various issues, including fuel delivery problems, air intake restrictions, or ignition system failures.

5. Examine Spark Plugs: Worn or dirty spark plugs can lead to poor engine performance and misfires. Regular inspection and replacement can enhance ignition efficiency and overall engine health.

6. Assess the Battery and Electrical System: A weak battery or faulty electrical connections can cause starting issues or erratic engine behavior. Ensure terminals are clean and connections are secure, and consider testing the battery’s voltage.

7. Check for Leaks: Look for any signs of oil, coolant, or fuel leaks under the vehicle. Fluid leaks can cause serious damage and lead to performance problems if not addressed promptly.

8. Review Maintenance Records: Understanding the maintenance history of your vehicle can provide insights into recurring issues. Regular maintenance can prevent many common engine problems from arising.

By following these troubleshooting tips, you can effectively identify and address engine issues, ensuring longevity and reliability in your vehicle’s performance.

Transmission Care and Repairs

The functionality of a vehicle’s power delivery system is crucial for optimal performance. Proper maintenance and timely interventions can significantly enhance the lifespan and efficiency of this integral component. Understanding the nuances of care and addressing issues promptly can prevent costly failures and ensure smooth operation.

Maintenance Tips

Regular checks and fluid changes are essential for preserving the condition of the powertrain. Monitoring fluid levels and quality can help detect potential problems early. Always refer to the specifications for the appropriate fluid type to ensure compatibility and effectiveness. Additionally, inspecting for leaks and ensuring seals are intact can prevent performance degradation.

Troubleshooting Common Issues

When symptoms arise, such as slipping gears or unusual noises, it’s important to diagnose the situation quickly. Common indicators of trouble include warning lights on the dashboard and difficulty shifting. Addressing these concerns through thorough inspections and necessary adjustments can avert more significant damage and ensure the system operates efficiently.

Suspension and Steering Maintenance

Maintaining the suspension and steering systems is crucial for ensuring optimal vehicle performance and safety. These components play a significant role in ride quality, handling, and overall driving experience. Regular inspection and upkeep can help identify potential issues before they escalate into major problems.

Key aspects of maintenance include:

- Regular inspections of all suspension components, including shocks, struts, and springs.

- Monitoring steering linkage for wear and proper alignment.

- Checking fluid levels and conditions in power steering systems.

- Replacing worn-out bushings and bearings to enhance stability.

It is advisable to follow a routine schedule for these checks:

- Every 5,000 miles: Inspect suspension and steering components for visible signs of wear.

- Every 15,000 miles: Rotate tires and check alignment to prevent uneven wear.

- Every 30,000 miles: Flush power steering fluid and replace if necessary.

- Every 60,000 miles: Replace shocks or struts if signs of leakage or damage are present.

By adhering to these maintenance guidelines, vehicle owners can enhance performance, prolong component lifespan, and ensure a safe driving experience.

Finding Reliable Replacement Parts

When maintaining a vehicle, sourcing dependable components is crucial for ensuring longevity and performance. Quality parts not only enhance the reliability of your automobile but also contribute to its overall safety. Understanding where to locate these items can save both time and money in the long run.

There are various avenues to explore when searching for trustworthy components. Each option has its advantages and disadvantages, so it’s important to consider factors such as cost, quality, and compatibility. Below is a comparison of some common sources for replacement parts:

| Source | Advantages | Disadvantages |

|---|---|---|

| OEM Dealers | Guaranteed fit and quality | Higher prices |

| Aftermarket Retailers | More variety and lower prices | Variable quality and fit |

| Online Marketplaces | Convenience and competitive pricing | Risk of counterfeit products |

| Salvage Yards | Cost-effective options | Limited availability and condition uncertainty |

Thorough research and reviews can guide you to the best sources for your needs. Always ensure the parts you choose meet safety standards and manufacturer specifications to maintain optimal vehicle performance.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for both the individual and the vehicle. Adhering to specific guidelines can prevent accidents and promote a secure working environment. This section emphasizes the importance of precautions to mitigate risks associated with mechanical work.

General Safety Guidelines

Before commencing any task, familiarize yourself with the tools and equipment required. Always wear appropriate personal protective gear, such as gloves and safety glasses, to shield against potential hazards. Ensure that the workspace is well-ventilated and free from clutter to minimize the risk of slips and falls.

Electrical and Mechanical Safety

When dealing with electrical components, disconnect the battery to prevent shocks or short circuits. For mechanical tasks, ensure that the vehicle is on a flat surface and securely supported using jack stands. This prevents the vehicle from rolling or collapsing during the process.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Wear gloves, goggles, and sturdy footwear. |

| Workspace Organization | Keep tools organized and the area clear of hazards. |

| Electrical Safety | Disconnect the battery before working on electrical systems. |

| Vehicle Stability | Use jack stands to support the vehicle securely. |