Understanding the basics of upkeep for your compact scooter ensures not only prolonged functionality but also enhances the riding experience. This section covers essential maintenance tips and common troubleshooting steps, providing reliable solutions to a variety of technical challenges. Whether you’re new to two-wheelers or have years of experience, these insights will help keep your scooter in top condition.

Routine care is key to preventing issues before they arise. Regular attention to parts such as the engine, tires, and battery can significantly extend the life of your vehicle. Following these easy-to-apply recommendations, you’ll be equipped to handle the primary needs of your ride without professional assistance, saving both time and resources.

For those unexpected moments when problems do occur, the following guidelines cover effective methods for identifying and resolving common mechanical and electrical issues. With step-by-step instructions, even complex tasks become manageable. This guide empowers every enthusiast to confidently address common obstacles and maintain their scooter in peak condition.

Honda Spree Maintenance Guide

Regular upkeep is essential to ensure the reliability and longevity of your scooter. By following basic care routines, riders can prevent common issues and enhance the performance of their vehicle.

Routine Inspections

Conducting regular inspections will help identify potential problems early. Pay close attention to areas that experience frequent wear and tear, and always check the condition of essential components before each ride.

- Fluid Levels: Monitor and top up as needed. Ensuring fluids are at proper levels helps avoid unnecessary strain on the engine.

- Tire Pressure: Check weekly to ensure optimal grip and stability. Proper inflation extends tire life and improves control.

- Brake System: Verify brake response and inspect pads for wear. Reliable brakes are vital for safe operation.

Cleaning and Lubrication

Regular cleaning and lubrication play a critical role in maintaining peak performance. A well-kept exterior and properly oiled parts reduce friction and prevent corrosion.

- Clean

Engine Troubleshooting Tips

Maintaining a well-functioning engine is essential for smooth performance and longevity. Understanding common engine issues and knowing how to address them can prevent minor problems from escalating. Below are some practical troubleshooting tips to help identify and resolve frequent engine challenges.

- Check Fuel Quality: Low-quality or old fuel can lead to performance issues. Ensure the fuel is fresh and meets recommended standards.

- Inspect Spark Plug Condition: A worn or fouled spark plug can cause starting problems and affect engine performance. Regularly clean and replace the spark plug as necessary.

- Examine Air Filter: A clogged air filter restricts airflow, impacting engine efficiency. Clean or replace it regularly to ensure optimal air intake.

- Monitor Oil Levels: Insufficient or dirty oil can damage internal components. Regularly check oil levels and change it as recommended to maintain proper lubrication.

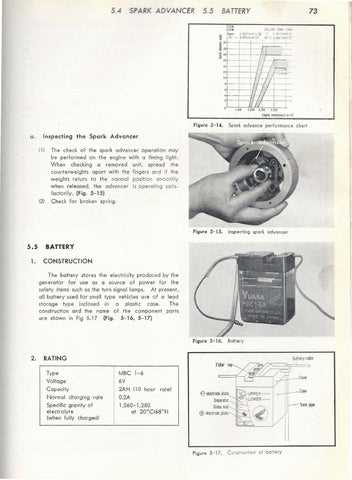

Battery Care and Replacement Steps Keeping the power source in top condition ensures reliable performance and prolongs the lifespan of the entire system. Regular attention to cleaning, charging, and periodic checks helps avoid unexpected issues and supports optimal energy retention.

Inspection and Cleaning: Begin by examining the battery for any signs of wear or corrosion around the terminals. Clean connections with a soft brush to remove any residue, which may obstruct proper power flow. Avoid using harsh chemicals, as they can damage sensitive components.

Charging Guidelines: Ensure the battery receives an adequate charge but avoid overcharging. Use a charger that matches the specifications of the power source to maintain stable performance. If the battery is not in regular use, consider periodic charging to prevent it from losing capacity over time.

Replacement Procedure: When replacing the battery, start by disconnecting it carefully, removing the negative terminal first to reduce risk. Handle the unit gently, avoiding any excessive pr

Fuel System Inspection Process

In this section, we will explore the essential steps to evaluate and maintain the fuel system’s effectiveness. A well-functioning fuel system is critical for optimal engine performance, ensuring smooth operation and preventing potential issues that may arise from impurities or component wear. This guide offers a systematic approach to examining each element within the system.

Initial Safety Measures

Before starting, make sure the engine is cool to prevent any risk of fire or burns. Work in a well-ventilated area and disconnect the power source to minimize hazards. Having the right tools and protective equipment will also aid in ensuring safety during this process.

Inspecting Key Components

Fuel lines are the first components to inspect for any cracks, leaks, or signs of wear. Replace any damaged lines immediately to avoid interruptions in fuel flow. Next, check the filter to ensure it is free from clogs

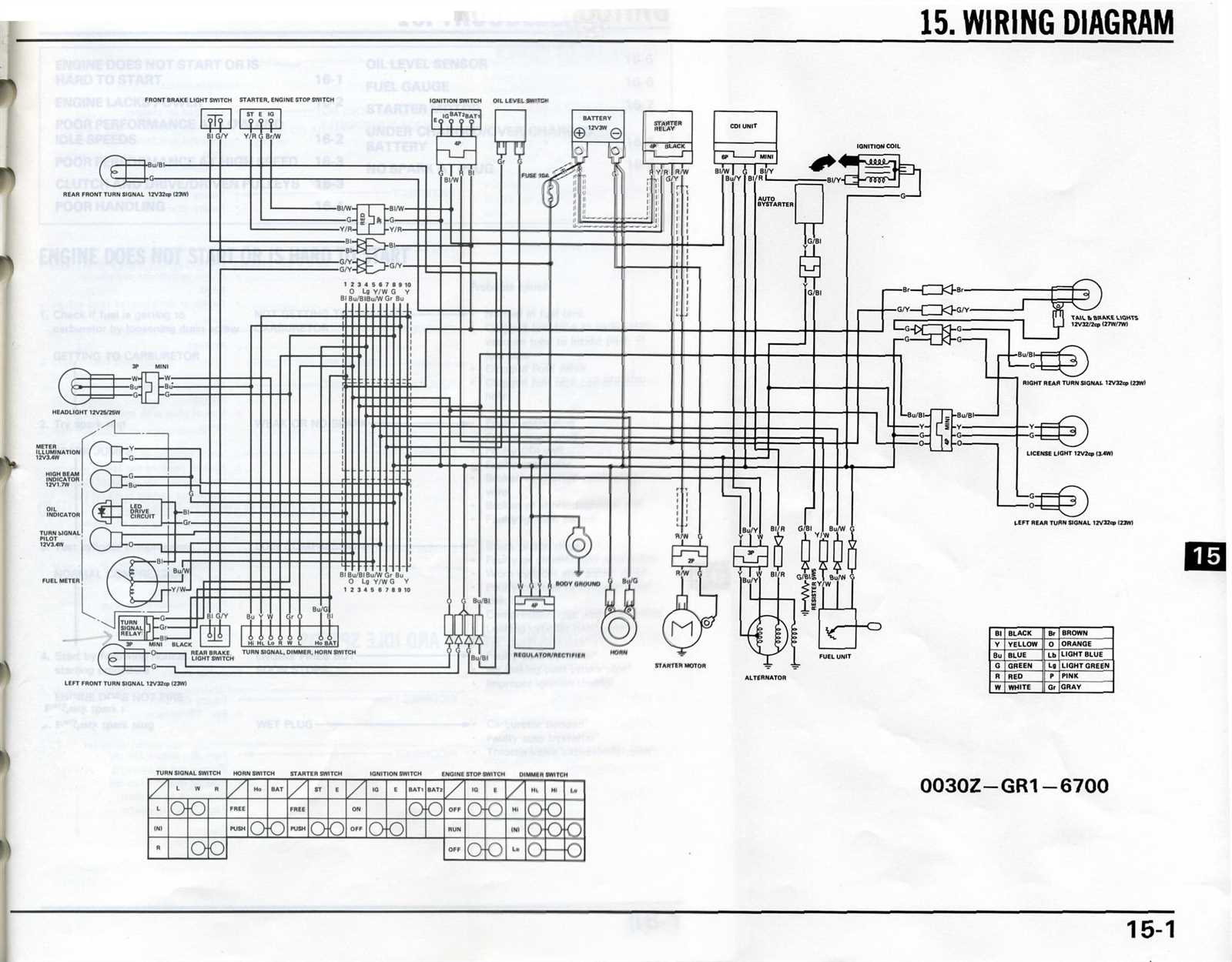

Understanding Electrical System Components

The electrical system in a motorized vehicle plays a crucial role in powering essential functions, from ignition to lighting. Comprehending the key elements of this system can help users recognize potential issues and maintain optimal performance. This section explores the primary parts involved in generating and managing electric power, ensuring the proper operation of various mechanisms.

Main Power Source

At the heart of the electrical system lies the main power source, often a battery that stores energy to be distributed as needed. This component is responsible for delivering the necessary initial power to start the engine and support electronic devices. Regularly checking the charge and connections of this power source is essential for consistent functionality.

Charging and Distribution

The charging and distribution units ensure that energy levels remain stable during operation. A charging device, like an alternator, replenishes the power source while redistribu

Brake System Adjustment Techniques

Ensuring optimal performance of the braking mechanism is crucial for safety and efficiency. Proper calibration of the braking system enhances responsiveness and prevents premature wear of components. This section provides essential techniques for adjusting the braking apparatus to maintain its effectiveness.

Common Adjustment Methods

- Lever Adjustment: Check the position of the brake lever to ensure it is comfortable to operate. Adjust the lever reach if necessary to improve control.

- Pad Alignment: Ensure the brake pads are aligned correctly with the rotor. Misalignment can lead to uneven wear and reduced braking power.

- Spring Tension: Examine the tension of the brake springs. Adjusting the tension can affect the feel and responsiveness of the braking action.

Maintenance Tips

- Regularly inspect the brake components for wear and damage.

- Clean the braking surfaces to remove dust and debris that can hinder performance.

- Lubricate moving parts where applicable to ensure smooth operation.

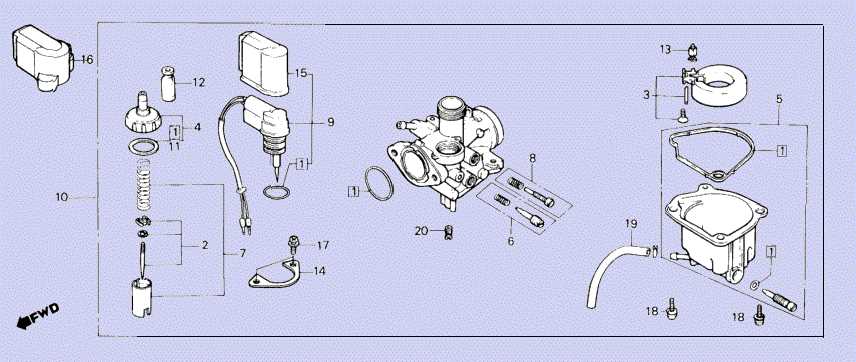

Cleaning and Tuning the Carburetor

Maintaining optimal performance of the engine requires regular attention to the fuel delivery system. Ensuring that the carburetor is clean and properly adjusted can significantly enhance efficiency and responsiveness. This section provides essential guidance on the best practices for achieving a well-tuned fuel system.

Initial Inspection is crucial before diving into the cleaning process. Start by checking for any visible signs of dirt or residue around the carburetor. If you notice any blockages or buildup, it may affect the overall function and lead to performance issues.

To clean the carburetor, remove it from the engine carefully, following the manufacturer’s guidelines. Use a suitable cleaner to remove grime and deposits, paying special attention to jets and passages. After soaking and scrubbing, rinse thoroughly with clean fuel to ensure all residues are eliminated.

Once cleaned, tuning involves adjusting the air-fuel mixture and idle speed. Begin by locating the adjustment screws and turning them according to the specifications. It is important to make small adjustments and test the engine’s performance after each change. Fine-tuning ensures the engine runs smoothly and efficiently.

Regular cleaning and adjustment of the carburetor can prolong the lifespan of the engine and improve overall performance. Following these steps will help maintain a reliable and efficient fuel delivery system.

Tire Maintenance and Replacement Guide

Proper upkeep of wheels is essential for ensuring a smooth and safe riding experience. Regular checks and timely replacements can significantly enhance performance, extend lifespan, and improve overall safety. This section outlines key practices for maintaining and replacing tires effectively.

Regular Inspection

Conducting routine inspections is crucial for identifying wear and tear early on. Here are some important points to consider:

- Check tire pressure regularly; inadequate pressure can lead to uneven wear.

- Inspect tread depth using a gauge; insufficient tread can compromise traction.

- Look for any visible damage, such as cuts or punctures, and assess their severity.

Replacement Considerations

When it’s time to replace your wheels, consider the following factors:

- Choose tires that are compatible with your vehicle’s specifications.

- Decide on a suitable tread pattern based on your riding conditions.

- Ensure proper installation by seeking professional assistance if needed.

Essential Tools for Honda Spree Repair

Having the right equipment is crucial when working on your two-wheeled vehicle. Whether you’re performing maintenance or troubleshooting issues, a well-equipped workspace can significantly enhance efficiency and effectiveness.

Below is a list of essential items that will aid in the upkeep and servicing of your machine:

- Socket Set: A comprehensive socket set allows for the quick loosening and tightening of various bolts and nuts.

- Wrenches: Both adjustable and fixed wrenches are necessary for gripping and turning different sized fasteners.

- Screwdriver Set: Various types of screwdrivers are required to handle different screws, including Phillips and flathead options.

- Pliers: Needle-nose and regular pliers can assist in gripping small parts and wires effectively.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: This device is essential for diagnosing electrical issues, measuring voltage, and ensuring proper circuit function.

- Oil Filter Wrench: Useful for changing the oil filter easily, preventing spills and mess.

- Chain Tool: Necessary for adjusting or replacing the drive chain, ensuring smooth operation.

Investing in these tools not only facilitates easier maintenance but also prolongs the life of your vehicle. Having the correct instruments on hand can transform a daunting task into a manageable one.

How to Diagnose Common Issues

Identifying typical problems with your vehicle is essential for ensuring its optimal performance and longevity. By understanding the most frequent symptoms and conducting a systematic evaluation, you can determine the root cause of any malfunction. This section provides guidance on recognizing and addressing various common concerns that may arise.

Start by observing any unusual sounds or changes in performance. Pay attention to any irregularities in acceleration, braking, or handling. If the engine struggles to start or runs inconsistently, these could indicate deeper issues. A thorough inspection of essential components, including the fuel system, electrical connections, and exhaust, will often reveal underlying problems.

Additionally, check for visible signs of wear or damage. Fluid leaks, worn belts, or corroded connections can contribute to operational failures. Utilizing a checklist can help streamline the diagnostic process, ensuring that you cover all potential problem areas. By methodically assessing these factors, you can effectively troubleshoot and remedy issues before they escalate.

Lubrication Points and Best Practices

Proper maintenance of your vehicle’s components is essential for ensuring longevity and optimal performance. Regular lubrication minimizes wear and tear on moving parts, reduces friction, and prevents overheating. This section highlights key areas that require lubrication and offers best practices for effective maintenance.

Key Lubrication Areas

Identifying critical points for lubrication is vital. The following table outlines the primary locations that benefit from regular application of lubricant:

Component Recommended Lubricant Frequency of Application Engine components High-quality oil Every 500 miles Wheels and axles Grease Every 1000 miles Cables and levers Light lubricant As needed Chain Chain oil Every 300 miles Best Practices for Lubrication

To ensure effective lubrication, follow these best practices:

- Clean the component surface before applying any lubricant to avoid trapping dirt.

- Use the appropriate type of lubricant specified for each component.

- Do not over-lubricate, as excess can attract dirt and lead to buildup.

- Check and maintain lubrication levels regularly to avoid running dry.

Preparing for Seasonal Storage

When the time comes to set aside your two-wheeled vehicle for the off-season, it is essential to take several precautions to ensure its longevity and optimal performance when you bring it back into use. Proper preparation involves a systematic approach to maintenance and care, allowing you to avoid potential issues and costly repairs later on.

Maintenance Steps

Prior to storage, follow these vital steps to guarantee your machine remains in excellent condition:

Task Description Clean Thoroughly wash the exterior and inspect for any damage that needs addressing. Fuel Treatment Add a fuel stabilizer to the gas tank to prevent deterioration of the fuel. Battery Maintenance Disconnect the battery and store it in a cool, dry place to prolong its life. Tire Care Inflate tires to the recommended pressure to avoid flat spots during storage. Lubrication Apply appropriate lubricants to moving parts to prevent rust and corrosion. Final Preparations

Before sealing your vehicle away for the season, ensure that all fluids are at the correct levels and that you have documented any maintenance performed. Creating a checklist can be an invaluable tool for easy reference when you are ready to prepare for the next riding season.