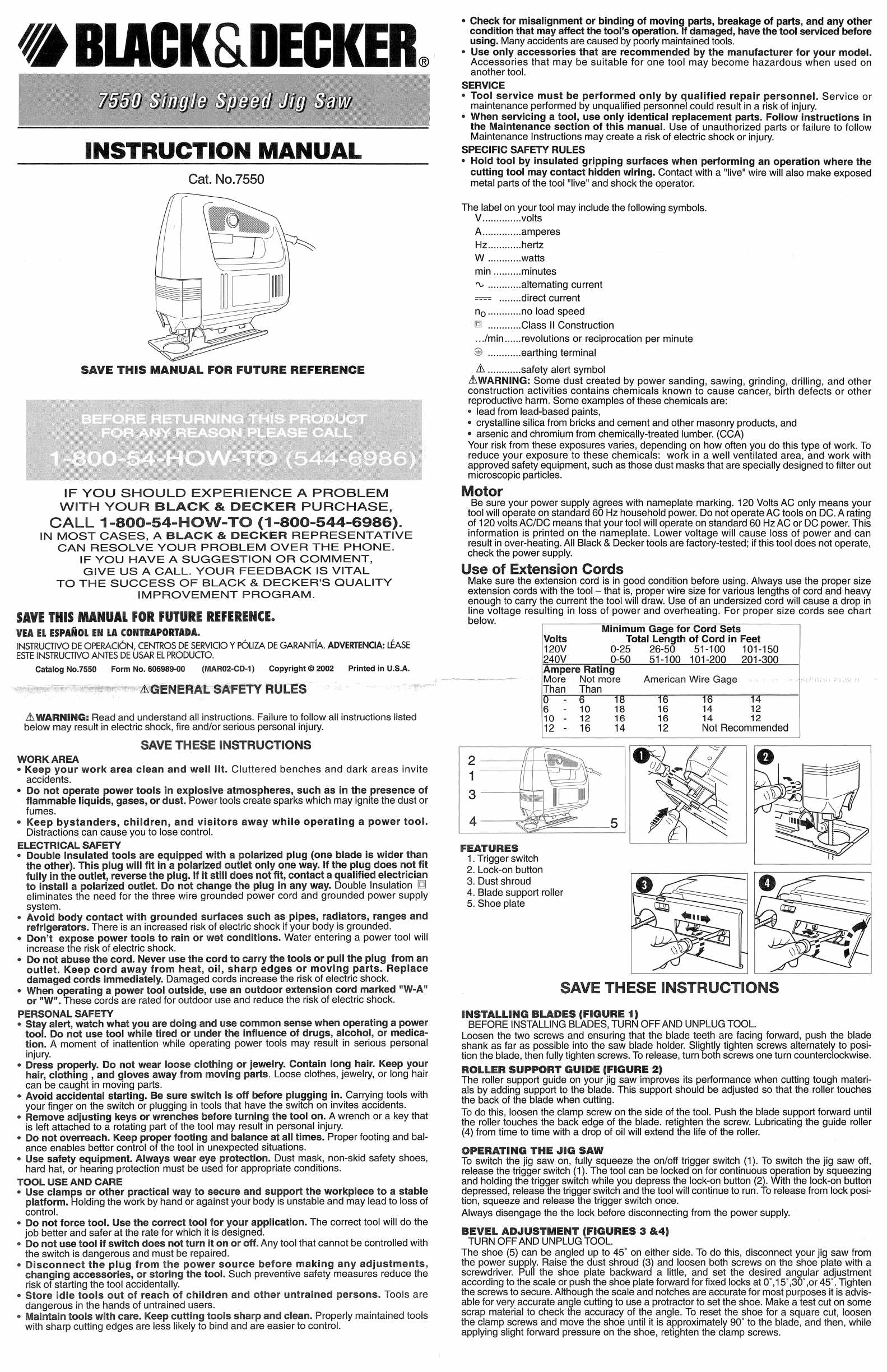

In the world of home improvement and DIY projects, understanding the intricacies of various devices can significantly enhance your experience. Comprehensive instructions and troubleshooting information are essential for anyone looking to maintain or restore their equipment to optimal functionality. Access to well-structured documentation allows users to navigate common issues with confidence and ease.

Whether dealing with handheld devices or larger machinery, having a reliable resource at hand can save both time and frustration. Detailed explanations and step-by-step procedures not only empower users to tackle repairs but also foster a deeper appreciation for the tools they use. This section aims to provide insightful resources to assist you in every aspect of maintaining your equipment.

Furthermore, these guides often include essential safety precautions, ensuring that users can operate their tools without unnecessary risk. Familiarity with operational guidelines and maintenance tips is invaluable, enhancing the longevity and performance of your devices. Dive into this wealth of knowledge to keep your equipment in peak condition.

Understanding Black and Decker Tools

This section explores the essentials of power equipment designed for various tasks, focusing on their functionality, efficiency, and user experience. These devices are vital for both professionals and DIY enthusiasts, offering a range of options to meet different needs.

Types of Equipment

- Drills: Versatile tools ideal for drilling holes and driving screws.

- Saws: Essential for cutting various materials, available in different styles.

- Sanders: Used for smoothing surfaces and preparing them for finishing.

- Blowers: Effective for cleaning up debris and maintaining outdoor spaces.

Features to Consider

- Power Source: Options include corded, cordless, and battery-operated devices.

- Ergonomics: Comfortable grip and lightweight design enhance user experience.

- Durability: Quality construction ensures longevity and reliability.

- Accessories: Many tools come with attachments to expand their versatility.

Understanding these elements can significantly enhance the efficiency and enjoyment of using these devices for various projects.

Importance of Repair Manuals

Understanding the significance of comprehensive guides is crucial for both novice and experienced users. These resources serve as essential tools, enabling individuals to troubleshoot issues effectively and perform necessary maintenance tasks. A well-structured guide empowers users to maximize the lifespan of their equipment while minimizing downtime.

Benefits of Detailed Guides

Accessing thorough documentation provides numerous advantages. It fosters confidence, enhances knowledge, and ensures that tasks are executed correctly. Moreover, having step-by-step instructions simplifies complex procedures, making them more approachable for everyone.

Common Features of Instructional Resources

| Feature | Description |

|---|---|

| Step-by-Step Instructions | Clearly outlined processes that guide users through tasks. |

| Troubleshooting Tips | Advice on diagnosing and resolving common problems. |

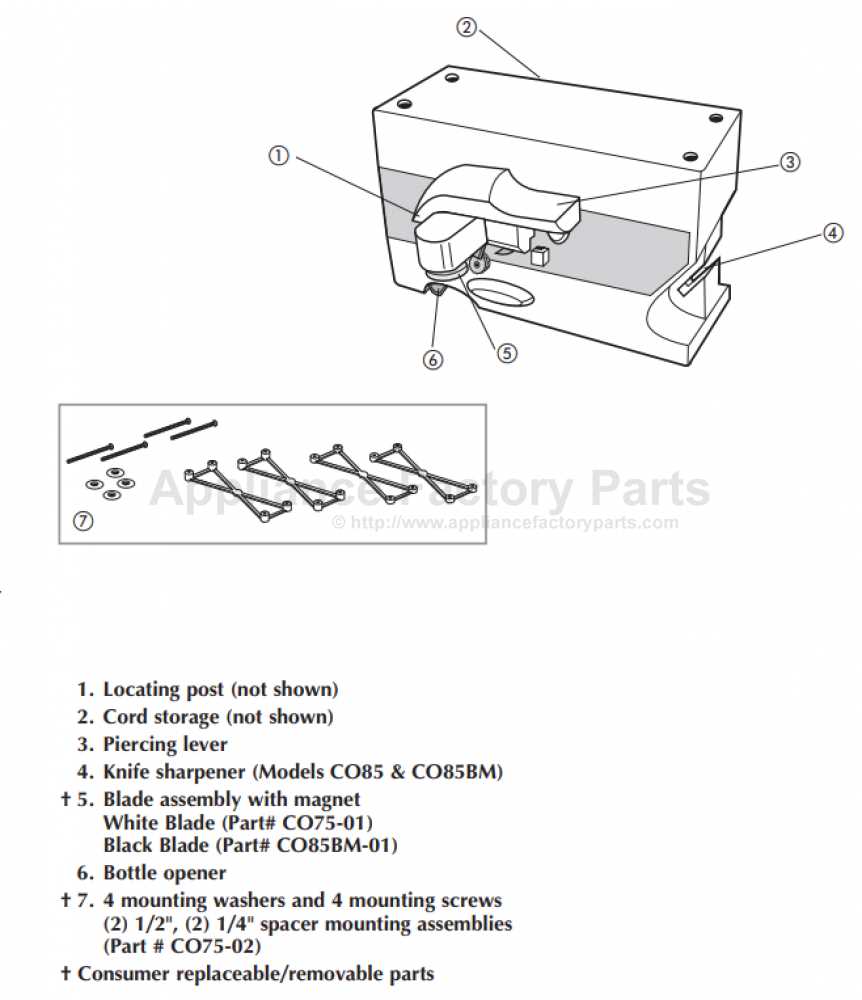

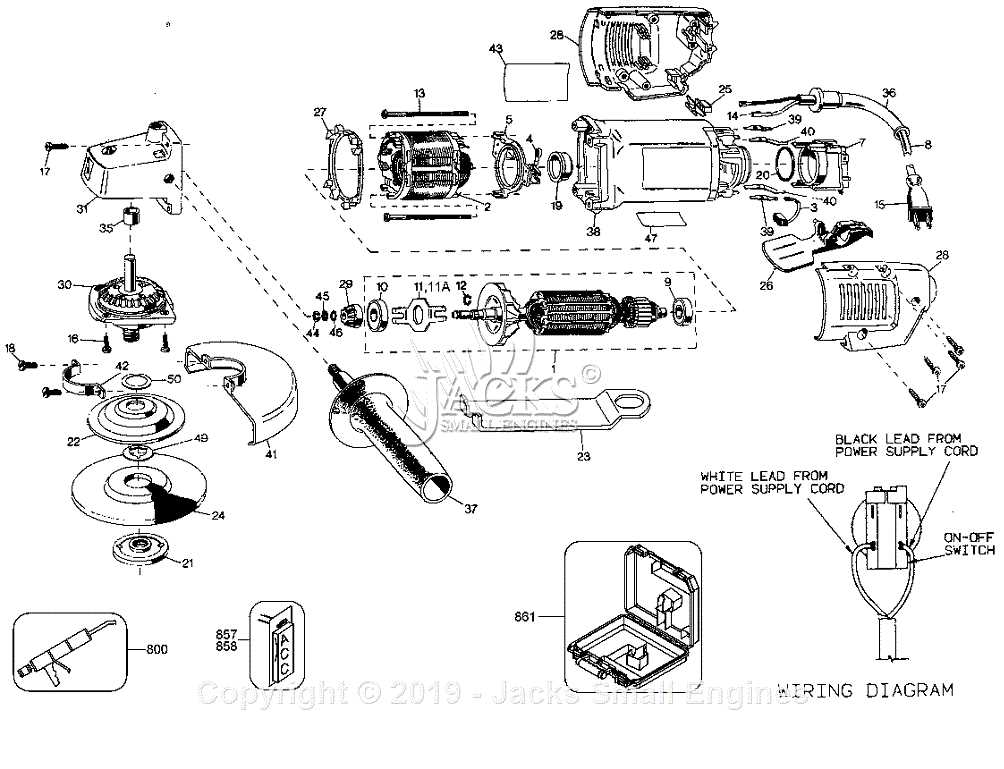

| Parts Identification | Visual aids or descriptions to help locate and understand components. |

| Safety Precautions | Guidelines to ensure safe handling and operation during maintenance. |

In summary, having access to these vital resources can significantly impact the efficiency and effectiveness of maintenance efforts, ultimately leading to better performance and longevity of devices.

Common Issues with Black and Decker Products

Many users encounter various challenges while using their household tools and appliances. Understanding these common problems can help in diagnosing issues more effectively and ensuring smoother operation. Whether it’s a power tool or a kitchen gadget, knowing what to look for is crucial for maintaining functionality.

Typical Problems

Users frequently report a range of issues that can arise during the lifespan of their devices. These problems can stem from various factors, including wear and tear, improper usage, or manufacturing defects. Being aware of these can assist in proactive maintenance and timely resolution.

Symptoms and Solutions

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Device won’t start | Dead battery or power source | Check battery charge or outlet |

| Unusual noises | Worn parts or debris | Inspect and clean components |

| Overheating | Blocked vents or extended use | Allow cooling and clean vents |

| Poor performance | Dull blades or improper settings | Sharpen or replace blades |

Finding the Right Manual Online

Locating the appropriate guide for your tools can be a daunting task, especially with the vast amount of information available on the internet. Understanding where to search and how to identify reliable resources is crucial for ensuring you have access to the correct documentation for your equipment.

Utilizing Manufacturer Websites

One of the best places to start is the official website of the manufacturer. These sites often provide a dedicated section for product documentation, where you can find downloadable PDFs or online resources. Make sure to have your product model number handy to streamline your search. This information is essential in helping you locate the precise resource you need.

Exploring Community Forums

Another valuable avenue is community forums and discussion boards. Users frequently share their experiences, tips, and links to specific guides. Engaging with these communities can not only lead you to the right document but also provide insights into troubleshooting and maintenance that you might not find elsewhere. Look for posts related to your particular tool for the most relevant advice.

Tools Required for Basic Repairs

When embarking on home maintenance tasks, having the right equipment is crucial for achieving effective outcomes. Essential tools not only simplify the process but also ensure safety and precision in your work. This section highlights the key instruments needed for routine fixes around the house.

1. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is essential for loosening or tightening screws in various appliances.

2. Wrenches: Adjustable wrenches and socket sets are vital for working with nuts and bolts, providing the necessary leverage for stubborn fasteners.

3. Pliers: Needle-nose pliers, slip-joint pliers, and cutting pliers help grip, twist, or cut wires and small components effectively.

4. Hammer: A good-quality hammer is necessary for driving nails or removing them, making it an indispensable tool for any task involving wood or other materials.

5. Utility Knife: This versatile tool is perfect for cutting through various materials, including cardboard, tape, and insulation.

6. Measuring Tape: Accurate measurements are key to successful projects, making a sturdy measuring tape an essential addition to your toolkit.

7. Level: A level ensures that your installations are straight and aligned, crucial for both aesthetics and functionality.

Equipped with these fundamental tools, you can confidently tackle a range of maintenance projects, ensuring your space remains functional and welcoming.

Step-by-Step Repair Process Overview

This section provides a comprehensive guide to effectively addressing issues with your power tools. It outlines a systematic approach to troubleshooting and restoring functionality, ensuring that you can tackle problems efficiently and confidently.

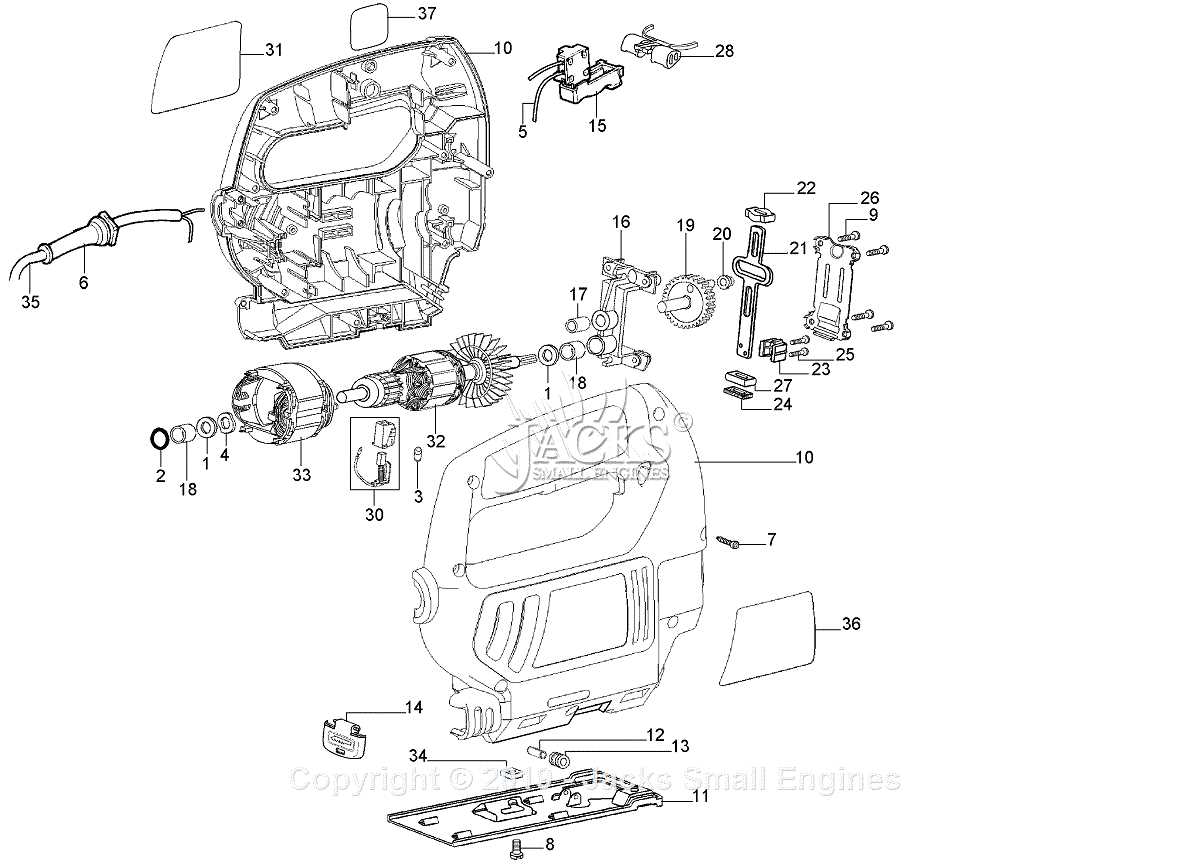

The process begins with identifying the symptoms of the malfunction. Careful observation helps to pinpoint the specific area that requires attention. Following this, gathering the necessary tools and replacement parts is crucial for a smooth workflow.

Once you have everything ready, the next step is to disassemble the equipment carefully. This involves removing screws and panels while keeping track of each component for reassembly. After disassembly, a thorough inspection allows you to assess wear and damage, determining what needs replacement or repair.

With the problematic parts identified, proceed to make the necessary repairs or substitutions. This may involve replacing worn-out components or making adjustments to improve performance. Ensure that all new parts are compatible and correctly installed.

After completing the repairs, reassemble the device methodically, reversing the disassembly steps. Double-check each connection and secure all screws properly to prevent future issues.

Finally, testing the tool in a controlled environment is essential to confirm that the repairs have been successful. Monitor its performance and make any additional adjustments if necessary. Following this structured approach will help extend the lifespan of your equipment and enhance its reliability.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount for both personal protection and the longevity of equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and enhance the effectiveness of the work being performed.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and masks to shield against dust and debris. |

| Disconnect Power Source | Unplug devices or remove batteries to prevent accidental activation during work. |

| Work in a Well-Lit Area | Ensure the workspace is adequately illuminated to spot potential hazards easily. |

| Keep Tools Organized | Maintain a tidy workspace to avoid tripping hazards and misplacing tools. |

| Follow Manufacturer Instructions | Refer to guidance provided by the manufacturer for safe handling and maintenance practices. |

| Stay Alert | Avoid distractions and focus on the task to ensure safety and accuracy. |

By implementing these safety measures, individuals can create a secure environment that promotes efficient and effective maintenance activities.

How to Replace Worn Parts

Over time, components within tools can become degraded, impacting their performance and efficiency. Understanding the process of substituting these items is crucial for maintaining functionality and extending the lifespan of your equipment. This guide outlines the essential steps for effectively replacing old components, ensuring optimal operation.

Identifying Worn Components

The first step in this process is recognizing which parts need replacement. Look for signs of wear such as unusual noises, decreased efficiency, or visible damage. Regular inspections can help you spot these issues early, preventing further complications.

Replacement Procedure

Once you have identified the worn parts, follow these steps to ensure a smooth replacement:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement parts. |

| 2 | Disconnect the power source for safety. |

| 3 | Remove the old part carefully, taking note of how it is installed. |

| 4 | Install the new component, ensuring it is secure and properly aligned. |

| 5 | Reconnect the power source and test the tool to confirm functionality. |

Following these guidelines will help you efficiently replace worn components, ensuring your tools continue to operate effectively.

Troubleshooting Electrical Problems

When dealing with malfunctioning tools or appliances, identifying and resolving electrical issues can often seem daunting. However, a systematic approach can simplify the process, making it easier to pinpoint the source of the problem and apply appropriate solutions. Understanding the fundamentals of electrical systems is crucial for effective troubleshooting.

Begin by inspecting the power source. Ensure that the device is properly plugged in and that the outlet is functional. A simple test with another device can confirm whether the outlet is providing power. If the outlet works, check for visible signs of damage to the power cord, such as fraying or cuts, which could lead to connectivity issues.

If the device still fails to operate, examine any fuses or circuit breakers associated with it. A blown fuse or tripped breaker can interrupt the power supply, rendering the equipment inoperable. Replacing a blown fuse or resetting a breaker may restore functionality.

Next, look for signs of internal electrical problems. This may include burnt components or loose connections. If you’re comfortable doing so, open the casing to inspect the wiring and internal parts. Ensure that all connections are secure and free from corrosion. If any components appear damaged, they may need replacement.

Finally, consult the documentation or resources available for specific guidance related to the model in question. This can provide valuable insights into common issues and their resolutions, aiding in the troubleshooting process. By following these steps, one can effectively address and resolve electrical complications with confidence.

Maintenance Tips for Longevity

Ensuring the durability of your tools requires consistent care and attention. By adopting a few key practices, you can enhance performance and extend the lifespan of your equipment. Regular maintenance not only prevents breakdowns but also ensures that your devices operate at their best, making your tasks more efficient.

Regular Cleaning

One of the simplest yet most effective ways to maintain your tools is through regular cleaning. Removing dust, debris, and residues helps to keep components functioning properly. Make it a habit to wipe down surfaces after each use and perform deeper cleanings periodically.

Proper Storage

Storing your equipment correctly is vital for preventing damage. Ensure tools are kept in a dry, cool environment, away from direct sunlight and moisture. Utilizing cases or racks can protect them from accidental falls and impacts, further prolonging their usability.

| Tip | Description |

|---|---|

| Check Battery | Regularly inspect and charge batteries to maintain optimal performance. |

| Inspect Cords | Look for frays or damage to power cords to prevent electrical hazards. |

| Lubricate Moving Parts | Apply lubricant to hinges and joints to ensure smooth operation. |

Frequently Asked Questions About Repairs

This section addresses common inquiries related to the maintenance and troubleshooting of tools. Whether you are facing an issue or looking for guidance on upkeep, the following information aims to assist users in navigating various challenges.

| Question | Answer |

|---|---|

| What should I do if my tool won’t start? | Check the power source, ensuring it is properly connected. Examine the switch for any signs of damage and consider replacing the battery if applicable. |

| How can I fix a tool that overheats? | Allow the tool to cool down and check for obstructions in the vents. Regular cleaning and ensuring proper lubrication can help prevent overheating. |

| Where can I find parts for my equipment? | Parts can often be found at authorized dealers, online marketplaces, or through the manufacturer’s website. Ensure compatibility with your specific model. |

| What maintenance is recommended for longevity? | Regularly clean the device, lubricate moving parts, and store it in a dry place. Following the manufacturer’s guidelines can enhance durability. |

| Is it safe to attempt repairs on my own? | DIY repairs can be safe if you follow safety protocols and possess the necessary skills. However, for complex issues, consulting a professional is advised. |

Where to Get Professional Help

Seeking expert assistance can be crucial for maintaining and troubleshooting your tools effectively. Professionals offer invaluable insights and can address complex issues that may arise during use. Understanding where to find qualified help ensures that your equipment functions optimally for years to come.

Authorized Service Centers

Visiting certified service centers guarantees that your devices are handled by trained technicians who specialize in specific brands. These facilities often have access to genuine parts and provide reliable solutions to various problems.

Online Communities and Forums

Engaging with online communities can also be beneficial. Websites and forums dedicated to tool enthusiasts often feature knowledgeable members who share experiences and tips. You can delve into discussions and ask questions to get insights from fellow users.

Exploring Warranty and Support Options

Understanding the coverage and assistance available for your equipment is crucial for ensuring long-term satisfaction and performance. Various policies and customer service resources can help you navigate any challenges that may arise with your tools. This section delves into the benefits and processes associated with warranty protection and support services, offering insights to make informed decisions.

Many manufacturers provide specific guarantees that outline what is covered, the duration of coverage, and the procedures for claiming support. Familiarizing yourself with these details can enhance your confidence in the product. Additionally, customer service channels, including online support, helplines, and community forums, serve as valuable resources for troubleshooting and guidance.

Taking advantage of these options not only maximizes the utility of your tools but also ensures you are prepared for any issues that may come up. By being proactive and informed, you can maintain the reliability and efficiency of your equipment over time.