Ensuring the optimal functionality of your machinery is essential for achieving peak performance. This section provides valuable insights into the upkeep and servicing of specific equipment, focusing on effective techniques and procedures. By following these guidelines, you can maintain efficiency and extend the lifespan of your devices.

The process of addressing common issues and restoring operational capability is outlined here. Understanding the intricacies of the equipment will empower you to tackle various challenges with confidence. Clear instructions and helpful tips are designed to facilitate the maintenance journey, making it accessible to users of all experience levels.

With a proactive approach, you can prevent minor complications from escalating into significant setbacks. This guide emphasizes the importance of regular checks and appropriate interventions, ensuring that your equipment remains in excellent working condition. Embracing these practices will not only enhance performance but also contribute to cost-effectiveness in the long run.

Common Issues with Aerzen Blowers

Understanding the typical challenges faced by these machines can enhance maintenance and extend their lifespan. Identifying problems early can prevent more significant breakdowns and costly repairs.

| Issue | Description | Possible Solutions |

|---|---|---|

| Noise | Unusual sounds may indicate mechanical wear or misalignment. | Inspect components for damage and ensure proper alignment. |

| Vibration | Excessive vibration can signal imbalance or loose parts. | Check for secure fittings and balance the rotating elements. |

| Reduced Performance | A drop in efficiency can occur due to blockages or leaks. | Examine for clogs in the intake or discharge paths. |

| Overheating | High temperatures may result from insufficient airflow or lubrication. | Ensure adequate ventilation and check oil levels. |

Tools Required for Repairs

When addressing maintenance tasks, having the right instruments is crucial for effective outcomes. Properly chosen equipment not only enhances efficiency but also ensures safety during the process.

Essential Equipment

Below is a list of fundamental tools that will assist in the maintenance activities:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts. |

| Screwdrivers | For driving screws into various components. |

| Pliers | For gripping and bending materials. |

| Socket Set | For accessing hard-to-reach fasteners. |

| Torque Wrench | For applying a specific torque to fasteners. |

Additional Supplies

In addition to the primary tools, certain supplementary items can further aid in the process:

| Supply | Use |

|---|---|

| Lubricants | To reduce friction and wear on moving parts. |

| Cleansers | For maintaining cleanliness of components. |

| Safety Gear | To ensure protection during maintenance work. |

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues encountered during maintenance of air-moving devices. Following a systematic method ensures efficiency and effectiveness in restoring functionality.

-

Initial Assessment:

Begin by inspecting the unit for visible signs of wear or damage. Check for unusual noises or vibrations during operation.

-

Gather Necessary Tools:

Collect all required tools, including wrenches, screwdrivers, and cleaning materials to facilitate the procedure.

-

Power Down the Unit:

Ensure the device is completely powered off and disconnected from any electrical source to prevent accidents.

-

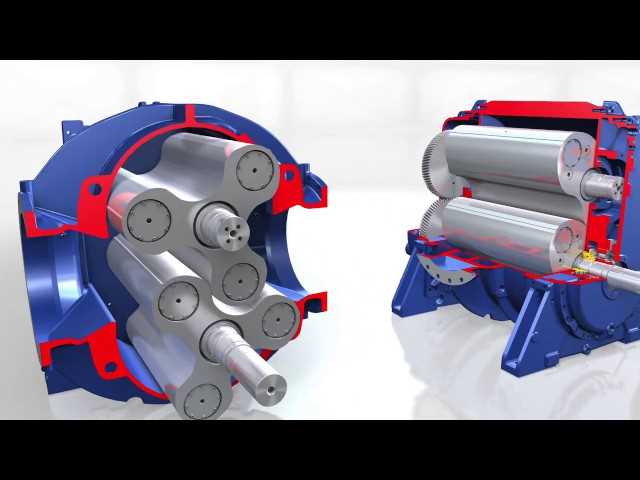

Dismantling Components:

Carefully remove outer casings and relevant parts to access internal mechanisms. Document the order of disassembly for easy reassembly.

-

Inspect Internal Parts:

Examine internal components for damage, dirt, or blockages. Clean or replace any parts as necessary.

-

Reassembly:

Put all components back together following the documented order. Ensure all parts are secured tightly.

-

Testing:

Reconnect the unit to the power source and conduct a thorough test to ensure proper operation. Monitor for any irregularities.

By adhering to these steps, one can effectively address issues and enhance the longevity of the air-moving apparatus.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent attention and care. Implementing a regular maintenance schedule can significantly extend its lifespan, minimize operational issues, and enhance overall performance.

Below are some essential practices to follow for optimal upkeep:

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Inspect seals and gaskets | Monthly | Prevent leaks and ensure airtight operation |

| Check lubrication levels | Weekly | Reduce friction and wear on moving parts |

| Clean intake filters | Every 3 months | Maintain airflow efficiency and performance |

| Tighten bolts and connections | Quarterly | Ensure structural integrity and safe operation |

| Inspect electrical connections | Every 6 months | Prevent electrical failures and maintain safety |

By adhering to these recommendations, you can help ensure the reliability and longevity of your system, ultimately saving time and resources in the long run.

Identifying Performance Problems

Recognizing issues related to efficiency and functionality in air-moving equipment is crucial for maintaining optimal operation. These challenges can manifest in various ways, affecting both output and reliability.

Common Symptoms of Underperformance

Several indicators can suggest that the equipment is not performing at its best. Users may notice unusual noises, vibrations, or fluctuations in airflow. Additionally, unexpected increases in energy consumption can signal underlying issues.

Initial Diagnostic Steps

To address potential inefficiencies, begin by checking the equipment’s operational parameters against the manufacturer’s specifications. Regular monitoring and routine inspections can help identify discrepancies early, preventing more severe complications in the future.

Replacing Key Components

Maintaining optimal performance in your system often requires the timely replacement of essential parts. Addressing these components not only enhances functionality but also prolongs the lifespan of the equipment. This section provides a comprehensive overview of the process involved in substituting vital elements effectively.

Identifying Components for Replacement

Before initiating the replacement process, it’s crucial to identify which parts need attention. Commonly replaced components include:

- Seals and Gaskets

- Filters

- Belts and Hoses

- Electrical Connectors

Steps for Component Replacement

Follow these steps to ensure a smooth replacement process:

- Power down the system and disconnect it from any power source.

- Remove the casing or cover to access the components.

- Carefully detach the old part, taking note of how it was installed.

- Install the new component, ensuring it is secure and properly aligned.

- Reassemble the casing and reconnect the power source.

- Test the system to verify functionality.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when conducting maintenance tasks on machinery. Taking proper safety measures minimizes risks and protects both the technician and the equipment. Adhering to established guidelines can significantly reduce the likelihood of accidents and injuries.

General Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Ensure the work area is well-ventilated to avoid inhaling harmful fumes.

- Keep the workspace organized to prevent slips, trips, and falls.

Equipment Handling

- Disconnect all power sources before starting any servicing to avoid electrical hazards.

- Use the correct tools for the job to prevent damaging components and ensure efficiency.

- Follow the manufacturer’s guidelines regarding disassembly and reassembly of parts.

Troubleshooting Electrical Issues

When facing complications with electrical components, a systematic approach can help identify and resolve the problems effectively. Understanding potential causes and applying the right techniques can lead to a successful diagnosis and solution.

Common Symptoms and Causes

Typical signs of electrical malfunctions include inconsistent power supply, unusual noises, and failure to start. These issues may arise from faulty connections, damaged wiring, or component wear. Careful inspection and testing can reveal the underlying cause.

Steps for Diagnosis

Begin by checking the power source to ensure proper voltage and current. Inspect connections for any signs of corrosion or looseness. If the problem persists, utilize a multimeter to test individual components for functionality. Documenting findings during this process aids in identifying patterns and solutions.

How to Properly Clean the Blower

Regular maintenance is essential to ensure optimal performance of your equipment. Cleaning is a critical step that helps prevent buildup and prolongs the lifespan of the system. By following a systematic approach, you can maintain efficiency and avoid potential issues.

Start by disconnecting the unit from the power source. This safety precaution is crucial before performing any maintenance work. Next, use a soft brush or cloth to remove dust and debris from the exterior surfaces. Pay close attention to any vents and air intakes, as these areas can accumulate particles that hinder airflow.

For a more thorough cleaning, consider using a vacuum with a nozzle attachment. This method allows you to reach tight spots and effectively remove dirt. Afterward, inspect any filters or screens and replace them if they show signs of wear or excessive dirt.

Finally, reassemble all components carefully, ensuring everything is secured properly. Once reconnected to the power source, conduct a brief operational test to confirm that the system is functioning smoothly. Regular cleaning not only enhances performance but also minimizes the risk of malfunctions.

Documentation for Reference

This section provides essential resources and guidelines that can assist users in understanding the functioning and maintenance of the equipment. By consulting these materials, individuals can gain valuable insights into the best practices for operating and troubleshooting.

Types of Resources Available

Various types of resources are at your disposal, including technical specifications, operational guidelines, and maintenance schedules. These documents offer comprehensive details that help ensure the equipment operates efficiently and effectively.

Accessing Additional Information

For those seeking further assistance, consider reaching out to qualified professionals or checking online forums where experienced users share their knowledge. This collaborative approach can enhance understanding and support effective problem-solving.

When to Seek Professional Help

Recognizing the right moment to consult an expert can prevent further complications and ensure efficient functioning of your equipment. Certain signs and symptoms may indicate that professional intervention is necessary to address underlying issues effectively.

If you encounter persistent problems that do not resolve with basic troubleshooting, it may be time to seek assistance. Ignoring these signs can lead to more significant damage and costly repairs.

| Symptoms | Recommended Action |

|---|---|

| Unusual noises during operation | Contact a technician for assessment |

| Frequent power failures | Seek expert advice to investigate |

| Overheating components | Schedule a service appointment |

| Loss of efficiency | Consider professional evaluation |