Ensuring the longevity and optimal performance of your outdoor equipment is essential for achieving a well-kept yard. Understanding the intricacies of machinery dedicated to landscaping tasks can make all the difference. This section delves into the essential practices and insights necessary for keeping your gear in peak condition.

By familiarizing yourself with the various components and their functions, you can troubleshoot common issues effectively. Knowledge of maintenance techniques not only enhances the functionality of your equipment but also extends its lifespan. Regular attention to detail can prevent minor problems from escalating into major repairs.

This guide aims to provide comprehensive instructions, helpful tips, and best practices that will empower you to confidently address maintenance challenges. Whether you are a novice or an experienced user, the information within will serve as a valuable resource in your quest for seamless operation.

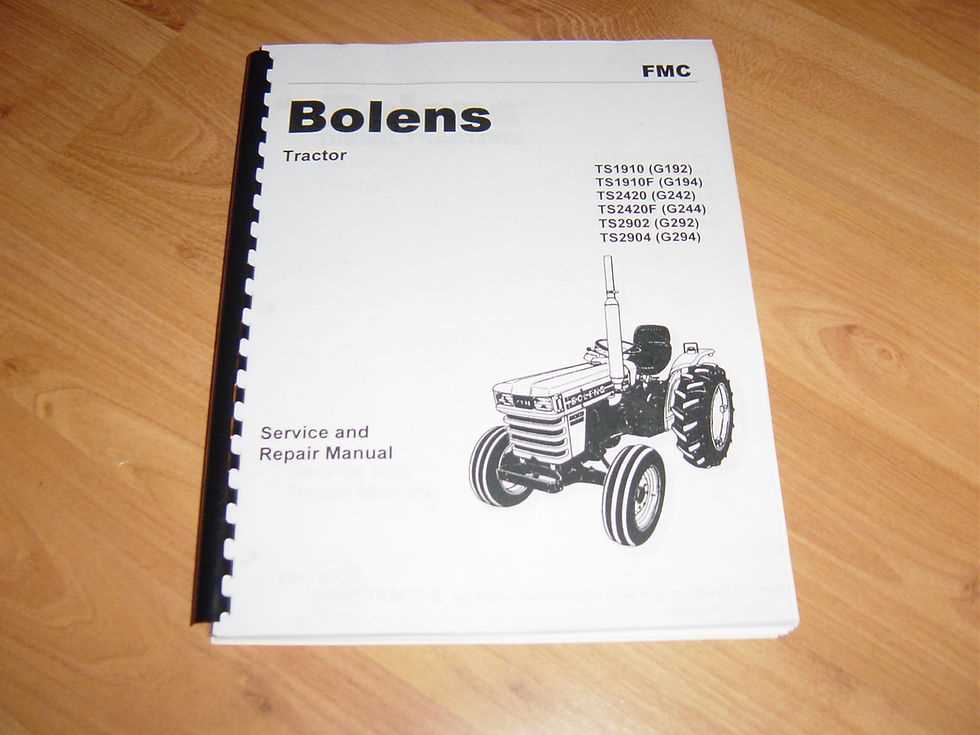

Understanding Bolens Lawn Tractors

This section aims to provide a comprehensive overview of the machines designed for garden maintenance. These devices are essential for efficient grass cutting and yard care, combining functionality with user-friendly features. Their design caters to both amateur gardeners and professional landscapers, ensuring ease of operation and reliable performance.

Key Features of These Machines

The units come equipped with various attributes that enhance their usability and effectiveness. Here are some notable characteristics:

| Feature | Description |

|---|---|

| Engine Power | Robust engines ensure powerful performance, suitable for various terrains. |

| Cutting Width | Multiple cutting widths available, allowing for flexibility in maintaining different yard sizes. |

| Comfort | Ergonomically designed seats and controls improve user comfort during operation. |

| Durability | Constructed with high-quality materials, these devices are built to last. |

Maintenance Tips

Common Issues with Bolens Models

Many users of these popular outdoor machines encounter a variety of challenges that can affect performance and efficiency. Understanding these frequent problems is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

1. Engine Starting Problems: A common issue faced by owners is difficulty in starting the engine. This can be attributed to several factors, such as a weak battery, faulty spark plugs, or fuel delivery issues. Regular checks of these components can help identify and resolve the problem early.

2. Uneven Cutting: An uneven cutting performance can lead to unsatisfactory results. This may be caused by dull blades, incorrect height settings, or debris buildup around the cutting deck. Keeping blades sharp and the deck clean is crucial for achieving a smooth finish.

3. Transmission Issues: Users might experience problems with gear shifting or loss of drive power. These issues can stem from low fluid levels, worn-out components, or incorrect adjustments. Regular maintenance and checks can mitigate these concerns.

4. Electrical Failures: Malfunctions in the electrical system, including issues with lights or ignition, can arise from corroded connections or blown fuses. Ensuring all electrical components are in good condition is vital for reliable operation.

5. Overheating: Machines may overheat during prolonged use, often due to inadequate airflow or clogged cooling fins. Regular cleaning and inspections can prevent overheating and enhance performance.

By recognizing and addressing these prevalent issues, users can ensure their machines remain reliable and effective in various outdoor tasks.

Essential Tools for Repairing Tractors

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial for efficiency and success. A well-equipped workspace can significantly ease the process of troubleshooting and restoring functionality to your equipment.

- Wrenches: Adjustable and socket varieties are indispensable for loosening and tightening bolts.

- Screwdrivers: A range of flathead and Phillips screwdrivers is necessary for handling various screws and components.

- Pliers: Needle-nose and slip-joint pliers provide versatility in gripping and manipulating parts.

- Jack and Stands: Essential for lifting the machinery safely to access the undercarriage or wheels.

- Multimeter: Useful for diagnosing electrical issues and checking voltage levels.

Additionally, a selection of specialty tools can prove invaluable:

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Oil Filter Wrench: Simplifies the removal and installation of oil filters during maintenance.

- Fuel Line Wrench: Designed for servicing fuel lines without damaging fittings.

Equipping yourself with these essential tools will not only streamline your maintenance tasks but also enhance your overall confidence in managing machinery challenges.

Step-by-Step Maintenance Guide

Proper upkeep of your outdoor equipment is essential for ensuring optimal performance and longevity. This comprehensive guide outlines a systematic approach to maintenance, helping you keep your machine in peak condition through a series of straightforward steps.

Begin by inspecting the exterior for any signs of wear or damage. Clean the chassis regularly to prevent the buildup of dirt and debris, which can lead to corrosion over time. Pay special attention to the undercarriage, as this area often collects grime that can hinder functionality.

Next, check the fluid levels, including oil, fuel, and coolant. Regularly changing the oil and replacing filters will enhance engine efficiency and prolong its lifespan. Ensure that you use the appropriate type of fluids recommended for your specific model.

Sharpening the blades is crucial for effective cutting. Dull blades not only compromise performance but can also stress the engine. Remove and sharpen the blades periodically, and make sure to balance them before reinstallation to avoid vibrations.

Examine the belts and cables for signs of wear, fraying, or cracks. These components are vital for proper operation, and replacing them when necessary can prevent more significant issues down the line. Regularly tighten any loose fittings to maintain optimal performance.

Lastly, conduct a seasonal check-up, focusing on the battery, tires, and electrical connections. Ensuring the battery is fully charged and terminals are clean will prevent starting issues. Properly inflated tires improve traction and reduce wear. Regular maintenance will lead to enhanced efficiency and a smoother experience with your equipment.

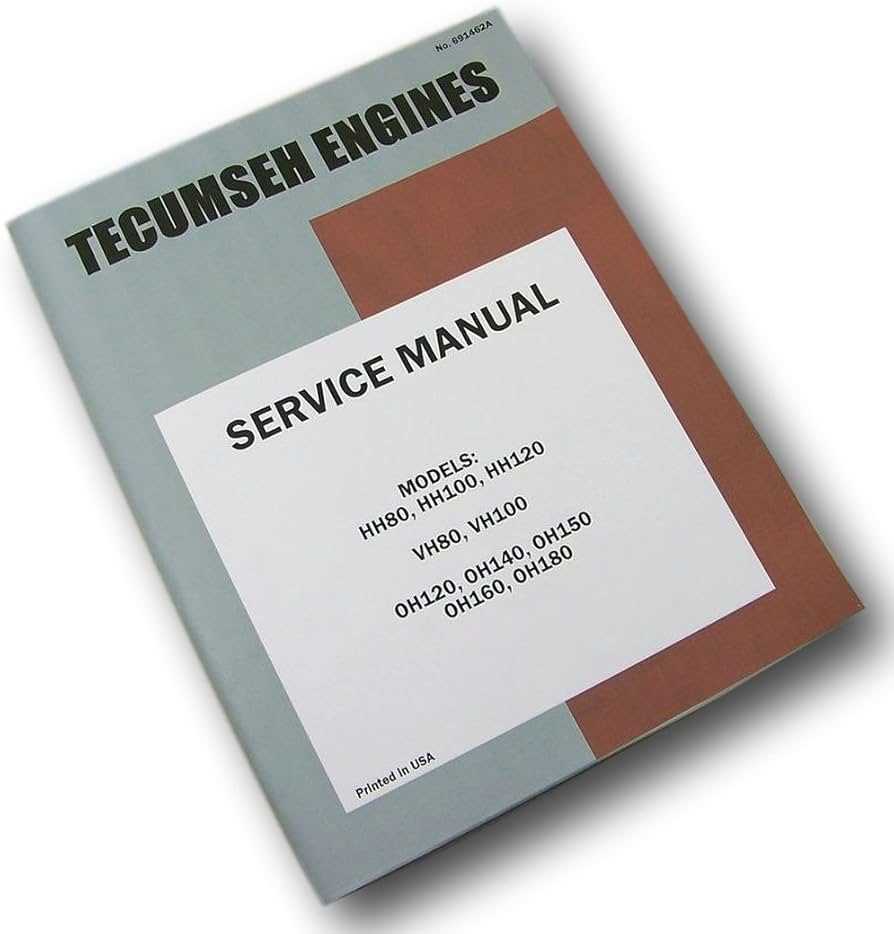

How to Troubleshoot Engine Problems

When faced with performance issues, it’s essential to systematically identify the root cause. Understanding common symptoms and their potential origins can streamline the diagnostic process, ensuring a more efficient resolution.

Common Symptoms and Their Causes

| Symptom | Possible Causes |

|---|---|

| Engine won’t start | Dead battery, faulty ignition switch, clogged fuel line |

| Unusual noises | Loose parts, worn bearings, lack of lubrication |

| Poor acceleration | Dirty air filter, fuel starvation, malfunctioning throttle |

| Overheating | Low coolant levels, blocked radiator, worn-out thermostat |

Troubleshooting Steps

To effectively address these issues, follow a structured approach. Start by inspecting the basics, such as fuel and battery condition. Then, utilize diagnostic tools to check for error codes or malfunctions. If necessary, consult specific guidelines for deeper inspection and testing procedures.

Replacing Belts and Blades Effectively

Maintaining the performance of your gardening equipment is crucial for ensuring its longevity and efficiency. Properly changing the driving components and cutting tools can enhance functionality, improve results, and prevent future malfunctions. This section provides guidance on how to carry out these essential tasks smoothly and safely.

Gathering Necessary Tools

Before starting the replacement process, ensure you have the right tools on hand. A socket set, wrenches, and a sturdy screwdriver are typically required. Additionally, gloves and safety glasses are recommended to protect yourself during the procedure. Having everything organized will make the task more efficient and reduce the risk of accidents.

Steps for Replacement

Begin by disconnecting the power source to eliminate any risk of accidental activation. For belts, locate the tension mechanism and release it before removing the old part. Carefully compare the new belt’s length and width to ensure proper fit. When it comes to blades, loosen the fastening bolts, remove the old blades, and securely attach the new ones, ensuring they are properly aligned.

After replacing both components, double-check all connections and settings. Reconnect the power source, and test the equipment to verify that everything operates smoothly. Regular maintenance not only enhances performance but also extends the lifespan of your essential gardening tools.

Electrical System Diagnostics and Fixes

The functionality of any machine heavily relies on its electrical components. Diagnosing and addressing issues within the electrical system is crucial for optimal performance. This section outlines essential steps and techniques for troubleshooting common electrical faults, ensuring efficient operation and longevity.

Common Electrical Issues

Understanding typical electrical problems can help in pinpointing the source of malfunction. Below are some prevalent issues encountered:

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Dead Battery | No start, dim lights | Age, corrosion, loose connections |

| Blown Fuse | Loss of specific functions | Overload, short circuit |

| Faulty Ignition Switch | Intermittent starting issues | Wear and tear, internal failure |

Troubleshooting Steps

To effectively address electrical issues, follow these systematic steps:

- Inspect the battery for corrosion and ensure connections are tight.

- Test fuses for continuity and replace any that are blown.

- Check the ignition switch operation with a multimeter to confirm proper functionality.

Fuel System Maintenance Tips

Ensuring the efficiency and longevity of your equipment involves regular attention to the fuel system. Proper upkeep can prevent common issues and enhance performance, allowing for smoother operation and reduced downtime. Here are some essential practices to maintain this critical component.

Regular Fuel Quality Checks

Consistently assess the quality of the fuel used in your machinery. Old or contaminated fuel can lead to poor performance and damage to the engine. Replace fuel that has been stored for an extended period and consider using fuel stabilizers to extend shelf life.

Cleaning Fuel Filters and Lines

Debris and dirt can accumulate in the fuel system, obstructing flow and causing inefficiencies. Regularly clean or replace fuel filters and inspect the fuel lines for any signs of wear or leaks. Clear pathways ensure optimal delivery of fuel to the engine, improving overall functionality.

Safety Precautions During Repairs

Ensuring safety is paramount when performing maintenance tasks on any machinery. By adhering to specific guidelines, you can protect yourself and others from potential hazards that may arise during the process. This section outlines essential precautions to follow for a secure working environment.

- Personal Protective Equipment (PPE): Always wear appropriate gear, such as gloves, safety goggles, and steel-toed boots.

- Work Area: Maintain a clean and organized workspace to prevent accidents. Remove any unnecessary tools or materials.

- Read Instructions: Familiarize yourself with the manufacturer’s guidelines before beginning any work.

- Disconnect Power: Ensure that the machine is turned off and disconnected from any power source to avoid accidental start-ups.

- Use Tools Properly: Utilize the correct tools for each task and inspect them for damage before use.

By implementing these measures, you can significantly reduce the risk of injury and ensure a more efficient working process.

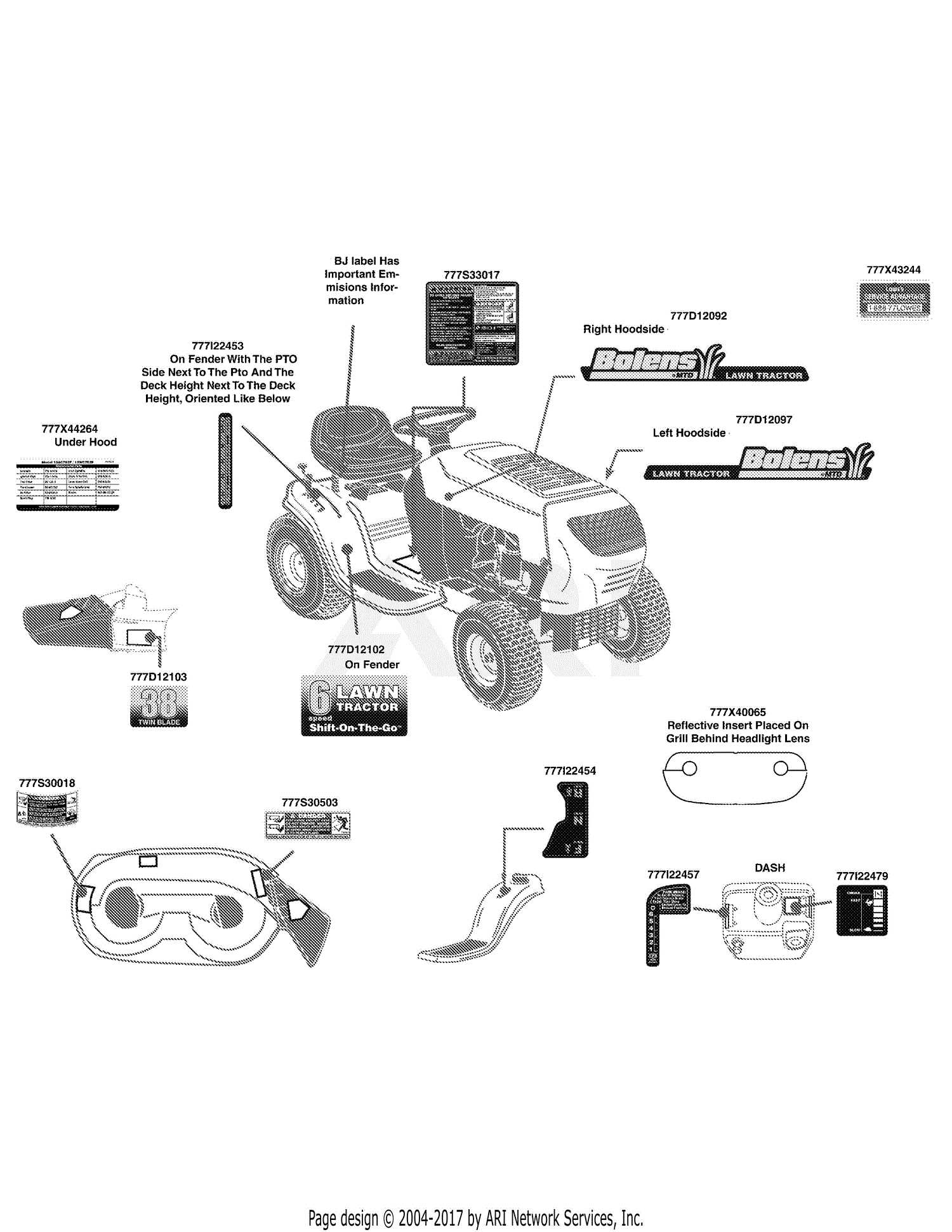

Finding Genuine Bolens Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Quality parts not only enhance functionality but also prevent potential damage caused by inferior alternatives. This section focuses on the importance of selecting the right replacement items and how to locate them effectively.

Identifying Authentic Components

To ensure that you are acquiring genuine items, it’s essential to recognize trusted suppliers and brands. Look for reputable retailers who specialize in original parts. Additionally, always verify the part numbers against the manufacturer’s specifications to confirm compatibility and authenticity.

Where to Find Reliable Suppliers

Start your search online through authorized dealers or the manufacturer’s official website. Many platforms offer a wide range of components, complete with detailed descriptions and specifications. Local hardware stores or specialty shops may also stock genuine items or can order them for you. Joining forums or community groups dedicated to your equipment can provide valuable recommendations on where to find the best components.

When to Seek Professional Help

Understanding the limitations of your own skills is essential when maintaining and fixing equipment. While some issues can be tackled with basic knowledge and tools, others may require specialized expertise. Knowing when to reach out to a professional can save time, prevent further damage, and ensure the longevity of your machinery.

Identifying Complex Issues

Some problems may be too intricate for a DIY approach. If you encounter unusual noises, persistent leaks, or significant performance drops, it’s wise to consult an expert. These symptoms often indicate underlying issues that require advanced diagnostic tools and technical know-how.

Safety Concerns

Your safety should always be a priority. If you feel uncertain about handling a particular task, especially those involving electrical systems or heavy components, it’s better to call in a professional. They have the training and experience to manage these risks effectively.