In the world of portable power solutions, understanding the intricacies of your device can significantly enhance its longevity and performance. This section delves into essential insights and methods for maintaining and fixing common issues that may arise with these compact power sources. Whether you are a seasoned user or a newcomer, knowing the basics can save you time and resources.

Modern generators are engineered for efficiency, yet they can encounter various challenges over time. From mechanical malfunctions to electrical failures, recognizing the symptoms and addressing them promptly is crucial. This guide will equip you with the necessary knowledge to identify problems and apply effective solutions.

By familiarizing yourself with key components and troubleshooting techniques, you can ensure your generator operates smoothly whenever needed. With a proactive approach, you can not only extend the life of your equipment but also enjoy uninterrupted power supply during critical moments.

Overview of Honda EU2200i Generator

This compact power solution is designed to provide reliable energy in a variety of settings, making it an essential tool for outdoor enthusiasts, contractors, and emergency preparedness. Its lightweight structure and efficient operation make it suitable for both recreational and professional applications.

Featuring advanced technology, this generator ensures a clean and stable power output, making it ideal for sensitive electronics. The quiet operation allows for use in noise-sensitive environments, enhancing the user experience. Additionally, it boasts impressive fuel efficiency, allowing for extended run times without frequent refueling.

The design emphasizes portability and ease of use, with convenient starting mechanisms and user-friendly controls. Maintenance is straightforward, contributing to its longevity and performance reliability. Overall, this generator serves as a versatile and dependable source of power, catering to various needs and preferences.

Common Issues with EU2200i Models

Portable power units, while reliable, can experience various challenges over time. Understanding these potential problems is essential for users to maintain optimal performance and longevity. Below are some frequently encountered issues and their possible causes.

- Starting Difficulties:

- Battery drain or failure.

- Fuel system blockages or stale fuel.

- Faulty spark plug or ignition components.

- Overheating:

- Clogged air filter.

- Insufficient oil levels.

- Poor ventilation around the unit.

- Inconsistent Power Output:

- Worn or damaged generator components.

- Electrical system malfunctions.

- Improper load management.

- Excessive Noise:

- Loose or damaged muffler.

- Worn engine mounts.

- Debris accumulation in the exhaust system.

Regular maintenance and inspections can help mitigate these issues, ensuring reliable operation for years to come. Familiarity with these common problems allows users to take proactive measures, enhancing their experience with the equipment.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing common issues that may arise with your portable power generator. By following these steps, you can identify and resolve problems effectively, ensuring optimal performance and longevity of your equipment.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Won’t Start | Low fuel level | Check and refill fuel tank |

| Engine Stalls | Dirty air filter | Inspect and clean or replace air filter |

| Weak Power Output | Overloaded circuit | Disconnect unnecessary appliances |

| Excessive Noise | Loose components | Tighten screws and bolts |

Detailed Troubleshooting Steps

Begin your troubleshooting process by ensuring the device is properly fueled and all connections are secure. Next, inspect key components such as the air filter, spark plug, and oil level. Following these checks, attempt to start the generator again. If issues persist, consult the table above for specific causes and their corresponding solutions.

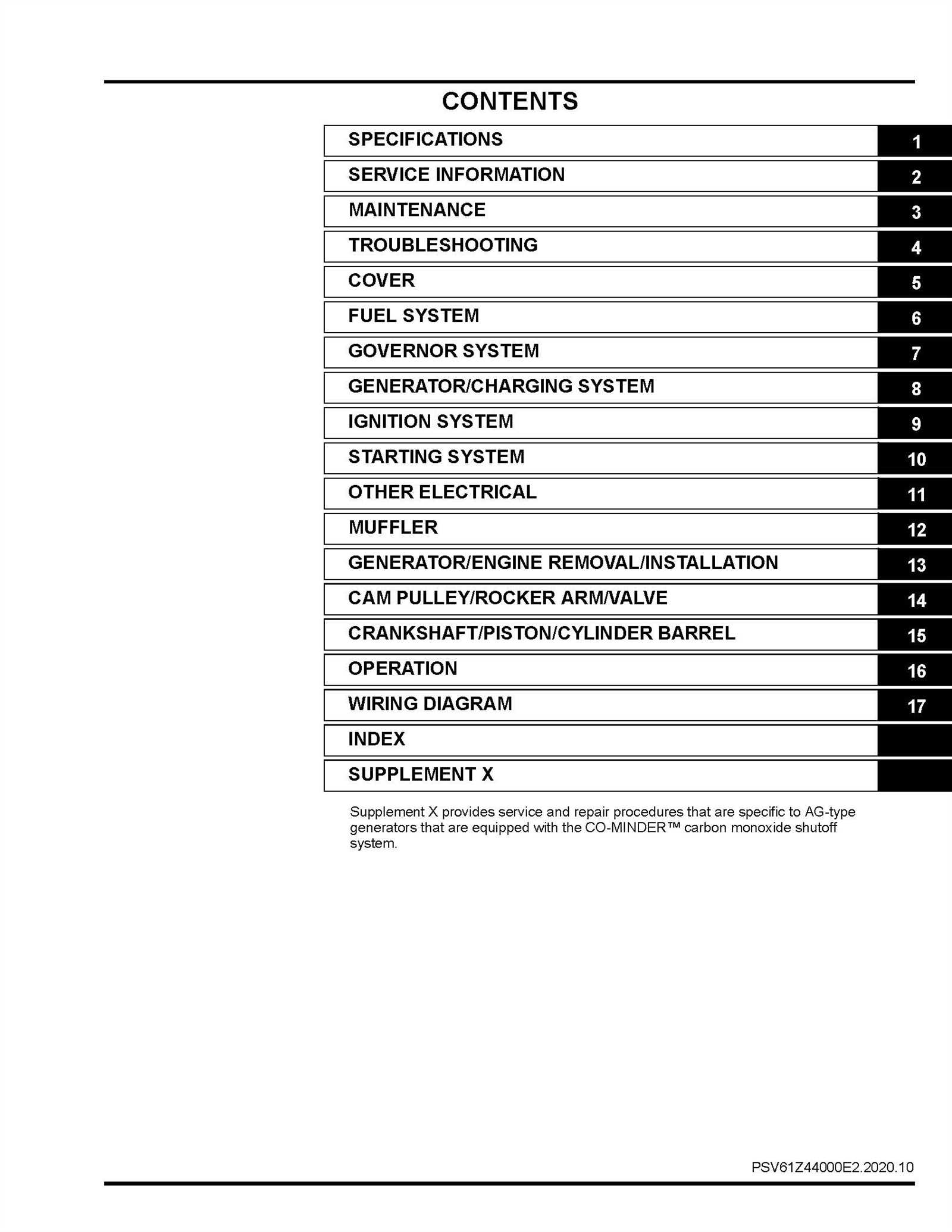

Essential Tools for Effective Repairs

Having the right instruments is crucial for accomplishing maintenance tasks efficiently. Whether you are a seasoned technician or a DIY enthusiast, the tools you choose can significantly impact the quality and speed of your work. A well-equipped workspace not only enhances your productivity but also ensures that repairs are carried out safely and effectively.

Basic Hand Tools are the foundation of any maintenance kit. These include screwdrivers, wrenches, and pliers, which are essential for disassembling and reassembling components. Investing in a set of high-quality hand tools can make a substantial difference in your ability to tackle various tasks.

Power Tools are invaluable for more demanding jobs. A reliable drill or impact wrench can save time and effort, allowing you to work through tougher materials with ease. When selecting power tools, consider battery-operated options for portability and convenience.

Diagnostic Equipment plays a pivotal role in identifying issues accurately. Having access to a multimeter or compression tester can help pinpoint problems quickly, making the repair process more straightforward and efficient.

Safety Gear should never be overlooked. Protecting yourself with gloves, goggles, and ear protection is essential to avoid injuries while working. Always prioritize safety to ensure a smooth and secure maintenance experience.

By equipping yourself with these fundamental instruments, you set the stage for successful maintenance and troubleshooting. The right tools not only facilitate effective work but also enhance your confidence as you tackle various tasks.

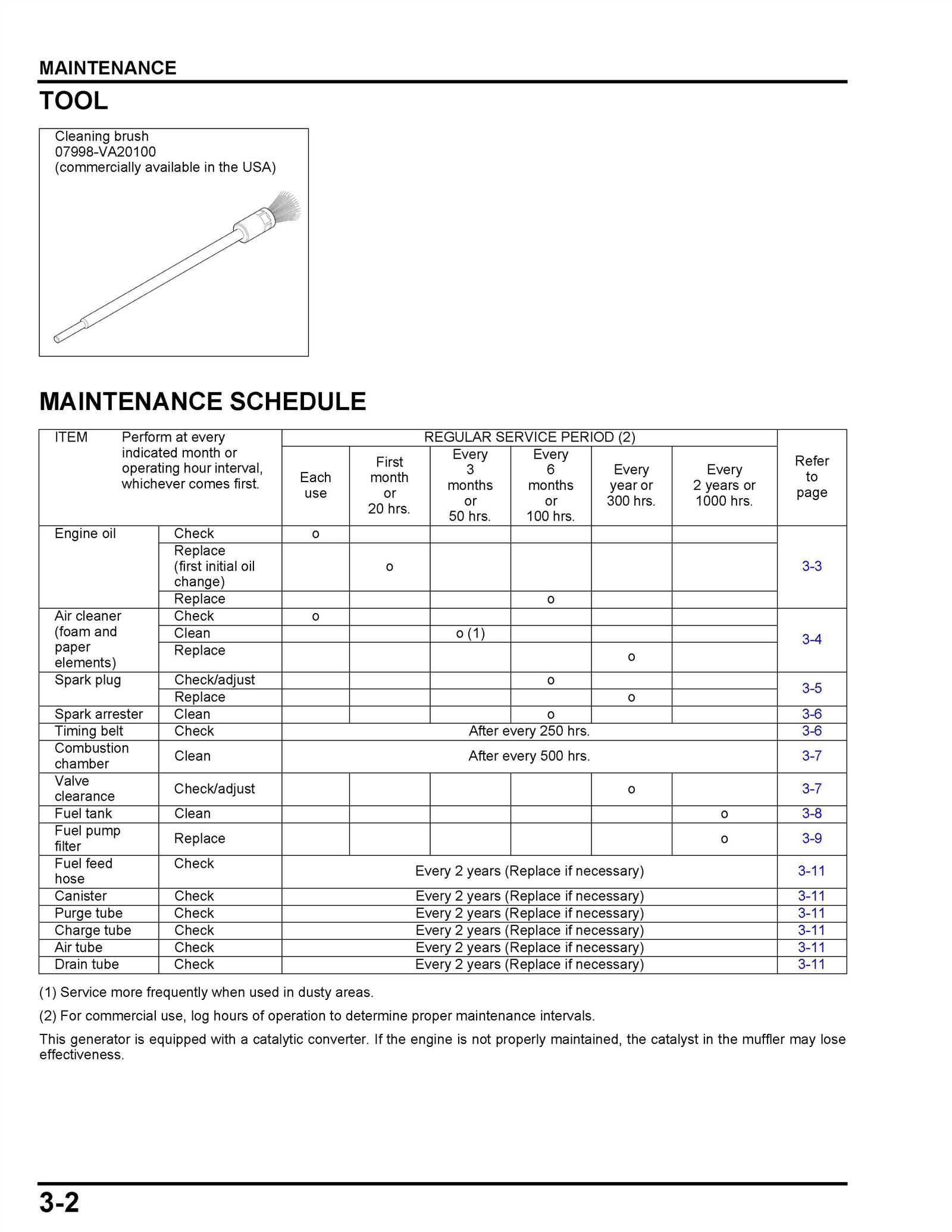

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your portable power unit. Regular attention to specific components not only enhances performance but also minimizes the likelihood of unexpected issues. By following these maintenance practices, you can enjoy reliable operation for years to come.

Regular Inspections

- Check the fuel system for leaks and ensure clean fuel is being used.

- Inspect air filters for dirt and replace them as needed.

- Examine electrical connections for corrosion or damage.

- Look for signs of wear on the casing and other exterior parts.

Routine Maintenance Tasks

- Change the oil at recommended intervals to keep the engine lubricated.

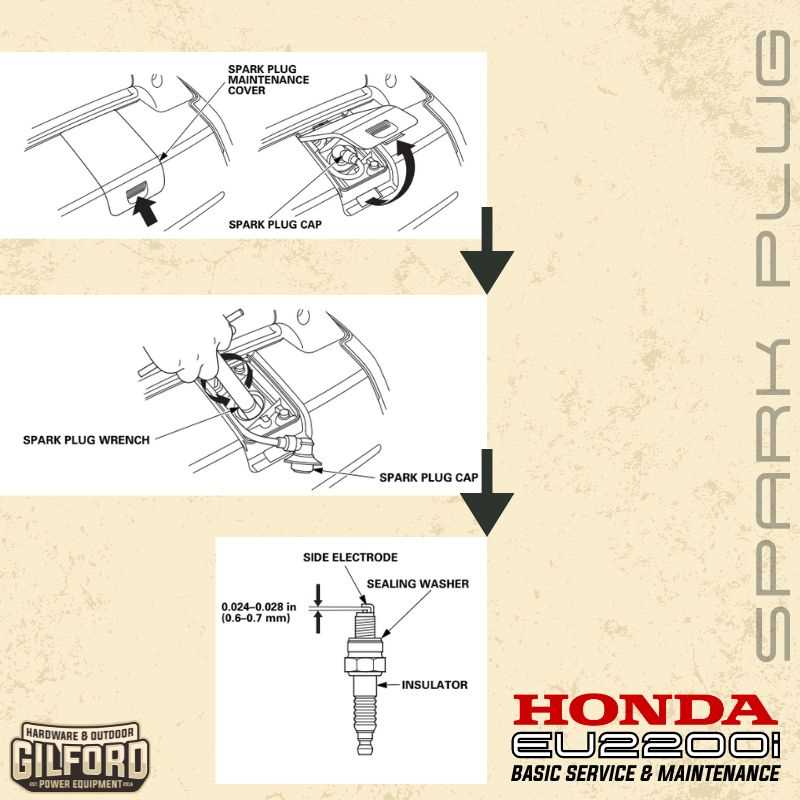

- Clean or replace the spark plug to ensure efficient ignition.

- Drain any stale fuel after extended periods of non-use to prevent clogging.

- Store the unit in a dry place to avoid rust and degradation.

By incorporating these practices into your regular schedule, you can significantly extend the lifespan of your equipment and maintain optimal performance levels.

Replacing Parts: What You Need

When it comes to maintaining your equipment, knowing how to replace components effectively is essential. Understanding the necessary tools and materials can make the process smoother and ensure optimal performance after repairs.

Essential Tools

- Socket Set: A variety of socket sizes for different bolts.

- Screwdrivers: Both flathead and Phillips for accessing various screws.

- Wrenches: Adjustable and fixed wrenches to handle different sizes.

- Pliers: Useful for gripping and twisting wires or small components.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

Replacement Parts

- Air Filter: Ensures clean airflow for optimal operation.

- Fuel Filter: Prevents debris from clogging the fuel system.

- Spark Plug: Vital for ignition and engine performance.

- Oil Filter: Helps maintain oil cleanliness and engine health.

- Battery: Provides necessary power for starting and operation.

Having the right tools and components at hand is crucial for a successful replacement. Always refer to specific guidelines to ensure compatibility and performance standards are met.

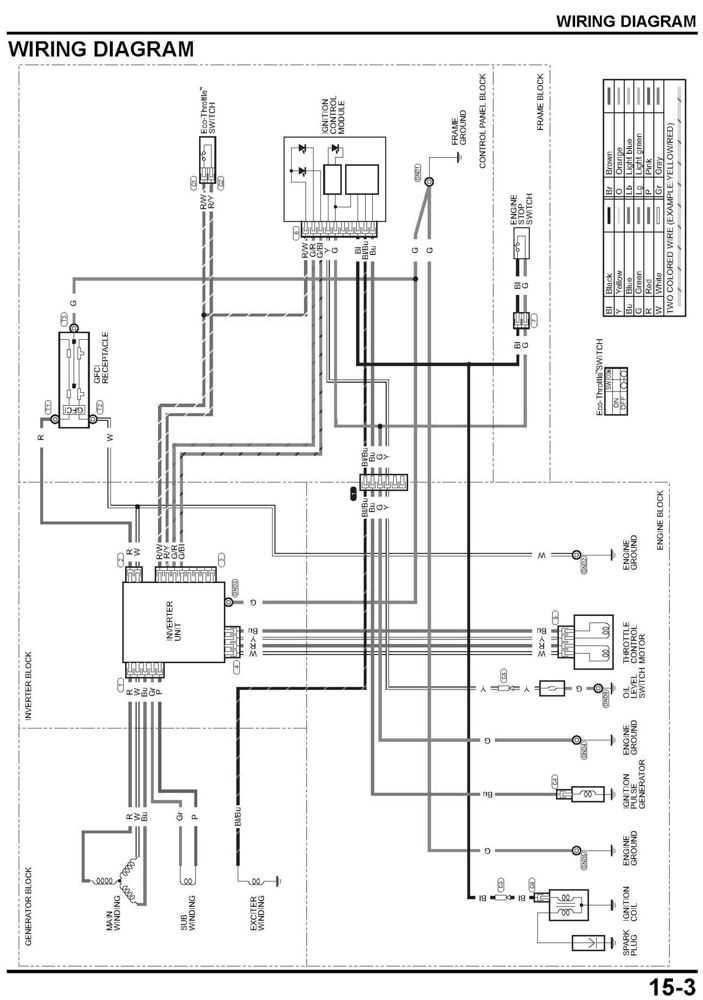

Understanding Electrical Components

The functionality of portable generators relies heavily on their electrical systems. A thorough understanding of these components is essential for effective troubleshooting and maintenance. Each part plays a critical role in the overall operation, ensuring that the device delivers power efficiently and safely.

Key Electrical Parts

Among the primary components are the alternator, voltage regulator, and battery. The alternator is responsible for converting mechanical energy into electrical energy, while the voltage regulator maintains a steady output voltage, protecting connected devices from fluctuations. The battery stores energy for starting the unit and provides backup power when necessary.

Common Issues and Solutions

Electrical issues can manifest in various ways, such as failure to start or inconsistent power output. Regular inspections of wiring and connections can prevent many problems. If issues arise, checking the battery’s charge and testing the alternator’s functionality are vital steps in diagnosing the source of the malfunction. Maintaining these components is crucial for ensuring long-term reliability and performance.

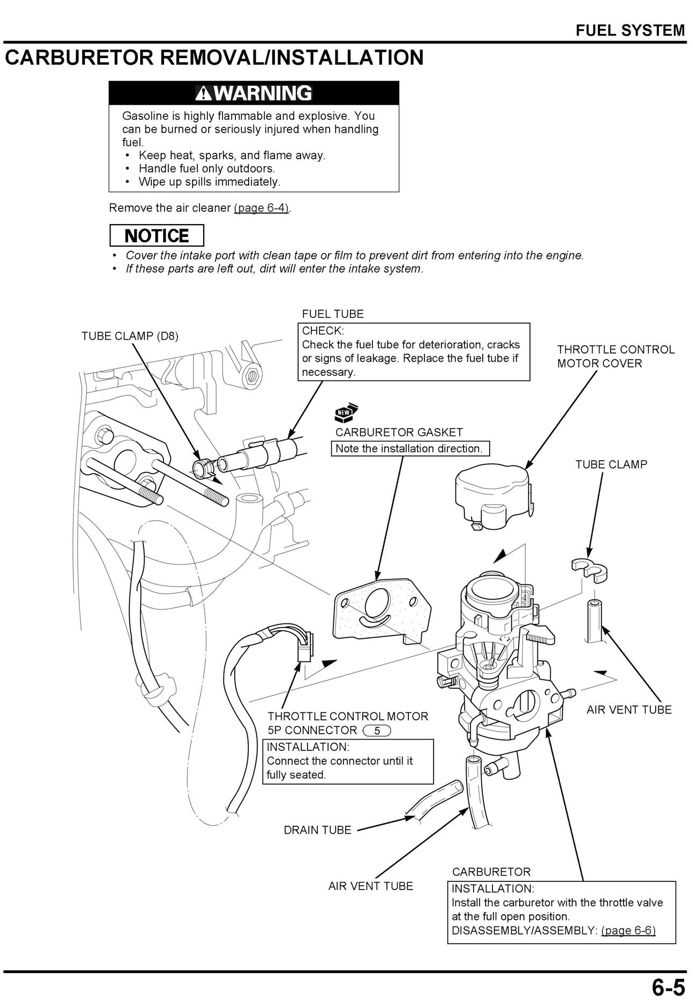

Fuel System Care and Repair

Maintaining the fuel system of your generator is essential for optimal performance and longevity. Proper attention to this component ensures efficient operation and minimizes the risk of potential issues. This section outlines key practices and troubleshooting tips to keep the fuel delivery system in excellent condition.

Regular Inspection: Periodically examine fuel lines, filters, and the tank for any signs of wear or leaks. Look for cracks or corrosion, which can compromise the integrity of the system. Replacing worn components promptly can prevent more significant problems down the line.

Fuel Quality: Always use fresh, high-quality fuel to prevent the build-up of deposits that can clog the system. Stale fuel can lead to starting difficulties and poor performance. If the unit has been idle for an extended period, consider draining old fuel and refilling with fresh product.

Cleaning Procedures: Regularly clean the fuel filter and ensure that the carburetor remains free of debris. A clogged filter can restrict flow, while a dirty carburetor can disrupt the air-fuel mixture, leading to inefficiencies. Utilize appropriate cleaning solutions designed for fuel systems.

Storage Considerations: If you plan to store the generator for an extended time, take precautions to protect the fuel system. Adding a fuel stabilizer can help prevent degradation, and it’s advisable to run the generator until the fuel lines are cleared before storage.

Symptoms of Trouble: Be aware of signs indicating fuel system issues, such as difficulty starting, irregular engine performance, or unusual noises. Addressing these symptoms quickly can save time and reduce repair costs.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting on any machinery, adhering to safety measures is essential to prevent accidents and injuries. Awareness of potential hazards and proper precautions can significantly reduce risks, ensuring a safer environment for the technician and the equipment.

Personal Protective Equipment

Utilizing appropriate personal protective gear is critical during any service task. This includes wearing safety goggles to protect the eyes from debris, gloves to safeguard the hands from sharp objects or chemicals, and sturdy footwear to prevent foot injuries. Additionally, consider using ear protection if noise levels exceed safe thresholds.

Work Environment Safety

Ensure that the workspace is well-ventilated and free from clutter. A clean area minimizes the risk of tripping and allows for easier access to tools and components. Furthermore, disconnect the power source before beginning any inspection or adjustment. This step is crucial to prevent electrical shocks and unintentional starts, which can lead to serious accidents.

By maintaining a focus on safety and using the right protective measures, the risks associated with maintenance tasks can be significantly mitigated, leading to a more efficient and secure working experience.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a crucial step in maintaining its performance and longevity. Various sources offer a wide selection of parts that cater to different needs, ensuring you can keep your machinery running smoothly.

Authorized Dealers: One of the most reliable sources for obtaining components is through authorized dealers. These outlets provide genuine parts, ensuring compatibility and quality. You can locate a dealer by visiting the manufacturer’s website or contacting their customer service.

Online Retailers: Numerous online platforms specialize in parts for various machinery. Websites like Amazon, eBay, and specialized parts retailers often have extensive inventories. Be sure to check customer reviews and seller ratings to ensure you’re purchasing from a reputable source.

Local Repair Shops: Local service centers or repair shops can be a great resource for parts. They may have inventory on hand or be able to order what you need directly from suppliers. Additionally, they can provide advice on installation and maintenance.

Aftermarket Suppliers: If you’re looking for more affordable options, aftermarket suppliers offer parts that may not be original but are compatible with your equipment. Research the reputation of these suppliers to ensure you receive quality components.

Forums and Communities: Engaging with online forums and user communities can also yield valuable information. Fellow users often share insights about where to find parts and might even have leads on used components in good condition.

Regardless of where you choose to source your parts, always ensure that they meet the required specifications to maintain the efficiency and safety of your equipment.