In the realm of agricultural machinery, understanding the intricacies of maintenance is essential for optimal performance and longevity. This section delves into the vital aspects of keeping your equipment in peak condition, ensuring it operates smoothly through various tasks.

Farmers and operators alike recognize the importance of having access to detailed information when it comes to troubleshooting and upkeep. With a focus on practical solutions and preventive care, this guide serves as a valuable resource for anyone seeking to enhance their machinery’s reliability.

From step-by-step procedures to expert tips, the content here is designed to empower users with the knowledge needed to address common issues effectively. Embracing a hands-on approach can lead to significant improvements in productivity and reduce downtime.

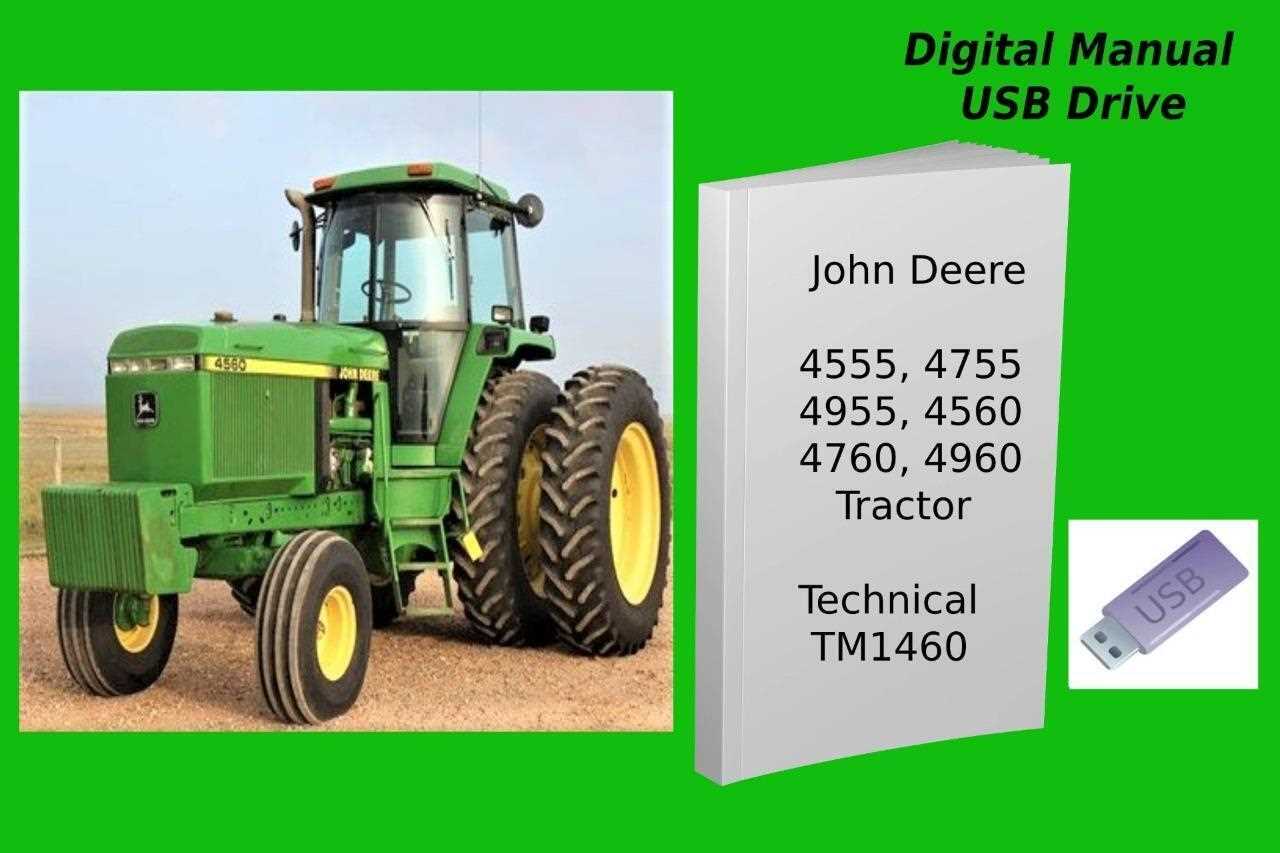

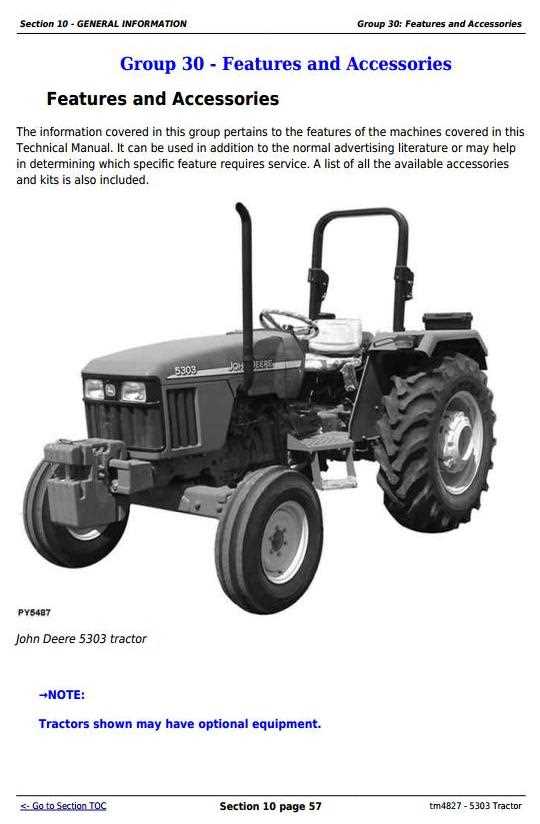

Overview of John Deere 5303

This segment delves into a versatile agricultural machine known for its reliability and efficiency. Designed to meet the diverse needs of farmers, this equipment combines power with ease of use, making it a popular choice in various agricultural settings.

Equipped with a robust engine, this model delivers impressive performance, capable of handling a wide array of tasks. Whether it’s tilling, plowing, or transporting materials, this machinery stands out due to its durability and adaptability.

Key features include an ergonomic operator station, allowing for comfortable use during long working hours. Additionally, its advanced hydraulic system enhances operational capabilities, enabling smooth and efficient task execution.

Maintenance is streamlined, with accessible components that facilitate routine checks and servicing. This practicality ensures longevity, making it a valuable asset on any farm.

Overall, this agricultural tool exemplifies a blend of technology and functionality, supporting farmers in optimizing their productivity and efficiency in daily operations.

Common Issues in John Deere 5303

This section addresses prevalent challenges faced by users of a specific agricultural machine. Understanding these issues can significantly enhance the maintenance experience and prolong the lifespan of the equipment. Proper identification and troubleshooting can mitigate downtime and improve overall performance.

Engine Performance Problems

One of the most frequently encountered difficulties involves the engine’s performance. Users often report symptoms such as rough idling, reduced power output, or unexpected stalling. These problems can stem from a variety of sources, including fuel system blockages, air filter obstructions, or faulty ignition components. Regular maintenance checks are essential to ensure that the fuel and air supply systems are functioning optimally.

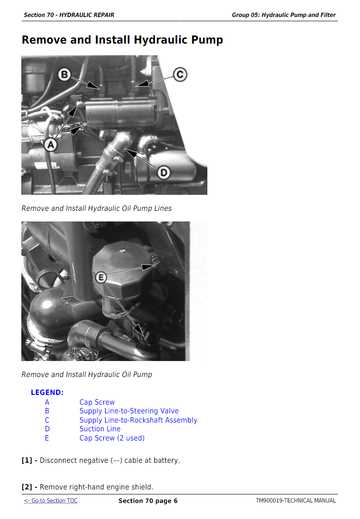

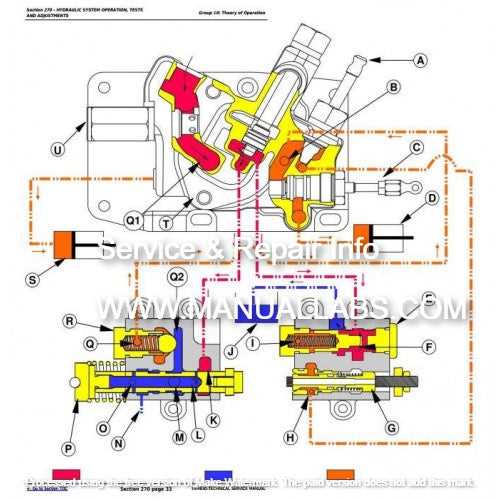

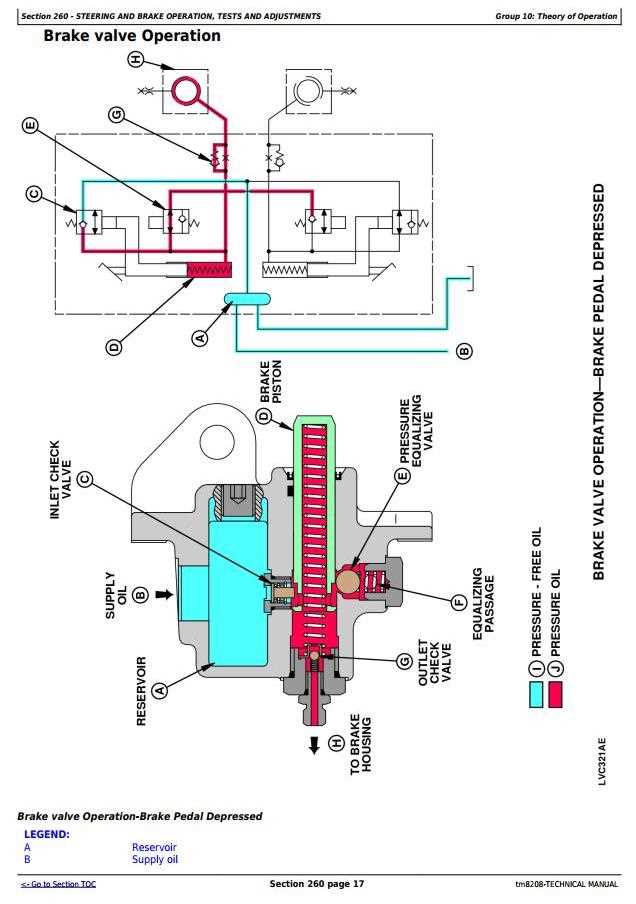

Hydraulic System Failures

The hydraulic system is critical for effective operation, and failures in this area can lead to significant disruptions. Common signs include slow response times, leaks, or complete loss of hydraulic power. Regular inspection of hoses, connections, and fluid levels is vital. Keeping the hydraulic fluid clean and ensuring that filters are changed regularly can prevent many of these issues.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. The following section outlines indispensable implements that ensure successful intervention and longevity of machinery. A well-equipped workspace not only enhances efficiency but also promotes safety during tasks.

Basic Hand Tools

Every technician should have a solid set of hand tools at their disposal. Wrenches, screwdrivers, and pliers are fundamental for loosening and tightening components. Opt for a variety of sizes to accommodate different fittings. Additionally, a reliable socket set is essential for more intricate tasks, providing the leverage needed to tackle stubborn bolts.

Diagnostic Equipment

In modern machinery, electronic diagnostics play a vital role. A quality multimeter helps assess electrical systems, while an OBD scanner can decode error codes and identify potential issues. Regular use of such diagnostic tools not only aids in immediate troubleshooting but also helps in predictive maintenance, ensuring optimal performance.

Step-by-Step Maintenance Guide

Ensuring the longevity and optimal performance of your agricultural machinery requires regular upkeep and attention to detail. This guide outlines essential procedures that will help you maintain your equipment effectively, enhancing its efficiency and reducing the likelihood of unexpected breakdowns.

| Maintenance Task | Frequency | Description |

|---|---|---|

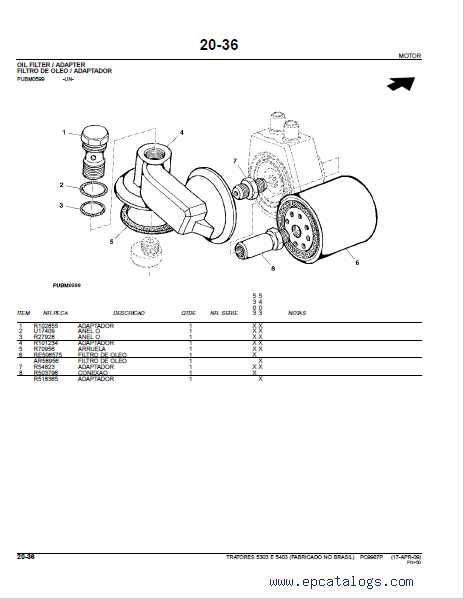

| Oil Change | Every 100 hours of operation | Replace engine oil and oil filter to ensure proper lubrication and performance. |

| Air Filter Inspection | Every 50 hours of operation | Check and clean or replace the air filter to maintain optimal airflow and engine efficiency. |

| Cooling System Check | Every 100 hours of operation | Inspect coolant levels and hoses for leaks; ensure the radiator is clean. |

| Fuel Filter Replacement | Every 200 hours of operation | Replace the fuel filter to prevent contaminants from affecting engine performance. |

| Tire Inspection | Every 50 hours of operation | Check tire pressure and tread condition; adjust or replace as necessary. |

| Belt and Hose Examination | Every 100 hours of operation | Inspect belts and hoses for wear, cracks, or fraying; replace if needed. |

| Battery Maintenance | Monthly | Check battery terminals for corrosion and ensure connections are secure. |

By following this comprehensive maintenance schedule, you can significantly extend the life of your machinery and maintain its efficiency. Always consult your equipment’s specifications for additional recommendations and procedures tailored to your model.

Engine Troubleshooting Techniques

Diagnosing issues within an engine requires a systematic approach to identify the root causes of malfunctions. Utilizing effective techniques can help isolate problems and ensure efficient repairs. A thorough understanding of engine components and their functions is essential for any technician aiming to resolve operational difficulties.

Common Symptoms and Diagnosis

Start by observing the symptoms exhibited by the engine. Common indicators such as unusual noises, loss of power, or difficulty starting can provide crucial clues. Visual inspections should also be conducted to check for leaks, damaged parts, or worn components. Employing diagnostic tools, like compression gauges or multimeters, can further assist in pinpointing specific issues.

Systematic Approach to Troubleshooting

Once symptoms are identified, follow a systematic process for diagnosis. Begin with the most accessible components and gradually progress to more complex systems. This method not only saves time but also minimizes the risk of overlooking potential issues. Documenting each step can aid in tracking progress and facilitate a more structured resolution process.

Hydraulic System Repair Insights

The efficiency of agricultural machinery often hinges on the performance of its fluid power systems. These systems are critical for facilitating various functions, from steering to lifting implements. Understanding the intricacies of hydraulic components can significantly enhance operational reliability and longevity.

Common Issues and Troubleshooting

Frequent complications include fluid leaks, pressure inconsistencies, and actuator malfunctions. Identifying the source of leaks is essential; check hoses, fittings, and seals for signs of wear. Pressure testing can help determine if the system is functioning within optimal parameters, ensuring that every component operates efficiently.

Maintenance Tips

Regular maintenance is vital for optimal performance. Changing hydraulic fluid at recommended intervals prevents contamination and promotes smooth operation. Additionally, inspecting filters and cleaning them helps maintain flow and pressure stability. Keeping an eye on fluid levels and checking for abnormal noises can provide early warnings of potential failures.

Electrical Components and Diagnostics

Understanding the electrical system is crucial for effective maintenance and troubleshooting of machinery. Proper knowledge of electrical components can significantly enhance performance and reliability. This section focuses on identifying key elements and implementing diagnostic techniques to ensure optimal functionality.

Key electrical components include:

- Battery: Provides the necessary power to start the engine and operate electrical systems.

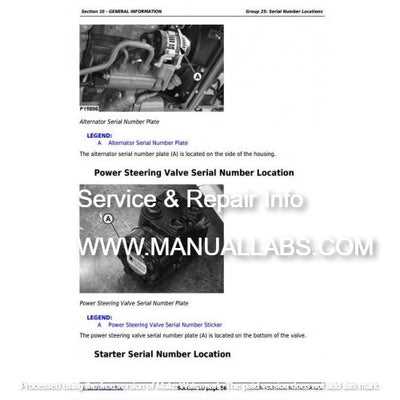

- Alternator: Charges the battery and powers electrical components while the engine is running.

- Starter Motor: Engages the engine to initiate the combustion process.

- Wiring Harness: Connects various electrical components, facilitating communication and power distribution.

- Fuses and Relays: Protect circuits from overloads and control power flow to different systems.

To diagnose electrical issues effectively, consider the following steps:

- Inspect the battery for corrosion or loose connections.

- Test the alternator output with a multimeter.

- Check the starter motor for proper operation.

- Examine the wiring harness for damage or wear.

- Replace blown fuses and verify relay functionality.

By familiarizing yourself with these components and diagnostic procedures, you can ensure a more efficient operation and prolong the life of your equipment.

Transmission Service Procedures

This section outlines essential methods for maintaining and servicing the transmission system of your agricultural machinery. Proper attention to this critical component ensures optimal performance and longevity, reducing the risk of operational failures.

1. Fluid Inspection: Begin by checking the transmission fluid level and quality. Use the dipstick to assess the fluid’s condition; it should be clean and free of debris. If the fluid appears dark or has a burnt odor, it may need to be replaced.

2. Filter Replacement: Over time, the transmission filter can become clogged with contaminants. Regular replacement is necessary to maintain efficient operation. Consult your specifications for the appropriate filter type and replacement interval.

3. Leak Detection: Regularly inspect the transmission casing for signs of leaks. Look for fluid pooling underneath the vehicle or staining on the casing. Addressing leaks promptly can prevent more severe damage.

4. Component Examination: Inspect the external components of the transmission, including hoses and connections. Look for wear, cracks, or other signs of deterioration that could affect performance.

5. Adjustments: Ensure that all linkage adjustments are correctly set. Misalignments can lead to shifting issues, impacting overall functionality. Follow the manufacturer’s guidelines for making these adjustments.

6. Performance Testing: After completing service tasks, conduct a performance test to confirm that the transmission operates smoothly. Pay attention to any unusual sounds or shifting difficulties, as these could indicate underlying issues.

Regular maintenance of the transmission system is vital for ensuring the machinery operates efficiently and effectively, minimizing downtime and enhancing productivity.

Safety Precautions During Repairs

Ensuring safety while performing maintenance on machinery is essential to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and promote a secure working environment. The following points outline crucial considerations that should be kept in mind during the servicing process.

General Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets.

- Maintain a clean and organized workspace to avoid tripping hazards.

- Ensure proper ventilation in the area to minimize exposure to harmful fumes.

- Be aware of your surroundings and keep tools and materials out of the way when not in use.

Equipment-Specific Precautions

- Disconnect power sources before beginning any work to prevent accidental starts.

- Use the correct tools for each task to avoid damage and enhance safety.

- Follow the manufacturer’s guidelines for specific operational procedures.

- Check for leaks or faults in machinery before conducting any inspections.

Using the Repair Manual Effectively

Leveraging a comprehensive guide can significantly enhance your ability to maintain and troubleshoot machinery. By familiarizing yourself with the structure and contents of the resource, you can streamline your approach to repairs and ensure efficient problem-solving.

Understanding the Layout

Each section of the guide is typically organized by specific tasks or issues, making it easier to locate the information you need. Take the time to explore the table of contents and familiarize yourself with the index. This will allow you to quickly navigate to relevant topics, saving valuable time during the repair process.

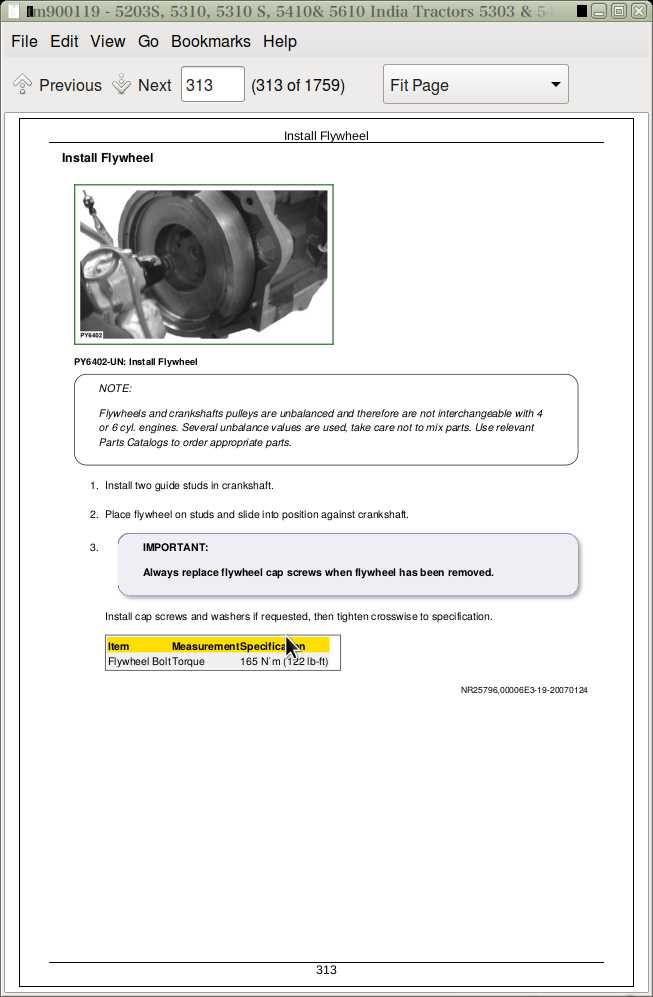

Utilizing Visual Aids

Many resources include diagrams and illustrations that provide visual context for the text. Pay close attention to these visuals as they can clarify complex instructions and highlight critical components. Combining written instructions with these visuals can lead to a better understanding and execution of tasks, minimizing the risk of errors.

Cost-Effective Parts Replacement Options

Finding affordable solutions for replacing essential components can significantly enhance machinery longevity and performance. By exploring various avenues for sourcing these parts, operators can save money while ensuring their equipment remains functional and efficient.

| Option | Description | Benefits |

|---|---|---|

| OEM Parts | Original equipment manufacturer parts ensure compatibility and quality. | Reliable performance and extended lifespan. |

| Aftermarket Parts | Third-party components often come at lower prices than OEM. | Cost savings and wider availability. |

| Used Parts | Pre-owned components can be sourced from salvage yards or online platforms. | Significant cost reductions, environmentally friendly. |

| Rebuilt Parts | Refurbished components that have been restored to a working condition. | Affordable alternative with similar quality to new parts. |

Finding Professional Repair Services

When it comes to maintaining complex machinery, enlisting the help of skilled technicians can make all the difference. Whether dealing with mechanical issues or electronic malfunctions, having access to qualified professionals ensures that your equipment operates efficiently and reliably. This section will explore various avenues to locate reputable service providers who specialize in these types of machinery.

Researching Local Experts

Start by conducting thorough research on local service providers. Online reviews, testimonials, and ratings can give valuable insight into the quality of their work. Additionally, seeking recommendations from fellow equipment owners or industry professionals can help identify trustworthy technicians with a solid reputation in your community.

Evaluating Qualifications and Experience

Once you’ve identified potential candidates, it’s essential to assess their qualifications and experience. Look for certifications, training programs, and years of service in the field. Experienced technicians are more likely to have encountered similar issues and can provide effective solutions, ultimately saving you time and resources.

Frequently Asked Questions about Repairs

This section addresses common inquiries related to maintenance and troubleshooting. Whether you’re facing mechanical issues or routine upkeep, understanding the typical concerns can streamline the process and enhance your equipment’s longevity.

Common Issues and Solutions

- What are the signs of a malfunctioning engine?

- Unusual noises during operation.

- Loss of power while performing tasks.

- Excessive smoke from the exhaust.

- How often should routine maintenance be performed?

- Check oil levels every 50 hours of use.

- Replace filters every 100 hours or annually.

- Inspect belts and hoses regularly for wear.

Troubleshooting Tips

- Start with the basics: Ensure that all controls are set correctly and that there is fuel in the tank.

- Check electrical connections: Loose wires can lead to various operational problems.

- Consult the documentation: Manufacturer guidelines provide valuable insights for specific issues.