Keeping your clothing care equipment in top condition ensures it serves you reliably over the years. Regular upkeep not only extends the life of the appliance but also maintains its efficiency, making it easier to achieve the best results when preparing clothes for wear. In this guide, we will look at essential tips and troubleshooting steps to help you keep your garment tool functioning smoothly.

From identifying common issues to implementing practical solutions, the information here aims to make maintenance straightforward and accessible. Learn which steps to take when your clothing tool shows signs of wear, ensuring that minor issues do not escalate into major concerns. Whether you’re a long-time user or new to such devices, understanding these basics will prove invaluable.

Expert advice is provided to address frequent challenges and give you simple techniques to handle them effectively. Following these insights can help you continue enjoying the dependable performance of your garment care device, keeping it ready for everyday use.

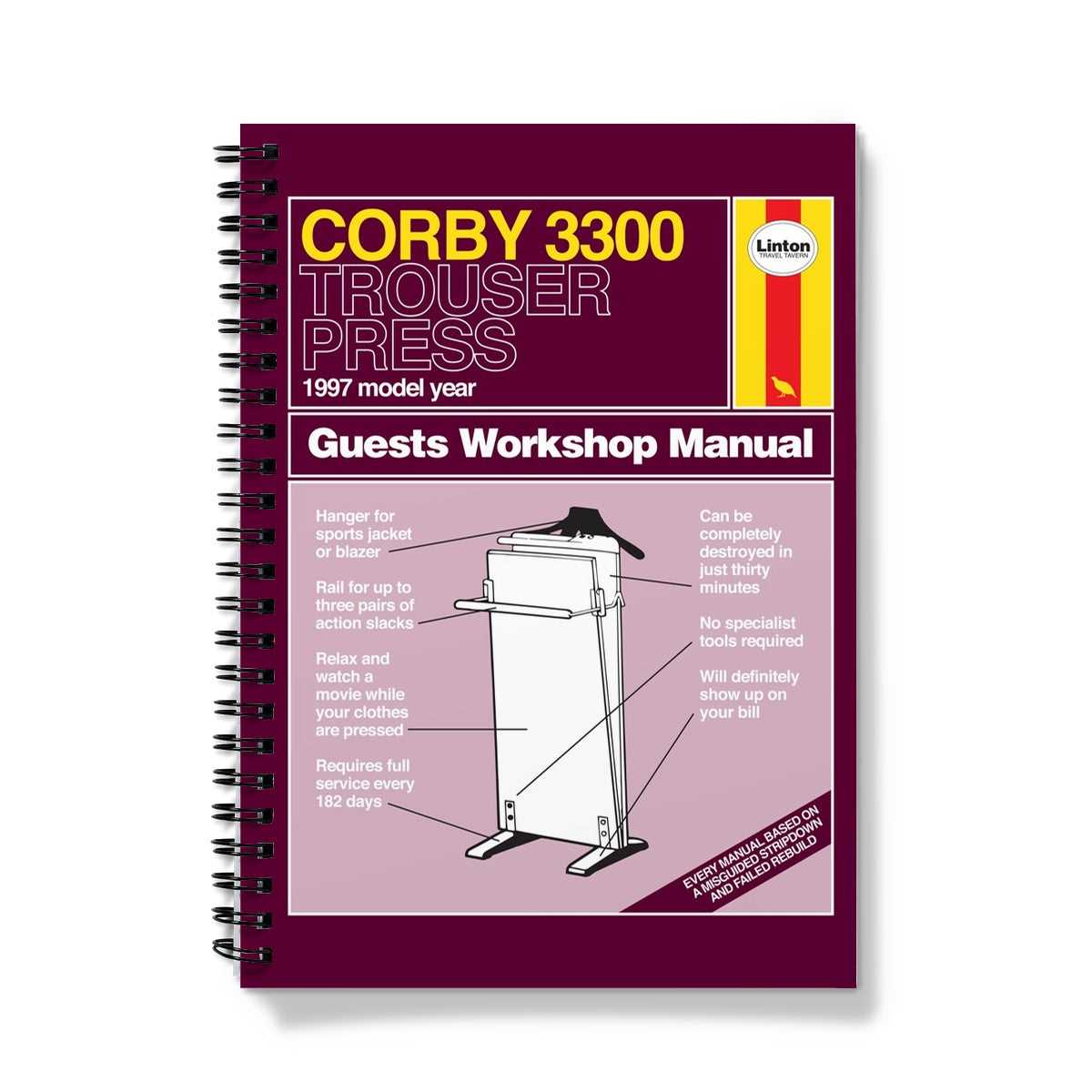

Corby Trouser Press Repair Guide

Maintaining and troubleshooting a garment care appliance can extend its lifespan and ensure optimal performance. When an appliance shows signs of wear or stops functioning as expected, a few targeted adjustments may restore its efficiency.

Inspection and Diagnosis

Start by examining key components, focusing on connectors, internal wiring, and controls. Often, power interruptions or loose connections are the culprits behind operational issues. Ensure all connections are secure and that no components show signs of visible damage.

Basic Component Adjustments

For minor fixes, check mechanisms responsible for garment pressing and heating. Clean these areas and confirm that moving parts operate without obstruction. Regular dusting and careful alignment can help restore functionality in many cases.

Testing and Reassembly

After adjustments, test the device to verify smooth operation. If the issue persists, consider consulting a technician for detailed analysis or part replacements. Routine care and occasional check-ups can prevent more significant issues and keep the appliance working effectively.

Identifying Common Issues in Corby Presses

This section covers frequent operational challenges and signs of malfunction that may arise in fabric-smoothing equipment, aiming to help users recognize problems before they escalate. Understanding these issues can be crucial for maintaining optimal functionality and preventing unnecessary wear.

| Issue | Description | Possible Cause | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heating Inconsistency | Device fails to reach or maintain the desired warmth, leading to ineffective performance. | May be caused by faulty thermostat or heating element connections. | ||||||||||||||||||||||||||||||||

| Electrical Failure | Equipment doesn’t power on or intermittently shuts down. | Could result from wiring issues, loose connections, or worn-out components. | ||||||||||||||||||||||||||||||||

| Mechanical Jam | The pressing mechanism gets stuck or fails to close properly. | Often due to misaligned parts, dirt buildup, or inadequate lubrication. | ||||||||||||||||||||||||||||||||

Over

Understanding the Main Components

In this section, we will explore the primary elements that make up this garment-care device. Familiarizing yourself with these parts can help enhance the overall understanding of how the equipment functions and how it maintains optimal performance.

By understanding these core parts, users can make the most of the device’s functionality and perform basic maintenance as needed, ensuring lasting performance and reliability. Essential Tools for Repairing

For anyone aiming to restore or maintain household devices effectively, having the right set of tools is crucial. This selection can make tasks easier, faster, and ensure that adjustments or replacements are accurate and secure. Below, we’ll cover essential items to keep on hand for a smooth, efficient restoration process. Basic Tool KitA standard toolkit is the backbone of any maintenance project. Screwdrivers, pliers, and adjustable wrenches are invaluable for loosening, tightening, and adjusting various parts. Make sure these tools are in good condition, as worn tips or dull edges can hinder progress. Specialized InstrumentsFor more specific adjustments, consider adding a multimeter and a precision screwdriver set to your collection. A multimeter allows you to test electrical connections and diagnose issues quickly, while precision tools ensure that smaller components can be adjusted without damage. These specialized instruments offer greater control and accuracy, especially when dealing with delicate mechanisms. Step-by-Step Disassembly InstructionsThese instructions provide a systematic guide for safely and effectively disassembling the device for maintenance purposes. Following each step carefully will help you access internal components and ensure a smooth reassembly later on.

|