For those who rely on robust agricultural machinery, understanding the nuances of upkeep and problem-solving is crucial. This section serves as a vital resource for operators seeking to enhance their knowledge and skills in managing their equipment. With an emphasis on practical advice and step-by-step procedures, users can confidently tackle various challenges that arise during operation.

Whether you’re dealing with mechanical issues, routine inspections, or performance enhancements, this guide is tailored to provide clear instructions and insightful tips. The information is structured to cater to both novices and seasoned professionals, ensuring that everyone can find valuable insights to improve their experience.

By delving into the intricacies of maintenance protocols, you will not only prolong the lifespan of your machinery but also maximize its efficiency. Embracing a hands-on approach to learning and troubleshooting empowers operators to address problems proactively, fostering a deeper connection with their equipment.

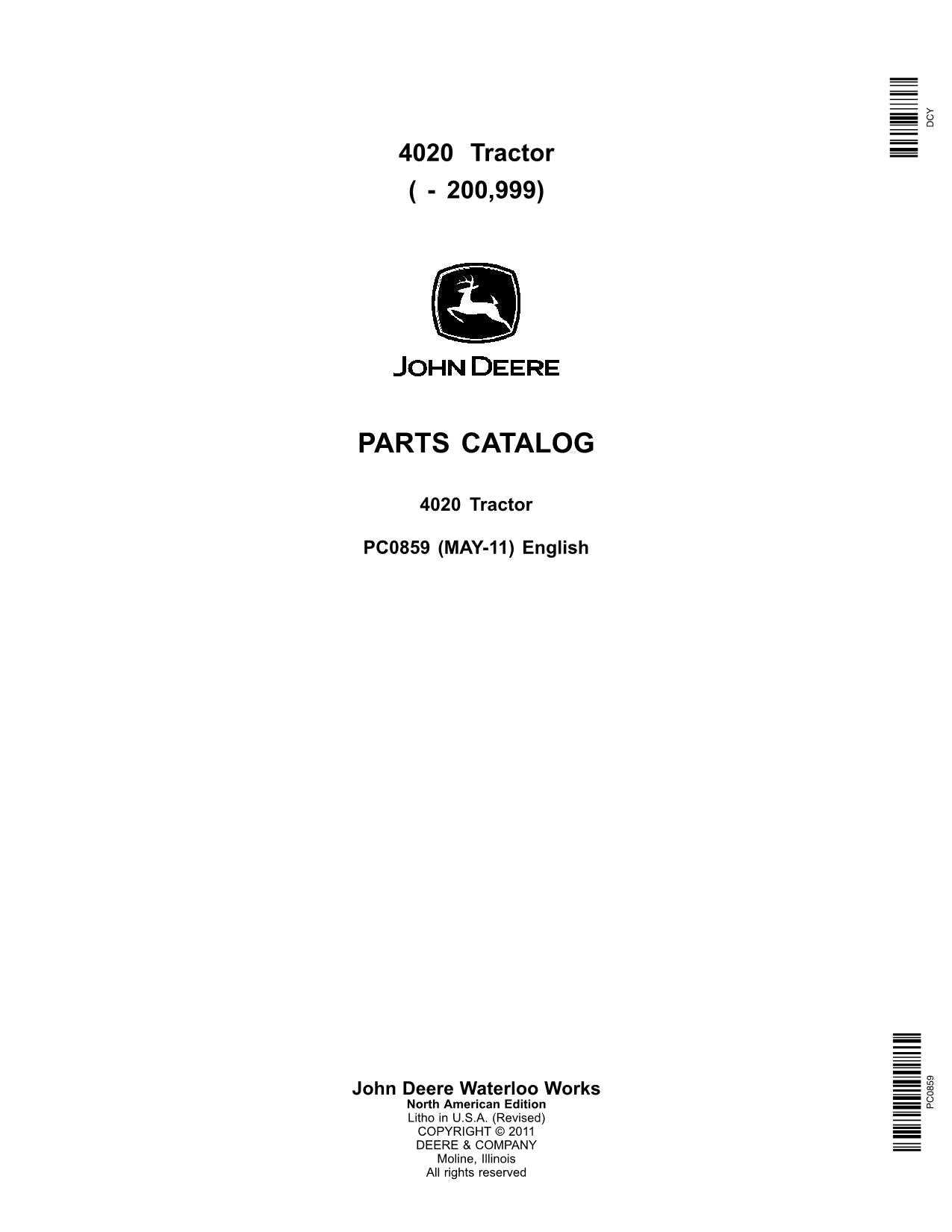

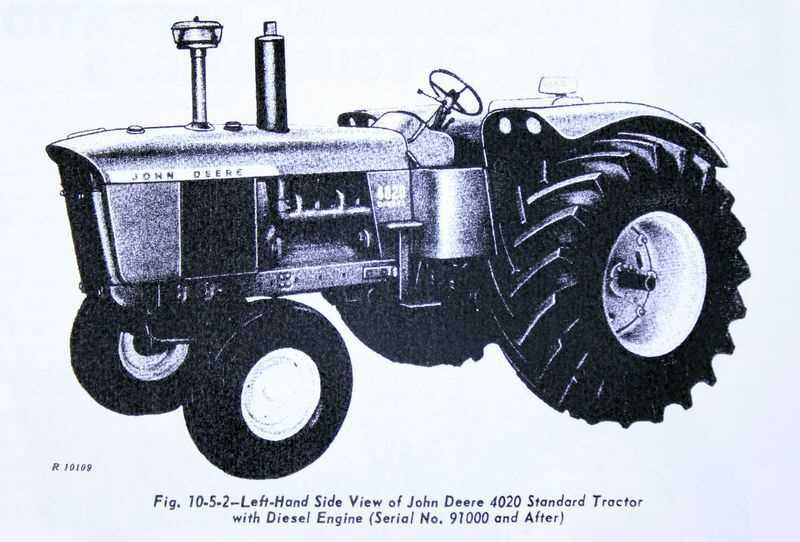

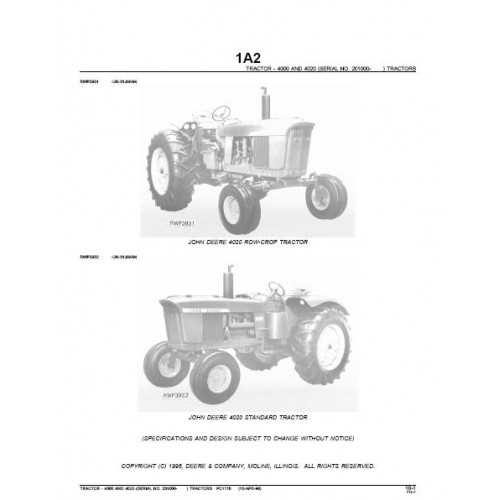

Overview of John Deere 4020

This section provides an insightful exploration of a prominent agricultural machine that has become a staple in the farming community. Known for its robust design and versatile functionality, this tractor has left a significant mark in the industry, appealing to both farmers and collectors alike.

Key Features

- Powerful engine options providing excellent performance.

- Durable build designed to withstand challenging working conditions.

- User-friendly controls for enhanced operator experience.

- Wide range of compatible attachments for various farming tasks.

Historical Significance

Launched in the mid-20th century, this machine revolutionized farming practices and set new standards for agricultural equipment. Its enduring legacy is reflected in its continued popularity and the affection shown by enthusiasts.

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details of the agricultural machinery model in question. Understanding these features is crucial for effective maintenance and optimal performance in various farming applications.

Performance and Efficiency

Designed for versatility, this machine offers exceptional power output, ensuring it meets the demands of various tasks in the field. The efficient fuel consumption rates contribute to cost savings, while the robust construction guarantees durability and longevity.

Technical Specifications

| Feature | Specification |

|---|---|

| Engine Type | Diesel, 6-cylinder |

| Horsepower | 95 HP |

| Transmission | Synchro-range, 8-speed |

| Weight | 4,700 lbs |

| Fuel Capacity | 30 gallons |

Understanding Common Issues

Every machine experiences wear and tear over time, leading to various operational challenges. Identifying these problems early can help in maintaining efficiency and extending the lifespan of the equipment. This section highlights frequent concerns encountered by users, along with suggestions for resolution.

Frequent Mechanical Problems

- Engine Performance: Reduced power or difficulty starting can indicate fuel delivery issues or ignition system failures.

- Hydraulic System: Leaks or sluggish operation may point to low fluid levels or worn-out seals.

- Transmission Issues: Hesitation or slipping during gear shifts can be caused by low transmission fluid or internal component wear.

Electrical Failures

- Battery Problems: Frequent battery drainage may result from faulty wiring or an aging battery.

- Lighting Malfunctions: Dim or non-functioning lights can often be traced back to blown fuses or corroded connections.

- Starter Concerns: If the starter does not engage, it might be a sign of a defective starter motor or relay.

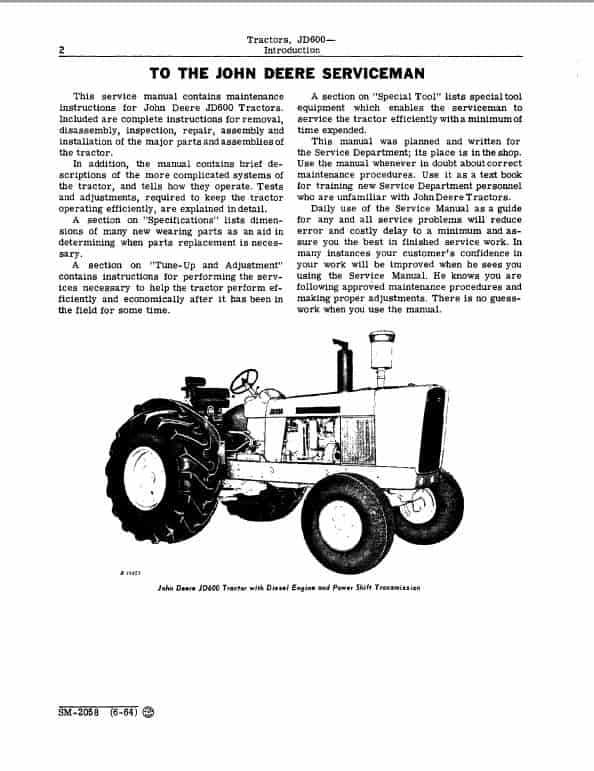

Importance of a Repair Manual

A comprehensive guide serves as an invaluable resource for anyone working with complex machinery. It offers essential insights and detailed instructions that empower operators and technicians to maintain and troubleshoot equipment effectively.

Understanding the Machinery: A well-crafted guide provides a deep understanding of the various components and systems of the equipment. This knowledge is crucial for diagnosing issues accurately and implementing the appropriate solutions.

Enhancing Safety: By following recommended procedures outlined in such a document, users can significantly reduce the risk of accidents and injuries. Safety protocols are often included, ensuring that operators are aware of potential hazards and how to mitigate them.

Maximizing Efficiency: Access to step-by-step instructions can streamline maintenance processes, allowing for quicker repairs and reduced downtime. This efficiency translates into improved productivity and ultimately benefits the overall operation.

Cost-Effective Solutions: Utilizing a thorough reference can help in identifying issues early on, which can prevent costly repairs down the line. Regular maintenance based on the guidelines can extend the lifespan of the machinery, providing significant savings over time.

Empowering Users: With the right information at hand, operators gain confidence in their abilities to tackle various challenges. This empowerment leads to a more proactive approach to maintenance and problem-solving, fostering a culture of competence and reliability.

Basic Maintenance Tips

Proper upkeep of machinery is essential for optimal performance and longevity. Regular maintenance not only prevents costly repairs but also ensures safety and efficiency in operation. Adopting a consistent maintenance routine can significantly enhance the lifespan of your equipment.

Routine Checks

Conducting frequent inspections is crucial. Pay close attention to fluid levels, including engine oil, coolant, and hydraulic fluids. Keeping these at recommended levels will help avoid overheating and mechanical failures. Additionally, examine belts and hoses for signs of wear or damage, replacing them as needed to prevent breakdowns.

Cleaning and Lubrication

Regular cleaning is vital to remove dirt and debris that can hinder performance. Ensure that air filters are clean to maintain proper airflow and efficiency. Furthermore, lubrication of moving parts is essential to reduce friction and wear. Use appropriate lubricants as specified in the guidelines to keep components functioning smoothly.

Tools Required for Repairs

When undertaking maintenance on agricultural machinery, having the right set of instruments is crucial for efficient and effective work. The proper tools not only enhance productivity but also ensure that tasks are completed safely and accurately. Below is a comprehensive list of essential items that will aid in servicing and fixing machinery components.

Essential Hand Tools

Basic hand tools form the foundation of any maintenance task. Wrenches, pliers, and screwdrivers of various sizes are vital for loosening and tightening bolts and screws. A good-quality socket set is also indispensable, as it allows for greater torque and ease in accessing hard-to-reach areas. Additionally, having a set of hammers and chisels can assist in more complex disassembly processes.

Specialized Equipment

In addition to hand tools, specialized equipment may be required depending on the specific tasks at hand. Torque wrenches are essential for ensuring that bolts are tightened to the manufacturer’s specifications. Diagnostic tools, such as multimeters and pressure gauges, can help in identifying issues with electrical and hydraulic systems. Furthermore, having a well-stocked toolbox with various replacement parts can minimize downtime during maintenance activities.

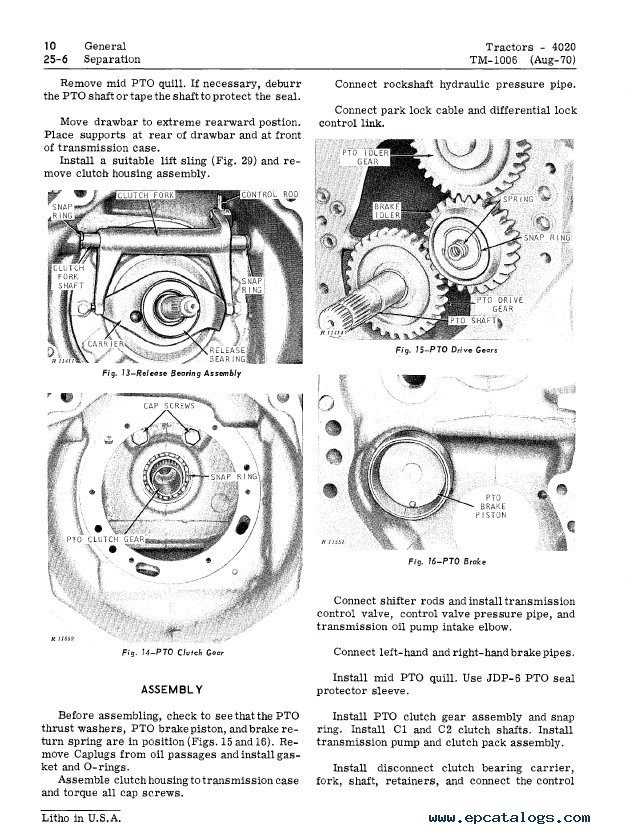

Step-by-Step Repair Procedures

This section provides a comprehensive guide to tackling maintenance tasks effectively. Whether addressing minor issues or performing extensive overhauls, following a structured approach ensures optimal results and extends the lifespan of your equipment. Each procedure is broken down into clear, actionable steps to facilitate understanding and execution.

| Step | Description |

|---|---|

| 1 | Identify the issue by conducting a thorough inspection of the machinery. |

| 2 | Gather all necessary tools and replacement parts to ensure a smooth workflow. |

| 3 | Disconnect power sources and secure the equipment to prevent accidents during maintenance. |

| 4 | Follow specific disassembly instructions, documenting each step for easier reassembly. |

| 5 | Inspect all components for wear or damage and replace as needed. |

| 6 | Reassemble the machinery in the reverse order of disassembly, ensuring all fasteners are tightened to specifications. |

| 7 | Reconnect power sources and conduct a final inspection to confirm proper operation. |

By adhering to these outlined procedures, users can effectively address various challenges and maintain equipment efficiency over time.

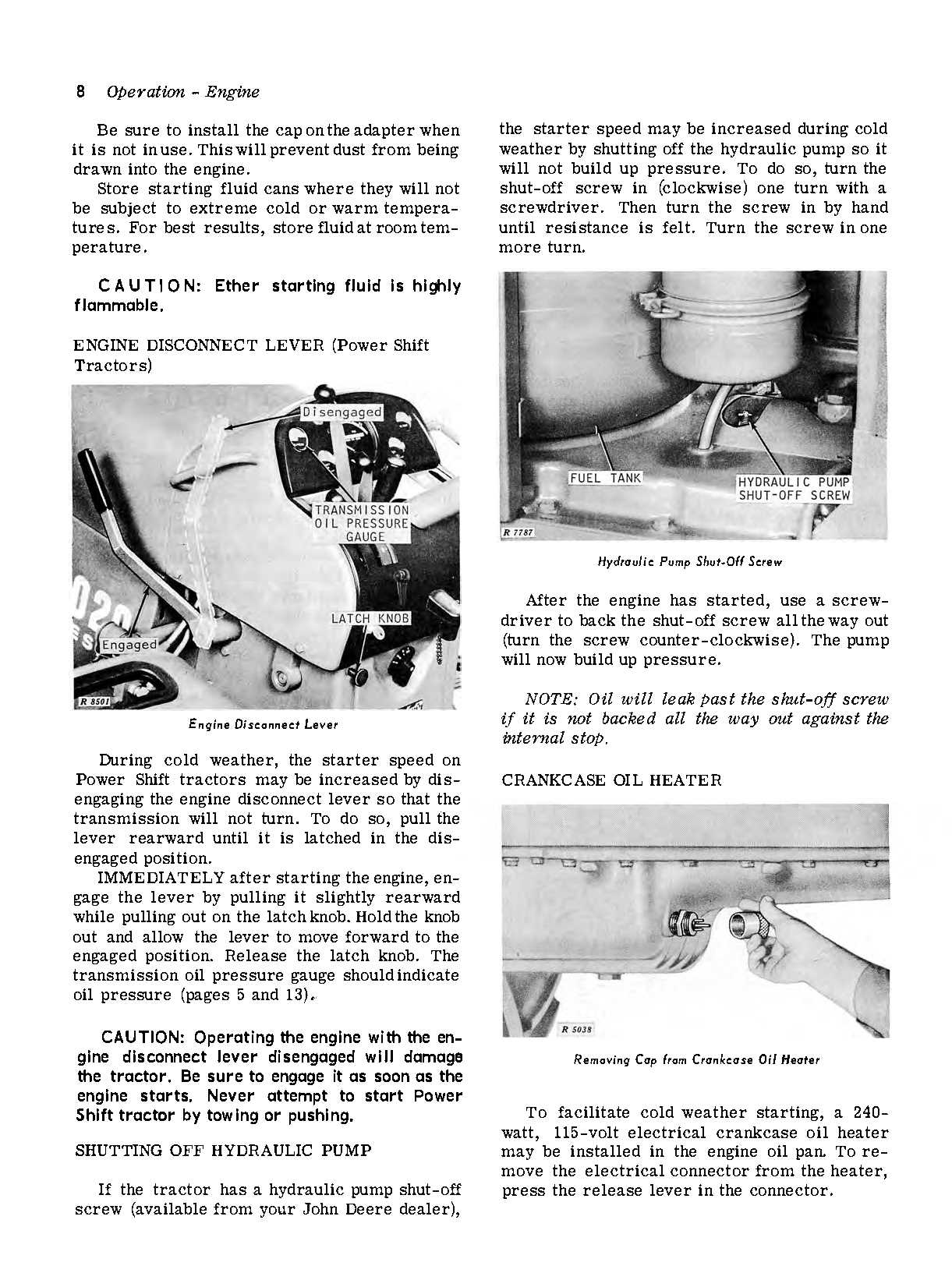

Engine Troubleshooting Guide

This section aims to assist operators in diagnosing and resolving common issues encountered with engine performance. By following a systematic approach, users can identify problems efficiently and take appropriate actions to ensure optimal functionality.

Below is a table summarizing typical engine symptoms, potential causes, and recommended solutions:

| Symptoms | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine won’t start | Dead battery, faulty ignition, or fuel blockage | Check battery charge, inspect ignition components, and ensure fuel flow |

| Overheating | Low coolant, blocked radiator, or faulty thermostat | Check coolant level, clean radiator, and test thermostat |

| Excessive smoke | Fuel quality issues, oil leaks, or worn piston rings | Use clean fuel, inspect for leaks, and consider engine rebuild |

| Loss of power | Clogged air filter, fuel starvation, or exhaust restrictions | Replace air filter, check fuel supply, and clear exhaust pathways |

| Unusual noises | Lack of lubrication, loose components, or bearing wear | Ensure proper oil levels, tighten loose parts, and inspect bearings |

By recognizing these signs and addressing them promptly, operators can prolong the life of their machinery and maintain performance standards effectively.

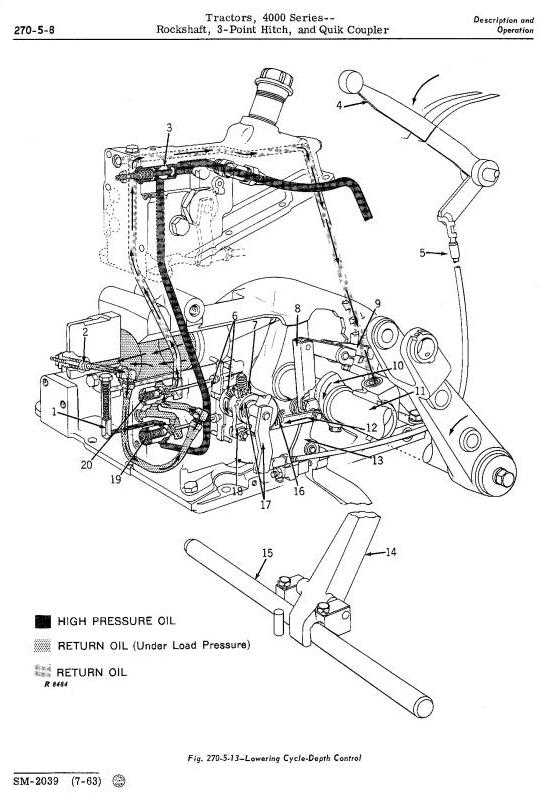

Transmission and Hydraulics Care

Maintaining the transmission and hydraulic systems is essential for optimal performance and longevity of agricultural machinery. Regular attention to these components ensures efficient operation and prevents costly breakdowns. Proper care includes monitoring fluid levels, checking for leaks, and performing routine maintenance tasks.

Here are key practices to consider for effective maintenance:

- Fluid Inspection: Regularly check the transmission and hydraulic fluid levels. Ensure that fluids are clean and at the appropriate levels for optimal function.

- Leak Detection: Routinely inspect for signs of leakage around hoses, seals, and connections. Address any leaks immediately to avoid further damage.

- Filter Replacement: Change hydraulic filters as recommended to maintain clean fluid and protect components from contaminants.

- System Testing: Perform regular tests of the hydraulic system to confirm pressure levels and response times. This helps identify potential issues before they escalate.

- Component Lubrication: Ensure that all moving parts within the transmission and hydraulic systems are adequately lubricated to reduce wear and tear.

By following these guidelines, operators can significantly extend the lifespan of their machinery and enhance overall efficiency. Regular maintenance not only preserves functionality but also improves safety during operation.

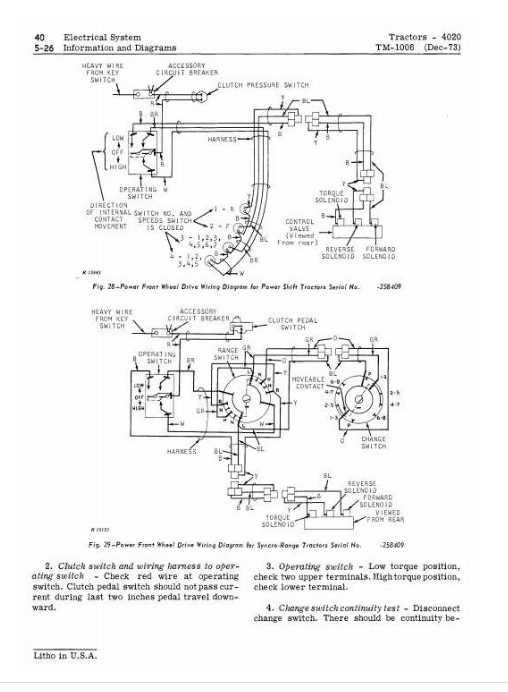

Electrical System Diagnostics

The electrical system is a crucial component of any machinery, ensuring that all systems operate efficiently and reliably. Proper diagnostics of electrical issues is essential for maintaining functionality and preventing unexpected breakdowns. This section will guide you through effective methods to identify and resolve electrical problems.

Understanding the Components

Familiarity with the various elements of the electrical system, including the battery, alternator, wiring, and fuses, is vital. Each component plays a specific role, and understanding their interactions can help in pinpointing faults.

Common Diagnostic Techniques

Utilizing tools such as multimeters and circuit testers can greatly aid in troubleshooting. Check voltage levels, resistance, and continuity to identify any irregularities. Visual inspections are also important; look for signs of wear, corrosion, or damage to wires and connectors.

Troubleshooting Steps

Begin diagnostics by ensuring the battery is fully charged. If the system is unresponsive, inspect the fuses and relays for any that may have blown. Follow the wiring harnesses to check for breaks or loose connections that could interrupt the flow of electricity.

Systematic Approach

A systematic approach will yield the best results. Start from the power source and work your way through the circuit, testing each component in turn. Document your findings to track down persistent issues more effectively.

Conclusion

By mastering electrical diagnostics, you can enhance the longevity and reliability of your machinery. Regular maintenance and thorough inspections will minimize downtime and ensure optimal performance.

Parts Replacement Essentials

Maintaining machinery in optimal condition requires a keen understanding of component substitution. Whether for enhancement or necessary fixes, knowing when and how to replace parts is vital for performance and longevity.

Identifying When to Replace Components

Recognizing the signs that indicate a need for substitution is crucial. Common indicators include:

- Unusual noises during operation

- Decreased efficiency or power

- Visible wear or damage on parts

- Frequent breakdowns or malfunctions

Steps for Effective Component Replacement

Following a systematic approach can ensure successful part substitutions:

- Assess the specific component for wear or damage.

- Consult the specifications for compatible replacements.

- Gather necessary tools and new parts before beginning.

- Carefully remove the faulty component, noting the installation method.

- Install the new part, ensuring proper alignment and securing.

- Test the machinery to confirm functionality.

By adhering to these practices, you can enhance the reliability and efficiency of your equipment, ensuring it operates smoothly for years to come.

Where to Find Replacement Parts

Finding the right components for agricultural machinery is crucial for maintaining optimal performance and longevity. Whether you’re looking for specific pieces or general maintenance supplies, knowing where to search can save you time and ensure quality.

Authorized Dealers and Distributors

One of the most reliable sources for replacement components is through authorized dealers and distributors. These establishments often have a comprehensive inventory of original equipment manufacturer (OEM) parts, ensuring compatibility and reliability. They can also provide expert advice tailored to your specific model.

Online Marketplaces and Auction Sites

For those seeking cost-effective options, online marketplaces and auction sites can be a treasure trove. Platforms like eBay and specialized agricultural websites often feature new, used, or refurbished parts. However, it’s essential to check seller ratings and return policies to ensure you’re getting quality items.

Utilizing these resources can streamline the process of sourcing necessary parts, helping you keep your equipment in peak condition.