In the realm of outdoor power equipment, understanding the intricacies of maintenance and troubleshooting can significantly enhance performance and longevity. Whether it’s a gardening tool or a landscaping machine, users often face various operational challenges that require careful examination and resolution. This section aims to provide essential insights and techniques for diagnosing common issues and ensuring smooth functionality.

Equipped with the right knowledge and techniques, owners can address problems effectively, saving time and money in the process. From identifying engine malfunctions to performing routine upkeep, this guide serves as a valuable resource for anyone looking to optimize their equipment. Emphasizing practical steps and user-friendly approaches, readers will find useful tips tailored to enhance their repair skills and boost confidence in handling their tools.

Through detailed exploration of components and their functions, individuals will gain a deeper understanding of how to troubleshoot effectively. This knowledge empowers users to take proactive measures in maintaining their machines, ensuring they remain reliable and efficient in any task. Let’s delve into the essential practices that will help you keep your equipment running at its best.

Poulan Pro 31cc Overview

This section provides an insightful examination of a popular outdoor power tool known for its efficiency and versatility. Designed for various tasks, this equipment caters to both casual users and professionals, making it a valuable addition to any toolkit.

Key features include:

- Lightweight design for ease of use

- Robust engine providing reliable performance

- Ergonomic handle for enhanced comfort during operation

- Easy start technology for quick usability

- Durable construction ensuring longevity

Maintenance is straightforward, allowing users to keep the machine in optimal condition with minimal effort. Regular checks on the fuel system, air filter, and spark plug contribute to sustained performance and efficiency.

In summary, this equipment is tailored for a range of applications, from gardening to light landscaping, making it an essential tool for outdoor enthusiasts.

Common Issues with Poulan Pro 31cc

When operating small engine equipment, users often encounter various challenges that can hinder performance and efficiency. Understanding these typical problems is crucial for maintaining optimal functionality and ensuring longevity.

Starting Difficulties

One of the most frequent issues is trouble starting the engine. This can stem from factors such as fuel quality, spark plug condition, or carburetor clogs. Regular maintenance and checks can help mitigate these concerns.

Power Loss

Experiencing a decrease in power during operation can indicate underlying issues. Common culprits include air filter blockages or improper fuel mixture. Identifying and resolving these factors is essential for restoring peak performance.

Essential Tools for Repair

When tackling any maintenance or troubleshooting task, having the right equipment is crucial for achieving optimal results. A well-equipped toolkit not only streamlines the process but also enhances safety and efficiency. Understanding which instruments are necessary can make a significant difference in your ability to address issues effectively.

Basic hand tools such as wrenches, screwdrivers, and pliers form the foundation of any maintenance endeavor. These items are indispensable for disassembling and reassembling components with precision. Additionally, specialized tools designed for specific tasks can provide an advantage in tackling complex problems.

Measuring devices, like calipers and gauges, are essential for ensuring that parts fit together correctly. Having a reliable source of power, such as a battery or a charger, is also important for operating various tools effectively. Furthermore, safety gear, including gloves and goggles, should not be overlooked to protect yourself during any hands-on work.

By assembling a comprehensive toolkit tailored to your needs, you’ll be well-prepared to handle a variety of challenges, ensuring that any maintenance tasks are completed efficiently and safely.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing common issues with small engine equipment. By following these steps, you can identify and resolve problems effectively, ensuring your machine operates smoothly and efficiently.

Step 1: Assess the Symptoms

Begin by observing the specific issues your equipment is experiencing. Note any unusual sounds, difficulties in starting, or performance irregularities. This initial assessment is crucial for narrowing down potential causes.

Step 2: Check the Fuel System

Inspect the fuel tank for adequate fuel levels and verify the quality of the fuel. Old or contaminated fuel can lead to poor performance. Ensure that the fuel lines are clear and the filter is clean.

Step 3: Examine the Air Filter

A clogged air filter can restrict airflow, causing the engine to run poorly. Remove the air filter and clean or replace it as needed. Ensure that it is securely reattached before testing the equipment.

Step 4: Spark Plug Inspection

The spark plug plays a vital role in engine ignition. Remove it and check for signs of wear or damage. Clean any buildup or replace the spark plug if necessary to restore optimal performance.

Step 5: Review the Ignition System

If the engine still fails to start, examine the ignition system components. Ensure all connections are secure and look for any signs of damage to the wires or coils.

Step 6: Test Compression

Low compression can indicate internal engine issues. Use a compression gauge to measure the pressure. If the readings are below the recommended level, further investigation may be necessary.

Step 7: Consult the Documentation

Refer to the user guide or technical documents specific to your equipment for detailed specifications and troubleshooting tips. This resource can provide valuable insights tailored to your model.

By following these steps, you can systematically address and resolve common issues, leading to a well-functioning machine. Remember to perform regular maintenance to prevent future problems.

Engine Maintenance Tips

Regular upkeep of your engine is essential for optimal performance and longevity. Implementing a few key practices can help ensure that your equipment runs smoothly and efficiently over time.

- Check and Change Oil: Regularly inspect the oil level and quality. Change the oil as recommended to prevent engine wear.

- Inspect Air Filters: Clean or replace air filters to maintain proper airflow and prevent dirt accumulation that can hinder performance.

- Examine Spark Plug: Regularly check the spark plug for wear and replace it if necessary to ensure efficient ignition.

- Fuel System Maintenance: Use fresh fuel and consider adding a fuel stabilizer if the engine will sit unused for an extended period.

- Clean Cooling Vents: Ensure that cooling vents and fins are free from debris to avoid overheating.

- Inspect Fuel Lines: Check for cracks or leaks in fuel lines and replace them to prevent potential hazards.

- Regularly Tighten Bolts: Periodically check and tighten all bolts and screws to ensure everything is secure and functioning properly.

By following these maintenance tips, you can enhance the performance and extend the lifespan of your engine, ensuring it operates at peak efficiency.

Replacing the Spark Plug

Maintaining optimal engine performance often hinges on a simple yet crucial component: the spark plug. This part plays a vital role in igniting the air-fuel mixture, ensuring smooth operation and efficiency. Regular inspection and replacement can prevent starting issues and enhance overall functionality.

To initiate the replacement process, first, ensure the engine is cool and disconnected from any power source. Remove the ignition lead and use a spark plug wrench to loosen and extract the old plug. Check for any wear or deposits that may indicate a need for change.

Next, prepare the new spark plug by checking the gap, which should align with the manufacturer’s specifications. Carefully install the new plug, ensuring it is tightened securely but not overly so, as this can cause damage. Reattach the ignition lead, and your engine will be ready for a more reliable performance.

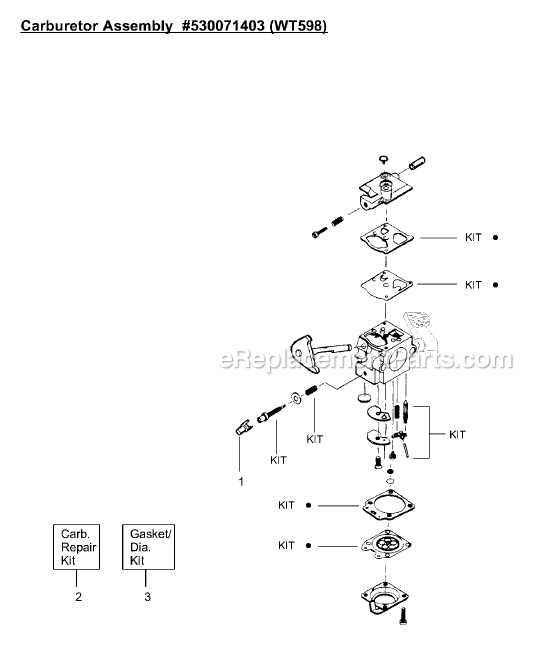

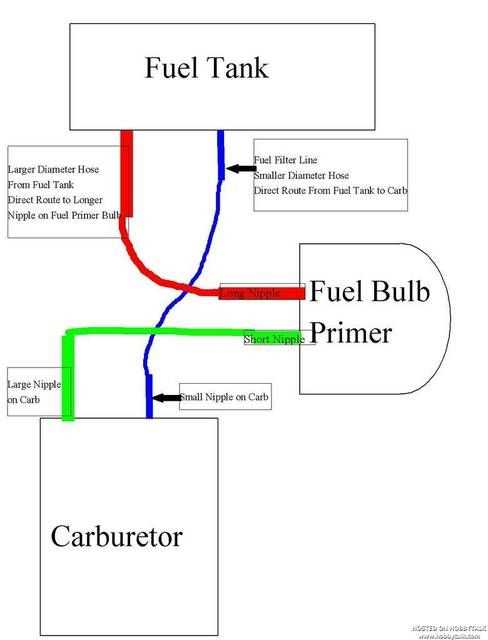

Fuel System Repairs Explained

The fuel delivery system is crucial for the efficient operation of small engines. Understanding the components and common issues can greatly enhance performance and longevity. This section outlines the typical problems encountered within this system and the steps to address them effectively.

Several elements contribute to the overall functionality of the fuel system, including the fuel tank, lines, filter, and carburetor. Regular maintenance and timely interventions can prevent more significant issues down the line.

| Component | Common Issues | Solutions |

|---|---|---|

| Fuel Tank | Contamination or leaks | Clean or replace the tank as necessary |

| Fuel Lines | Cracks or blockages | Inspect and replace damaged lines |

| Fuel Filter | Clogging | Replace the filter regularly |

| Carburetor | Improper mixture or buildup | Clean or adjust the carburetor settings |

By recognizing these common issues and implementing the suggested solutions, users can maintain an efficient fuel system and ensure reliable operation of their equipment.

How to Clean the Air Filter

Maintaining the air filter is essential for optimal performance and longevity of your equipment. A clean filter ensures that the engine receives adequate airflow, which is crucial for efficient combustion and reduced emissions. Regular cleaning can help prevent unnecessary wear and improve overall functionality.

Tools and Materials Needed

- Soft brush

- Soap and water

- Clean cloth

- Protective gloves

Step-by-Step Cleaning Process

- Remove the Air Filter: Start by carefully detaching the air filter from its housing. Refer to the user guidelines if needed.

- Brush Off Dust: Use a soft brush to remove loose dirt and debris from the filter surface.

- Wash the Filter: Prepare a solution of soap and water. Submerge the filter and gently scrub it to eliminate stubborn grime.

- Rinse Thoroughly: Rinse the filter under clean running water to remove any soap residue.

- Dry Completely: Use a clean cloth to pat the filter dry. Ensure it is fully dry before reinstalling.

- Reattach the Filter: Once dry, securely place the air filter back into its housing.

Regular cleaning of the air filter contributes to maintaining the equipment’s performance and efficiency. Make this a part of your routine maintenance schedule for best results.

Blade Replacement Procedures

Replacing the cutting blade is essential for maintaining optimal performance and ensuring safety during operation. This process involves careful attention to detail and the use of appropriate tools to ensure a secure fit and proper alignment.

Preparation Steps

Before beginning the replacement, ensure that the device is powered off and disconnected from any power source. Gather the necessary tools, including a wrench, a protective glove, and the new blade. It is advisable to consult the manufacturer’s guidelines for specific instructions related to your model.

Replacement Process

Start by removing any existing blade carefully. Loosen the mounting bolts using the wrench, ensuring to keep the hardware for reinstallation. Once the old blade is detached, position the new blade onto the mounting platform. Align it correctly and secure it by tightening the bolts firmly, but avoid over-tightening to prevent damage. Finally, double-check the alignment and ensure everything is in place before reconnecting the power source.

Following these steps will help maintain the efficiency of your equipment and enhance its lifespan.

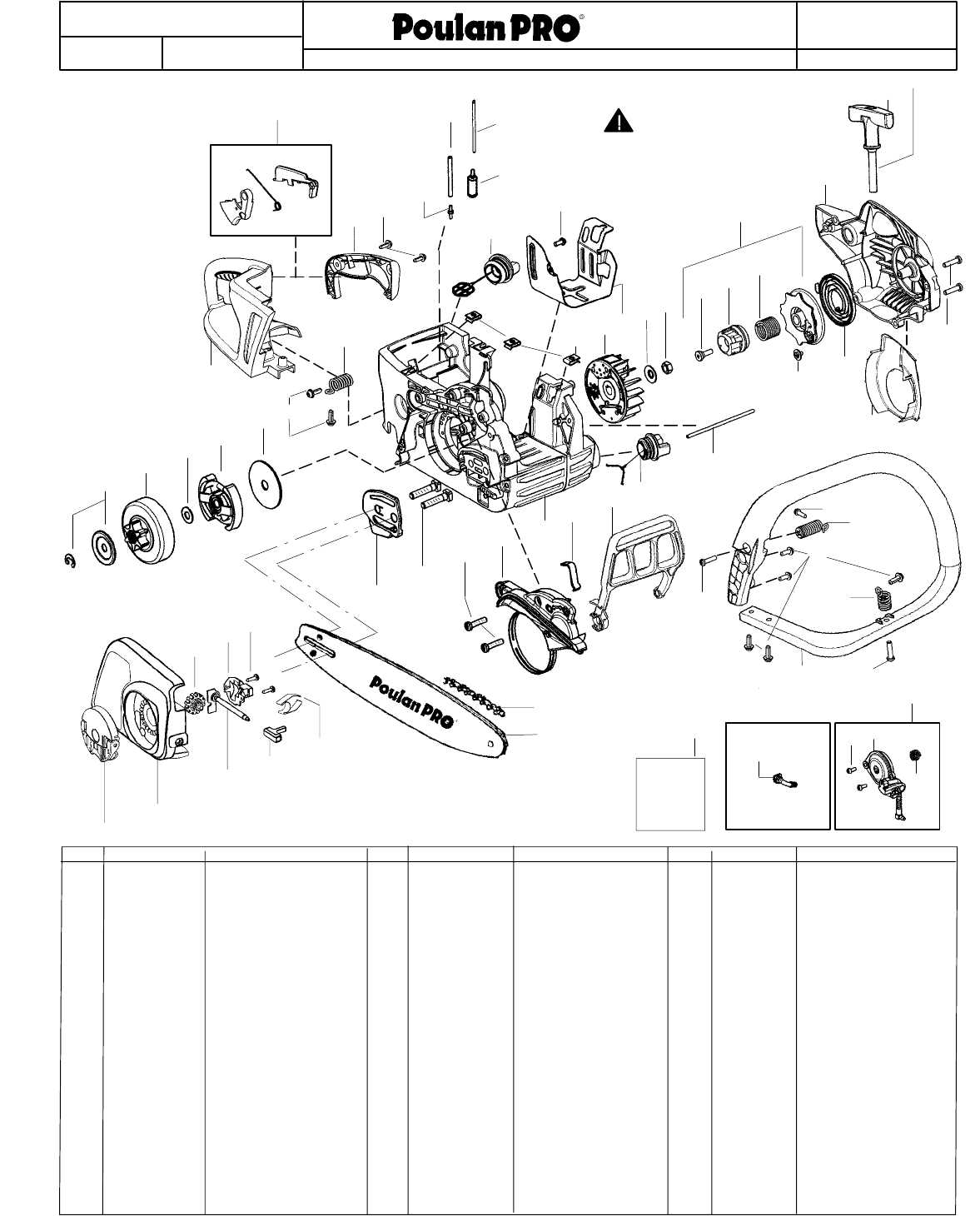

Chain and Bar Maintenance

Maintaining the cutting components of your equipment is crucial for optimal performance and longevity. Proper care ensures smooth operation, reduces wear, and enhances safety during use. Regular attention to the chain and bar not only improves cutting efficiency but also prevents potential damage.

Inspection Procedures

Routine inspections should be conducted to identify any signs of wear or damage. Key areas to examine include:

- Chain Tension: Ensure the chain is neither too loose nor too tight.

- Bar Condition: Check for any cracks or unusual wear on the bar.

- Chain Links: Look for bent or damaged links that may affect performance.

- Lubrication System: Verify that the oiling system is functioning properly to prevent overheating.

Maintenance Tips

Adopting a consistent maintenance routine can extend the life of your cutting tools. Consider the following recommendations:

- Clean Regularly: Remove debris and buildup from the bar and chain after each use.

- Sharpen the Chain: Regularly sharpen the chain to maintain cutting efficiency.

- Lubricate Adequately: Use appropriate oil to keep the chain and bar well-lubricated.

- Store Properly: When not in use, store your equipment in a dry place to prevent rust and corrosion.

By following these guidelines, you can ensure the reliability and effectiveness of your cutting tools for years to come.

Understanding the User Manual

The user guide serves as a vital resource for understanding the operation and maintenance of your equipment. It provides essential insights that help users navigate features, troubleshoot issues, and ensure longevity. Familiarizing oneself with this document can significantly enhance the experience and performance of the tool.

Key Sections to Explore

| Section | Description |

|---|---|

| Safety Precautions | Essential tips to ensure safe operation and minimize risks. |

| Operating Instructions | Step-by-step guidance on using the equipment effectively. |

| Maintenance Guidelines | Recommendations for regular upkeep to prolong the lifespan. |

Utilizing the Guide Effectively

Safety Precautions During Repairs

When engaging in maintenance or troubleshooting tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure that the equipment remains in optimal condition. Understanding potential hazards and implementing safety measures can significantly reduce risks associated with mechanical tasks.

Always wear appropriate personal protective equipment. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges and chemicals, and sturdy footwear to guard against heavy objects. Using such gear is fundamental in minimizing injury risks.

Ensure that the workspace is organized and free from clutter. A tidy environment allows for better focus and reduces the chance of accidents. Additionally, working in a well-ventilated area helps to avoid inhaling harmful fumes that may be released during maintenance processes.

Disconnect power sources before starting any task. Whether dealing with electric components or fuel systems, ensuring that all power sources are safely turned off mitigates the risk of electric shock or accidental ignition. This simple step is vital for personal safety.

Finally, always refer to relevant documentation before beginning any work. Understanding the specifics of the equipment, including potential hazards and troubleshooting tips, will enhance safety and effectiveness. Taking these precautions can lead to a safer and more efficient maintenance experience.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance. Whether you’re looking to replace a worn-out item or upgrade for better efficiency, understanding where to source these parts can make all the difference.

Online Retailers

- Search popular e-commerce platforms that specialize in outdoor equipment.

- Check manufacturer websites for direct purchases and authenticity.

- Explore third-party vendors that offer a wide range of components at competitive prices.

Local Stores

- Visit hardware stores that carry lawn and garden supplies.

- Inquire at specialized shops that focus on small engines or landscaping tools.

- Attend local trade shows or fairs where vendors may sell replacement parts.

By utilizing both online and local resources, you can ensure you find the correct items to keep your machinery in excellent working order.