In the realm of automotive engineering, ensuring optimal functionality of gear systems is crucial for vehicle performance. This section delves into the intricacies of maintaining these complex mechanisms, emphasizing the importance of proper upkeep and the methodologies involved.

Comprehending the various components and their interactions within the gearbox can significantly enhance longevity and efficiency. By following best practices and utilizing effective troubleshooting techniques, vehicle owners can avoid common pitfalls that lead to premature wear or failure.

Through detailed guidance, this resource aims to empower individuals with the knowledge necessary to navigate the challenges of gearbox maintenance. From basic adjustments to intricate diagnostics, understanding these processes is essential for both enthusiasts and professionals alike.

A6MF1 Transmission Overview

The A6MF1 unit represents a significant advancement in automotive engineering, designed to enhance efficiency and performance. This system is engineered to optimize gear shifts, providing a seamless driving experience under various conditions.

Featuring a sophisticated architecture, the component incorporates advanced technologies that improve fuel consumption while maintaining power delivery. The integration of electronic controls allows for precise management of gear engagement, ensuring responsiveness and reliability.

Maintenance and troubleshooting are essential to prolonging the lifespan of this assembly. Regular inspections can identify potential issues, while understanding its operational principles can aid in effective diagnostics. A solid grasp of this assembly’s functionalities will empower users to make informed decisions regarding upkeep and service.

Common Issues with A6MF1

This section explores frequent problems associated with a specific automatic gearbox system. Understanding these issues can aid in diagnostics and enhance the overall performance of the vehicle. Various factors can contribute to complications, leading to suboptimal operation and potential malfunctions.

Frequent Complications

Owners may encounter several recurring difficulties that can affect drivability. Notable symptoms include slipping, delayed shifting, and unusual noises during operation. These indicators often signify underlying mechanical or electronic concerns that require attention.

Common Symptoms and Causes

| Symptom | Possible Cause |

|---|---|

| Slipping during acceleration | Worn clutch plates or insufficient fluid levels |

| Delayed shifting | Faulty sensors or solenoids |

| Unusual noises | Mechanical wear or fluid contamination |

| Fluid leaks | Deteriorated seals or gaskets |

Addressing these complications promptly can help maintain optimal function and longevity of the system, ensuring a smooth driving experience.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing issues within the specified system. It outlines a methodical approach to diagnose and fix common problems, ensuring that each phase is executed with precision for optimal results.

Begin by gathering all necessary tools and components. Ensure that the workspace is organized to facilitate efficient workflow. Start with an initial assessment, identifying symptoms and potential causes. Document any irregularities observed during this phase.

Proceed to disassemble the relevant parts carefully, following the designated sequence to prevent damage. Clean all components thoroughly, removing any debris or contaminants that may affect performance. Inspect each element for wear and tear, replacing any damaged items as needed.

Reassemble the unit by reversing the disassembly steps, ensuring that all connections are secure. Conduct a final inspection to verify that everything is in place and functioning as intended. Finally, perform a test run to confirm that the issues have been resolved, making any necessary adjustments for optimal functionality.

Essential Tools for Repair

Undertaking maintenance on complex machinery requires a specific set of instruments to ensure effective functioning. Having the right equipment at your disposal can greatly enhance the efficiency and accuracy of the process. This section highlights the key items that are essential for successful maintenance tasks.

Basic Hand Tools

Essential hand tools such as wrenches, screwdrivers, and pliers form the foundation of any toolkit. These versatile implements enable you to tighten or loosen components with ease. Investing in high-quality tools not only increases durability but also reduces the likelihood of damaging sensitive parts during the procedure.

Diagnostic Equipment

Diagnostic tools play a crucial role in identifying issues within the system. Devices like multimeters and scan tools help monitor performance and pinpoint malfunctions. Utilizing such technology allows for a more systematic approach, leading to quicker and more accurate resolutions.

Overall, equipping yourself with these fundamental tools will facilitate a smoother workflow and contribute to achieving optimal performance of the machinery.

Fluid Specifications and Maintenance

Proper management of fluid types and their maintenance is crucial for ensuring optimal performance and longevity of the vehicle’s drivetrain system. Understanding the specifications for these liquids is essential for effective operation and preventing potential issues.

It is recommended to utilize fluids that meet the manufacturer’s guidelines to ensure compatibility and efficiency. Regular checks and changes according to the service intervals outlined in the guidelines will help maintain the system’s functionality. Using the correct viscosity and formulation is vital, as it directly affects the system’s ability to operate smoothly under varying conditions.

Additionally, monitoring fluid levels and conditions can prevent significant wear and tear. Identifying any signs of contamination or degradation early allows for timely intervention, which can save on costly repairs down the line. Regular maintenance routines should include inspections and fluid replacements as specified to uphold the integrity of the entire mechanism.

Diagnosing Transmission Problems

Identifying issues within a vehicle’s shifting system requires careful observation and analysis of various symptoms. Understanding how these problems manifest can greatly assist in troubleshooting effectively and ensuring smooth functionality.

Common Symptoms to Watch For

Several indicators may suggest underlying complications. Paying attention to these signs can help pinpoint the source of the trouble:

| Symptom | Description |

|---|---|

| Slipping Gears | Unintentional disengagement from selected gears during operation. |

| Delayed Engagement | Noticeable lag when shifting into drive or reverse. |

| Fluid Leaks | Visible fluid accumulation beneath the vehicle, indicating a potential seal or gasket failure. |

| Noisy Operation | Unusual sounds, such as grinding or whining, during gear changes. |

Initial Diagnostic Steps

To begin troubleshooting, consider the following steps:

- Check fluid levels and condition.

- Inspect for visible leaks or damage.

- Listen for abnormal sounds during gear shifts.

- Test the response time of gear changes.

By following these guidelines, one can effectively narrow down potential issues and facilitate timely interventions, ensuring the vehicle remains in optimal working condition.

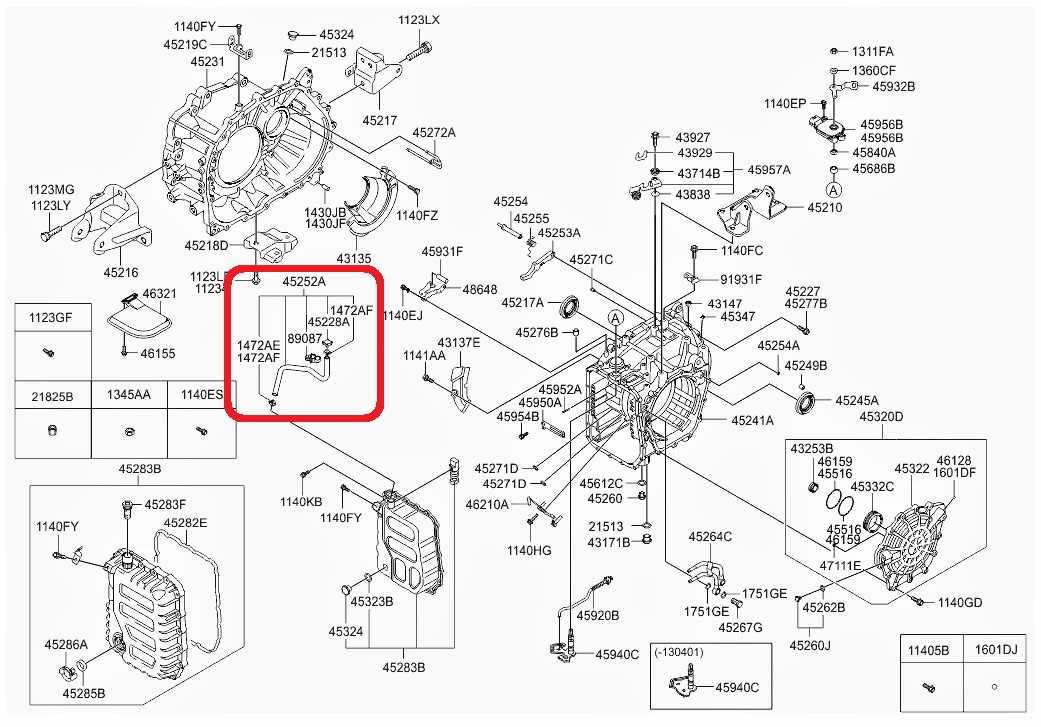

Component Replacement Techniques

Replacing various elements in complex mechanical systems requires precision and a clear understanding of the procedures involved. This section outlines effective methods for swapping out components, ensuring optimal functionality and longevity of the system. Proper techniques can significantly enhance performance and reduce the risk of future issues.

Preparation and Tools

Before commencing any replacement, it is crucial to gather the necessary tools and prepare the workspace. An organized area can prevent loss of small parts and facilitate a smoother process. Commonly required tools include:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts |

| Screwdrivers | For various types of screws |

| Torque Wrench | To ensure correct bolt tightness |

| Puller | For removing tightly fitted parts |

Step-by-Step Replacement Process

Adopting a systematic approach is essential during the replacement procedure. Follow these general steps:

- Disconnect power sources and drain any fluids if applicable.

- Remove the exterior casing or any obstructions to access the component.

- Carefully detach the old part, ensuring no surrounding elements are damaged.

- Install the new component, securing it in place and reconnecting any necessary connections.

- Test the system to confirm successful installation and proper operation.

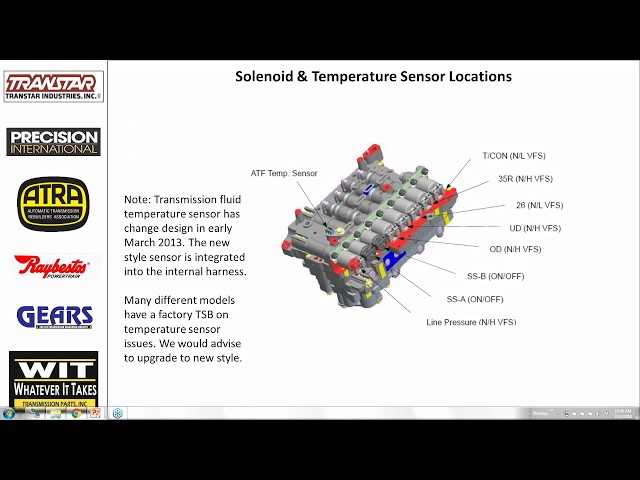

Wiring Diagrams and Schematics

Understanding electrical connections and layouts is crucial for effective troubleshooting and maintenance of complex systems. Clear visual representations help technicians identify components, track wiring paths, and ensure accurate assembly during reconfiguration or upgrades.

These diagrams typically include:

- Color Codes: Indicate specific functions and connections for wires.

- Component Symbols: Represent various parts such as sensors, relays, and actuators.

- Connection Points: Show where wires link to components, facilitating easier identification during repairs.

When analyzing schematics, consider the following steps:

- Familiarize with Symbols: Understand the meaning of each symbol used in the diagram.

- Trace Circuits: Follow the wiring paths to visualize the flow of electricity.

- Identify Critical Points: Locate key components that may affect system performance.

Utilizing these diagrams effectively can significantly enhance problem-solving capabilities and ensure proper functionality in electronic assemblies.

Testing and Calibration Methods

This section outlines essential techniques for evaluating and fine-tuning automotive systems to ensure optimal performance. Accurate assessment and adjustment are critical for maintaining efficiency and reliability in mechanical components.

Various methodologies exist for effective evaluation, including visual inspections, functional tests, and diagnostic scans. Each method serves to identify issues and calibrate settings appropriately, enhancing overall system functionality.

| Method | Description | Tools Required |

|---|---|---|

| Visual Inspection | Examine components for wear, damage, or leaks. | Flashlight, inspection mirror |

| Functional Testing | Assess system performance under various conditions. | Scan tool, multimeter |

| Diagnostic Scanning | Utilize electronic tools to retrieve fault codes and data. | OBD-II scanner |

| Pressure Testing | Measure fluid pressure to ensure proper operation. | Pressure gauge, adapters |

Implementing these techniques effectively can prevent future complications and extend the lifespan of key systems. Regular assessments contribute to smoother operation and enhanced vehicle reliability.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle’s components. Implementing consistent maintenance practices can prevent costly repairs and enhance overall performance.

- Regular Fluid Checks: Monitor levels of essential fluids, including oil, coolant, and hydraulic fluid.

- Routine Inspections: Schedule periodic inspections to identify potential issues before they escalate.

- Filter Replacements: Replace filters at recommended intervals to ensure optimal operation.

- Drive Smoothly: Adopt gentle driving habits to reduce wear on various parts.

- Keep it Clean: Regularly wash and clean the undercarriage to remove dirt and debris.

By following these tips, you can significantly enhance the performance and reliability of your vehicle, leading to a more enjoyable driving experience.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and troubleshooting of a specific automotive system. It aims to provide clarity and support for users seeking to understand various aspects of this complex mechanism.

What are the signs of a malfunction?

Common indicators of an issue include unusual noises, difficulty shifting gears, or fluid leaks. If you notice any of these symptoms, it is advisable to investigate further to prevent more significant problems.

How often should I perform maintenance?

Regular upkeep is crucial for optimal performance. It is generally recommended to check the system at regular intervals, following the guidelines specified by the manufacturer. Maintaining proper fluid levels and quality is essential.

Note: Consulting with a professional can provide additional insights tailored to your specific vehicle’s needs.

Resources for Further Learning

Expanding your knowledge on automotive systems can greatly enhance your understanding and ability to tackle various mechanical challenges. Numerous materials are available to assist enthusiasts and professionals in mastering complex topics related to vehicle performance and functionality.

Consider exploring online forums and communities where experts and hobbyists share their experiences and advice. These platforms provide a wealth of information, often including troubleshooting tips and innovative solutions to common issues.

Additionally, educational videos on platforms like YouTube can offer visual demonstrations that make complex concepts easier to grasp. Many creators focus on practical applications and step-by-step guides, catering to various skill levels.

Books and guides dedicated to automotive mechanics are also invaluable resources. These publications often delve into the intricacies of vehicle systems, providing detailed explanations and illustrations to aid understanding.

Lastly, consider enrolling in workshops or courses that focus on automotive technology. Hands-on training can significantly enhance your skills, allowing you to apply theoretical knowledge in real-world scenarios.