Maintaining outdoor power tools requires an understanding of their components, as well as the skills needed to address any challenges that arise over time. This guide provides insights into diagnosing common issues and offers step-by-step instructions for ensuring optimal function. From mechanical adjustments to preventative care, each section is designed to help users keep their equipment in peak condition.

Power equipment often faces wear and tear due to frequent use and exposure to outdoor elements. Knowing how to address these challenges can extend the lifespan of the machine. This guide explores common symptoms of malfunctions, essential checks for each part, and practical solutions that enable users to resolve these issues efficiently.

In addition to troubleshooting, regular upkeep practices are highlighted to prevent future breakdowns. Readers will find information on inspecting mechanical parts, recognizing when replacements are needed, and making simple fixes that improve overall performance. The goal is to empower users with the knowledge and confidence to handle various tasks, ensuring equipment longevity and reliability.

Honda Self-Propelled Lawn Mower Repair Manual

This section provides essential guidance for maintaining and troubleshooting your gardening device. Proper care can enhance performance and longevity, ensuring optimal functionality during use. Whether addressing minor issues or conducting routine maintenance, understanding the key components and procedures is crucial.

Understanding Common Issues

Identifying frequent challenges can simplify the troubleshooting process. From engine difficulties to handling malfunctions, recognizing symptoms early can save time and effort. Ensure that you familiarize yourself with the common problems that may arise, such as starting failures or irregular movement.

Maintenance Practices

Regular upkeep is vital for peak performance. Performing routine checks on vital parts, including the power unit and drive system, will help you avoid unexpected breakdowns. Adopting best practices for cleaning and lubricating components will significantly contribute to the longevity of your device.

Identifying Common Lawn Mower Problems

Understanding the frequent issues that can arise with grass cutting machines is essential for maintaining their functionality and performance. By recognizing these challenges, users can take appropriate measures to address them promptly, ensuring a well-kept outdoor space.

Here are some common complications that one might encounter:

- Engine Won’t Start: This can stem from various reasons such as fuel blockage, spark plug issues, or battery problems.

- Inconsistent Cutting: When the cutting device struggles to maintain even heights, it may be due to dull blades or uneven wheel alignment.

- Excessive Vibration: Unusual shaking can indicate loose components or imbalanced blades.

- Smoke Emission: If visible smoke appears, it could signal engine overheating or oil leaks.

- Difficulty in Maneuvering: If steering becomes hard, check for obstructions or tire issues.

Regular maintenance and early detection of these problems can significantly prolong the lifespan of your equipment. Keeping a checklist for routine checks can also help in identifying issues before they escalate.

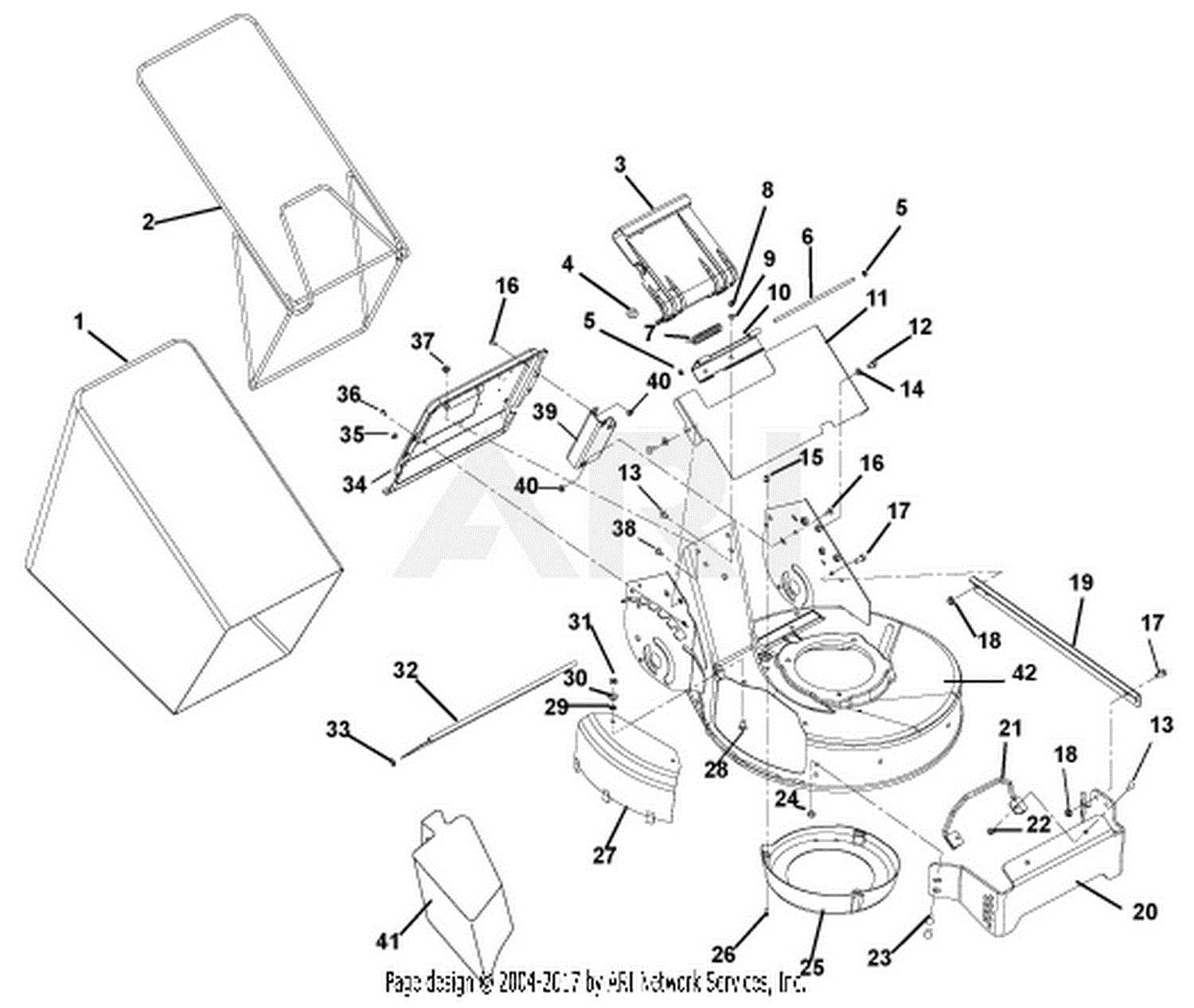

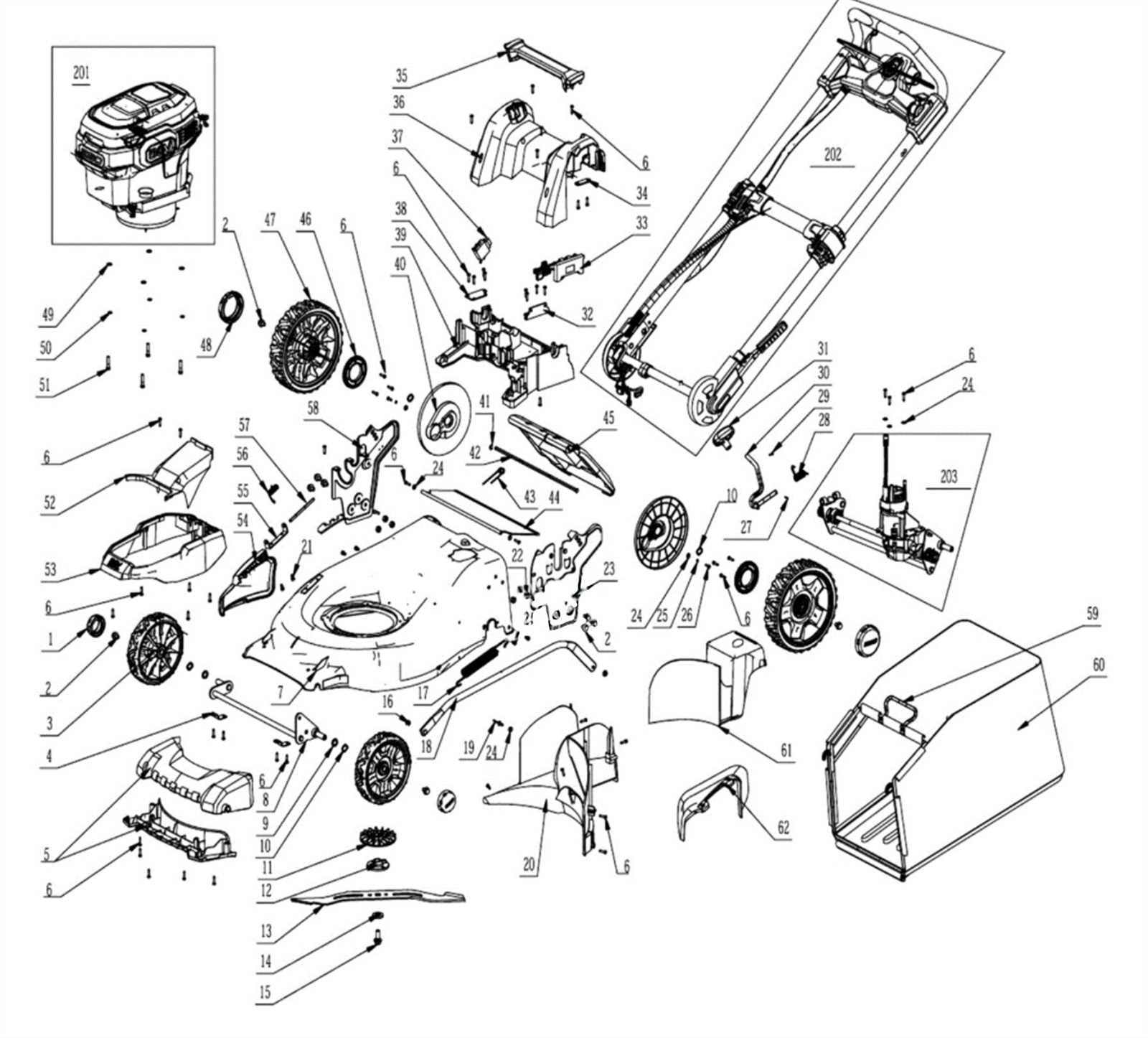

Understanding the Self-Propelled Drive System

The drive mechanism of a garden equipment unit designed for grassy areas is essential for its operation, allowing for efficient movement across various terrains. This system is composed of several components that work in harmony to ensure smooth functionality.

Key elements of this drive mechanism include:

- Transmission: This component controls the speed and direction of the unit, enabling it to adapt to different mowing conditions.

- Drive Wheels: These wheels receive power from the transmission and propel the device forward, allowing for ease of movement.

- Control Handle: Operators utilize this feature to adjust speed and maintain control while navigating the equipment.

Understanding how these components interact can aid in diagnosing issues and performing maintenance effectively. Regular inspection of the drive mechanism can prevent common problems and enhance performance.

For optimal operation, consider the following maintenance tips:

- Check the drive belt for wear and replace if necessary.

- Ensure that the transmission is adequately lubricated.

- Inspect the wheels for damage or debris that may hinder movement.

By familiarizing oneself with the intricacies of the drive system, users can improve the longevity and reliability of their equipment, ensuring it remains a valuable tool for maintaining grassy areas.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By following a consistent maintenance routine, you can enhance performance and prevent potential issues that may arise over time.

- Regular Cleaning: Keep the exterior and components free of debris and grass clippings to prevent buildup and corrosion.

- Check the Oil: Frequently inspect and change the lubricant according to the manufacturer’s recommendations to ensure smooth operation.

- Sharpen the Blades: Maintain sharp cutting edges for a clean cut, which reduces strain on the engine and improves overall effectiveness.

- Inspect the Air Filter: Clean or replace the filter as needed to ensure proper airflow, enhancing performance and efficiency.

- Examine the Spark Plug: Regularly check the spark plug for wear and replace it if necessary to guarantee reliable starting and operation.

- Fuel Quality: Use fresh fuel and consider adding a stabilizer if storing for extended periods to prevent degradation and starting issues.

Implementing these practices not only enhances the functionality of your equipment but also helps in extending its lifespan, ensuring you get the most out of your investment.

Essential Tools for Lawn Mower Repairs

When maintaining outdoor equipment, having the right instruments is crucial for effective service and upkeep. Proper tools not only enhance efficiency but also ensure safety during the process.

Among the fundamental items, wrenches and screwdrivers are essential for loosening and tightening various components. These hand tools come in different sizes to accommodate a range of fasteners. Socket sets are equally important, allowing for easier access to hard-to-reach areas.

Another vital aspect includes cleaning supplies, which help remove dirt and debris from the machinery. A wire brush is particularly useful for clearing stubborn buildup, while compressed air can effectively blow away loose particles.

Lastly, protective gear such as gloves and safety glasses should not be overlooked. These items ensure that individuals remain safe while handling tools and equipment, minimizing the risk of injury during maintenance tasks.

Inspecting and Cleaning the Carburetor

Regular examination and maintenance of the fuel delivery component are essential for optimal engine performance. This process ensures that fuel flows smoothly and that any buildup of residues is addressed, preventing potential operational issues.

Preparation for Inspection

Before starting the examination, ensure the engine is off and cool. Disconnect the spark plug to avoid accidental starts. Gather necessary tools such as a screwdriver, a cleaning brush, and carburetor cleaner for an effective cleaning process.

Steps to Clean

Begin by removing the air filter to access the fuel system easily. Carefully detach the carburetor from the engine, taking note of the position of each part for reassembly. Use the cleaner to eliminate deposits and debris from the component. Pay special attention to the jets and passages, as these areas are prone to clogging. Once cleaned, reassemble the parts and reconnect them to the engine.

Following these steps will enhance the efficiency and longevity of your equipment, ensuring it operates smoothly.

Troubleshooting the Engine Ignition System

Addressing issues related to the ignition mechanism is essential for maintaining optimal performance. When starting difficulties or irregular operation occur, it’s crucial to investigate various components that contribute to ignition efficiency.

Consider the following steps to diagnose potential problems:

- Inspect the Spark Plug:

- Check for wear or damage.

- Ensure proper gap measurement.

- Clean or replace if necessary.

- Examine the Ignition Coil:

- Verify the connections and wiring for any signs of corrosion or breakage.

- Test for continuity using a multimeter.

- Evaluate the Battery:

- Confirm that it is adequately charged.

- Check terminals for cleanliness and secure connections.

- Assess the Safety Switches:

- Ensure that all safety mechanisms are engaged properly.

- Inspect for faulty wiring or malfunctioning components.

By systematically examining these areas, you can identify and resolve issues within the ignition system, leading to improved functionality.

Adjusting Drive Belt Tension and Alignment

Maintaining the proper tension and alignment of the drive belt is crucial for optimal performance and longevity of the equipment. Ensuring these aspects are correctly adjusted can prevent slippage and extend the life of the components involved. This section outlines the steps necessary to achieve the ideal settings.

Begin by examining the current tension of the drive belt. It should be snug enough to avoid slippage yet loose enough to prevent excessive wear. Use the following table to determine the appropriate tension levels based on your specific model’s specifications.

| Model | Recommended Tension (lbs) | Alignment Check (degrees) |

|---|---|---|

| Model A | 10-15 | 5-10 |

| Model B | 12-18 | 8-12 |

| Model C | 15-20 | 10-15 |

To adjust the tension, locate the tensioner mechanism, typically found near the drive system. Loosen the adjustment bolt and modify the position of the tensioner to achieve the recommended tension. Once adjusted, tighten the bolt securely to maintain the new setting.

Next, verify the alignment of the drive belt. Misalignment can cause premature wear and inefficient operation. Check the belt’s path and ensure it sits evenly on all pulleys. If misaligned, adjust the position of the pulleys or the mounting brackets accordingly, ensuring everything is properly secured afterward.

Regular checks and adjustments will contribute to smoother operation and enhance the lifespan of the drive components. Adhering to these guidelines will help maintain efficient functionality.

Replacing Worn or Damaged Blades

Maintaining the cutting elements of your equipment is essential for optimal performance. Over time, blades can become dull or suffer from wear, affecting the quality of the cut. Timely replacement ensures that your device operates efficiently and provides the desired results.

Identifying When to Replace

Recognizing the signs of wear is crucial. Look for uneven cuts, fraying edges, or noticeable damage to the blades. If the cutting performance diminishes, it’s time to consider a replacement. Regular inspections can help in early detection and prolong the lifespan of your equipment.

Steps for Replacement

Begin by disconnecting the power source to ensure safety. Next, tilt the machine to access the blades easily. Remove the fastening bolts using appropriate tools, taking care to note the orientation of the blades. Install the new cutting elements in the same position, securing them firmly. Finally, restore the machine to its upright position and reconnect the power before testing the performance.

Fixing Issues with Fuel Line Blockages

Blockages within the fuel delivery system can significantly hinder the performance of equipment. Identifying and addressing these issues is essential for ensuring smooth operation and optimal efficiency. Below are common causes of obstructions and steps to resolve them.

- Common Causes:

- Dirt and debris accumulation

- Old or contaminated fuel

- Cracked or damaged lines

- Improperly seated connections

To effectively tackle these challenges, follow these steps:

- Inspect Fuel Lines:

Examine all fuel lines for signs of wear, cracks, or blockages. Replace any damaged components to restore proper flow.

- Clean the Fuel Filter:

If your system includes a fuel filter, ensure it is clean and free from obstructions. Replace it if necessary.

- Use Fresh Fuel:

Always utilize fresh fuel that meets the manufacturer’s specifications. Discard any old or contaminated fuel before refueling.

- Clear Blockages:

If blockages are detected, use appropriate tools to carefully clear the lines. Ensure no debris is left behind that could cause future issues.

By following these guidelines, you can effectively resolve fuel delivery issues and maintain the efficiency of your equipment.

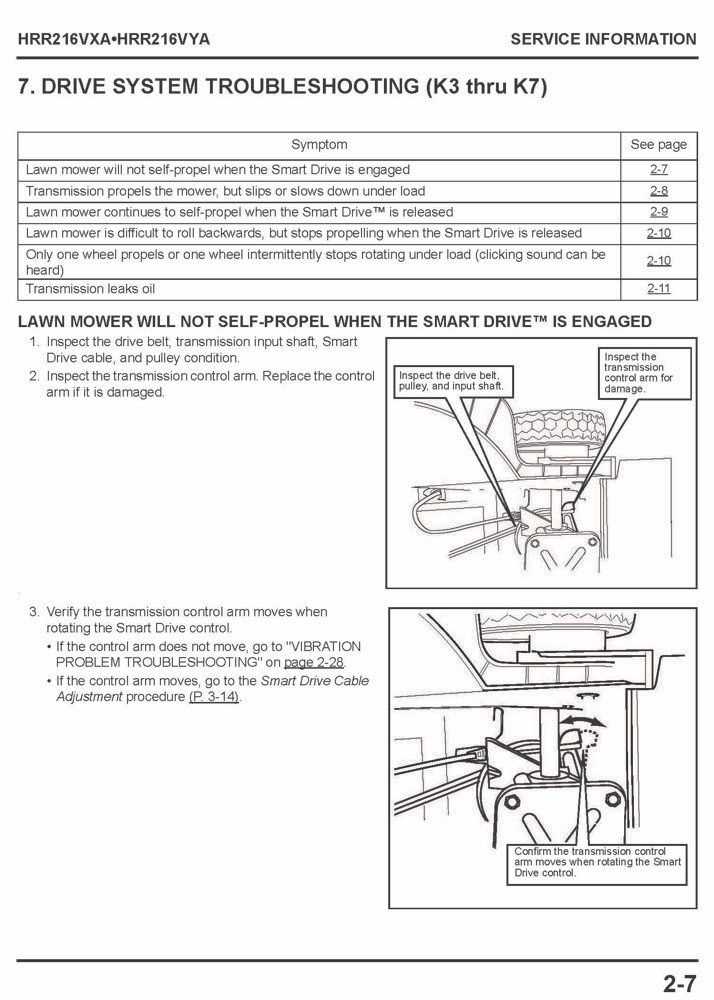

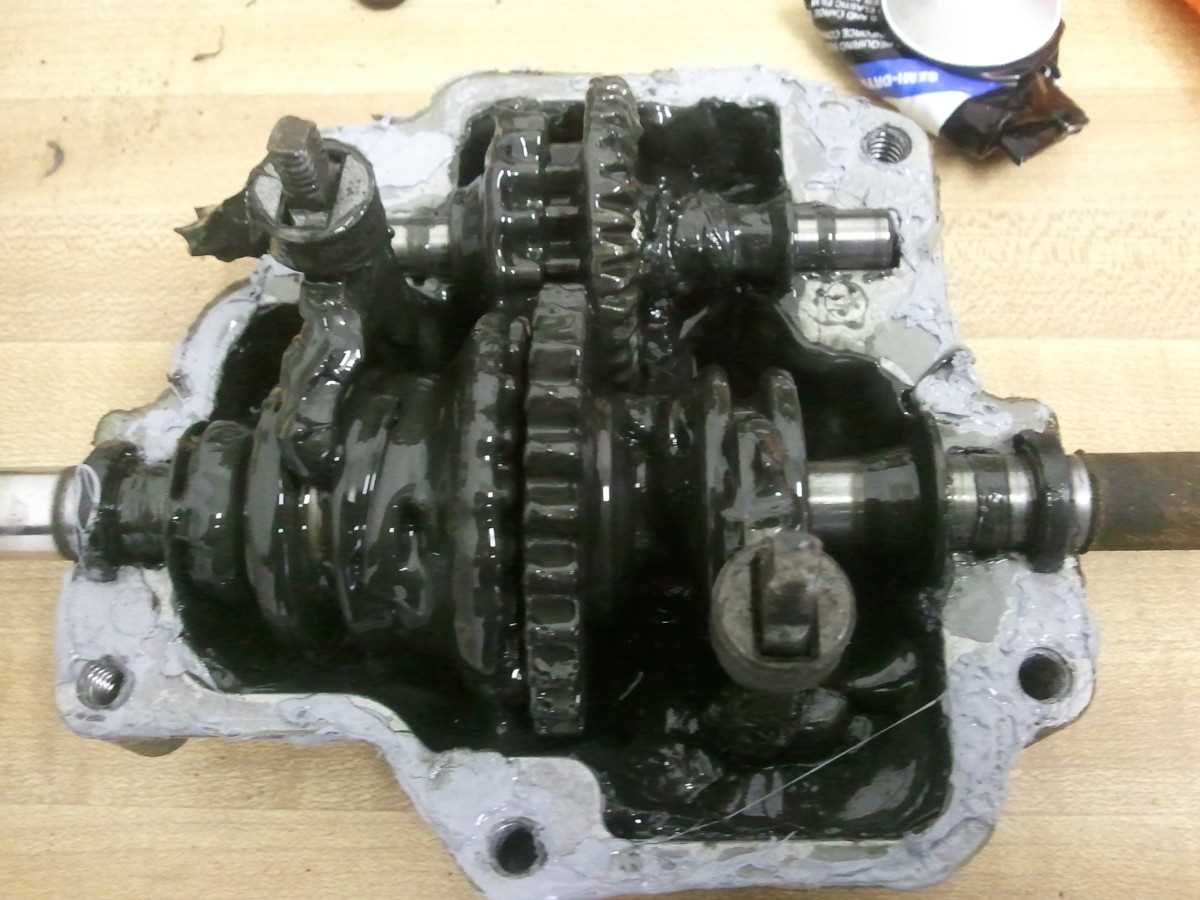

Understanding the Transmission Mechanics

The mechanics behind the transmission system are crucial for ensuring smooth operation and optimal performance of the equipment. This section delves into the essential components and functions of this system, providing insights into how they work together to facilitate movement.

Key Components of the Transmission System

- Gears: These elements play a vital role in adjusting the speed and torque, enabling effective power transfer.

- Belts: They serve as connectors between various parts, allowing for flexibility and smooth operation during transitions.

- Clutches: These devices engage and disengage components, ensuring that power is distributed appropriately based on the operator’s input.

Common Issues and Troubleshooting

Understanding potential problems within the transmission system can aid in effective maintenance and enhance longevity. Some common issues include:

- Slipping Gears: This can indicate worn components or improper adjustments.

- Noisy Operation: Unusual sounds may suggest misalignment or lack of lubrication.

- Inconsistent Speed: Fluctuations in performance often point to issues with belts or clutches.

Checking and Replacing Spark Plugs

Maintaining optimal performance in outdoor power equipment often hinges on the condition of essential components. Among these, the ignition element plays a crucial role in ensuring the engine operates efficiently. Regular inspection and replacement of this part can prevent operational issues and enhance the longevity of the device.

Identifying the Need for Replacement

Signs indicating that this element requires attention include difficulty starting, uneven acceleration, or decreased power output. Additionally, a visual inspection may reveal deposits or wear that suggest it’s time for a change. Regular checks are recommended to catch any issues early, avoiding more extensive problems down the line.

Steps for Replacement

To replace the ignition component, first ensure the equipment is turned off and disconnected from any power source. Using a spark plug wrench, carefully remove the old part. Inspect the new component for compatibility and proper gap settings. Install it by hand, ensuring a snug fit, and finally reconnect everything as needed. Proper reinstallation is key to restoring functionality.

Battery Care for Electric Start Models

Maintaining the power source in electric ignition devices is crucial for ensuring optimal performance and longevity. Proper attention to the battery not only enhances reliability but also contributes to the efficiency of the overall machinery. Following a few essential practices can help users maximize the lifespan and effectiveness of their units.

Regular inspections and maintenance routines are necessary to keep the power unit in good working order. Below are some key points to consider:

| Tip | Description |

|---|---|

| Charge Regularly | Ensure the battery is charged fully before use. Avoid letting it discharge completely, as this can reduce its lifespan. |

| Keep Clean | Regularly clean the terminals to prevent corrosion, which can hinder connectivity and performance. |

| Store Properly | If not in use for an extended period, store the battery in a cool, dry place, ideally at a partial charge. |

| Check Water Levels | For maintenance-free batteries, ensure water levels are adequate, if applicable. Refill with distilled water when necessary. |

By adhering to these maintenance practices, users can ensure their electric ignition systems remain functional and efficient, avoiding potential issues down the line.