Maintaining small power units is essential for ensuring their longevity and optimal performance. This segment delves into the intricacies of servicing and troubleshooting, equipping users with the knowledge needed to tackle common issues. Understanding the mechanisms and components involved can significantly enhance your ability to manage any challenges that arise.

In the following sections, we will explore various aspects of upkeep, from routine checks to more complex repairs. With a focus on practical advice and detailed procedures, this guide aims to empower individuals to take control of their machinery. Whether you’re a seasoned technician or a novice, the insights provided will be invaluable in fostering confidence and competence in handling these compact powerhouses.

By familiarizing yourself with the vital parts and their functions, you can ensure efficient operation and extend the lifespan of your equipment. Dive into the specifics of diagnostics, part replacements, and preventive measures to keep your unit running smoothly. Let this guide be your companion in the journey of maintaining reliable performance and achieving satisfactory results.

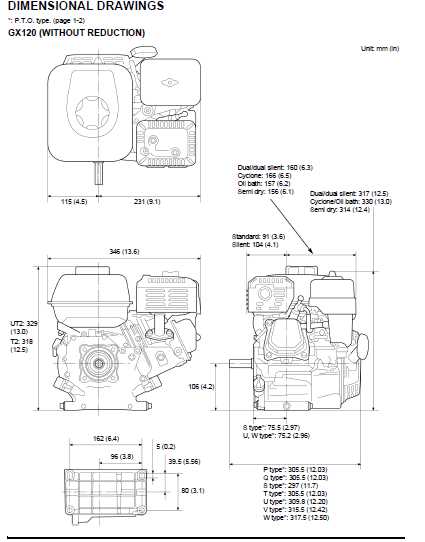

Understanding the Honda GX140 Engine

This section aims to provide insights into a specific type of power unit, highlighting its design, functionality, and applications. By exploring its features, users can better appreciate its capabilities and maintenance requirements.

Key Features

- Compact design for versatile use

- Air-cooled system for efficient temperature management

- Four-stroke operation for improved fuel efficiency

- Reliable performance across various applications

Common Applications

- Garden equipment

- Construction tools

- Pressure washers

- Generators

Understanding these aspects allows users to make informed decisions regarding usage and maintenance, ensuring longevity and optimal performance of the unit.

Common Issues with the GX140 Engine

When it comes to small power units, several recurring problems can hinder performance and efficiency. Understanding these common challenges can help users troubleshoot and maintain their machinery effectively.

Frequent Challenges

- Starting Difficulties: Many users report trouble initiating operation, which can stem from fuel issues or battery malfunctions.

- Overheating: Excessive heat can lead to component wear, often caused by insufficient lubrication or blocked cooling passages.

- Vibration: Unusual shaking during operation may indicate imbalance or worn parts that require attention.

Preventive Measures

- Regular Maintenance: Scheduled checks and servicing can prevent many issues from escalating.

- Fuel Quality: Always use high-quality fuel to minimize the risk of clogs and performance drops.

- Check Air Filters: Clean or replace filters regularly to ensure proper airflow and prevent overheating.

Tools Needed for Repairs

When undertaking maintenance or fixing tasks on small power units, having the right tools is essential for ensuring efficiency and safety. Each task may require specific instruments, so it’s crucial to be well-prepared before starting your work.

Essential Tools

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: A set including flathead and Phillips for versatility.

- Socket Set: Ideal for loosening and tightening bolts quickly.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Additional Equipment

- Oil Catch Pan: To collect used oil during maintenance.

- Fuel Container: For safe transport and storage of fuel.

- Work Gloves: To protect hands while handling components.

- Safety Glasses: Essential for eye protection during work.

- Multimeter: Useful for diagnosing electrical issues.

Step-by-Step Disassembly Process

This section outlines a comprehensive approach to dismantling the unit methodically and safely. By following each stage carefully, you can ensure that every component is handled properly, minimizing the risk of damage and facilitating a smoother reassembly later on. Understanding the order of disassembly is crucial, as it allows for easier identification and management of parts.

Preparation and Tools

Before beginning the disassembly, gather all necessary tools and equipment. Commonly required items include wrenches, screwdrivers, and pliers. Ensure that you have a clean workspace to organize the components as they are removed. Taking notes or using a camera to document the configuration can also be beneficial for later reference.

Disassembly Steps

Start by removing any external attachments, such as covers and filters. Proceed with the unfastening of bolts and screws in a systematic manner, keeping track of where each piece belongs. It’s advisable to work from the outside in, carefully detaching components while noting any special fittings or connections. As you disassemble, place each part in labeled containers to avoid confusion during reassembly.

Inspecting Key Components for Damage

Regular examination of vital parts is essential for maintaining optimal functionality and preventing unexpected failures. Identifying signs of wear or harm can significantly extend the lifespan of the machinery and enhance its overall performance.

Visual Assessment

Begin with a thorough visual check of accessible components. Look for cracks, corrosion, or any irregularities that may indicate potential issues. Pay special attention to areas prone to friction and heat, as these are more likely to suffer damage over time.

Functional Testing

Once the visual inspection is complete, proceed with functional evaluations. Engage various systems to observe any unusual noises or vibrations. Testing performance under different conditions can help pinpoint malfunctions that may not be immediately visible.

Addressing these concerns promptly will lead to a more reliable and efficient operation, ensuring that your machinery continues to perform at its best.

Reassembling the Engine Correctly

Putting components back together is a critical stage in the overall process of restoring functionality to the power unit. Proper alignment and meticulous attention to detail ensure that all parts function harmoniously, contributing to optimal performance. This section provides essential guidelines to help you navigate the reassembly process effectively.

Before starting, gather all necessary tools and parts. Organizing everything beforehand will streamline your workflow and minimize the risk of forgetting components. Here are some key steps to follow:

- Inspect Components: Thoroughly examine each part for wear or damage. Replace any worn items to ensure reliability.

- Follow Manufacturer Specifications: Refer to specifications for torque settings and assembly sequences. Adhering to these guidelines will prevent issues later on.

- Use Quality Gaskets and Seals: Ensure all gaskets and seals are new and properly placed to avoid leaks and ensure a tight fit.

- Assemble in Reverse Order: If disassembly followed a specific sequence, reassemble in reverse. This approach aids in maintaining order and consistency.

- Double-Check Alignment: Ensure that all parts fit snugly together. Misalignment can lead to premature failure or inefficiencies.

- Secure Fasteners Properly: Tighten all bolts and screws according to the specified torque. Use a torque wrench for accuracy.

After reassembly, conduct a thorough inspection to confirm everything is in its proper place. This final check can prevent potential issues and enhance the longevity of your machinery.

Essential Maintenance Tips for Longevity

Proper care and regular upkeep are vital for ensuring the long-lasting performance of any small power unit. Following a few key practices can significantly enhance reliability and efficiency, ultimately prolonging its lifespan. Here are some essential tips to keep in mind.

Regular Inspections

Conducting frequent checks is crucial for identifying potential issues before they escalate. Consider the following:

- Examine fuel and oil levels regularly.

- Inspect air filters for dirt and blockages.

- Look for leaks or unusual noises during operation.

Scheduled Maintenance Tasks

Establishing a routine for specific maintenance tasks will help maintain optimal performance. Prioritize these activities:

- Change oil at recommended intervals.

- Replace air and fuel filters as needed.

- Sharpen or replace blades on cutting equipment.

- Clean spark plugs to ensure proper ignition.

Troubleshooting Common Performance Problems

When facing issues with your small combustion unit, it’s essential to identify and resolve performance-related concerns efficiently. This section outlines various common problems and their potential causes, enabling you to restore optimal functionality with ease.

Identifying Symptoms

- Inconsistent power output

- Difficulty starting or failure to start

- Unusual noises or vibrations

- Excessive smoke production

Common Causes and Solutions

- Fuel Issues:

- Check for stale or contaminated fuel; replace with fresh gasoline.

- Inspect fuel lines for blockages or leaks; clean or replace as necessary.

- Air Intake Problems:

- Examine the air filter for dirt and debris; clean or replace if clogged.

- Ensure that the air intake system is free from obstructions.

- Ignition Failures:

- Test the spark plug for wear; replace if necessary.

- Check ignition components for proper function; repair or replace faulty parts.

- Mechanical Wear:

- Listen for unusual sounds indicating internal wear; perform a compression test.

- Consult with a technician if excessive wear is suspected.

By systematically addressing these common issues, you can enhance the performance and longevity of your unit, ensuring it operates smoothly and efficiently.

Fuel System Repair and Maintenance

The proper functioning of the fuel system is crucial for optimal performance and longevity of any combustion power source. Regular upkeep and timely interventions are essential to prevent common issues such as blockages, leaks, and inefficiencies. Understanding the components and their maintenance requirements can greatly enhance the reliability and efficiency of the unit.

Inspection and Cleaning

Routine inspection of the fuel system components is vital. Check for any signs of wear, corrosion, or damage in the fuel lines, filter, and tank. Cleaning these parts can significantly improve fuel flow and performance. Using a suitable solvent and a soft brush, carefully clean the fuel filter and tank to eliminate any deposits or contaminants that may hinder operation.

Replacement of Worn Parts

Over time, components such as filters and hoses may degrade. Regularly replace these parts to maintain peak performance. Ensure that the replacement components meet the specified standards for compatibility and durability. Additionally, check for any leaks and promptly address them to prevent fuel wastage and safety hazards.

Electrical System Overview and Repairs

The electrical system is a crucial component that ensures proper functionality and efficiency in small machinery. It comprises various elements that work together to provide power, facilitate ignition, and enable the operation of various accessories. Understanding the fundamentals of this system is essential for effective troubleshooting and maintenance.

Key components of the electrical system include:

- Ignition Coil: Generates high voltage for spark plug firing.

- Starter Motor: Initiates the starting process by cranking the machine.

- Battery: Provides power for starting and operating electrical devices.

- Wiring Harness: Connects various components and ensures proper electrical flow.

Regular inspection and maintenance can prevent common issues associated with the electrical system. Here are some common repairs that may be necessary:

- Inspecting Wiring: Look for frayed or damaged wires that could cause short circuits.

- Testing the Ignition Coil: Use a multimeter to ensure the coil is functioning correctly.

- Checking the Battery: Verify the battery’s charge and connections for corrosion.

- Starter Motor Troubleshooting: Ensure the starter engages properly; replace if defective.

Maintaining the electrical system is vital for optimal performance and longevity. Regular checks and timely repairs can significantly enhance reliability and prevent unexpected breakdowns.

Upgrading Parts for Better Performance

Enhancing the capabilities of your machinery involves the strategic replacement of components with higher-performing alternatives. This not only improves efficiency but can also lead to a more enjoyable experience while operating the device. By investing in quality upgrades, users can achieve significant gains in power and reliability.

Key Components to Consider

- Air Filter: Upgrading to a high-flow air filter can improve airflow, resulting in better combustion and increased power output.

- Exhaust System: A performance exhaust can reduce back pressure and enhance exhaust flow, allowing the system to breathe better.

- Carburetor: Replacing the carburetor with a larger or more efficient model can improve fuel delivery, optimizing performance.

Benefits of Upgrading

- Improved Efficiency: Enhanced parts can lead to better fuel efficiency, allowing for longer operational times between refueling.

- Increased Power: Upgraded components can provide a noticeable boost in torque and horsepower, making tasks easier.

- Longer Lifespan: Quality aftermarket parts often offer greater durability, resulting in less frequent replacements and repairs.

Safety Precautions During Repairs

When undertaking maintenance tasks on any machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to safety guidelines ensures that the working environment remains secure and that all procedures are conducted without unnecessary risks. Proper preparation and awareness of potential hazards can significantly reduce the likelihood of mishaps.

Before starting any maintenance work, it is crucial to equip oneself with the right protective gear. Wearing safety goggles, gloves, and steel-toed boots can help shield against harmful substances and physical injuries. Additionally, ensuring that the workspace is well-lit and organized can enhance visibility and minimize the risk of tripping or falling.

Always disconnect the power source before beginning any work to avoid electrical shocks or accidental start-ups. If applicable, allowing the machinery to cool down is vital to prevent burns. Keeping flammable materials away from the workspace also helps mitigate fire hazards.

Be familiar with the tools being used and follow the manufacturer’s guidelines for their operation. Misuse of tools can lead to injuries or damage to components. Furthermore, it is important to have a first aid kit readily available in case of emergencies, along with knowing the procedures for addressing common injuries.

Finally, ensuring that others are aware of the ongoing work can prevent unexpected interruptions that could lead to accidents. By maintaining clear communication and following established safety protocols, individuals can effectively safeguard themselves while performing necessary maintenance tasks.