Understanding the intricacies of two-wheeled vehicles can significantly enhance your riding experience. Whether you’re an avid enthusiast or a casual rider, being familiar with the upkeep of your machine is crucial for optimal performance. This resource delves into the essential practices for maintaining a popular model, ensuring longevity and reliability on every journey.

From routine inspections to troubleshooting common issues, this guide provides detailed insights into the components that require attention and care. Emphasizing a hands-on approach, you’ll discover how to address potential problems before they escalate, ultimately safeguarding your investment and enhancing safety on the road.

Equipped with step-by-step instructions and helpful tips, this comprehensive resource aims to empower riders with the knowledge needed to tackle maintenance tasks confidently. Whether you’re looking to perform basic servicing or more advanced repairs, understanding your vehicle’s mechanics can transform your relationship with your ride.

Understanding the Honda CRF230F

This section explores the intricacies of a popular off-road motorcycle, emphasizing its features and capabilities. With a focus on versatility, this machine appeals to both novice and experienced riders alike, offering a balance of performance and ease of handling.

Key Features

Equipped with a robust engine and a lightweight frame, this two-wheeler is designed for navigating various terrains. Its suspension system ensures a smooth ride, while the ergonomic design enhances rider comfort during extended journeys.

Performance and Maintenance

Regular upkeep is essential for optimal functioning. Understanding the components, from the ignition system to the tires, allows for better performance management. Emphasizing proper care not only prolongs the lifespan but also maximizes the ultimate riding experience.

Key Features of the CRF230F

This model is designed to offer an exceptional balance of performance and usability, making it a top choice for both novice and experienced riders. With its thoughtful engineering, it provides a reliable and enjoyable riding experience across various terrains.

Engine Performance: The powertrain is equipped with a robust engine that delivers smooth acceleration and ample torque. This ensures that riders can tackle hills and rough paths with confidence.

Suspension System: The advanced suspension setup allows for excellent handling and comfort. It absorbs shocks effectively, enhancing stability and control during off-road adventures.

Lightweight Frame: The lightweight chassis contributes to agile maneuverability. This makes it easy for riders to navigate through tight spots and challenging landscapes.

Durability: Crafted with high-quality materials, this model is built to withstand the rigors of off-road riding. Its resilient components ensure longevity and reliability under demanding conditions.

Ergonomic Design: The thoughtful design of the seat and controls provides optimal comfort, allowing for extended riding sessions without fatigue. This aspect is especially beneficial for those who enjoy long trails.

Fuel Efficiency: The engine is designed to be fuel-efficient, allowing riders to go further on a single tank. This feature is ideal for those who love exploring remote areas without frequent stops for refueling.

Common Issues with the CRF230F

Every off-road motorcycle can experience certain challenges that riders should be aware of. Understanding these potential problems can enhance maintenance practices and improve overall performance. This section highlights frequent concerns encountered with this model, offering insights into how to recognize and address them effectively.

One notable issue is the tendency for the carburetor to become clogged, especially if the bike is not used regularly. Stale fuel can lead to deposits that hinder performance, causing difficulty in starting or inconsistent acceleration. Regular cleaning and maintenance of the fuel system can help mitigate this problem.

Another common concern involves the suspension components. Over time, wear and tear can lead to reduced handling capabilities. Riders may notice a decrease in comfort or stability, signaling that adjustments or replacements might be necessary. Routine inspections can help catch these issues early.

Electrical components can also be a source of frustration. Problems with the battery or wiring can lead to starting issues or malfunctioning lights. Ensuring connections are secure and keeping the electrical system clean can prevent many of these headaches.

Lastly, tire wear is a frequent challenge, especially for those who ride on varied terrains. Keeping an eye on tread depth and ensuring proper inflation can greatly enhance safety and performance. Addressing these concerns promptly can lead to a smoother and more enjoyable riding experience.

Essential Tools for Repairs

When tackling maintenance and troubleshooting tasks, having the right equipment is crucial. The proper tools not only simplify the process but also enhance safety and effectiveness. This section outlines the must-have instruments for anyone looking to keep their vehicle in optimal condition.

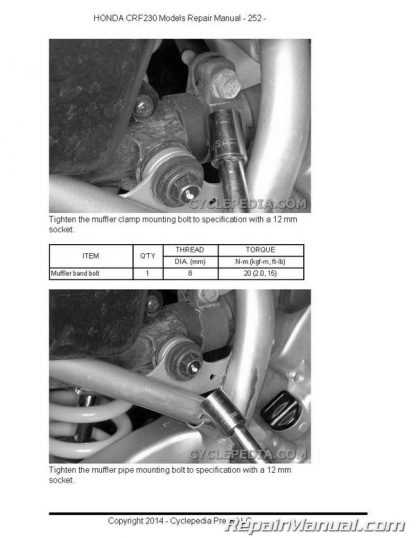

Basic Hand Tools

Starting with the fundamentals, a good set of hand tools is indispensable. This includes wrenches, screwdrivers, and pliers. A versatile toolkit ensures that you can handle various fasteners and components without hassle. Additionally, having a torque wrench is essential for achieving the correct tightness on critical parts, preventing potential damage.

Specialized Equipment

For more advanced tasks, certain specialized tools can make a significant difference. A service manual is invaluable for understanding specific procedures and specifications. Furthermore, tools like a multimeter and a compression tester are essential for diagnosing electrical issues and engine performance, respectively. Investing in these tools will not only save time but also provide peace of mind during maintenance activities.

Step-by-Step Maintenance Guide

Regular upkeep of your off-road machine is essential for optimal performance and longevity. This guide provides a comprehensive approach to routine tasks that ensure your vehicle remains in top condition. Following these steps will help you identify potential issues early and maintain the efficiency of your ride.

1. Pre-Ride Inspection

Before each outing, conduct a thorough examination. Check tire pressure and tread condition, ensuring they are within recommended specifications. Inspect the brakes for responsiveness and examine the chain for wear and proper tension. Additionally, ensure that fluid levels, including oil and coolant, are adequate. Address any abnormalities before hitting the trail.

2. Regular Servicing

Schedule routine servicing every few months or after a specific number of hours of use. This includes changing the oil and filter, cleaning or replacing the air filter, and inspecting spark plugs. Pay attention to the fuel system and ensure it is free from contaminants. Keep an eye on electrical components and wiring to prevent potential failures.

By adhering to this maintenance routine, you can enhance your vehicle’s reliability and performance, allowing for enjoyable and trouble-free rides.

Engine Troubleshooting Tips

Addressing engine issues can be challenging, yet understanding common problems and their solutions can simplify the process. This section outlines practical advice to diagnose and rectify typical performance concerns, ensuring a smoother operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hard Starting | Engine cranks but doesn’t start | Check fuel level and quality, inspect spark plug condition, ensure battery is charged. |

| Loss of Power | Sluggish acceleration or reduced top speed | Examine air filter for clogs, check fuel delivery system, inspect exhaust for blockages. |

| Overheating | Temperature gauge rises above normal | Inspect coolant level, check radiator for leaks, ensure proper airflow around engine. |

| Unusual Noises | Knocking or grinding sounds | Listen for loose components, check for oil level and quality, inspect timing components. |

| Excessive Smoke | Blue, white, or black smoke from exhaust | Identify oil leaks, check fuel mixture, inspect piston rings and valve seals. |

Regular maintenance and prompt attention to symptoms can significantly enhance engine longevity and performance. Being proactive will help in addressing issues before they escalate, leading to a more reliable machine.

Replacing the Air Filter

Ensuring optimal performance of your off-road vehicle requires regular maintenance, including the replacement of the air filtration system. This component plays a critical role in keeping the engine clean by preventing dirt and debris from entering. A clogged or damaged filter can lead to reduced efficiency and potential engine damage.

To successfully replace the air filter, follow these steps to ensure a smooth process:

| Step | Description |

|---|---|

| 1 | Locate the air filter compartment, usually found near the engine. |

| 2 | Remove any screws or clips securing the cover. |

| 3 | Carefully take off the cover to expose the filter. |

| 4 | Gently pull out the old air filter, checking for any debris. |

| 5 | Insert the new filter, ensuring a snug fit without gaps. |

| 6 | Replace the cover and secure it with the screws or clips. |

| 7 | Start the engine and listen for any unusual sounds, confirming proper installation. |

Regular checks and timely replacements of the air filtration system can significantly enhance the longevity and performance of your vehicle, ensuring a smoother ride through any terrain.

Brake System Inspection Procedures

Regular evaluation of the braking mechanism is crucial for ensuring optimal performance and rider safety. This section outlines essential steps to effectively examine the components involved in the braking system, enabling timely detection of any issues that could compromise functionality.

1. Visual Examination: Begin by inspecting the brake pads and rotors for signs of wear or damage. Look for uneven wear patterns, cracks, or excessive scoring on the rotors. Replace any components that show significant deterioration.

2. Fluid Check: Verify the brake fluid level and its condition. The fluid should be clear and free of contaminants. If the fluid appears dark or murky, it may require replacement to maintain effective braking performance.

3. Brake Line Integrity: Inspect the brake lines for leaks, bulges, or cracks. Any signs of wear could indicate a need for replacement. Ensure all connections are secure to prevent fluid loss.

4. Test Lever Feel: Squeeze the brake lever and observe the responsiveness. It should engage smoothly without excessive play. If the lever feels spongy or requires a long pull to engage, it may suggest air in the lines or a need for adjustment.

5. Performance Testing: Conduct a test ride in a safe environment to assess braking effectiveness. Pay attention to any unusual noises, vibrations, or pulling to one side when applying the brakes, as these could signal underlying issues.

By systematically following these inspection procedures, riders can ensure their braking system remains reliable and responsive, contributing to overall safety and performance on the trail.

Suspension Adjustment Techniques

Fine-tuning the suspension of an off-road motorcycle is crucial for optimizing performance and comfort. Proper adjustment can enhance handling, improve stability, and provide a smoother ride over various terrains. Understanding the fundamental principles of suspension dynamics allows riders to adapt their machines to personal preferences and riding conditions.

Understanding Compression and Rebound Settings

Compression and rebound settings play a vital role in suspension behavior. Compression damping controls how quickly the suspension compresses under a load, while rebound damping determines how quickly it returns to its original position. Adjusting these settings can help achieve a balance between comfort and control. A stiffer compression setting may be beneficial for aggressive riding, while a softer setting can improve comfort on rough trails.

Preload Adjustment for Rider Weight

Preload adjustment is essential for accommodating different rider weights and ensuring the suspension performs optimally. By adjusting the preload, the rider can change the initial height of the suspension, affecting how it responds to bumps and obstacles. Proper preload helps maintain the bike’s geometry and enhances handling, ensuring a more enjoyable riding experience regardless of the terrain.

Electrical System Diagnostics

The effectiveness of any vehicle relies significantly on its electrical framework. Understanding how to assess and troubleshoot this system is crucial for maintaining optimal performance and ensuring longevity. This section provides insights into diagnostic procedures that can help identify electrical issues efficiently.

Common Electrical Issues

Several typical problems may arise within the electrical system. These can include weak battery performance, malfunctioning lights, or irregular starting behavior. Symptoms such as dimming lights or intermittent electrical failures often signal underlying issues that require immediate attention.

Diagnostic Steps

Begin by conducting a visual inspection of the wiring and connections. Look for signs of wear, corrosion, or loose terminals. Next, utilize a multimeter to measure voltage levels across various components, ensuring they align with manufacturer specifications. Testing continuity can further pinpoint disruptions in circuits. Documenting these findings will aid in isolating faults and guiding subsequent repairs.

Handling Fuel System Problems

Addressing issues within the fuel system is crucial for maintaining optimal performance and reliability in your vehicle. Various symptoms may indicate a malfunction, and understanding these signs can help you diagnose and resolve the problem efficiently. Regular maintenance and keen observation can prevent minor issues from escalating into significant repairs.

Common Symptoms of Fuel System Issues

Recognizing the early indicators of fuel system troubles is essential. Here are some typical signs to watch for:

- Difficulty starting the engine

- Uneven acceleration or hesitation during driving

- Decreased fuel efficiency

- Unusual noises from the fuel pump

- Engine stalling or misfiring

Troubleshooting Steps

If you encounter any of the above symptoms, consider the following troubleshooting steps:

- Inspect the fuel level and ensure adequate supply.

- Check for fuel leaks in hoses and connections.

- Examine the fuel filter for clogs or blockages.

- Test the fuel pump to ensure it is operating correctly.

- Consider the quality of the fuel being used; contaminants can cause issues.

By systematically addressing these areas, you can effectively manage fuel system complications and enhance the longevity of your vehicle’s performance.

Upgrading CRF230F Components

Enhancing the performance and durability of your off-road machine can lead to an exhilarating riding experience. By focusing on specific parts, you can achieve improvements in power delivery, handling, and overall efficiency. Whether you’re a seasoned rider or just starting, upgrading components can significantly enhance your adventure on rugged terrains.

One of the most impactful areas to consider is the suspension system. Upgrading to higher-quality forks and shocks can provide better stability and control, allowing for smoother rides over bumps and rough surfaces. Additionally, tweaking the geometry can improve cornering and overall responsiveness.

Next, consider the exhaust system. A performance-oriented exhaust can boost horsepower while also providing a more aggressive sound. Pairing this with a high-flow air filter can optimize air intake, further enhancing engine performance.

Don’t overlook the importance of tires. Selecting the right rubber for your riding style and conditions can dramatically affect traction and handling. Whether you prefer mud, sand, or rocky paths, there’s a suitable option available to elevate your ride.

Lastly, upgrading the braking system can greatly enhance safety and performance. Installing larger rotors or high-performance pads can provide more stopping power and improved modulation, crucial for navigating challenging landscapes.

Safety Tips for DIY Repairs

When embarking on maintenance tasks for your vehicle, ensuring personal safety is paramount. Understanding the potential risks involved and taking proactive measures can prevent accidents and injuries. This guide offers essential precautions to keep in mind while working on your machine.

Wear Appropriate Safety Gear

Always equip yourself with suitable protective equipment. This includes gloves, safety glasses, and sturdy footwear. Wearing a helmet is advisable if you’re working on or around moving parts. Ensuring that you are properly dressed can significantly reduce the risk of injury.

Maintain a Clean Workspace

A clutter-free area is crucial for safe and efficient work. Keep tools organized and remove any unnecessary items that could pose tripping hazards. Adequate lighting is also essential to ensure clear visibility of all components, reducing the likelihood of mistakes.