Ensuring the optimal condition of your off-road companion is crucial for a smooth and reliable riding experience. In this guide, we cover essential practices and insights on how to maintain and rejuvenate your vehicle for continued durability on diverse terrains. Whether you’re addressing minor adjustments or tackling larger system enhancements, this article offers practical steps and solutions.

Understanding Key Maintenance Areas is vital to a successful restoration process. From examining critical engine components to evaluating suspension setups, we’ll walk you through the necessary procedures to keep your vehicle responsive and trail-ready. Paying attention to these areas not only extends the life of the machine but also enhances safety and performance.

For both beginners and seasoned enthusiasts, maintaining this type of vehicle offers an opportunity to deepen your technical skills and enjoy a more resilient riding experience. By following these organized and easy-to-understand methods, you’ll be well-equipped to handle common issues and keep your trail companion in top condition.

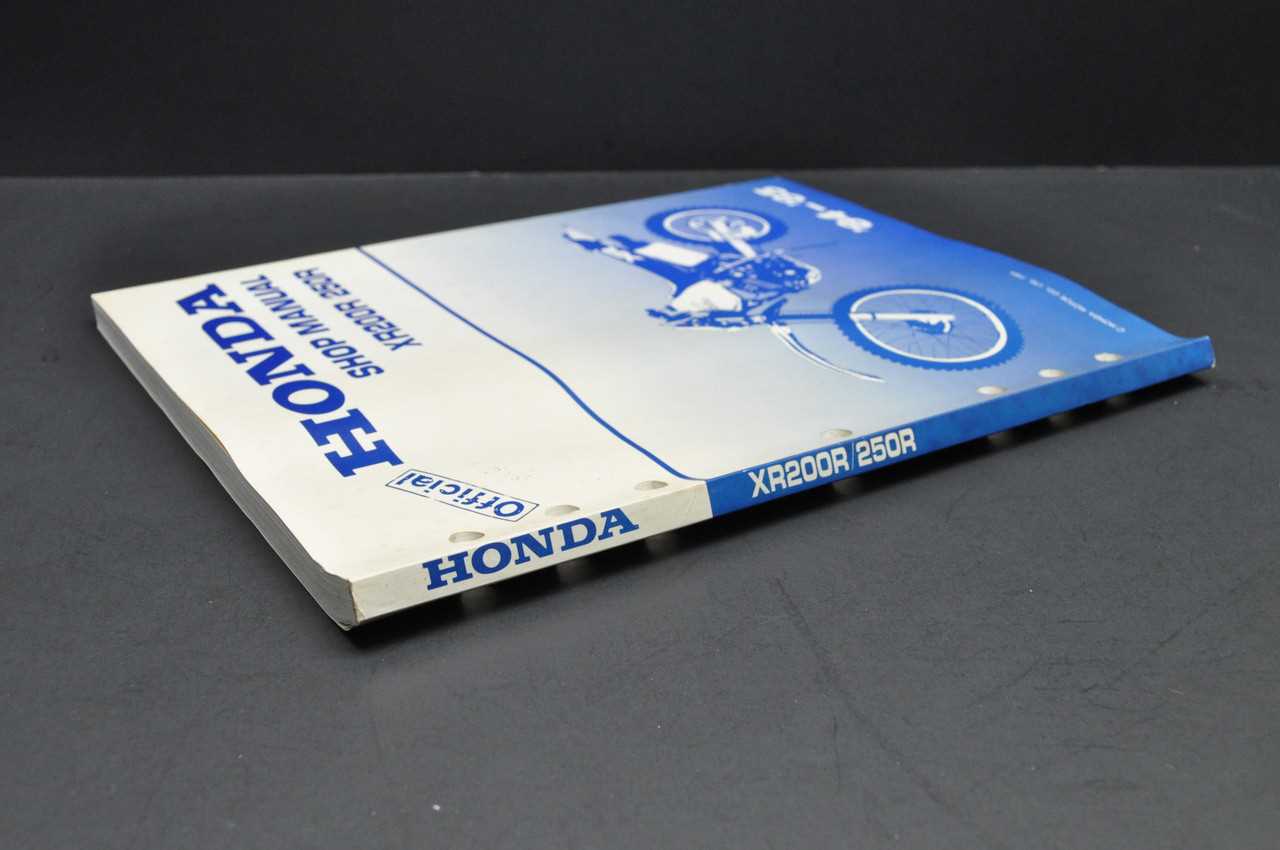

Honda XR200 Repair Guide

Maintaining and restoring off-road motorcycles requires attention to detail and an understanding of the essential systems involved. This guide covers fundamental processes for inspecting, troubleshooting, and addressing common issues to keep your ride in optimal condition.

Regular maintenance tasks help to extend the vehicle’s lifespan and enhance performance. Below are crucial steps to take for successful upkeep and problem prevention.

- Engine Inspection: Regularly check engine components for signs of wear, including seals and gaskets, which help prevent leaks and ensure efficient operation.

- Fuel System: Clean the carburetor periodically to maintain fuel efficiency, and inspect the fuel lines for any blockages or damage.

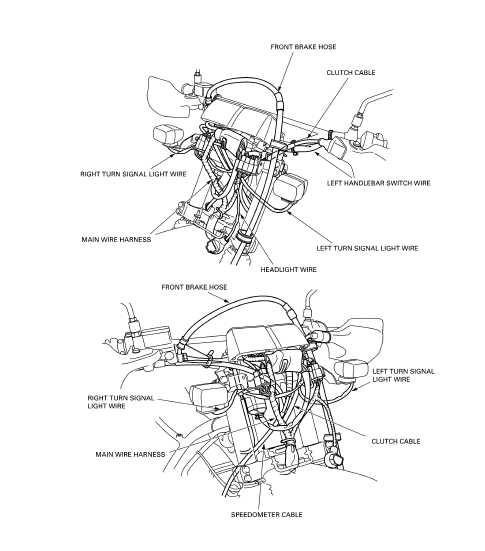

- Electrical Components: Examine the wiring and connectors for corrosion or fraying, as these can impact electrical functions and safety features.

- Suspension and Brakes: Ensure that the shocks, springs, and brake components are in good condition. Properly functioning suspension and brakes are essential for safe riding on rough terrain.

- Chain and Sprockets: Lubricate the chain and inspect sprockets for wear to ensure smooth power transfer and prevent chain-related issues.

Following these key steps

Common Engine Issues and Solutions

Engines often experience recurring challenges that, if identified early, can prevent more significant problems and ensure smoother performance. This section outlines typical engine complications and provides practical guidance on addressing them effectively.

Starting Difficulties: One common issue is the engine struggling to start, especially in colder conditions. Often, this can be attributed to fuel quality, carburetor adjustments, or spark plug condition. Regularly inspecting and, if needed, cleaning or replacing these components can resolve starting issues.

Overheating Problems: Engines are prone to overheating, especially during extended or intensive use. This is often linked to insufficient coolant, blockages in the cooling system, or restricted airflow. Ensuring a clear airflow path and maintaining proper coolant levels can help prevent overheating and prolong engine life.

Power Loss: Reduced engine power or performance can result from various factors, including clogged air filters, issues with the fuel system, or worn-out internal components. Periodic checks of the air filter and fuel system, alongside routine component maintenance, help in sustaining op

Essential Tools for Effective Repairs

Achieving high-quality maintenance requires the right set of equipment to ensure every task is performed efficiently and safely. A well-prepared toolkit can simplify complex work and provide confidence in handling unexpected challenges.

- Socket Set: A complete socket set allows for a precise fit on various fasteners, minimizing wear and ensuring a secure connection when loosening or tightening bolts.

- Torque Wrench: This tool helps apply the correct amount of force, crucial for avoiding damage or ensuring parts are securely fastened without over-tightening.

- Screwdriver Set: Both flathead and Phillips screwdrivers in multiple sizes are essential for versatile use in small and large tasks.

- Hex Keys: A set of hex keys provides essential reach in tight spaces, especially for bolts requiring hexagonal fittings.

- Pliers and Cutters: From gripping to cutting wires or hoses, pliers and wire cutters are vital for a variety of adjustments.

- Lubricants and Cleaners: Quality lubricants reduce friction and wear, while cleaners help remove buildup, prolonging component lifespan.

- Multimeter

How to Replace the Brake Pads

Changing brake pads is an essential part of maintaining reliable braking performance and ensuring a safe ride. This process involves several steps to securely replace worn-out pads, improve stopping power, and extend the lifespan of the braking system. Follow the steps below to understand how to change brake pads effectively and keep the system in optimal condition.

Tools and Materials Needed

Tool Purpose Socket Wrench To remove and tighten bolts Allen Key Set For specific bolt sizes in the brake assembly C-Clamp To compress the brake caliper piston New Brake Pads Replacement for worn-out pads Cleaning Solution For clearing debris Engine Tuning for Optimal Performance

Achieving peak efficiency and power in an engine requires a focus on precise tuning techniques that enhance combustion and overall engine response. Fine adjustments to the fuel and air mixture, ignition timing, and valve clearances can significantly impact performance.

- Fuel and Air Mixture: Balancing the fuel-to-air ratio ensures the engine runs efficiently without unnecessary strain, optimizing both power output and fuel economy.

- Ignition Timing: Adjusting ignition timing can improve throttle response and combustion efficiency, allowing the engine to generate maximum power during each cycle.

- Valve Clearance: Maintaining accurate valve clearance allows the engine’s intake and exhaust systems to function smoothly, ensuring proper airflow and enhancing performance.

- Carburetor Adjustments: A well-tuned carburetor regulates the fuel flow, matching engine demands across various speeds and loads, resulting in smoother acceleration and consistent power.

Regular tuning not only enhances the

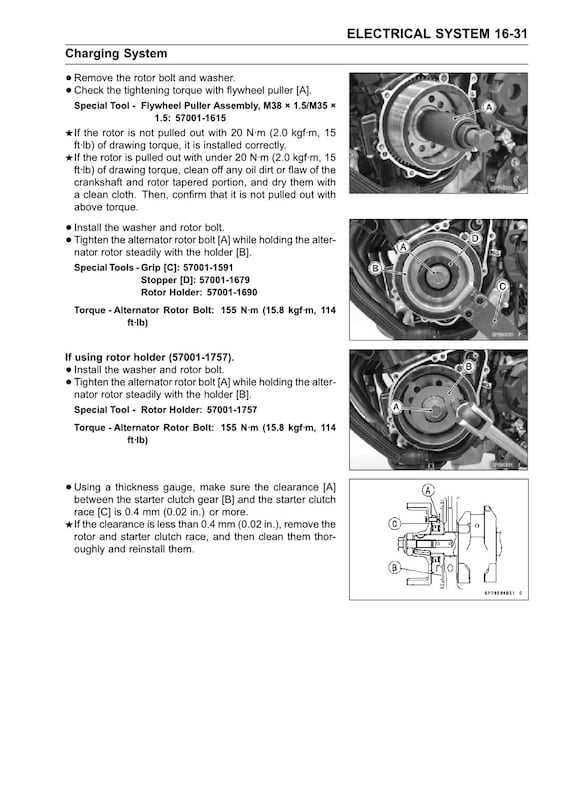

Electrical System Troubleshooting Tips

Diagnosing issues within the electrical system of a vehicle requires careful observation and systematic testing. Proper understanding of the components involved can aid in identifying the root cause of malfunctions, ensuring efficient repairs. Here are some helpful guidelines to assist you in troubleshooting electrical problems effectively.

Checking Battery Health

The battery serves as the heart of the electrical system. Regular checks for corrosion on terminals and ensuring a secure connection can prevent many common issues. Use a multimeter to measure voltage levels; a fully charged battery should read around 12.6 volts. If the voltage is significantly lower, recharging or replacing the battery may be necessary.

Inspecting Wiring and Connections

Worn or damaged wires can lead to shorts or interruptions in power. Examine all visible wiring for signs of wear, fraying, or disconnection. Ensure that connectors are tight and free of debris. If you suspect a short circuit, use a multimeter to check continuity and identify the problematic sections.

Proper Chain Maintenance and Adjustment

Ensuring optimal performance of your motorcycle involves regular attention to the chain system. Proper upkeep not only prolongs the lifespan of the chain but also enhances the overall riding experience. This section covers essential practices for maintaining and adjusting the chain to ensure smooth operation.

Regular Inspection: It is crucial to examine the chain periodically for signs of wear, rust, or damage. A well-maintained chain should be clean and adequately lubricated to prevent friction and deterioration. Look for any irregularities in links or tension that may require immediate attention.

Cleaning: Keeping the chain clean is vital. Use a suitable degreaser to remove dirt and grime. After cleaning, rinse thoroughly and dry before applying lubricant. This process helps in preventing the buildup of debris that can cause premature wear.

Lubrication: Regular lubrication is essential for reducing friction. Use a high-quality chain lubricant and apply it evenly along the entire length of the chain while rotating the wheel. Avoid over-lubrication, as excess grease can attract dirt and lead to additional wear.

Adjustment: Correct tension is necessary for optimal performance. If the chain is too loose, it can slip off the sprockets; if it’s too tight, it can cause undue stress on components. Refer to your vehicle’s specifications for the correct tension settings and adjust as needed using the appropriate tools.

By adhering to these maintenance practices, you can ensure a longer lifespan for your chain and enhance your motorcycle’s performance on the road.

Inspecting and Replacing the Suspension

The suspension system plays a crucial role in ensuring a smooth and comfortable ride. Regular inspection and timely replacement of worn components are essential for maintaining optimal performance and safety. This section outlines the key steps for evaluating and updating the suspension system to enhance riding experience.

Steps for Inspection

- Visual Check: Begin with a thorough visual inspection of the suspension components. Look for signs of wear, damage, or rust.

- Shock Absorbers: Assess the shock absorbers for any leaks or irregularities in movement. Ensure they compress and extend smoothly.

- Springs: Inspect the springs for sagging or any unusual bending. Verify that they are securely mounted.

- Mounting Points: Examine all mounting points and bushings for deterioration or play, which may indicate the need for replacement.

Replacing Suspension Components

- Gather Necessary Tools: Prepare the required tools such as wrenches, sockets, and a jack.

- Lift the Vehicle: Safely lift the vehicle to access the suspension components easily.

- Remove Old Parts: Carefully remove the old suspension components, following the manufacturer’s guidelines for disassembly.

- Install New Components: Position the new parts and ensure they are securely fastened according to specifications.

- Test the Setup: After installation, lower the vehicle and perform a test ride to confirm that the suspension is functioning correctly.

Understanding Carburetor Cleaning Techniques

Maintaining optimal performance in small engines often requires attention to the carburetor, a critical component that regulates fuel and air mixture. Regular cleaning can prevent issues such as poor acceleration, engine stalling, and rough idling. Understanding effective cleaning techniques is essential for ensuring longevity and efficiency in operation.

There are several techniques for cleaning carburetors effectively:

- Dismantling the Carburetor: Start by carefully removing the carburetor from the engine. Take note of the assembly order for reinstallation.

- Soaking Method: Place the disassembled parts in a carburetor cleaner solution for a specified duration. This helps dissolve built-up deposits.

- Brush Cleaning: Use a soft brush to scrub intricate passages and surfaces, ensuring all debris is removed.

- Compressed Air: After soaking, utilize compressed air to blow out any remaining residue from the carburetor’s jets and passages.

- Reassembly: Once cleaned and dried, carefully reassemble the carburetor, ensuring all components are correctly aligned.

Implementing these techniques can greatly enhance the performance of the engine. Regular maintenance not only ensures a smoother operation but also extends the lifespan of the machinery.

Clutch Repair and Adjustment Guide

This section provides essential information on servicing and fine-tuning the clutch mechanism in your motorcycle. Proper maintenance is crucial for optimal performance and longevity, ensuring smooth operation and effective power transfer.

Understanding Clutch Components

Before starting any adjustments, it’s important to familiarize yourself with the key components of the clutch system:

- Clutch plates

- Pressure plate

- Clutch springs

- Release mechanism

Steps for Adjustment

Follow these steps to achieve the correct clutch adjustment:

- Locate the clutch adjustment mechanism, typically found near the lever.

- Loosen the lock nut while turning the adjustment screw to set the desired tension.

- Ensure the lever has the appropriate amount of free play, usually around 2-5 mm.

- Tighten the lock nut after achieving the correct setting.

- Test the clutch operation by engaging and disengaging while riding.

Preventative Care to Extend Lifespan

Implementing regular maintenance practices is essential for maximizing the longevity of your vehicle. By focusing on preventative measures, you can significantly reduce the likelihood of unexpected breakdowns and costly repairs. This proactive approach ensures that your machine remains in optimal condition, providing reliable performance over time.

Maintenance Task Frequency Benefits Oil Change Every 3,000 miles Reduces engine wear and enhances performance Air Filter Replacement Every 12,000 miles Improves fuel efficiency and engine lifespan Tire Inspection Monthly Ensures safety and optimal handling Brake Check Every 6,000 miles Enhances safety and performance Battery Maintenance Twice a year Prevents unexpected failures and ensures reliability