This section aims to provide essential insights into the upkeep and troubleshooting of a specific vehicle model. Whether you are a seasoned mechanic or a novice enthusiast, having access to detailed information can significantly enhance your understanding and skills in vehicle care.

In the realm of automotive knowledge, familiarity with various components and their functions is crucial. From engine diagnostics to electrical systems, each aspect requires attention to ensure optimal performance. This guide serves as a valuable resource, offering step-by-step procedures and practical tips to assist you in maintaining and repairing your vehicle effectively.

Understanding the nuances of your vehicle can lead to improved longevity and reliability. With a focus on common issues and maintenance practices, this guide equips you with the knowledge necessary to address challenges confidently. Explore the intricacies of your vehicle’s systems and empower yourself to take on maintenance tasks with ease.

Overview of 1993 Ford E350

This section provides a comprehensive look at a popular vehicle model known for its versatility and functionality. Designed for various applications, it has been widely utilized for both personal and commercial purposes. Its robust build and reliable performance make it a favored choice among users who require a dependable transport solution.

The vehicle features a spacious interior, accommodating both passengers and cargo with ease. Key aspects include:

- Ample seating capacity for larger groups

- Flexible storage options to suit different needs

- Powerful engine choices for enhanced performance

Additionally, this model is equipped with various technological advancements for its time, contributing to a more comfortable driving experience. Maintenance is straightforward, allowing for easier upkeep and longevity.

In summary, this model represents a blend of practicality and durability, appealing to a wide range of users seeking reliable transport solutions.

Common Issues and Solutions

Vehicles from this era often face several recurring challenges that can hinder their performance and reliability. Understanding these common problems is essential for effective troubleshooting and maintenance.

One frequent issue is the electrical system malfunctions, which may result in dim lights or failure to start. Inspecting connections and replacing faulty components can often resolve these issues.

Another typical concern involves the braking system, where worn-out pads or fluid leaks can lead to decreased stopping power. Regular checks and timely replacements are crucial for ensuring safety.

Additionally, engine performance problems, such as rough idling or stalling, can stem from issues like clogged filters or faulty sensors. Routine maintenance and prompt repairs can help restore optimal functioning.

Lastly, transmission difficulties may arise, manifesting as slipping gears or delayed engagement. Checking fluid levels and addressing any leaks can often mitigate these concerns.

Engine Maintenance Guidelines

Regular upkeep of the power unit is essential for ensuring optimal performance and longevity. Implementing a structured maintenance routine can help identify potential issues before they escalate and prolong the life of the vehicle.

- Regular Inspections: Conduct frequent checks on engine components to ensure everything is functioning properly.

- Oil Changes: Replace engine lubricant at recommended intervals to maintain proper lubrication and reduce wear.

- Coolant System Maintenance: Check and replace coolant as necessary to prevent overheating and corrosion.

- Air Filter Replacement: Replace the air filtration system periodically to ensure efficient airflow and improve combustion.

- Spark Plug Checks: Inspect and replace spark plugs to ensure smooth ignition and fuel efficiency.

Following these guidelines can lead to improved engine performance and efficiency. Always consult the appropriate resources for specific procedures and recommendations related to your vehicle’s power unit.

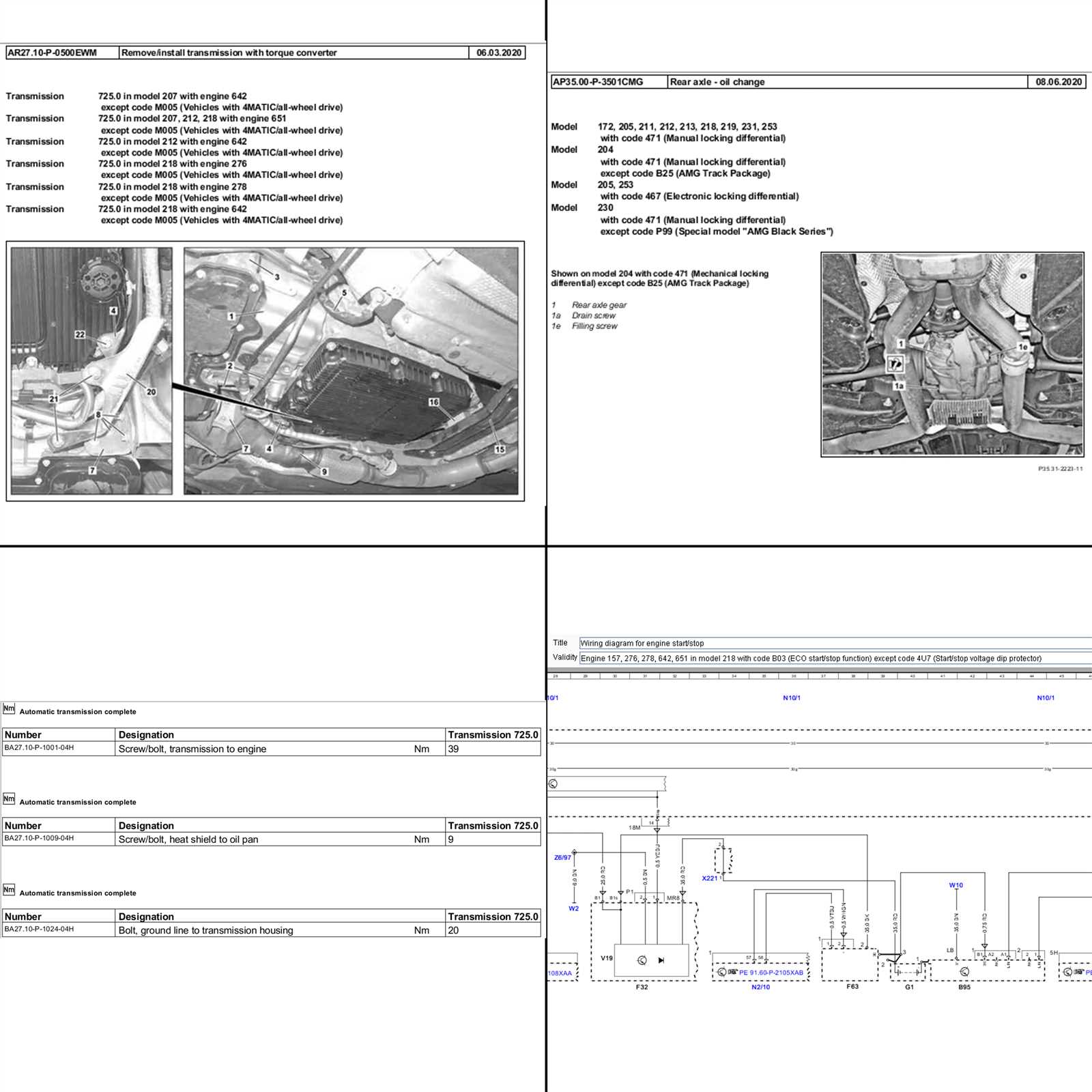

Transmission Care and Repair

Maintaining and fixing the transmission system is crucial for ensuring smooth performance and longevity of your vehicle. Regular attention to this component can prevent serious issues, enhance efficiency, and prolong its operational life.

Routine Maintenance is essential for optimal function. Regular fluid checks and changes help keep the system clean and prevent wear. It is advisable to inspect the transmission fluid for proper levels and condition, as clean fluid allows for better lubrication and cooling.

Common Issues may arise over time, including slipping gears, unusual noises, or leaks. Addressing these symptoms promptly can save time and resources. If any abnormalities are detected, it is important to consult a qualified technician for accurate diagnosis and intervention.

Repairs should be approached with care. Depending on the extent of the problem, a simple fluid replacement may suffice, or more complex issues might require part replacements or comprehensive servicing. Keeping records of any maintenance or repairs performed can be beneficial for future reference.

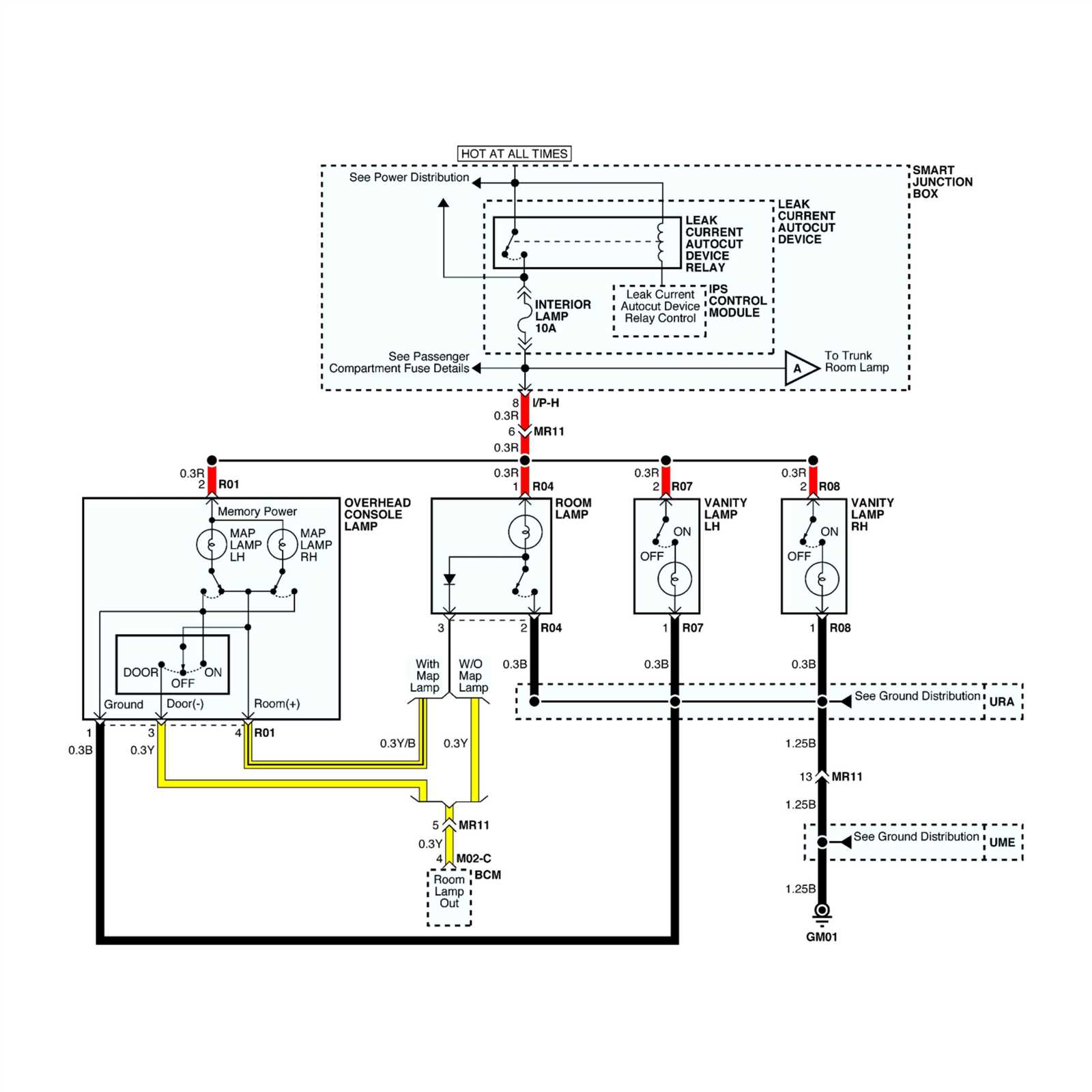

Electrical System Troubleshooting

Addressing issues within the electrical network of a vehicle can often be a complex task. A systematic approach is essential to identify and resolve malfunctions effectively. Understanding the components involved and their interactions is key to diagnosing problems efficiently.

Step 1: Visual Inspection

Begin by conducting a thorough visual assessment of the wiring, connectors, and related components. Look for any signs of damage, corrosion, or loose connections that may indicate potential issues. Ensuring a clean and secure environment is vital for optimal performance.

Step 2: Testing Voltage Levels

Utilize a multimeter to check voltage levels at various points in the system. This can help determine whether power is reaching critical components. If voltage readings are outside expected ranges, further investigation into the source may be necessary.

Step 3: Circuit Continuity Check

Perform a continuity test to verify that current can flow through the circuits as intended. Interruptions can lead to malfunctioning systems. Identifying breaks or shorts can direct you to the specific area requiring attention.

Step 4: Component Functionality Assessment

Evaluate the performance of individual components such as relays, fuses, and sensors. Ensure that each part operates according to specifications. Replacing faulty elements can often restore the system to full functionality.

By following these steps, one can systematically troubleshoot electrical system challenges, ensuring reliability and performance in the vehicle’s operation.

Brake System Inspection Procedures

Regular examination of the braking mechanism is essential for ensuring vehicle safety and performance. A systematic approach helps identify potential issues before they escalate into serious problems. This section outlines effective methods for inspecting the brake assembly and related components.

Visual Inspection

Begin with a thorough visual check of the braking components. Look for signs of wear, damage, or fluid leaks. Pay special attention to the following parts:

| Component | Inspection Criteria |

|---|---|

| Brake Pads | Check for thickness and uneven wear patterns. |

| Brake Discs | Inspect for scoring, cracks, or warping. |

| Brake Lines | Look for leaks, corrosion, and damage. |

| Fluid Reservoir | Ensure the fluid level is adequate and fluid condition is clean. |

Functional Testing

After visual inspection, conduct functional tests to assess the effectiveness of the braking system. Test drive the vehicle in a safe environment to evaluate braking response, pedal feel, and any unusual noises during operation. Listen for grinding sounds or vibrations that may indicate underlying issues.

Fuel System Diagnosis Tips

Identifying issues within the fuel delivery system is essential for maintaining optimal engine performance. Understanding common symptoms and potential causes can lead to effective troubleshooting. Here are some valuable suggestions to aid in diagnosing problems related to fuel flow and efficiency.

Common Symptoms to Observe

- Engine stalling or difficulty starting

- Decreased power during acceleration

- Unusual fuel odor around the vehicle

- Engine misfiring or running roughly

Diagnostic Steps

- Check the fuel level to ensure it is adequate.

- Inspect fuel lines for any signs of leaks or damage.

- Examine the fuel filter for blockages that could restrict flow.

- Test the fuel pump to confirm it is functioning correctly.

- Evaluate the fuel injectors for proper operation.

Cooling System Maintenance Strategies

Proper upkeep of the cooling system is essential for the efficient operation of any vehicle. Regular maintenance not only prolongs the lifespan of the components but also ensures optimal performance during operation. Implementing effective strategies can prevent overheating and other related issues, ultimately saving time and resources.

Regular Inspection and Fluid Levels

Routine checks of the cooling liquid are crucial to maintaining system efficiency. Ensure that the reservoir is filled to the appropriate level and inspect for any signs of leaks. Additionally, checking the condition of the hoses and clamps can prevent unexpected failures.

Flushing the Cooling System

Periodic flushing of the cooling system is recommended to remove contaminants and deposits that can accumulate over time. This process enhances heat exchange and improves the overall effectiveness of the system. Follow manufacturer guidelines for intervals and fluid types to ensure compatibility and performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and clamps | Every 3 months | Look for cracks or wear |

| Check coolant level | Monthly | Ensure proper levels |

| Flush cooling system | Every 2 years | Use recommended fluids |

Suspension and Steering Repairs

This section focuses on the maintenance and correction of suspension and steering components, ensuring optimal performance and handling. Proper attention to these systems not only enhances driving comfort but also promotes safety on the road. Understanding the fundamentals of these assemblies is essential for effective troubleshooting and service.

Key areas to consider during maintenance include the inspection of various components, such as control arms, shocks, struts, and linkages. Regular checks can prevent potential issues and extend the lifespan of these crucial parts.

| Component | Symptoms of Wear | Recommended Action |

|---|---|---|

| Shocks/Struts | Excessive bouncing, uneven tire wear | Replace if leaking or damaged |

| Control Arms | Clunking noises, misalignment | Inspect and replace bushings or arms if needed |

| Steering Linkage | Difficulty in steering, vibrations | Check for play and replace worn joints |

Addressing these areas promptly can prevent more significant issues down the line, ensuring a smoother and safer driving experience.

Body and Frame Restoration Techniques

Restoring the exterior and structural components of a vehicle requires a blend of skill, patience, and the right techniques. This process not only enhances the aesthetic appeal but also ensures the durability and safety of the automobile. Below are several key strategies for effective restoration.

- Assessment: Begin by thoroughly examining the body and frame for any signs of damage or wear. Identifying rust, dents, or structural issues early on is crucial for a successful restoration.

- Rust Removal: Utilize tools such as wire brushes, sanders, or chemical rust removers to eliminate corrosion. Ensure all affected areas are treated to prevent future deterioration.

- Structural Repairs: For any frame damage, employ welding techniques to reinforce weakened areas. Proper alignment is vital, so consider using frame jigs if necessary.

- Body Work: Fill dents and imperfections with appropriate fillers, then sand and smooth the surface for painting. A well-prepared surface is essential for achieving a flawless finish.

- Paint Application: Choose high-quality paint suited for automotive use. Apply in multiple thin layers to achieve a professional look, allowing each layer to dry completely before the next.

By following these restoration techniques, vehicle enthusiasts can breathe new life into their machines, ensuring both aesthetic beauty and structural integrity for years to come.

Routine Service Intervals Explained

Regular maintenance is essential for keeping a vehicle in optimal condition and ensuring its longevity. Adhering to scheduled service intervals helps prevent unexpected issues and promotes overall performance. Understanding these intervals allows owners to maintain their vehicles effectively and avoid costly repairs.

Service intervals typically include a variety of tasks designed to enhance the reliability of a vehicle. These may encompass:

- Oil changes

- Fluid checks and replacements

- Filter replacements

- Tire rotations

- Brake inspections

- Battery checks

It is advisable to follow a specific timeline or mileage to ensure that each task is completed as recommended. Here are some common intervals for various services:

- Oil and filter change: every 3,000 to 5,000 miles

- Fluid checks: every 6 months or 5,000 miles

- Brake inspection: every 10,000 miles

- Tire rotation: every 6,000 to 8,000 miles

- Battery check: every year

Following these intervals not only aids in maintaining vehicle performance but also enhances safety and efficiency. Regular assessments can identify potential problems early, allowing for timely intervention and peace of mind on the road.

Aftermarket Parts Considerations

When it comes to enhancing vehicle performance and reliability, opting for alternatives to original components can be a practical choice. These options often provide cost savings and improved specifications, catering to various needs and preferences of drivers. However, careful evaluation is essential to ensure compatibility and quality.

Before making a purchase, it’s important to research the manufacturer’s reputation and reviews from other consumers. Understanding the warranty offered can also provide insight into the longevity and reliability of the products. Some aftermarket solutions might offer enhanced features or better performance than standard parts, but this is not universally true.

Installation can vary significantly between original and aftermarket components. While some parts may fit seamlessly, others might require modifications or professional installation. Always consider the implications of such changes on the overall system of the vehicle to avoid complications in performance or safety.

Lastly, ensure that any modifications comply with local regulations. Certain jurisdictions may have specific laws regarding emissions and safety standards, which can affect the legality of certain aftermarket installations. Prioritizing compliance can save time and money in the long run.

Tools Needed for Repairs

Successful maintenance of your vehicle requires a variety of instruments to address various tasks effectively. Having the right equipment not only simplifies the process but also ensures safety and precision during each procedure. Below is a list of essential tools that will help facilitate your projects.

Basic Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle-nose and regular)

- Hammers (ball-peen and rubber)

Specialized Equipment

- Torque wrench

- Jack and jack stands

- Multimeter for electrical diagnostics

- Oil filter wrench

- Scan tool for computer diagnostics

Gathering these instruments will prepare you for a range of maintenance tasks, enabling you to tackle issues with confidence and efficiency.