Maintaining outdoor tools is essential for their longevity and efficiency. Understanding how to care for these devices can enhance their performance and ensure they serve you well over time. This section focuses on the important aspects of upkeep, providing you with useful insights into common issues and effective solutions.

Whether you’re a seasoned gardener or a novice, having a basic understanding of how to troubleshoot and maintain your equipment is crucial. Regular checks and simple adjustments can prevent larger problems and extend the lifespan of your tools. By following the guidelines outlined here, you can tackle various challenges and keep your equipment in top shape.

Moreover, being familiar with the components and functions of your gardening tools will empower you to handle minor malfunctions with confidence. This knowledge not only saves time but can also reduce the need for professional assistance, allowing you to focus on what you love–caring for your garden.

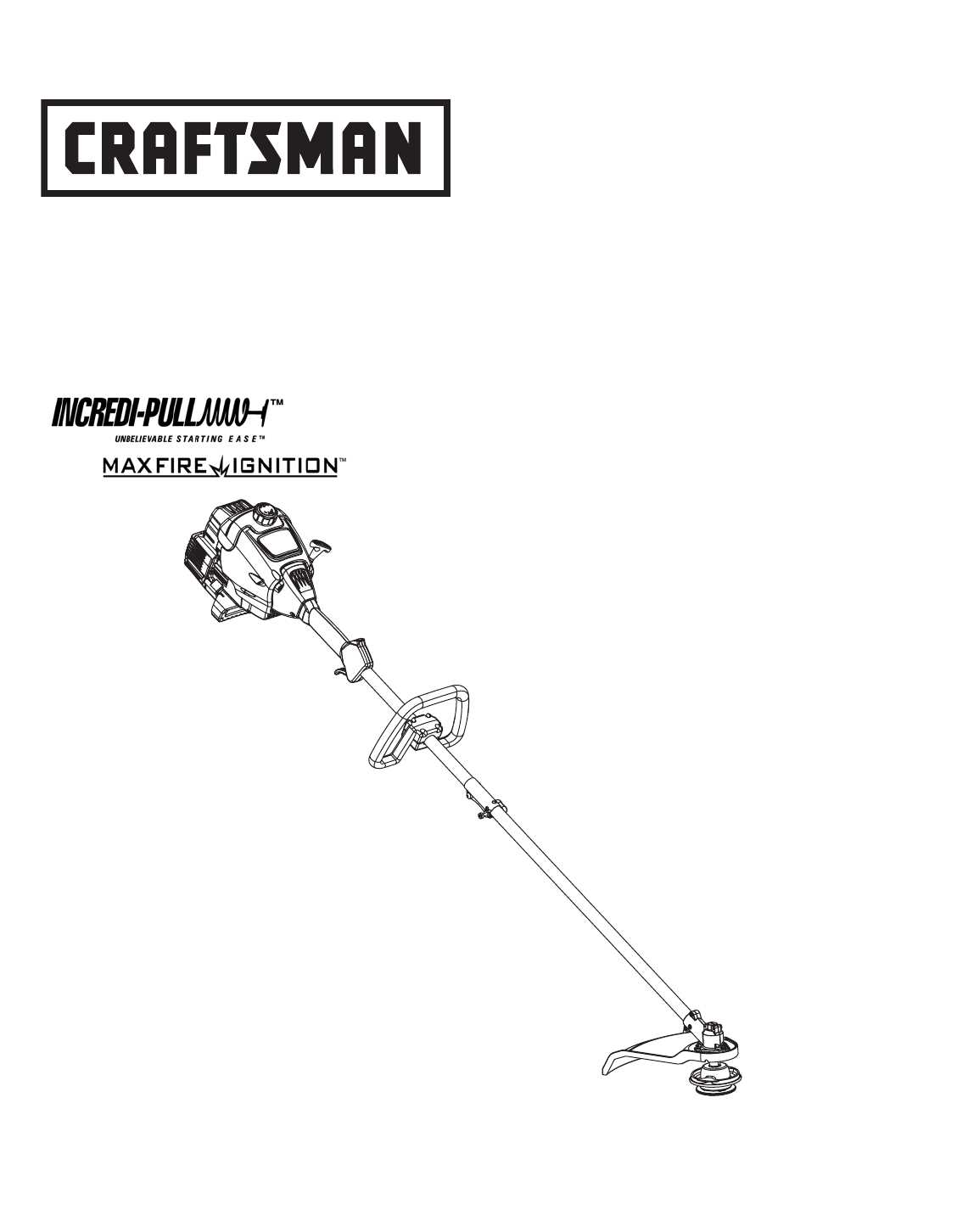

This section provides a comprehensive understanding of a specific type of gardening tool designed for trimming and maintaining outdoor spaces. These tools are essential for achieving a well-groomed landscape, combining efficiency and ease of use.

Features of the Tool

- Lightweight design for easy handling

- Variety of cutting attachments for different tasks

- Ergonomic grip for user comfort

- Powerful motor for enhanced performance

Common Issues and Solutions

- Starting difficulties – ensure the fuel mixture is correct and the spark plug is functioning.

- Insufficient cutting power – check for dull blades and clean any debris from the cutting head.

- Vibrations during operation – inspect for loose components and ensure the tool is properly assembled.

Common Issues with Weed Eaters

String trimmers are essential tools for maintaining a neat outdoor space. However, users often encounter several frequent problems that can hinder their performance. Understanding these issues can help in diagnosing and addressing them effectively.

Starting Difficulties

One of the most prevalent concerns is difficulty in starting the equipment. This can be attributed to several factors, including fuel-related issues, spark plug malfunctions, or even problems with the ignition system. Regular maintenance and ensuring the right fuel mixture can prevent these challenges.

Uneven Cutting Performance

Another common issue is inconsistent cutting, which can be frustrating. This may stem from a dull line, improper line length, or even the cutting head not functioning correctly. Regularly checking the trimmer line and ensuring it is properly installed can enhance cutting efficiency.

Essential Tools for Repair

When it comes to maintaining garden equipment, having the right instruments is crucial. This section highlights the fundamental items that facilitate effective servicing and ensure longevity of your tools. By using the proper equipment, you can address common issues and keep your devices in optimal condition.

Wrenches are indispensable for loosening and tightening various components. A good set of wrenches allows for adjustments and replacements of different parts with ease.

Screwdrivers, both flathead and Phillips, are necessary for accessing screws that hold different sections together. A variety of sizes will ensure you can tackle any fastening challenge.

Cleaning Brushes help maintain the equipment’s performance by removing debris and buildup that can affect functionality. Keeping components clean is key to efficient operation.

Protective Gear is essential to safeguard yourself while working. Gloves, goggles, and masks provide safety against dust and debris, ensuring a secure working environment.

By equipping yourself with these essential tools, you can enhance your ability to perform maintenance tasks effectively and keep your outdoor equipment running smoothly.

Step-by-Step Maintenance Guide

Proper upkeep of your outdoor equipment is essential for optimal performance and longevity. This section outlines a systematic approach to maintaining your tools, ensuring they remain efficient and reliable throughout their use.

Essential Tools and Supplies

- Protective gloves

- Cleaning brush

- Fuel mixture

- Screwdriver set

- Replacement parts

Maintenance Steps

- Start by inspecting the equipment for any visible damage or wear.

- Clean the exterior thoroughly to remove dirt and debris.

- Check and replace the fuel mixture as needed to ensure proper combustion.

- Inspect and, if necessary, replace any worn or damaged components.

- Store the equipment in a dry, protected area to prevent rust and corrosion.

How to Replace the String

Replacing the cutting line on your gardening tool is essential for maintaining its performance and efficiency. This process is straightforward and can be done with a few simple steps, ensuring that your device operates at its best.

Gather Your Tools

Before starting, ensure you have the necessary tools at hand. You will need a replacement line suitable for your model, scissors or a cutting tool, and safety gloves to protect your hands during the process.

Steps to Replace the Line

Begin by disconnecting the power source for safety. Next, locate the spool where the line is housed. Carefully remove the spool from the device and unwind any remaining line. Cut the new line to the appropriate length, usually specified in your device’s guidelines. Thread the new line through the spool, ensuring it is wound tightly and evenly. Finally, reattach the spool to the device and reconnect the power source. Test the tool to confirm that it operates correctly.

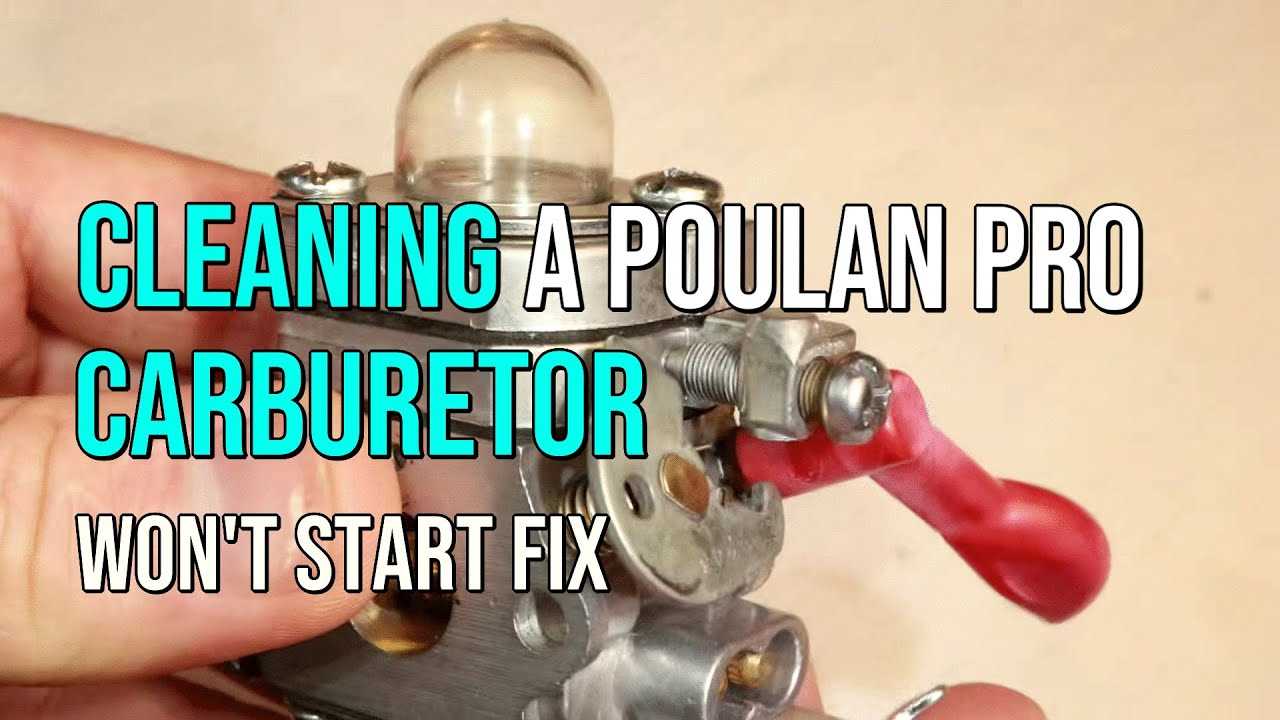

Cleaning the Fuel System

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity of your equipment. Regular cleaning helps to prevent blockages and ensures that fuel flows smoothly, allowing the engine to operate efficiently.

Steps for Cleaning

To effectively clean the fuel system, follow these simple steps:

| Step | Description |

|---|---|

| 1 | Remove the fuel lines carefully, ensuring no residue remains in the lines. |

| 2 | Use a suitable cleaning solution to flush the fuel filter and tank, removing any deposits. |

| 3 | Inspect and replace any damaged components to prevent future issues. |

Tips for Maintenance

Regular maintenance can enhance the lifespan of the fuel system. Consider the following tips:

- Use high-quality fuel to minimize the buildup of impurities.

- Inspect the system periodically for leaks or cracks.

- Store the equipment in a clean, dry place to avoid contamination.

Troubleshooting Engine Problems

Engine issues can significantly hinder the performance of your equipment. Identifying the root causes of these problems is essential for effective resolution. This section will guide you through common symptoms and potential solutions, helping you restore functionality.

1. Starting Difficulties: If your engine refuses to start, check the fuel supply. Ensure the tank is filled with fresh fuel and inspect the fuel lines for blockages. A faulty spark plug can also be a culprit, so consider replacing it if it’s worn or dirty.

2. Poor Performance: A decline in power output may indicate an air filter that needs cleaning or replacement. Additionally, examine the carburetor for proper adjustment and ensure it’s free from debris. Regular maintenance of these components can prevent performance issues.

3. Unusual Noises: If you hear strange sounds while the engine is running, it may be a sign of internal wear or damage. Inspect the muffler and exhaust for any blockages. Listening carefully can help pinpoint the source of the noise.

4. Overheating: Overheating can lead to severe engine damage. Check for adequate coolant levels if applicable and ensure that the cooling fins are clean. Additionally, verify that the oil is at the proper level to lubricate the engine effectively.

By following these guidelines and performing regular checks, you can effectively troubleshoot engine problems and maintain optimal performance.

Repairing the Starter Mechanism

The starter mechanism is a crucial component that enables the initial ignition of the engine. Proper functioning of this system ensures that the device operates smoothly and efficiently. If you encounter difficulties in starting the engine, it may be necessary to inspect and address issues related to the starting assembly.

Identifying Common Issues

Several factors can affect the performance of the starter mechanism. Understanding these issues can help you troubleshoot effectively:

- Worn-out recoil spring

- Faulty pull cord

- Debris obstructing the mechanism

- Damaged starter housing

Steps for Troubleshooting

Follow these steps to diagnose and resolve issues with the starting system:

- Inspect the pull cord for any signs of wear or fraying.

- Remove any debris that may be blocking the starter assembly.

- Check the recoil spring for damage or fatigue, replacing it if necessary.

- Reassemble the components and test the starter to ensure proper functionality.

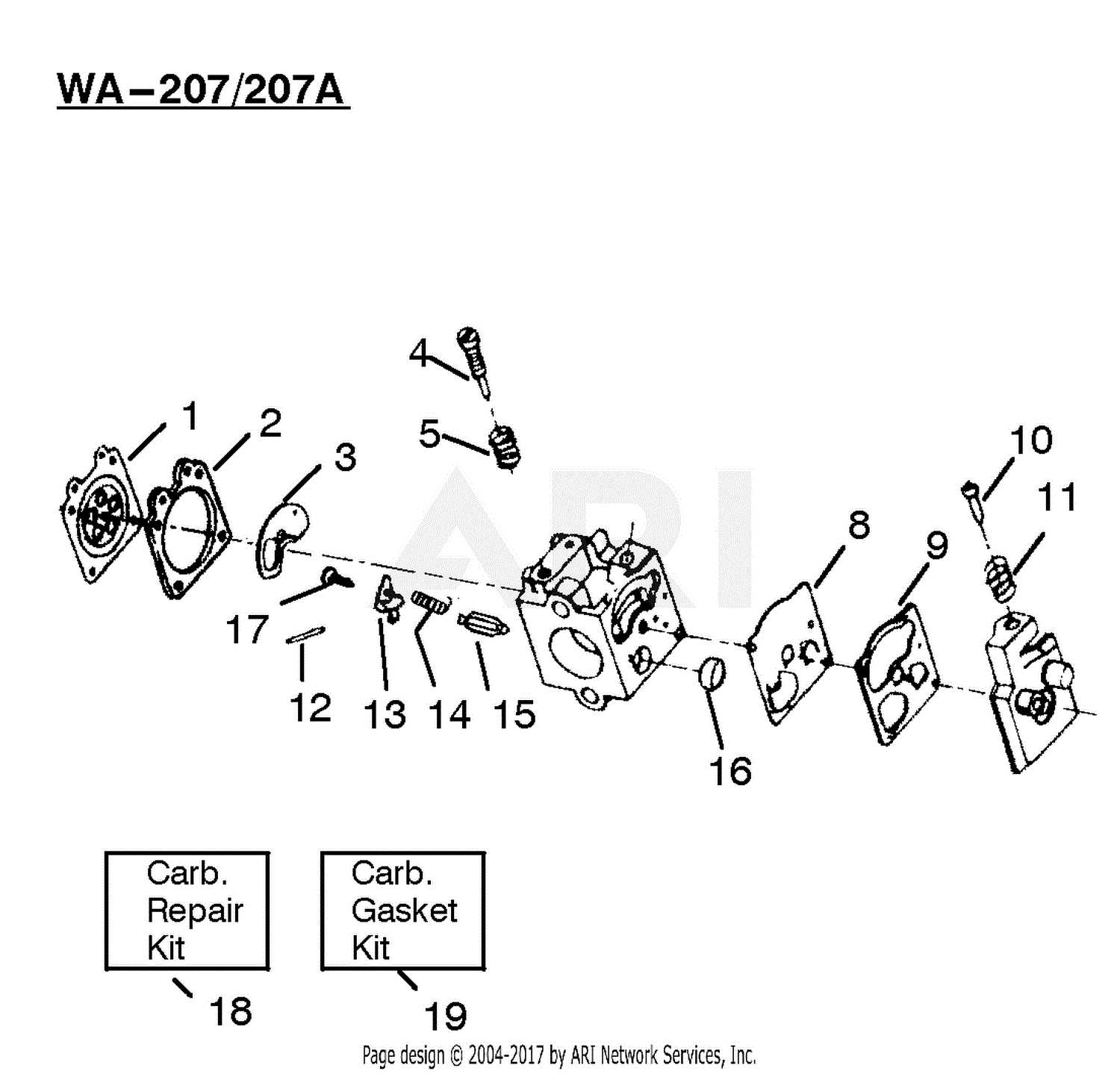

Adjusting the Carburetor Settings

Proper adjustment of the fuel delivery system is essential for optimal engine performance. Fine-tuning these settings can lead to better efficiency, smoother operation, and reduced emissions.

To begin, locate the adjustment screws on the unit, typically labeled as low-speed and high-speed. These screws control the mixture of fuel and air entering the engine. Using a screwdriver, carefully turn the low-speed screw clockwise to enrich the mixture or counterclockwise to lean it out. For the high-speed adjustment, follow the same procedure to achieve the desired performance.

After making adjustments, it is advisable to test the engine under various operating conditions. Listen for any irregularities in sound or performance, which can indicate the need for further tuning. Remember, achieving the perfect balance may require several attempts, so patience is key.

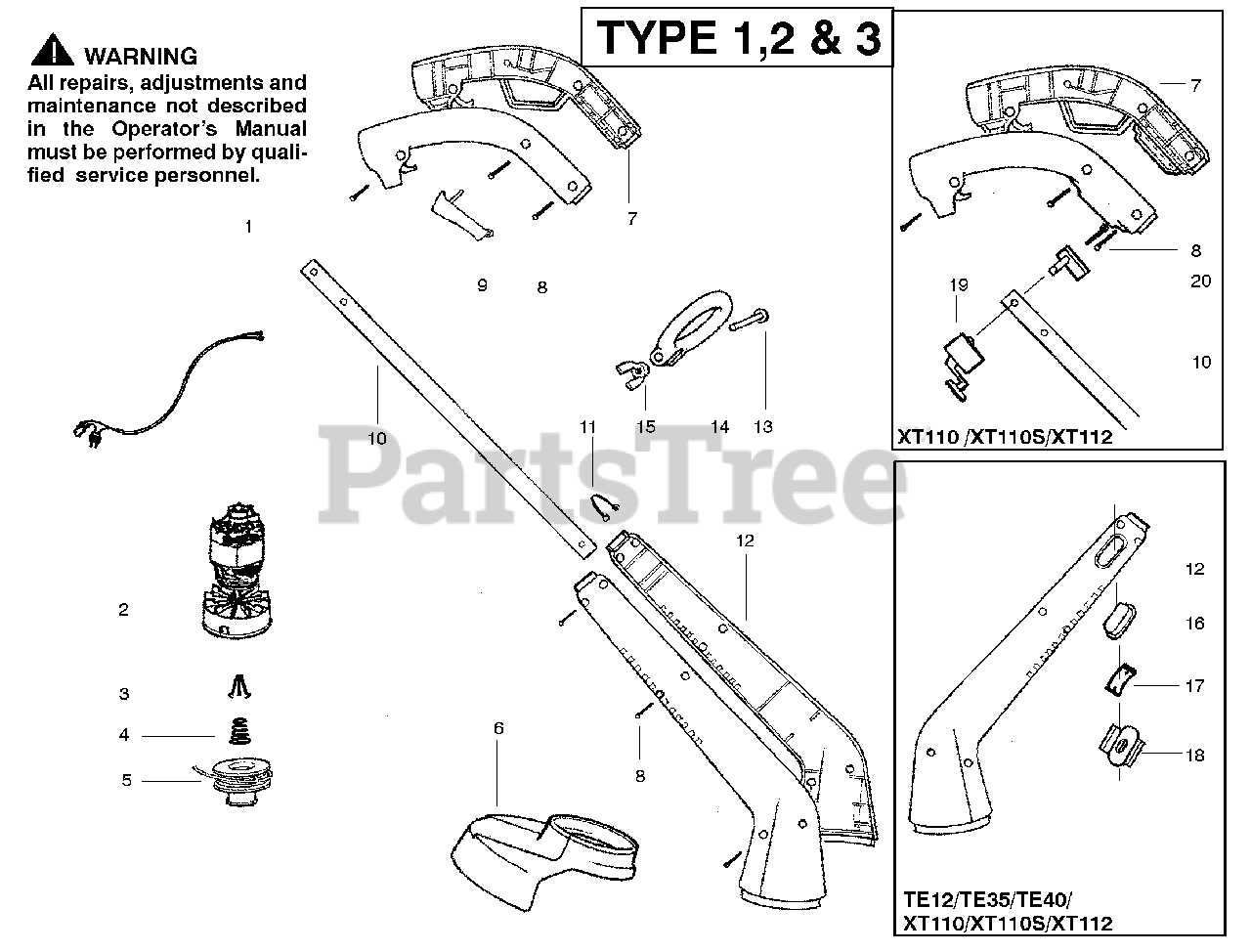

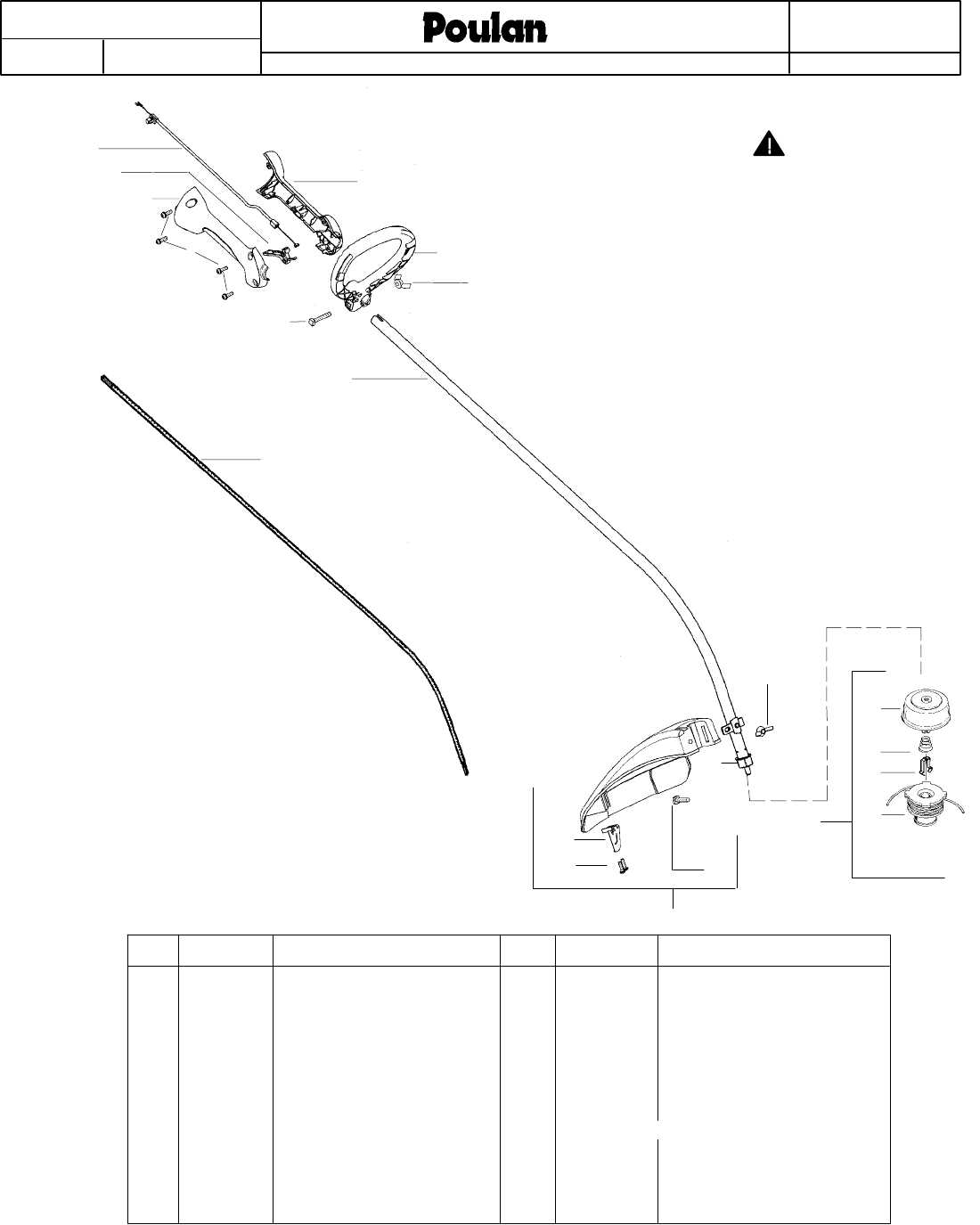

Replacing Worn-Out Parts

Maintaining the efficiency of your gardening tool is crucial for optimal performance. Over time, various components may experience wear and tear, leading to diminished functionality. Addressing these issues promptly can enhance the longevity and reliability of your equipment.

Start by identifying the parts that show signs of fatigue, such as reduced power output or difficulty in operation. Common components that often require attention include blades, filters, and spark plugs. Regular inspections will help in determining which elements need replacement.

Once you have identified the worn parts, ensure you acquire high-quality replacements. Following the manufacturer’s specifications is essential for achieving compatibility and maintaining performance standards. After replacing the components, conduct a thorough test to confirm that the tool operates smoothly and efficiently.

Safety Precautions During Repair

When undertaking maintenance tasks on outdoor power equipment, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly enhance your protection while working with machinery.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This gear helps shield you from potential hazards like flying debris or sharp components.

Before beginning any work, ensure the equipment is disconnected from power sources to avoid accidental starts. Familiarize yourself with the machinery’s components and consult relevant documentation for detailed information about safety measures.

Maintain a clean and organized workspace to minimize risks of slips and falls. Keep tools and materials stored properly and ensure all surfaces are free from obstacles.

Lastly, if you’re uncertain about any procedure, seek assistance or consult a professional. Prioritizing safety not only protects you but also ensures the longevity of your equipment.

Tips for Regular Maintenance

Maintaining your gardening tool is essential for ensuring its longevity and optimal performance. By following a consistent care routine, you can prevent issues and enhance efficiency during use.

- Clean After Use: Always remove debris and dirt from the device after each session. This helps prevent buildup that can affect performance.

- Inspect Components: Regularly check all parts for wear and tear. Replace any damaged components to maintain effectiveness.

- Sharpen Blades: Keeping the cutting edges sharp is crucial. Dull blades can strain the motor and reduce cutting efficiency.

- Check Fuel System: Ensure that fuel is fresh and the fuel lines are clear. Old fuel can lead to starting issues and reduced power.

- Store Properly: After use, store the tool in a dry place to avoid rust and corrosion. Consider using a protective cover for added safety.

By implementing these maintenance tips, you can extend the life of your equipment and ensure it remains a reliable tool in your gardening tasks.