Maintaining complex machinery requires a thorough understanding of its components and functionality. This section delves into essential practices for ensuring optimal performance and longevity of agricultural equipment. By following systematic guidelines, operators can effectively troubleshoot issues and implement necessary solutions.

Effective maintenance not only enhances the efficiency of machinery but also prevents costly downtime. A detailed approach to regular check-ups, diagnostics, and part replacements is crucial for any operator aiming to maximize productivity. Understanding the intricacies of these machines empowers users to address potential problems before they escalate.

In this guide, you will discover a wealth of information ranging from basic upkeep tips to advanced troubleshooting techniques. Each aspect is designed to support operators in maintaining their equipment in peak condition, ultimately leading to improved yields and operational success. Embrace the knowledge contained herein to cultivate a more efficient working environment.

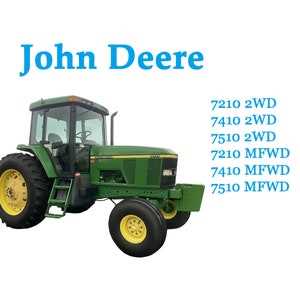

Understanding the John Deere 7410

This section aims to provide insights into a powerful agricultural machine that has gained recognition for its reliability and performance in the field. By exploring its features and capabilities, users can appreciate its role in enhancing productivity and efficiency in various farming tasks.

Key Features

The machine is equipped with an advanced engine that delivers robust power while maintaining fuel efficiency. Its versatile design allows it to tackle a wide range of applications, from tilling to harvesting. Additionally, the ergonomic controls and spacious cabin ensure operator comfort during extended hours of use.

Maintenance Considerations

Regular upkeep is essential for optimal functioning. It includes routine checks on fluid levels, tire conditions, and overall system diagnostics. Implementing a scheduled maintenance plan can significantly prolong the lifespan of the machinery and prevent costly downtimes.

In summary, understanding this agricultural machine’s operational intricacies and maintenance requirements is crucial for maximizing its potential on the farm. By investing time in familiarization and care, users can achieve enhanced productivity and reliable performance.

Key Features of the 7410 Model

This model is recognized for its robust performance and versatility, making it a popular choice among agricultural professionals. Designed to handle a variety of tasks efficiently, it boasts several characteristics that enhance productivity and ease of use.

Power and Performance

- Equipped with a powerful engine that provides ample horsepower for demanding tasks.

- Advanced transmission options ensure smooth operation across different terrains.

- Efficient fuel consumption, allowing for longer operational hours without frequent refueling.

Comfort and Control

- Ergonomically designed cab that prioritizes operator comfort during extended use.

- User-friendly controls and displays for easy navigation and management of functions.

- Exceptional visibility, reducing blind spots and enhancing safety during operation.

Overall, this model exemplifies reliability and efficiency, catering to the diverse needs of modern farming. Its combination of power, comfort, and intelligent design makes it an invaluable asset for agricultural endeavors.

Common Issues and Solutions

In the realm of agricultural machinery, certain challenges often arise that can hinder performance and efficiency. Understanding these prevalent problems and their corresponding solutions is crucial for maintaining optimal functionality. Below are some frequently encountered issues along with effective strategies for resolution.

Engine Performance Problems

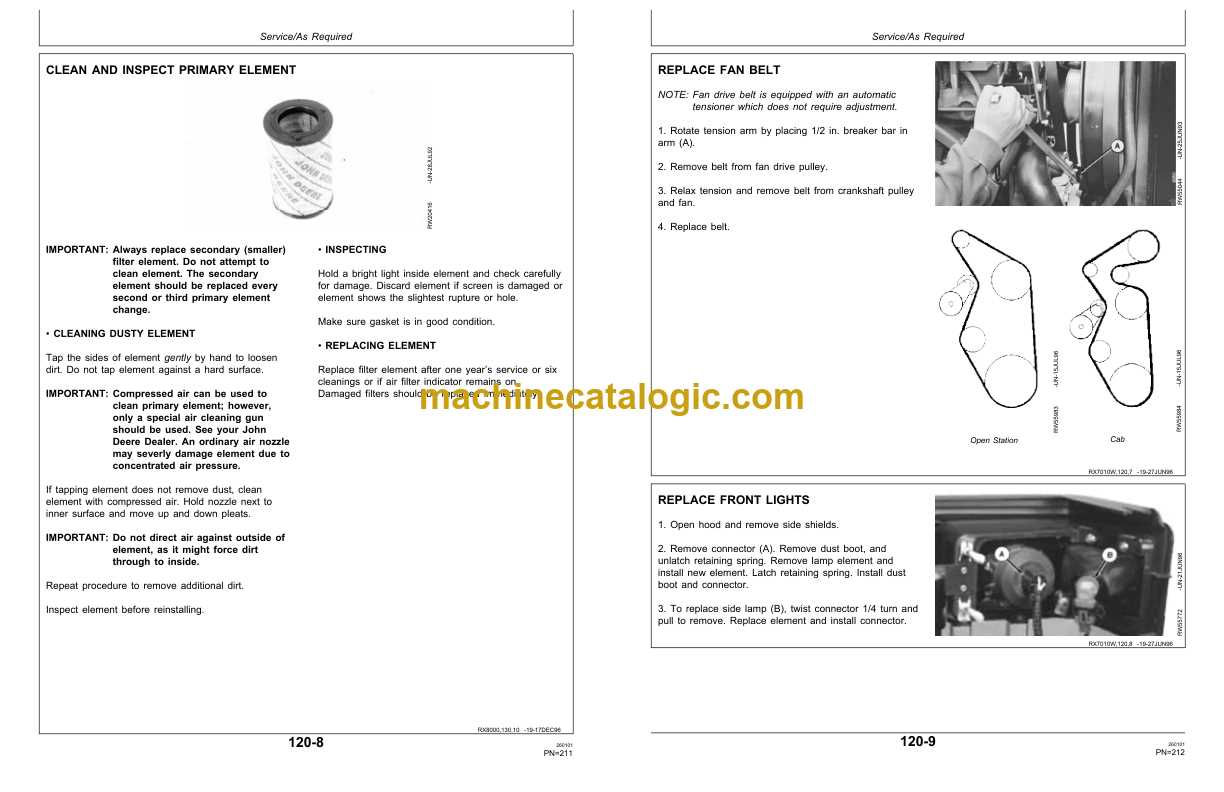

One of the most common complications involves engine performance. Symptoms may include rough idling, reduced power, or stalling. These issues can often be traced back to fuel quality or air intake blockages. To address this, ensure that fuel filters are clean and that the fuel used is free from contaminants. Regularly checking the air filters and replacing them when necessary can also significantly enhance engine performance.

Hydraulic System Failures

Hydraulic system failures are another frequent concern. Users might notice slow or unresponsive hydraulic functions, which can be indicative of low fluid levels or leaks. To resolve these issues, first check the hydraulic fluid level and top it up if necessary. Inspecting hoses and connections for any signs of wear or damage will help identify potential leaks, allowing for timely repairs to restore functionality.

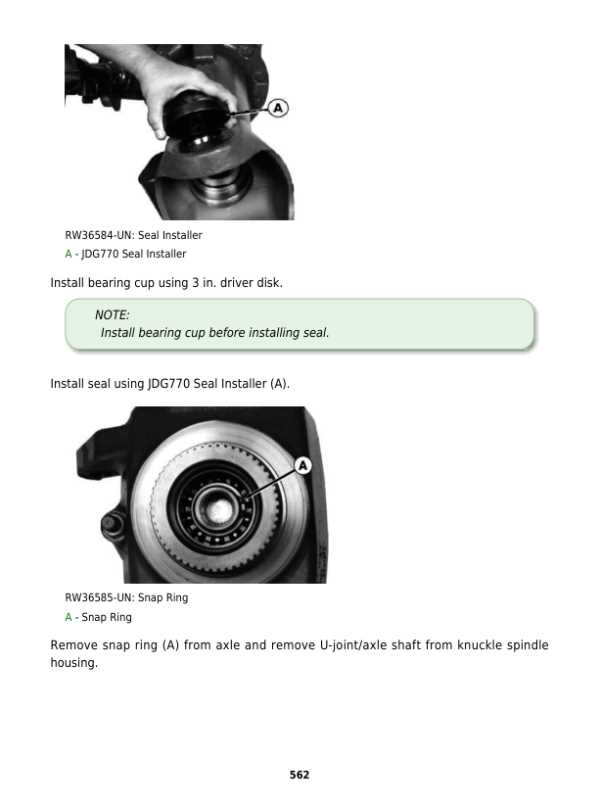

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right equipment is crucial. The effectiveness of any maintenance task largely depends on the quality and appropriateness of the tools used. A well-equipped toolkit not only enhances efficiency but also ensures safety during the process. Understanding which tools are indispensable can make all the difference in achieving successful outcomes.

Basic Hand Tools

Hand tools form the foundation of any maintenance task. These are versatile and essential for various functions, from tightening bolts to making precise adjustments. Here are some of the must-have hand tools:

| Tool | Purpose |

|---|---|

| Wrenches | Loosening and tightening nuts and bolts. |

| Screwdrivers | Driving screws in and out. |

| Plier Set | Gripping, twisting, and cutting wire. |

| Socket Set | Providing a more secure grip on fasteners. |

Specialized Equipment

In addition to basic tools, certain specialized equipment can greatly enhance the repair process. These tools cater to specific tasks that require precision and strength:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensuring proper tension on fasteners. |

| Multimeter | Measuring electrical properties. |

| Hydraulic Jack | Lifting heavy components safely. |

| Diagnostic Scanner | Identifying issues through error codes. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your equipment in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of your machinery. Follow these outlined steps to ensure that your device operates smoothly and efficiently.

-

Gather Necessary Tools and Supplies:

- Wrenches and sockets

- Screwdrivers

- Oil and lubricants

- Filters

- Cleaning supplies

-

Inspect the Equipment:

- Check for visible signs of wear and tear.

- Look for leaks in fluids.

- Ensure all safety features are functioning properly.

-

Change the Oil:

- Warm up the engine slightly to thin the oil.

- Drain the old oil completely.

- Replace the oil filter.

- Fill with new oil according to the manufacturer’s specifications.

-

Replace Filters:

- Air filter: Clean or replace as necessary.

- Fuel filter: Check and replace if needed.

-

Check Belts and Hoses:

- Inspect for cracks or fraying.

- Ensure all connections are secure.

- Replace any damaged components.

-

Grease Moving Parts:

- Apply lubricant to all pivot points.

- Use appropriate grease for specific components.

-

Test Functionality:

- Start the engine and listen for unusual sounds.

- Check all controls and indicators.

- Perform a test run to ensure everything operates smoothly.

By following these steps, you can maintain your machinery effectively, ensuring that it remains reliable and ready for any task at hand.

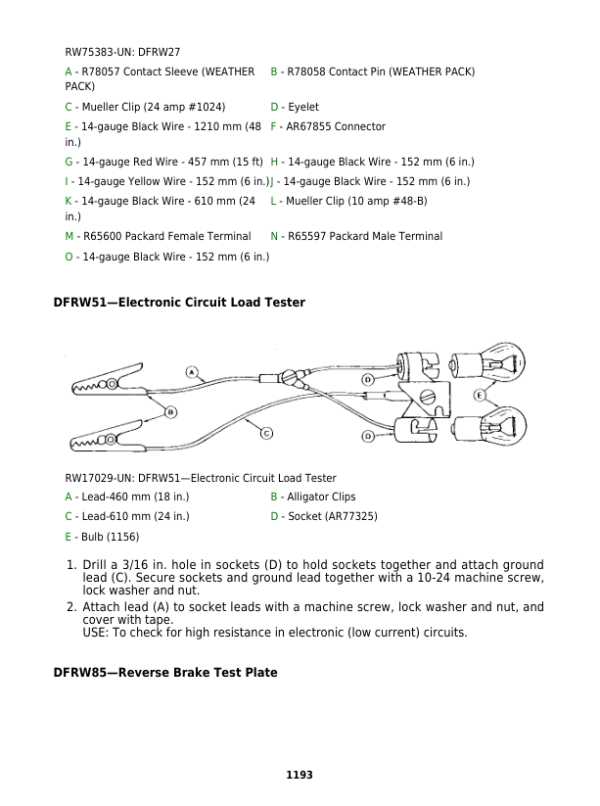

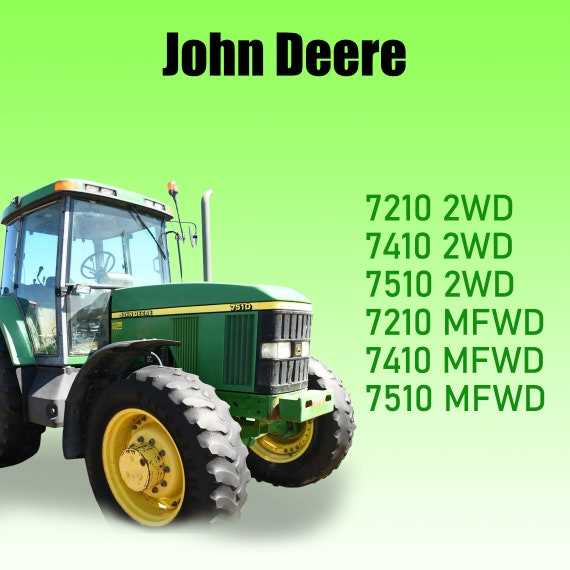

Electrical System Troubleshooting Tips

Maintaining the electrical components of machinery is crucial for optimal performance and longevity. Understanding common issues and applying systematic approaches can significantly enhance the reliability of the system. Below are some practical strategies to assist in identifying and resolving electrical faults effectively.

1. Check the Battery Voltage: Always start by inspecting the battery voltage. A weak or discharged battery can lead to various malfunctions. Use a multimeter to ensure the voltage is within the recommended range.

2. Inspect Wiring and Connectors: Visually examine all wiring and connectors for signs of wear, corrosion, or damage. Loose or frayed connections can disrupt the electrical flow and cause intermittent issues.

3. Test Fuses and Relays: Blown fuses or faulty relays can prevent components from receiving power. Replace any defective fuses and test relays to ensure they are functioning correctly.

4. Use Diagnostic Tools: Employ diagnostic tools to read error codes from the control module. This can provide valuable insights into specific problems within the electrical system.

5. Follow a Systematic Approach: When troubleshooting, follow a logical sequence, starting from the power source and moving through to the component in question. This method reduces the chances of overlooking critical aspects.

6. Consult Wiring Diagrams: Reference wiring diagrams to understand the layout and connections of the electrical system. This will aid in identifying potential trouble spots quickly.

By implementing these tips, you can enhance your troubleshooting skills and effectively address electrical issues, ensuring your equipment remains in top condition.

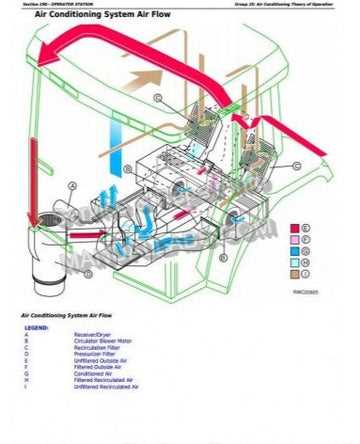

Hydraulic System Maintenance Procedures

Maintaining the hydraulic system is crucial for ensuring optimal performance and longevity of agricultural machinery. Regular upkeep helps prevent breakdowns and enhances the efficiency of various hydraulic functions. This section outlines essential procedures to keep the hydraulic components in excellent condition.

Regular Fluid Checks

Monitoring hydraulic fluid levels is vital. Low fluid levels can lead to inadequate lubrication and overheating. Check the reservoir regularly and top off with the recommended type of hydraulic fluid. Cleanliness is equally important; ensure that the fluid remains free from contaminants, which can cause wear and reduce efficiency.

Filter Inspection and Replacement

Hydraulic filters play a critical role in removing impurities from the fluid. Inspect these filters routinely and replace them as needed. A clogged filter can restrict fluid flow, resulting in poor system performance. Regular replacement not only protects components but also extends the lifespan of the entire hydraulic system. Be proactive to ensure seamless operation and reliability.

Engine Performance Enhancements

Boosting the efficiency and output of an engine can significantly improve overall functionality and responsiveness. Various modifications and upgrades can lead to enhanced power, better fuel economy, and improved durability. This section explores effective strategies to elevate engine performance.

Key Enhancement Strategies

- Tuning the engine control unit (ECU) for optimal performance.

- Upgrading the air intake system to increase airflow.

- Installing a high-performance exhaust system for better exhaust flow.

- Using premium fuels that enhance combustion efficiency.

- Regular maintenance to ensure all components operate at peak efficiency.

Potential Benefits

- Increased horsepower and torque.

- Improved fuel efficiency, leading to cost savings.

- Enhanced throttle response for a more dynamic driving experience.

- Longer engine life through reduced stress on components.

Using Diagnostic Equipment Effectively

Utilizing diagnostic tools can significantly enhance troubleshooting and maintenance processes for various machinery. These devices provide valuable insights into operational issues, allowing for accurate assessments and efficient solutions.

To maximize the effectiveness of diagnostic equipment, consider the following strategies:

- Familiarize Yourself: Understand the specifications and functionalities of the tools at your disposal. Comprehensive knowledge ensures proper usage.

- Regular Calibration: Keep diagnostic devices calibrated to maintain accuracy. Regular checks help avoid discrepancies in readings.

- Data Analysis: Learn to interpret the data generated. Recognizing patterns can lead to quicker identification of underlying problems.

- Stay Updated: Follow manufacturer updates or software upgrades to ensure compatibility and access to new features.

Implementing these practices can lead to more effective diagnostics and ultimately extend the lifespan of equipment.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance on machinery is crucial for preventing accidents and injuries. Adhering to specific guidelines and protocols can significantly reduce risks associated with technical work. Awareness and preparation are key components of a safe working atmosphere.

Essential Safety Measures

Prior to beginning any service task, it’s vital to implement the following precautions:

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and helmets to shield against potential hazards. |

| Proper Ventilation | Ensure the workspace is well-ventilated to avoid inhaling harmful fumes or dust. |

| Disconnect Power Sources | Before starting work, make sure to disconnect batteries or unplug equipment to prevent accidental startups. |

| Use of Tools | Utilize tools that are in good condition and suitable for the task to avoid injuries. |

Emergency Preparedness

In the event of an accident, having a plan is essential. Familiarize yourself with the location of first aid kits and emergency exits. Additionally, ensure that fire extinguishers are accessible and properly maintained. Training in basic first aid can be invaluable and enhance overall safety during technical operations.

Finding Replacement Parts Easily

Locating suitable components for machinery can often feel daunting, but with the right strategies, it becomes a straightforward task. Understanding the available resources and knowing where to search can significantly simplify the process of acquiring essential items.

One effective method is to utilize online platforms that specialize in spare components. These websites typically offer extensive catalogs that allow users to search by part numbers, equipment models, or even specific descriptions. This not only saves time but also helps in comparing prices and availability.

Additionally, connecting with local dealers and suppliers can provide immediate access to necessary items. Establishing a good relationship with these vendors can also yield helpful advice and insights on alternative options when specific parts are not readily available.

| Resource Type | Benefits |

|---|---|

| Online Retailers | Wide selection, price comparisons, user reviews |

| Local Suppliers | Quick access, personalized service, expert advice |

| Manufacturer Websites | Original parts, warranty information, technical support |

| Online Forums | Community support, shared experiences, alternative solutions |

By leveraging these resources, individuals can enhance their ability to find the necessary components quickly and efficiently, ensuring that their machinery remains in optimal working condition.

Upgrading Your John Deere 7410

Enhancing the performance and functionality of your agricultural machinery can lead to significant improvements in productivity. Whether you’re looking to increase efficiency, improve comfort, or boost capability, there are numerous ways to elevate your equipment.

Benefits of Upgrading

- Increased efficiency in operations

- Enhanced comfort for the operator

- Improved fuel economy

- Greater versatility with attachments

Key Areas for Improvement

- Engine Performance: Consider installing a performance chip or tuning module to optimize power output.

- Hydraulic System: Upgrading hoses and pumps can enhance lifting capabilities and responsiveness.

- Cab Comfort: Adding ergonomic seats, improved climate control, or advanced sound insulation can significantly enhance the operator’s experience.

- Technology Integration: Implementing GPS and precision farming technologies can streamline operations and improve yield monitoring.