This section serves as an essential resource for individuals seeking to enhance their understanding of sewing equipment functionality and upkeep. By providing clear instructions and insights, it aims to empower users to effectively address common challenges and optimize the performance of their machines.

Throughout the guide, readers will discover various strategies and techniques designed to simplify the maintenance process. From basic adjustments to more intricate solutions, each aspect is explored with the intention of fostering confidence and competence in managing one’s sewing apparatus.

Ultimately, this compilation not only focuses on resolving issues but also emphasizes the importance of regular care and attention. By adopting these practices, users can extend the lifespan of their devices and ensure a smooth sewing experience.

Singer Heavy Duty Repair Manual

This section provides essential guidance for maintaining and troubleshooting sewing machines designed for robust tasks. The information contained here aims to assist users in achieving optimal performance through proper care and understanding of their equipment.

Common Issues and Solutions

Users may encounter various challenges during operation. Some frequent problems include thread jamming, uneven stitching, and motor malfunctions. Identifying these issues early can prevent further complications. Simple adjustments and routine cleaning often resolve many concerns.

Maintenance Tips

Regular upkeep is crucial for extending the lifespan of sewing machines. Cleaning the components, lubricating moving parts, and checking tension settings are vital steps. Following these practices ensures reliable operation and enhances the quality of the finished projects.

Understanding Your Sewing Machine

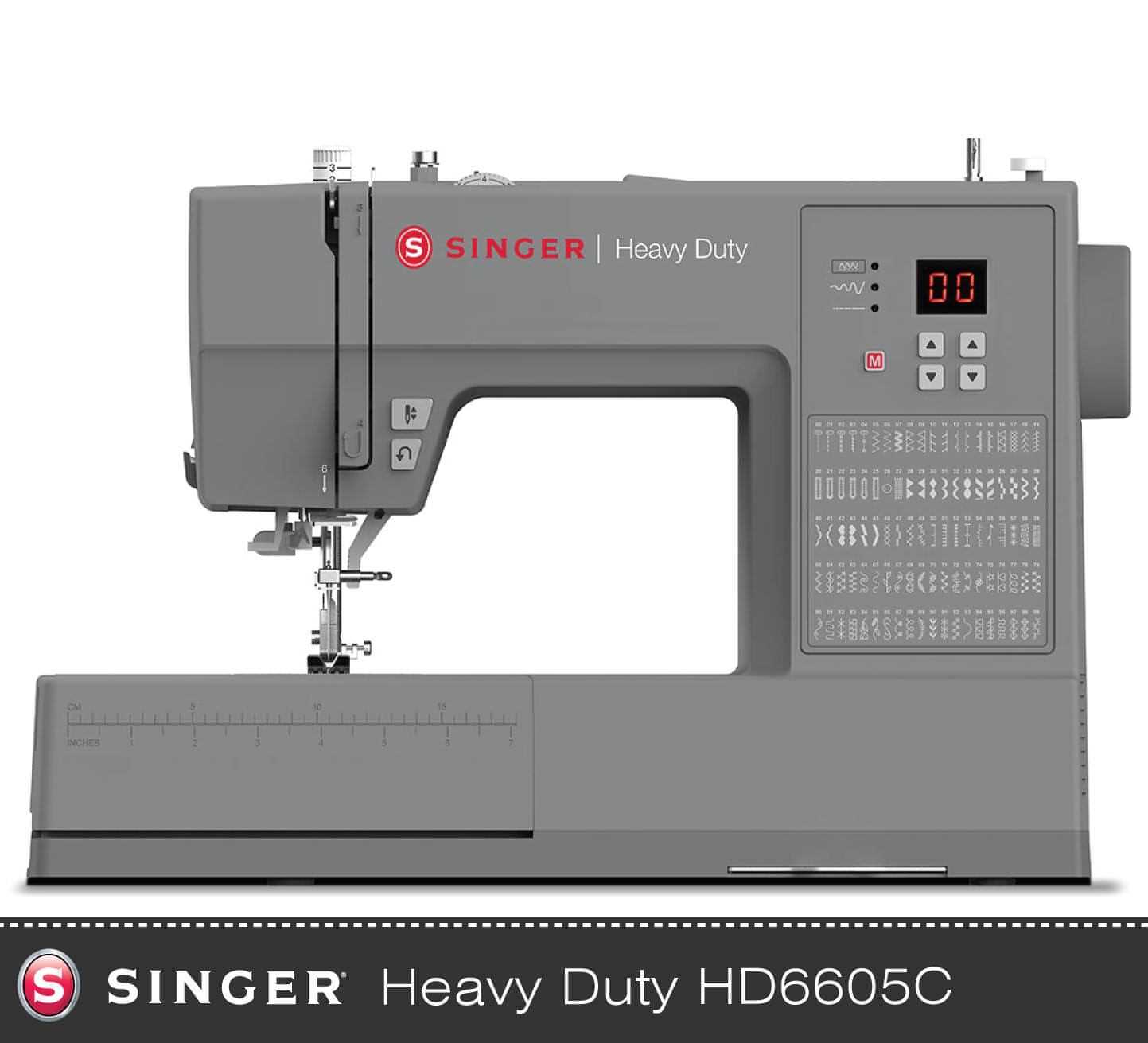

Grasping the fundamentals of your stitching device is essential for achieving optimal performance and creative expression. This section explores the key components and functionalities that contribute to the effectiveness of your equipment.

Key Components

- Needle: This sharp element is crucial for puncturing fabric and creating stitches.

- Foot: The presser mechanism holds the material in place while sewing.

- Bobbin: A small spool that supplies the lower thread, essential for forming stitches.

- Thread Tension: Adjusting this helps manage how tight or loose the stitches are.

- Stitch Selector: This feature allows you to choose different stitch patterns based on your project needs.

Maintenance Tips

- Regularly clean the machine to remove lint and dust.

- Check the needle for wear and replace it when necessary.

- Ensure proper threading to prevent jams and uneven stitches.

- Lubricate moving parts according to the manufacturer’s recommendations.

By familiarizing yourself with these elements and practices, you can enhance your sewing experience and ensure your device remains in excellent working condition.

Common Issues with Heavy Duty Models

Many users encounter similar challenges when operating robust sewing machines designed for demanding tasks. Understanding these common problems can help in effectively addressing them, ensuring smooth functionality and longevity.

Thread Jamming: A frequent concern arises when the thread gets tangled or stuck in the mechanism. This issue often leads to frustrating interruptions during sewing sessions. Regular cleaning and proper threading can mitigate this problem.

Tension Problems: Inconsistent stitching is often a result of improper tension settings. Users may notice that the stitches are either too tight or too loose, affecting the overall quality of the work. Adjusting the tension dial according to the fabric type is crucial for optimal performance.

Needle Breakage: Another common occurrence is needle breakage, which can be caused by using the wrong type of needle or sewing through thick layers. Selecting the appropriate needle size and type for specific projects is essential to prevent this issue.

Motor Overheating: Extended use can lead to overheating of the motor, resulting in temporary shutdowns. Allowing the machine to rest after prolonged operation can help avoid this situation and extend its lifespan.

Bobbin Issues: Problems with the bobbin, such as misalignment or incorrect winding, can lead to uneven stitching. Ensuring the bobbin is properly installed and filled can resolve most related issues.

Essential Tools for Repairs

Having the right instruments is crucial for maintaining and restoring sewing machines. A well-equipped toolkit ensures that tasks can be completed efficiently and effectively, reducing the likelihood of further issues. Understanding the variety of tools available is key to achieving successful outcomes in any restoration project.

Among the fundamental items, a quality screwdriver set is indispensable. Different sizes and types allow for the removal of screws that secure various components. Additionally, pliers are essential for gripping, twisting, and manipulating small parts, providing the necessary leverage in tight spaces.

Another important tool is a seam ripper, which simplifies the process of undoing stitches and correcting mistakes. Furthermore, a small brush is useful for cleaning out lint and debris from hard-to-reach areas, ensuring that the machine operates smoothly.

Lastly, having a reliable set of replacement needles is critical for optimal performance. Different needle types cater to various fabrics, enabling precise stitching. By equipping yourself with these essential instruments, you can ensure that your sewing equipment remains in peak condition.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise during the operation of your sewing equipment. By following this structured methodology, users can efficiently diagnose problems and implement appropriate solutions, ensuring smooth functionality.

Identifying Common Issues

Begin by observing the machine’s performance closely. Look for signs such as unusual noises, skipped stitches, or inconsistent thread tension. Document these symptoms to narrow down potential causes. Checking the user interface for error messages can also offer valuable insights.

Implementing Solutions

Once you have pinpointed the issues, refer to the suggested remedies for each symptom. Common solutions may include adjusting tension settings, cleaning the feed dogs, or replacing the needle. Systematically testing each adjustment can help restore optimal performance and enhance the overall sewing experience.

Replacing Needles and Threads

Properly changing the components that pierce the fabric and the material used for stitching is essential for achieving optimal performance. This process ensures that your sewing tasks proceed smoothly and the quality of the finished product meets expectations.

Choosing the Right Needle

Selecting an appropriate needle is crucial for different types of fabrics. Consider the following factors:

- Type of Fabric: Use a needle that complements the texture and thickness of the material.

- Needle Size: Smaller needles are better for lightweight fabrics, while larger ones work well for heavier materials.

- Needle Type: Different tasks may require specific needle types, such as ballpoint for knits or sharp for woven fabrics.

Thread Selection

Choosing the right thread can enhance your sewing experience. Keep these points in mind:

- Material: Select polyester for strength or cotton for a natural look.

- Weight: Match the thread weight to the fabric weight for better results.

- Color: Consider colorfast options to prevent fading or bleeding on fabrics.

Following these guidelines ensures that your sewing machine operates efficiently, yielding high-quality results in your projects.

Maintaining Your Machine’s Performance

Ensuring optimal functionality of your sewing device requires regular attention and care. By following a few simple practices, you can enhance its longevity and efficiency. This section provides essential tips to keep your apparatus running smoothly, allowing for seamless stitching and creativity in your projects.

One of the key aspects of maintaining performance is regular cleaning. Dust and fabric debris can accumulate, affecting operation. Here’s a quick reference table to guide you in your cleaning routine:

| Task | Frequency | Notes |

|---|---|---|

| Clean feed dogs | After every project | Remove lint with a soft brush. |

| Check needle condition | Weekly | Replace if bent or dull. |

| Oil moving parts | Monthly | Use recommended oil to avoid damage. |

| Inspect thread tension | Before each project | Adjust for optimal results. |

Additionally, it’s essential to use the correct materials and threads. This choice can significantly impact performance and the overall outcome of your work. By following these maintenance practices, you ensure a reliable experience and enhance the quality of your sewing endeavors.

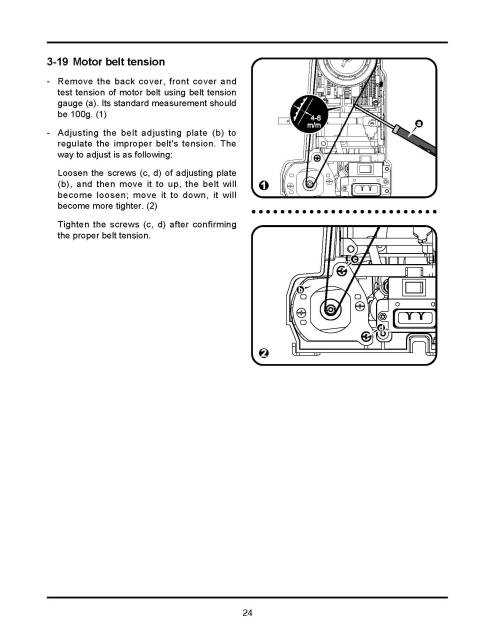

Cleaning and Lubricating Mechanisms

Maintaining optimal performance of sewing equipment requires regular attention to its internal components. Proper cleaning and lubrication are essential to ensure smooth operation, reduce wear, and extend the lifespan of the machine. This section outlines the best practices for caring for these intricate mechanisms.

Essential Cleaning Techniques

To begin, it is important to remove any accumulated dust and lint from the machine. Use a soft brush or a lint-free cloth to gently clean areas around the needle, bobbin, and feed dogs. Regularly cleaning these parts helps prevent blockages and ensures uninterrupted functionality.

Effective Lubrication Practices

After cleaning, the next step is to apply appropriate lubricant to moving parts. Focus on areas such as gears, shafts, and bearings, where friction occurs. A few drops of high-quality oil can significantly enhance performance. Always refer to manufacturer recommendations for specific lubrication points to avoid over-oiling, which can attract dust.

Adjusting Tension Settings Correctly

Achieving the perfect balance in thread tension is crucial for optimal sewing performance. Proper adjustment ensures even stitches and enhances the overall quality of the fabric being worked on. This section outlines essential steps to effectively modify these settings.

Understanding Tension Mechanisms

The tension system consists of several components that work together to regulate how tightly the thread is pulled. Familiarizing yourself with these elements can simplify the adjustment process:

- Tension discs

- Thread guides

- Tension regulator

Steps for Adjusting Tension

Follow these steps to ensure accurate adjustments:

- Start with the machine threaded correctly.

- Test on a scrap piece of fabric to observe stitch quality.

- Adjust the tension dial slightly to see changes.

- Repeat the test until the desired result is achieved.

- Document the settings for future reference.

Regularly checking and adjusting thread tension can significantly enhance your sewing experience and lead to better outcomes in your projects.

Repairing the Feed Dog System

The mechanism responsible for the movement of fabric during stitching plays a crucial role in ensuring smooth operation. Understanding how to maintain and fix this component can enhance the overall performance of your sewing machine.

Common Issues

- Insufficient movement causing fabric to bunch up

- Excessive noise during operation

- Inconsistent feeding leading to uneven stitches

Maintenance Steps

- Start by removing the needle plate to gain access to the mechanism.

- Clean the area thoroughly, removing any lint or debris that may obstruct movement.

- Inspect the feed dogs for wear and tear; replace if necessary.

- Check the height adjustment mechanism to ensure proper positioning.

- Reassemble the components and test the machine for functionality.

Electrical Components and Their Functions

This section explores the various electrical elements found within sewing machines, focusing on their roles and interactions. Understanding these components is essential for effective operation and troubleshooting.

- Power Supply: Converts mains electricity into a usable form for the machine, ensuring all functions operate smoothly.

- Motor: Drives the needle and other moving parts, providing the necessary speed and power for stitching.

- Control Unit: Manages the machine’s functions, allowing users to select different settings and modes for various tasks.

- Switches: Enable or disable specific functions, such as starting and stopping the machine or controlling the speed.

- Circuit Board: Acts as the central hub for electrical signals, connecting various components and ensuring proper communication between them.

- LED Indicators: Provide visual feedback on the machine’s status, alerting users to issues like threading errors or maintenance needs.

Each of these elements plays a crucial role in the overall functionality, contributing to a seamless sewing experience.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if you know where to look. This section will guide you through various avenues for sourcing necessary items, ensuring you maintain the functionality of your device without unnecessary hassle.

Online Retailers

Many online stores specialize in various components, offering a wide range of options. Utilizing reputable websites can help you find exactly what you need quickly.

Local Suppliers

Don’t overlook local shops that may carry parts for your equipment. Visiting these establishments can yield immediate results and personal assistance.

| Source | Advantages | Disadvantages |

|---|---|---|

| Online Retailers | Convenience, wide selection | Shipping time, potential for delays |

| Local Suppliers | Immediate access, personal service | Limited inventory, potentially higher prices |

Tips for Long-Term Care

Ensuring the longevity of your equipment requires consistent maintenance and attention. By following a few simple guidelines, you can enhance performance and extend the lifespan of your device.

- Regularly clean the components to prevent dust buildup.

- Lubricate moving parts to ensure smooth operation.

- Store the unit in a dry, cool place to avoid moisture damage.

- Inspect the wiring and connections periodically for signs of wear.

In addition to these practices, it’s essential to handle the device with care during usage. Avoid forcing any mechanisms and ensure that you follow operational guidelines to prevent unnecessary strain.

- Use appropriate needles and threads for your tasks.

- Keep the workspace organized to minimize the risk of accidents.

- Consider using a cover when the device is not in use to protect it from dust and debris.

By implementing these strategies, you can maintain optimal functionality and enjoy years of reliable service from your equipment.