This section provides essential information for individuals seeking guidance on the upkeep and restoration of specific equipment. Understanding the intricacies of your device is vital for ensuring its longevity and optimal performance. This guide will equip users with the knowledge to effectively address common issues that may arise during usage.

In the following paragraphs, readers will discover a wealth of tips and techniques designed to assist in the proper care of their machinery. From identifying potential problems to executing straightforward solutions, this resource aims to empower users with confidence in their repair capabilities. With the right approach, even the most daunting challenges can be overcome with ease.

By familiarizing yourself with the operational aspects of your device, you can significantly reduce the likelihood of malfunctions. This section emphasizes the importance of routine checks and maintenance procedures, highlighting how proactive measures can enhance performance and reliability. Users will find practical steps that can be easily integrated into their regular maintenance routines.

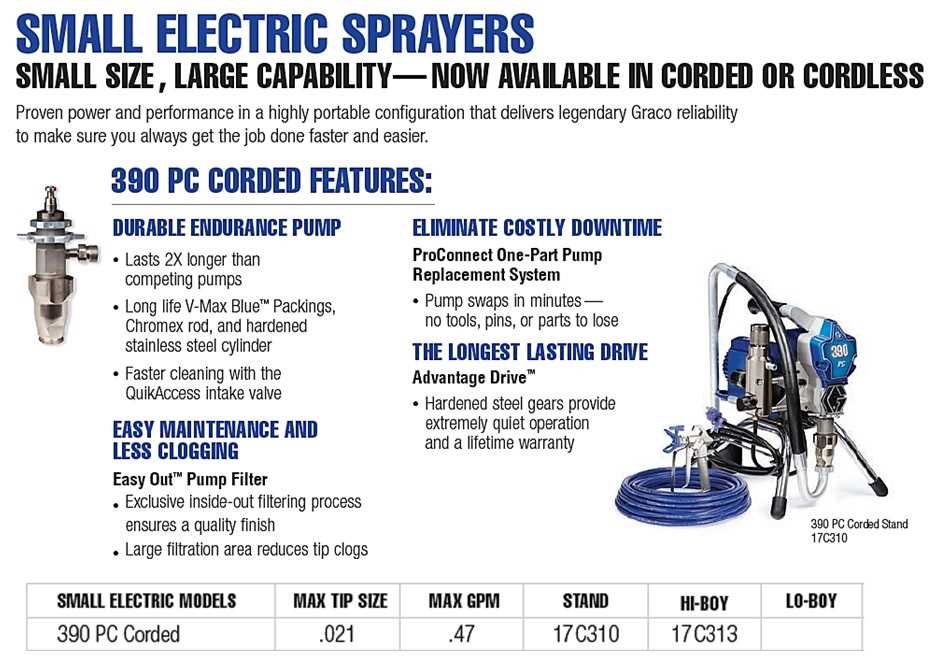

Graco 390 Overview

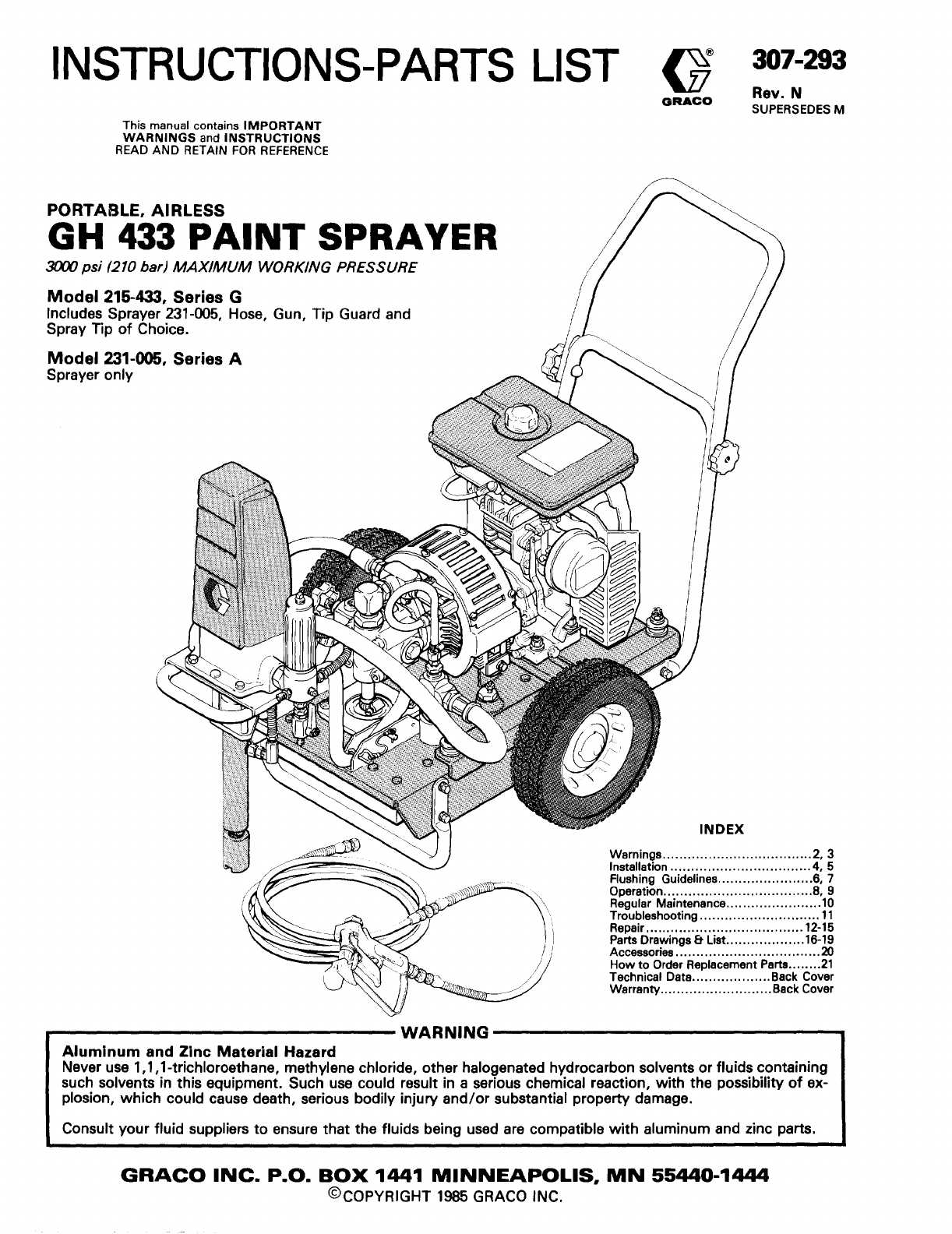

This section provides a comprehensive overview of a popular airless spray device known for its reliability and performance. It is designed for both professional and DIY users, offering an efficient solution for a variety of painting and coating applications. The equipment is recognized for its durable construction and user-friendly features, making it a preferred choice in the market.

Key Features

The device boasts several essential attributes that enhance its functionality. One notable aspect is its powerful motor, which ensures consistent pressure and smooth operation, enabling users to achieve high-quality finishes. Additionally, the lightweight design facilitates easy handling and portability, allowing for convenient use across different job sites.

Applications

Ideal for a wide range of applications, this equipment can handle various coatings, including paints, stains, and sealers. Its versatility makes it suitable for residential, commercial, and industrial projects. Whether working on exterior surfaces or intricate interior details, this tool delivers impressive results, ensuring customer satisfaction with every job.

Key Features of Graco 390

This section outlines the significant characteristics that distinguish this model within its category, emphasizing its performance and user-centric design.

- Powerful Performance: Engineered for high efficiency, this unit excels in delivering consistent pressure, making it ideal for various applications.

- Durability: Constructed with robust materials, it ensures longevity and withstands rigorous use in demanding environments.

- User-Friendly Controls: Intuitive controls allow for easy operation, enabling users to adjust settings without hassle.

- Portability: Designed with mobility in mind, it features lightweight components and an ergonomic handle for convenient transportation.

- Versatile Applications: Suitable for a wide range of projects, from residential tasks to industrial jobs, enhancing its usability across different fields.

These attributes not only enhance functionality but also contribute to a seamless user experience, ensuring that tasks are completed efficiently and effectively.

Common Issues and Solutions

In the realm of equipment maintenance, various challenges may arise during operation. Identifying these frequent problems and understanding their resolutions can greatly enhance performance and prolong the lifespan of the device. Below are some of the most typical complications faced and their corresponding solutions.

Frequent Complications

| Issue | Symptoms | Resolution |

|---|---|---|

| Inconsistent Flow | Uneven application of materials | Check for blockages in the nozzle and clean or replace as necessary. |

| Overheating | Device shuts down unexpectedly | Ensure proper ventilation and allow the machine to cool down before further use. |

| Poor Spray Pattern | Irregular patterns during operation | Inspect and adjust the spray tip or clean any debris that may be affecting the output. |

Preventive Measures

To mitigate potential issues, regular maintenance is crucial. This includes routine inspections, cleaning, and adhering to usage guidelines. By staying proactive, users can minimize the likelihood of complications and ensure optimal performance over time.

Essential Tools for Repair

When undertaking maintenance tasks, having the right equipment is crucial for achieving optimal results. A well-prepared toolkit can significantly enhance efficiency and effectiveness, making the process smoother and less time-consuming. This section highlights the necessary implements to facilitate various restoration activities.

1. Wrenches: These are indispensable for loosening and tightening fasteners. A set of both standard and adjustable wrenches is recommended to handle various sizes of nuts and bolts.

2. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are essential for working with different types of screws. Consider a set that includes various sizes for versatility.

3. Pliers: Pliers come in handy for gripping, twisting, and cutting wires or other materials. Needle-nose pliers are particularly useful for reaching tight spaces.

4. Multimeter: This tool is vital for troubleshooting electrical components, allowing you to measure voltage, current, and resistance accurately.

5. Safety Gear: Protecting yourself during any maintenance work is paramount. Always have safety goggles, gloves, and a dust mask on hand to ensure personal safety.

6. Cleaning Supplies: Keeping your workspace and tools clean is essential. Stock up on rags, brushes, and appropriate solvents to maintain a tidy environment.

Equipping yourself with these fundamental implements will greatly aid in addressing various tasks effectively. Whether tackling minor adjustments or more extensive modifications, the right tools make all the difference.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to effectively addressing common issues that may arise during operation. Following these detailed steps will help ensure a successful troubleshooting process and restore functionality to the equipment.

Step 1: Preparation

Before beginning the process, gather all necessary tools and components. Ensure that the workspace is clean and well-lit to facilitate efficient repairs.

Step 2: Disassembly

Carefully disassemble the unit by removing any external coverings and components. Take note of the order in which parts are removed, as this will aid in reassembly later.

Step 3: Inspection

Examine each part for signs of wear or damage. Pay special attention to seals, valves, and hoses, as these are common areas of failure. Replace any faulty components as necessary.

Step 4: Cleaning

Thoroughly clean all parts using appropriate cleaning solutions. Ensure that no debris remains that could interfere with the operation of the equipment.

Step 5: Reassembly

Once all components are inspected and cleaned, begin reassembling the unit. Follow the order of disassembly to avoid confusion. Make sure all connections are secure.

Step 6: Testing

After reassembly, conduct a thorough test to ensure everything is functioning properly. Check for leaks and listen for unusual sounds during operation. Make adjustments as needed.

Conclusion

By following these systematic steps, users can confidently address issues and maintain the equipment’s optimal performance. Regular maintenance and timely interventions can significantly extend the lifespan of the machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of any equipment. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected failures. By adopting systematic care practices, users can significantly extend the lifespan of their devices.

Here are some key maintenance strategies to consider:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean the exterior and components | After each use | Prevents buildup of debris and improves airflow |

| Check fluid levels | Weekly | Ensures optimal operation and prevents damage |

| Inspect hoses and connections | Monthly | Identifies wear or leaks early |

| Lubricate moving parts | Every three months | Reduces friction and wear |

| Replace filters | As needed | Maintains efficiency and air quality |

Following these guidelines will help maintain peak performance and longevity of your equipment, ensuring it serves you well for years to come.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance on equipment. Proper precautions help prevent accidents and injuries, safeguarding both the technician and the machinery. Adopting a systematic approach to safety can enhance the effectiveness of the service process and contribute to a safer work environment.

Before beginning any servicing tasks, it is essential to follow these guidelines:

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and masks.

- Ensure the work area is well-ventilated to prevent the buildup of hazardous fumes.

- Disconnect power sources before starting work to eliminate the risk of electrical shock.

- Utilize tools and equipment correctly to avoid damage or personal injury.

- Be aware of potential hazards related to the specific machinery being serviced.

It is also important to familiarize yourself with the equipment’s specifications and instructions. Following the manufacturer’s guidelines can help mitigate risks and ensure that all maintenance tasks are performed efficiently.

Regularly inspect your tools and protective gear to ensure they are in good condition. Keeping your workspace tidy and organized can also prevent accidents and allow for a more streamlined workflow.

In summary, prioritizing safety measures not only protects individuals but also contributes to the longevity and optimal performance of the equipment.

Parts Replacement Guide

This section provides essential information for identifying and replacing various components of your equipment. Understanding when and how to change parts can enhance performance and prolong the lifespan of the unit. Proper maintenance ensures optimal functionality and minimizes potential downtime.

Follow these guidelines to facilitate the process of component substitution:

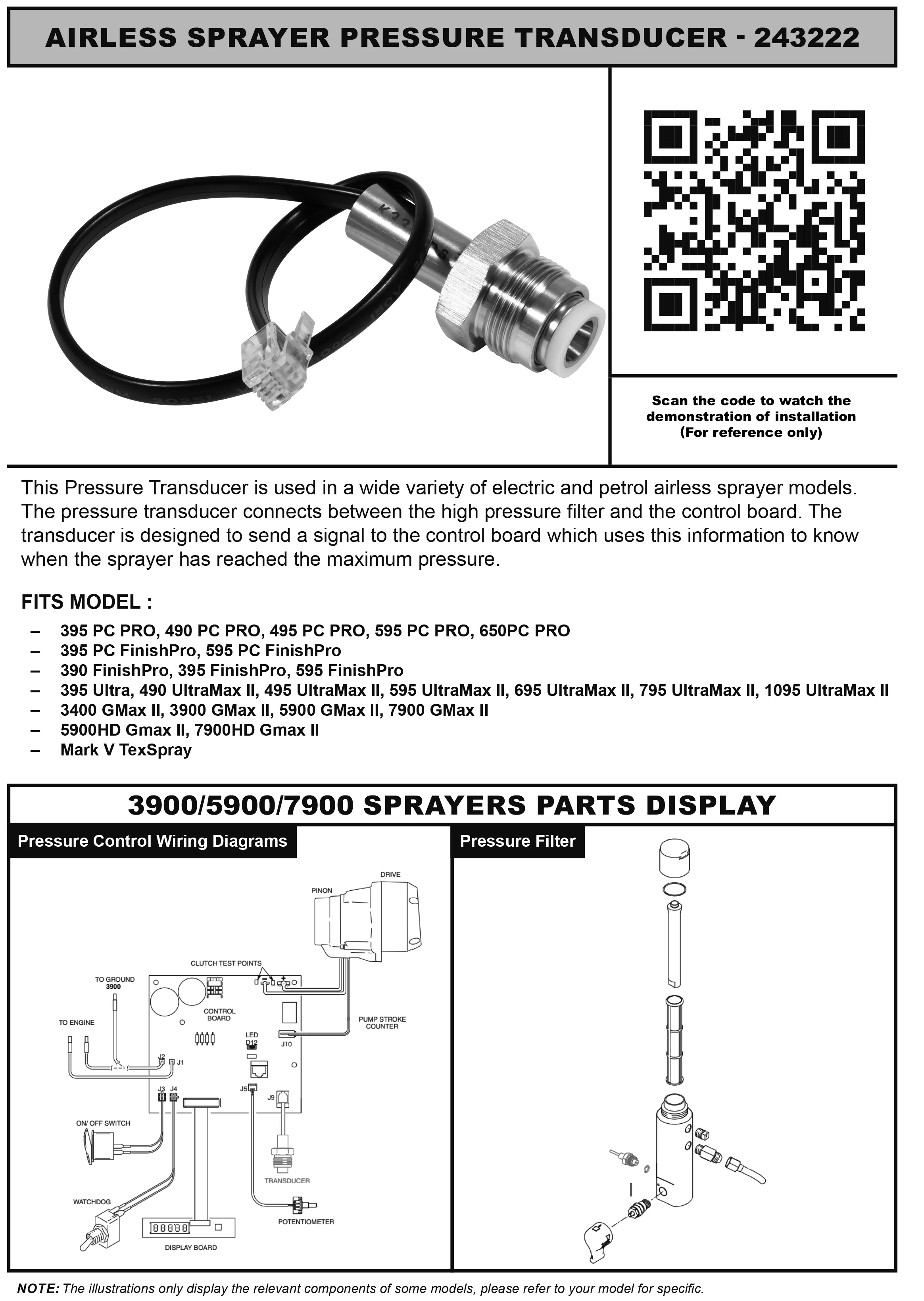

- Identify the Component: Before initiating the replacement, accurately determine which part needs to be swapped out. Refer to the product specifications or diagrams if available.

- Gather Necessary Tools: Ensure you have the required tools at hand. Common tools may include wrenches, screwdrivers, and pliers.

- Turn Off Power Supply: For safety, always disconnect the power supply before attempting to change any parts.

- Remove the Old Component: Carefully unscrew or detach the malfunctioning part. Take care not to damage surrounding areas.

- Install the New Part: Align the new component correctly and secure it in place. Ensure it fits snugly and is properly connected.

- Test the Equipment: After installation, reconnect the power supply and test the unit to ensure the new part operates correctly.

Regular inspections and timely replacements can help maintain peak performance and avoid costly repairs down the line. Always consult with a qualified technician if uncertain about any step in the process.

How to Troubleshoot Performance Problems

Troubleshooting performance issues in a spray painting system can often seem daunting, but a systematic approach can simplify the process. Identifying the underlying causes of inefficiency or malfunction is key to restoring optimal operation. This section will guide you through essential steps to diagnose and rectify common performance-related concerns effectively.

Common Issues and Their Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent Spray Pattern | Clogged nozzle | Clean or replace the nozzle to ensure proper flow. |

| Poor Paint Flow | Insufficient pressure | Check and adjust the pressure settings as needed. |

| Excessive Overspray | Incorrect tip size | Switch to the appropriate tip size for the material being used. |

| Frequent Motor Shutdown | Overheating | Allow the motor to cool down and check for blockages. |

Steps for Effective Troubleshooting

To effectively address performance issues, follow these steps:

1. Identify the Symptoms: Observe the equipment’s operation and note any irregularities in performance.

2. Review the Operating Manual: Consult the documentation for specific guidelines related to maintenance and troubleshooting.

3. Perform Regular Maintenance: Ensure that all components are clean and well-maintained to prevent issues before they arise.

4. Test After Each Adjustment: After implementing a solution, test the equipment to verify if the issue is resolved.

Understanding Graco 390 Specifications

This section delves into the key characteristics and features of a popular paint sprayer model, which is essential for achieving optimal performance in various applications. Recognizing the specific attributes allows users to make informed decisions about the equipment and its suitability for particular tasks.

| Specification | Description |

|---|---|

| Maximum Pressure | Up to 3,000 PSI, enabling efficient spray patterns and finishes. |

| Flow Rate | Capable of delivering up to 0.47 gallons per minute, suitable for medium to large projects. |

| Weight | Lightweight design at approximately 25 pounds for enhanced portability. |

| Power Source | Electric motor ensures consistent performance without the need for additional fuel. |

| Tip Size | Compatible with tip sizes ranging from 0.011 to 0.017 inches, providing versatility for different coatings. |

Understanding these specifications is crucial for users to optimize their usage and ensure effective application, leading to professional results in their projects.

Upgrading Your Graco 390 Model

Enhancing the performance and capabilities of your spraying equipment can lead to more efficient projects and better results. This section will provide insights on how to improve your unit, ensuring it meets your evolving needs.

Consider the following upgrades:

- Change the Spray Tip: Upgrading to a finer or wider spray tip can optimize your application process, allowing for better coverage and precision.

- Install a Higher Capacity Pump: A more powerful pump can increase the flow rate, making it easier to handle larger jobs more efficiently.

- Upgrade to a Flexible Hose: A more flexible and durable hose can enhance maneuverability, reducing strain during operation.

- Incorporate Advanced Filters: High-quality filters can prevent clogs and ensure a smoother spraying experience.

- Improve Air Supply: Adding a high-performance compressor can provide consistent air pressure for better atomization.

Before making any modifications, it’s essential to consult the manufacturer’s guidelines and ensure compatibility with your current setup. Proper upgrades can significantly enhance the efficiency and output of your device, leading to more successful applications.

Where to Find Spare Parts

Locating replacement components for your equipment can enhance its longevity and performance. Understanding the various sources available for procuring these items is crucial for maintaining your machinery in optimal condition.

Official Distributors

One of the most reliable methods to acquire replacement items is through authorized distributors. These outlets ensure that you receive genuine components designed specifically for your equipment. Here are some steps to follow:

- Visit the manufacturer’s website to find a list of authorized dealers.

- Contact local distributors to inquire about availability.

- Check for any warranty or support services they might offer.

Online Retailers

Numerous online platforms specialize in providing a wide range of components. Shopping online can save time and often provide competitive pricing. Consider the following tips:

- Use reputable websites with customer reviews to ensure product quality.

- Compare prices across different sites to find the best deals.

- Look for bulk purchasing options to save on costs if multiple components are needed.