Maintaining a high-performance vehicle requires a solid understanding of its components and systems. This section is designed to provide essential insights and practical advice for enthusiasts looking to keep their prized possession in peak condition. From routine servicing to troubleshooting specific issues, having access to detailed information is crucial for any vehicle owner.

Understanding the intricacies of your automobile can enhance both your driving experience and the longevity of the machine. This guide will delve into various aspects of upkeep, highlighting common challenges and effective solutions. Whether you’re an experienced mechanic or a novice car owner, the knowledge contained within will serve as a valuable resource.

By following the instructions and tips outlined here, you can tackle maintenance tasks with confidence and ensure your vehicle continues to perform at its best. This comprehensive approach will not only save you time and money but also deepen your appreciation for the engineering marvel that is your vehicle.

Overview of BMW 135i Specifications

This section provides a comprehensive look at the essential features and technical details of a compact performance vehicle. Understanding the specifications is crucial for both enthusiasts and those seeking to maintain or enhance their driving experience.

| Feature | Specification |

|---|---|

| Engine Type | 3.0L Inline-6 Turbocharged |

| Power Output | 300 hp @ 5,800 rpm |

| Torque | 300 lb-ft @ 1,200 – 5,000 rpm |

| Transmission | 6-Speed Manual / 7-Speed Dual-Clutch |

| 0-60 mph | 5.1 seconds |

| Top Speed | 155 mph (electronically limited) |

| Fuel Economy | 19 mpg city / 26 mpg highway |

| Wheelbase | 102.5 inches |

| Weight | 3,200 lbs |

These specifications highlight the performance-oriented design and engineering of the vehicle, making it a popular choice among automotive enthusiasts. Understanding these elements is vital for effective upkeep and maximizing driving pleasure.

Common Issues and Troubleshooting Techniques

This section addresses frequent challenges encountered by vehicle owners, along with effective methods for resolving them. Understanding these common problems can help streamline the diagnostic process and facilitate quicker repairs.

Below is a table summarizing some typical issues and their corresponding troubleshooting steps:

| Issue | Troubleshooting Techniques |

|---|---|

| Engine Misfire | Check spark plugs, ignition coils, and fuel injectors for faults. Inspect wiring for corrosion or damage. |

| Overheating | Examine the cooling system for leaks, ensure the coolant is at the correct level, and inspect the thermostat and radiator. |

| Brake Warning Light | Inspect brake fluid levels, check for worn brake pads, and ensure the brake sensor is functioning properly. |

| Transmission Slipping | Check fluid levels, inspect for leaks, and ensure proper adjustment of the transmission linkage. |

| Battery Drain | Test the battery’s charge, inspect the alternator for proper function, and check for parasitic drains in the electrical system. |

By familiarizing oneself with these common issues and their solutions, vehicle owners can enhance their maintenance efforts and potentially reduce repair costs.

Essential Tools for DIY Repairs

Undertaking maintenance and modifications on your vehicle can be a rewarding experience, provided you have the right equipment at your disposal. Having the necessary tools not only streamlines the process but also ensures safety and efficiency while working on various tasks.

Basic Hand Tools

- Wrenches: A set of both metric and imperial sizes is crucial for loosening and tightening bolts.

- Screwdrivers: Flathead and Phillips screwdrivers are essential for various fastening needs.

- Pliers: Needle-nose and adjustable pliers help in gripping and bending components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Specialty Tools

- OBD-II Scanner: Useful for diagnosing issues through error codes.

- Jack and Jack Stands: Essential for lifting the vehicle safely for undercarriage work.

- Brake Bleeder Kit: Facilitates the process of bleeding brake lines effectively.

- Oil Filter Wrench: Simplifies the removal of stubborn oil filters.

Investing in quality tools tailored for automotive work will enhance your ability to perform maintenance tasks effectively. A well-stocked toolbox enables you to tackle a wide range of projects with confidence.

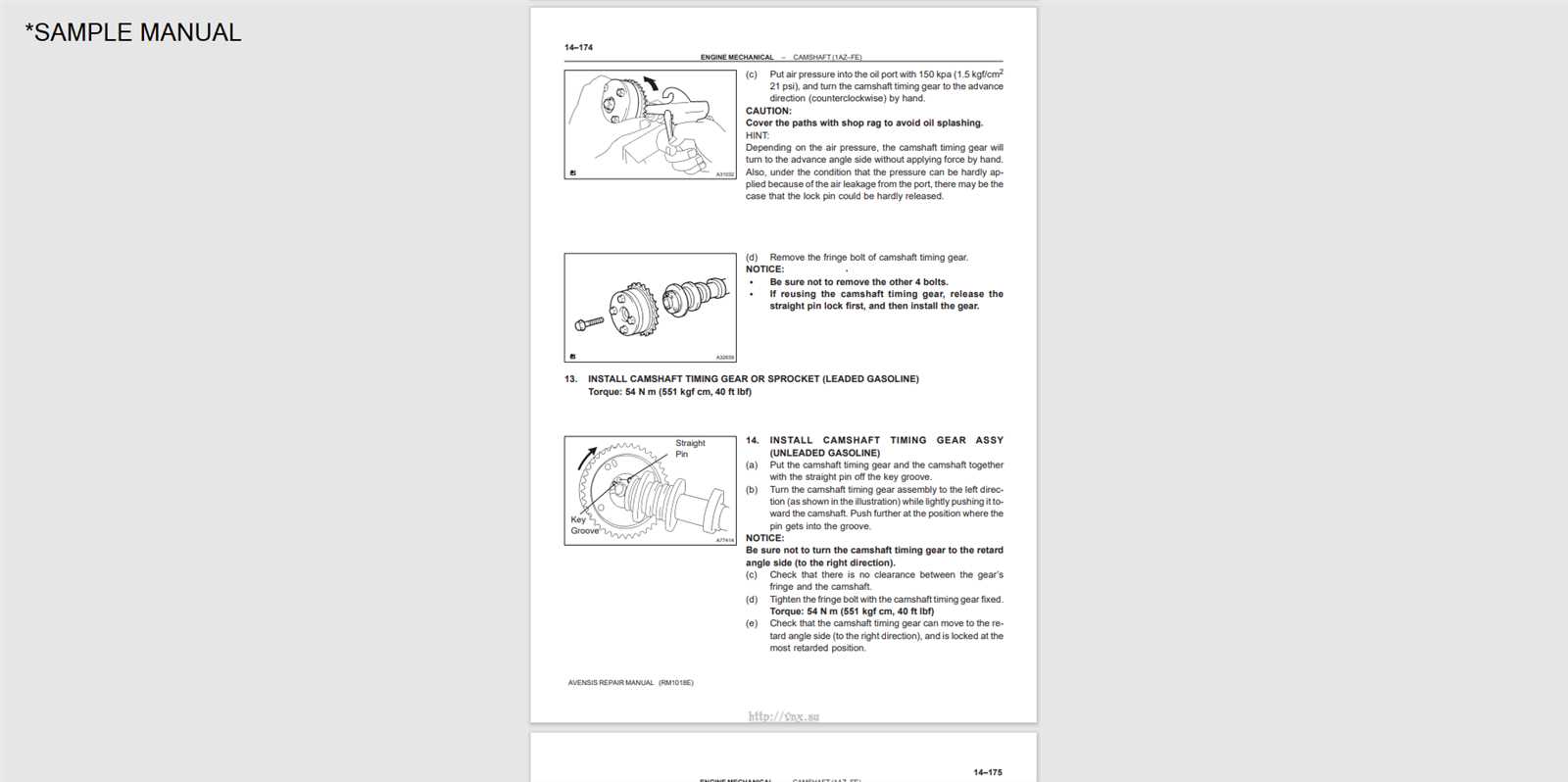

Step-by-Step Maintenance Procedures

Proper upkeep of your vehicle is essential for ensuring longevity and optimal performance. This section provides a comprehensive guide to routine care, allowing you to tackle various tasks with confidence and efficiency. Each procedure is designed to help you maintain critical systems and components effectively.

1. Engine Oil Change

Regularly changing the engine oil is vital for the smooth operation of your vehicle. Follow these steps:

- Warm up the engine slightly to thin the oil, making it easier to drain.

- Securely lift the vehicle and place it on jack stands.

- Remove the oil drain plug and let the old oil drain into a pan.

- Replace the oil filter using an appropriate tool, ensuring a tight seal.

- Reinstall the drain plug and refill the engine with fresh oil through the designated opening.

- Start the engine and check for leaks before disposing of the old oil responsibly.

2. Brake Inspection

Ensuring your braking system functions properly is crucial for safety. To inspect the brakes:

- Remove the wheels to access the brake components.

- Examine the brake pads for wear; replace them if they are less than 3mm thick.

- Inspect the rotors for grooves or scoring; resurface or replace if necessary.

- Check the brake fluid level and top it off if low, ensuring to use the recommended type.

- Reassemble the wheels and lower the vehicle, then perform a brake test to confirm proper operation.

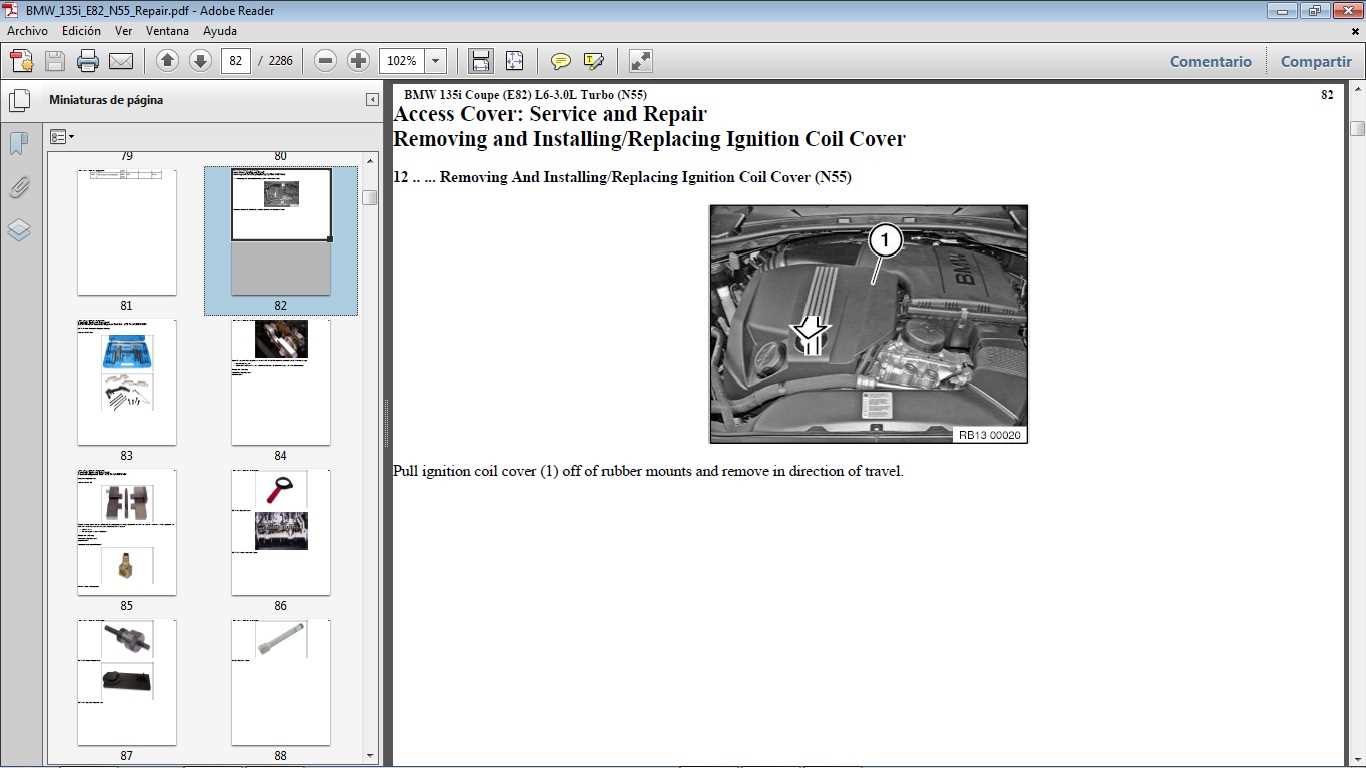

Understanding the Engine Components

The engine is the heart of any vehicle, responsible for converting fuel into motion. Its intricate assembly consists of various parts, each playing a vital role in ensuring optimal performance and efficiency. By comprehending these components, one can gain insight into how they work together to power the machine.

Key Elements of the Engine

At the core of the engine lies the combustion chamber, where the fuel-air mixture ignites, creating the force needed for movement. Surrounding this chamber are components such as pistons, which convert the explosive energy into mechanical motion, and crankshafts, which transmit this motion to the vehicle’s drivetrain. Additional parts like camshafts regulate the timing of valve openings, allowing for proper air intake and exhaust flow.

Supporting Systems

Beyond the primary elements, various supporting systems enhance engine functionality. The cooling system, for instance, prevents overheating by circulating coolant, while the lubrication system ensures that moving parts operate smoothly, reducing friction. Understanding these interrelated systems is essential for anyone looking to maintain or troubleshoot engine issues effectively.

Electrical System Diagnostics and Repairs

The electrical system of a vehicle is crucial for its overall functionality, encompassing everything from the ignition to the lighting and various sensors. Understanding how to diagnose and address issues within this system can significantly enhance the vehicle’s performance and reliability. This section outlines key diagnostic techniques and common repair procedures to assist in resolving electrical faults.

To effectively troubleshoot electrical problems, it is essential to follow a systematic approach. Begin by inspecting the battery and its connections, as well as checking for any blown fuses. Next, utilize a multimeter to measure voltage and resistance across various components, ensuring they operate within specified parameters. Below is a table summarizing common electrical components and their typical diagnostic checks:

| Component | Diagnostic Check |

|---|---|

| Battery | Check voltage and connections for corrosion |

| Fuses | Inspect for continuity and replace if blown |

| Starter Motor | Test for voltage during cranking |

| Alternator | Measure output voltage under load |

| Wiring Harness | Inspect for damage or shorts |

Once the diagnostic checks are complete, repairs may involve replacing faulty components, securing loose connections, or repairing damaged wiring. It is crucial to ensure that all repairs comply with manufacturer specifications to maintain safety and functionality. Regular maintenance of the electrical system can prevent future issues and extend the life of the vehicle.

Brake System Inspection and Servicing

The braking mechanism is crucial for vehicle safety, requiring regular examination and maintenance to ensure optimal performance. This section outlines essential procedures for inspecting and servicing the braking system, ensuring reliability and safety on the road.

Regular inspections should focus on several key components, including brake pads, rotors, fluid levels, and lines. Below is a checklist that can guide the inspection process:

| Component | Inspection Criteria | Servicing Actions |

|---|---|---|

| Brake Pads | Check for wear; thickness should be above the minimum specification. | Replace if worn beyond limits. |

| Brake Rotors | Inspect for warping, scoring, or cracking. | Resurface or replace if damaged. |

| Brake Fluid | Check for contamination and moisture content. | Flush and replace fluid if necessary. |

| Brake Lines | Look for leaks, cracks, or corrosion. | Repair or replace damaged lines. |

Adhering to these inspection and servicing protocols will enhance braking efficiency, contributing to overall vehicle safety. Regular attention to the braking system not only prevents potential failures but also extends the lifespan of its components.

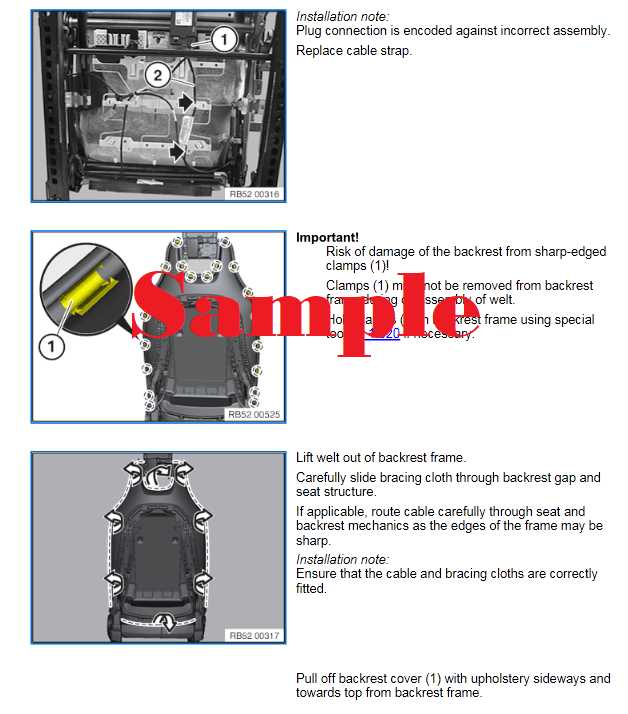

Suspension Upgrades and Modifications

Enhancing the suspension system is a popular approach among automotive enthusiasts seeking improved handling and ride quality. Upgrading components can lead to a more responsive driving experience, allowing for better control during cornering and improved stability on various road surfaces.

Types of Upgrades

Several modifications can be implemented to achieve desired performance characteristics. Upgrading to high-performance shocks and struts can provide improved damping, which translates to better control during dynamic driving conditions. Additionally, replacing stock springs with sport springs can lower the vehicle’s center of gravity, reducing body roll and enhancing cornering capabilities.

Installation Considerations

When considering suspension modifications, it is essential to account for proper alignment and fitment. After any upgrade, a professional alignment is crucial to ensure optimal tire wear and handling. Moreover, selecting components that are compatible with existing systems will prevent potential issues and maximize performance gains.

Transmission Fluid Change Process

Maintaining optimal performance in your vehicle involves regular servicing of the transmission system. One crucial aspect is the timely replacement of transmission fluid, which ensures smooth gear shifts and prolongs the lifespan of components. This process can be straightforward with the right tools and knowledge.

Preparation Steps

Before commencing the fluid change, gather the necessary equipment: a wrench set, a fluid pump, a drain pan, and the appropriate type of fluid. Ensure the vehicle is parked on a level surface and that the engine is off and cool to prevent any injuries.

Fluid Replacement Procedure

Start by removing the drain plug from the transmission pan to let the old fluid flow into the drain pan. Once fully drained, replace the drain plug securely. Next, use the pump to introduce the new fluid through the fill hole. It’s essential to check the level periodically to avoid overfilling. Finally, run the engine briefly and shift through the gears to circulate the fluid, then check the level once more to ensure it is adequate.

Regularly changing transmission fluid not only enhances performance but also helps in avoiding costly repairs in the long run. Make this maintenance task a part of your vehicle care routine.

Cooling System Maintenance Essentials

Maintaining the cooling system is crucial for ensuring optimal engine performance and longevity. Regular attention to this system can prevent overheating, reduce wear, and enhance efficiency. Below are key components and practices for effective upkeep.

- Coolant Quality: Regularly check the coolant for contamination and proper levels. Replace it as per manufacturer guidelines to avoid corrosion and scale buildup.

- Hoses and Clamps: Inspect hoses for cracks, leaks, or wear. Ensure that all clamps are tight and secure to prevent any fluid loss.

- Radiator Condition: Keep the radiator free from debris and inspect it for damage. Cleaning the exterior ensures proper airflow.

- Thermostat Functionality: Test the thermostat to confirm it opens and closes at the correct temperatures. Replace if faulty to maintain consistent operating temperatures.

- Water Pump Efficiency: Check the water pump for leaks and unusual noises. A functioning pump is vital for circulating coolant throughout the system.

- Temperature Gauge Monitoring: Regularly monitor the temperature gauge to catch any signs of overheating early. This can help prevent severe engine damage.

Implementing these maintenance practices will contribute to the overall health of the engine and enhance driving experience.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when conducting maintenance or modifications on vehicles. Proper precautions help to mitigate risks, protect personal well-being, and maintain the integrity of the machine. Understanding and implementing these guidelines can lead to a more efficient and secure experience.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves to shield hands from chemicals and sharp edges, safety goggles to protect eyes from debris, and steel-toed boots to prevent foot injuries. Additionally, consider wearing a face mask when working with substances that produce fumes or dust.

Workspace Organization

A tidy workspace significantly reduces the likelihood of accidents. Keep tools organized and within reach, and ensure that any spills are promptly cleaned up. Remove any unnecessary items from the work area to minimize distractions. Proper lighting is also vital; ensure that the area is well-lit to avoid errors during the process.