When it comes to ensuring the longevity and efficiency of your aquatic propulsion systems, having access to comprehensive resources is vital. These invaluable guides provide step-by-step instructions and insights, empowering enthusiasts and professionals alike to tackle various challenges associated with their marine equipment. Whether you’re facing minor adjustments or significant overhauls, a well-structured reference can make all the difference.

Understanding the intricacies of marine propulsion systems is essential for anyone looking to maximize performance and reliability. From troubleshooting common issues to performing routine maintenance, these resources offer a wealth of information. They not only cover technical specifications but also delve into best practices, allowing users to gain confidence in their capabilities.

Furthermore, having a clear roadmap for upkeep can save time and prevent costly mistakes. With detailed illustrations and explanations, these guides break down complex tasks into manageable steps, making them accessible to individuals with varying levels of experience. Embracing this knowledge ensures that every journey on the water is both safe and enjoyable.

Understanding Mercury Mariner Outboard Motors

This section delves into the essential aspects of propulsion systems designed for watercraft, focusing on their design, functionality, and maintenance. Gaining insight into these engines is crucial for enthusiasts and operators who wish to optimize performance and longevity while ensuring safety on the water.

Key Components

Each engine comprises several integral parts that work harmoniously to deliver power and efficiency. Familiarity with these components allows users to troubleshoot issues effectively and perform routine upkeep. Below is a summary of the primary elements involved:

| Component | Function |

|---|---|

| Powerhead | Generates thrust and houses critical systems. |

| Gearcase | Transmits power from the engine to the propeller. |

| Propeller | Propels the vessel through the water. |

| Fuel System | Delivers the necessary fuel for combustion. |

| Cooling System | Regulates engine temperature to prevent overheating. |

Maintenance Essentials

Regular upkeep is vital to ensure optimal performance and reliability. Key practices include checking fluid levels, inspecting electrical systems, and monitoring for signs of wear. Adhering to a maintenance schedule not only prolongs the life of the engine but also enhances safety and efficiency during operation.

Common Issues with Outboard Motors

Understanding frequent complications that arise with watercraft propulsion systems is essential for maintaining optimal performance and ensuring safety. Many factors contribute to these challenges, ranging from mechanical failures to environmental influences. Recognizing these common problems can help users troubleshoot effectively and minimize downtime.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Engines may fail to start due to fuel delivery issues or battery problems. | Check fuel lines and connections; inspect the battery for charge. |

| Overheating | Excess heat can cause serious damage and is often due to blocked cooling passages. | Clear any obstructions; ensure the water intake is functioning properly. |

| Vibration | Excessive shaking may indicate misalignment or damaged components. | Inspect for loose bolts; check the propeller for wear or damage. |

| Stalling | Unexpected shutdowns can occur due to fuel contamination or air leaks. | Replace contaminated fuel; check for leaks in the intake system. |

| Loss of Power | Reduced thrust can result from various factors including propeller issues or engine malfunctions. | Examine the propeller for damage; perform a full engine diagnostics. |

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of aquatic propulsion systems. Proper tools enhance efficiency and accuracy, ensuring optimal performance and longevity.

Basic Toolkit

- Socket Wrenches

- Screwdrivers (Flathead and Phillips)

- Pliers (Standard and Needle-Nose)

- Adjustable Wrench

Specialized Equipment

- Compression Tester

- Multimeter

- Fuel Pressure Gauge

- Service Manual for Reference

Investing in high-quality tools not only simplifies tasks but also ensures that repairs are conducted safely and effectively.

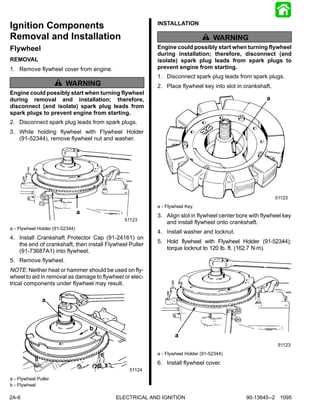

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively addressing common issues encountered in marine propulsion units. By following a systematic approach, you can enhance performance and longevity while minimizing potential complications.

1. Identification of the Issue: Begin by observing any symptoms or irregularities. Listen for unusual sounds and note any performance drops, which will help you pinpoint the underlying problem.

2. Gather Necessary Tools: Collect all essential instruments and components required for the task. Having everything at hand will streamline the process and reduce downtime.

3. Safety Precautions: Always prioritize safety by ensuring the unit is powered off and disconnected from any fuel sources. Wear appropriate personal protective equipment to safeguard against potential hazards.

4. Disassembly: Carefully dismantle the relevant sections of the unit. Take photos or notes during this process to assist in reassembly later.

5. Inspection: Examine each part for wear, damage, or obstructions. Pay special attention to seals and gaskets, as these are common sources of issues.

6. Replacement of Faulty Components: If you identify any defective parts, replace them with high-quality alternatives. Ensure compatibility with your specific unit to avoid further complications.

7. Reassembly: Reassemble the unit by following your earlier documentation. Make sure all fasteners are securely tightened, and components are properly aligned.

8. Testing: Once reassembled, conduct a thorough test to ensure everything functions as expected. Monitor for any signs of leaks or abnormal behavior during operation.

9. Final Adjustments: If necessary, make any fine-tuning adjustments to optimize performance. This step is crucial for achieving the best possible efficiency and reliability.

By adhering to these detailed steps, you can effectively troubleshoot and resolve issues, ensuring your marine propulsion unit remains in peak condition.

Maintenance Tips for Longevity

Ensuring the lasting performance of your aquatic propulsion system requires diligent upkeep and attention to detail. Regular maintenance not only enhances efficiency but also extends the lifespan of the equipment. Here are some essential practices to consider.

- Routine Inspections: Regularly check for signs of wear, corrosion, and any leaks. Early detection of issues can prevent more significant problems.

- Fluid Changes: Regularly replace essential fluids, including oil and fuel, according to the manufacturer’s recommendations to maintain optimal performance.

- Cleaning: Keep the exterior and interior components clean. Remove any debris and salt build-up, which can cause damage over time.

- Check Electrical Systems: Ensure all wiring and connections are secure and free from corrosion. Replace any frayed wires immediately.

- Protective Coatings: Apply protective coatings to metal surfaces to prevent rust and deterioration, especially if used in saltwater environments.

- Storage Practices: During off-seasons, store the unit in a dry and covered area to protect it from harsh weather conditions.

Following these tips can significantly enhance the reliability and lifespan of your equipment, ensuring smooth operations for years to come.

Choosing the Right Repair Manual

Selecting the appropriate guide for maintenance and troubleshooting is crucial for ensuring optimal performance of your aquatic propulsion system. The right resource can provide valuable insights into the workings of your equipment, making it easier to address any issues that may arise.

When evaluating various options, consider factors such as the age of your device, its specific model, and the types of challenges you anticipate facing. A comprehensive resource tailored to your equipment’s specifications can greatly enhance your understanding and efficiency in handling repairs.

Additionally, look for guides that offer clear illustrations and step-by-step instructions. These features can simplify complex processes, making it easier to follow along and execute necessary tasks with confidence.

Finally, seek out materials that include troubleshooting sections and maintenance tips. This will not only aid in resolving immediate concerns but also help in prolonging the lifespan of your device through regular upkeep.

How to Troubleshoot Engine Problems

Identifying issues within an engine can be a challenging task, but a systematic approach can help pinpoint the underlying causes. Understanding the various components and their functions is crucial for effective diagnosis. By following a series of methodical steps, you can isolate the problem and determine the necessary corrective actions.

Step-by-Step Diagnostic Process

Begin by observing the symptoms. Take note of any unusual sounds, vibrations, or performance issues. Next, check for visible signs of wear or damage, such as leaks or cracks. Ensure that all connections are secure and that there are no loose wires or hoses. Conducting a visual inspection is often the first step in troubleshooting.

Testing and Analysis

Once initial observations are made, proceed with testing key components. Utilize appropriate tools to measure parameters like compression, fuel delivery, and electrical continuity. Performing these tests can reveal discrepancies that indicate specific areas needing attention. If the problem persists, consider consulting documentation for detailed specifications and troubleshooting guidance.

In conclusion, thorough observation and methodical testing are essential for effectively addressing engine issues. A careful and structured approach will facilitate a clearer understanding of the problem and lead to timely solutions.

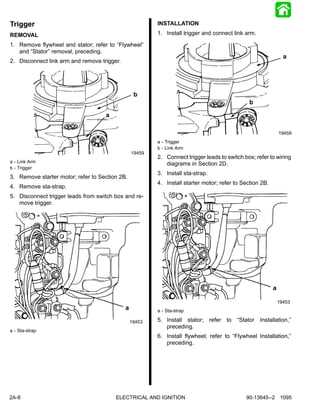

Wiring and Electrical System Insights

The intricate network of wires and electrical components plays a crucial role in the functionality of marine propulsion systems. Understanding the layout and operation of these systems is essential for ensuring reliability and efficiency. Proper maintenance and troubleshooting of electrical configurations can significantly enhance performance and longevity.

Common Electrical Components

Various elements form the backbone of any marine electrical system. Batteries, switches, connectors, and circuit breakers each contribute to the overall operation. Batteries provide the necessary power, while switches control the flow of electricity. Reliable connectors ensure secure connections, and circuit breakers protect against overloads, preventing potential damage.

Troubleshooting Tips

Identifying electrical issues can often be a daunting task. Start by inspecting connections for corrosion or looseness. Testing voltage levels with a multimeter can reveal discrepancies in power supply. Additionally, examining fuses and breakers for faults is crucial. Regular checks and preventive measures can help avoid costly repairs and enhance safety on the water.

Parts Replacement Guide for Beginners

Understanding how to replace essential components in your equipment can seem daunting, but with a little guidance, it becomes an achievable task. This section aims to provide a straightforward approach for novices, breaking down the process into manageable steps and highlighting key considerations to ensure a smooth experience.

Essential Tools and Materials

Before starting any replacement, gather the necessary tools and parts. Common items include wrenches, screwdrivers, and replacement components specific to your model. Having everything on hand will minimize interruptions and help maintain focus during the process.

Step-by-Step Replacement Process

Begin by identifying the component that needs attention. Carefully consult your specific documentation to locate the exact procedures. When ready, proceed methodically: remove the faulty part, install the new one, and finally test for proper functionality. Always double-check connections and ensure everything is secured before concluding your work. Patience and attention to detail are crucial for success.

Seasonal Preparation and Storage Tips

Preparing and storing your aquatic equipment properly can enhance its lifespan and ensure optimal performance when it’s time to use it again. Taking the right steps during seasonal transitions helps prevent damage and maintains functionality, allowing for a worry-free experience on the water.

Essential Preparation Steps

Before putting your equipment away for an extended period, follow these key actions to ensure it’s in top condition:

| Action | Description |

|---|---|

| Cleaning | Thoroughly rinse with fresh water to remove salt, dirt, and debris. |

| Fuel Treatment | Add a stabilizer to the fuel to prevent degradation during storage. |

| Battery Care | Disconnect and store the battery in a cool, dry place, and consider a trickle charger. |

| Lubrication | Apply appropriate lubricants to moving parts to prevent rust and corrosion. |

Storage Best Practices

Choosing the right storage environment is crucial. Follow these guidelines to protect your equipment:

| Storage Tip | Details |

|---|---|

| Indoor vs. Outdoor | Store indoors when possible to shield from harsh weather conditions. |

| Temperature Control | Avoid extreme temperatures; a climate-controlled area is ideal. |

| Covering | Use a breathable cover to protect from dust and moisture without trapping humidity. |

| Regular Inspections | Check periodically for signs of wear or damage to address any issues promptly. |

Resources for Further Learning

Enhancing your knowledge in the field of aquatic propulsion systems can significantly improve your skills and confidence. There are numerous resources available that cater to both beginners and experienced enthusiasts. These tools not only provide practical insights but also deepen your understanding of the intricate workings of various devices.

Online Forums and Communities: Engaging with online platforms dedicated to watercraft enthusiasts can be incredibly beneficial. Websites like Boat Forums or Reddit groups allow users to exchange tips, ask questions, and share experiences. This collaborative environment fosters learning from real-world scenarios.

Video Tutorials: Platforms such as YouTube host a wealth of instructional videos. These visual guides can help demystify complex processes, making it easier to follow along and gain hands-on experience. Look for channels that focus specifically on aquatic equipment maintenance and troubleshooting.

Books and eBooks: Consider exploring literature that specializes in marine technology. Numerous titles cover essential topics, ranging from basic principles to advanced techniques. Local libraries or online retailers can provide a variety of options suited to your level of expertise.

Workshops and Courses: Participating in local workshops or enrolling in courses can provide invaluable hands-on experience. Check with community colleges or marine associations for classes that focus on practical skills and in-depth knowledge of watercraft systems.

By utilizing these resources, you can significantly enhance your proficiency and gain confidence in managing aquatic propulsion devices. Continuous learning is key to mastering this specialized field.