Ensuring the longevity and optimal performance of vintage farming equipment is essential for enthusiasts and professionals alike. This guide offers a comprehensive overview of essential techniques and troubleshooting tips tailored for these powerful machines. Whether you’re a seasoned operator or a newcomer, understanding the nuances of these vehicles can enhance both your knowledge and your machinery’s efficiency.

Familiarizing yourself with the components is a critical step in preserving the functionality of these engines. Recognizing each part’s role allows for targeted interventions, reducing the likelihood of major issues. With a focus on practical advice, this resource aims to empower users to tackle common challenges confidently.

Furthermore, routine checks and maintenance practices can dramatically extend the lifespan of your equipment. By implementing a structured approach to upkeep, users can ensure that their machines operate at peak performance. This guide will explore various strategies to keep your equipment in prime condition, enabling smooth operations for years to come.

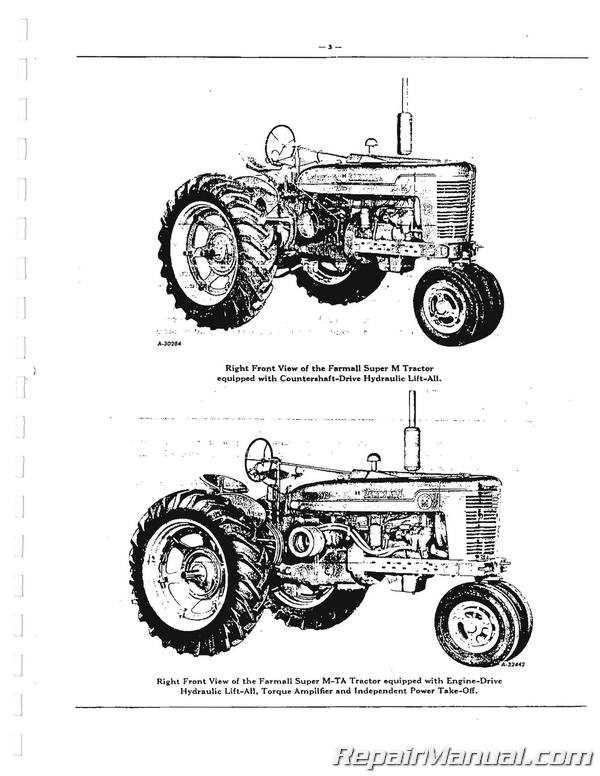

Understanding the Farmall M Tractor

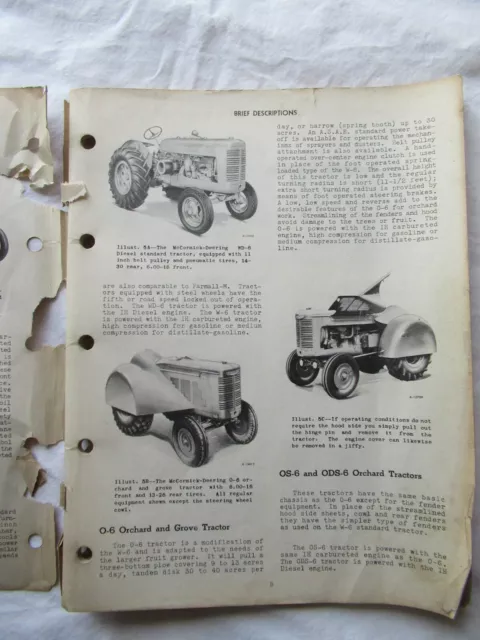

The Farmall M represents a pivotal moment in agricultural innovation, merging power and efficiency to meet the demands of mid-20th-century farming. This robust machine has become a symbol of reliability and versatility in the field, catering to a variety of tasks and environments.

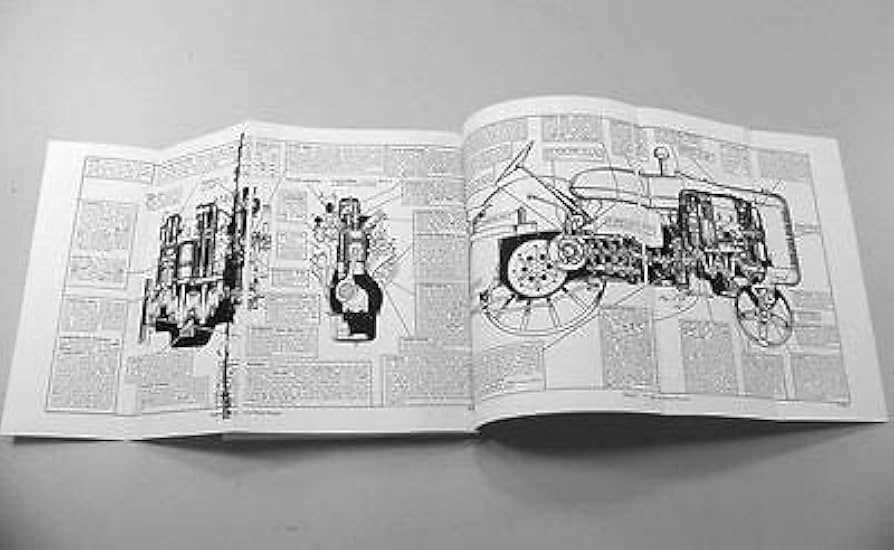

Characterized by its distinct design and engineering, this equipment features several key components that enhance its functionality. Understanding these parts is essential for anyone looking to maximize performance and longevity.

| Component | Description |

|---|---|

| Engine | A powerful unit that delivers exceptional torque and fuel efficiency. |

| Transmission | Offers multiple gears to adapt to different operational needs. |

| Hydraulics | Facilitates lifting and moving implements with ease. |

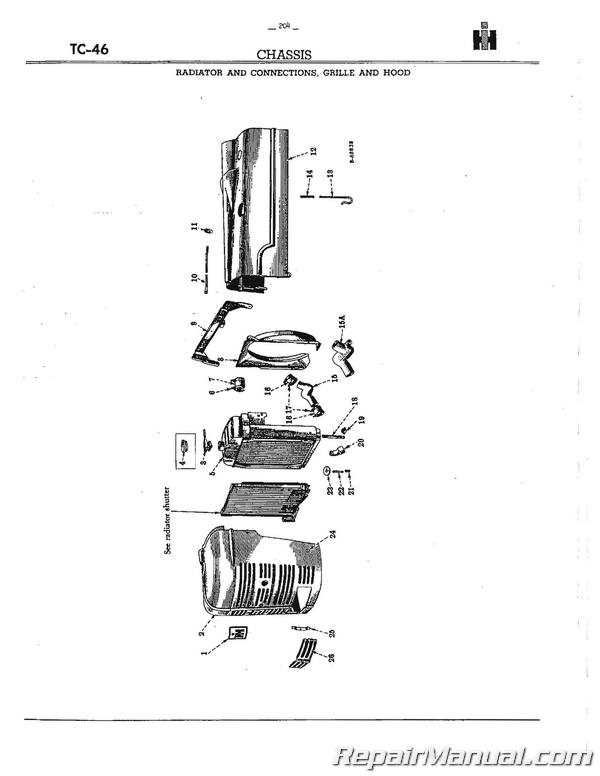

| Chassis | Sturdy frame designed for stability and durability on various terrains. |

| Steering | Precision steering system for enhanced maneuverability. |

By familiarizing oneself with these essential elements, operators can ensure efficient use and maintenance of this iconic machine, ultimately enhancing productivity in agricultural practices.

Common Issues with Farmall M Tractors

When operating classic agricultural machinery, owners often encounter a range of typical problems that can hinder performance and efficiency. Understanding these common challenges is essential for maintaining optimal functionality and ensuring longevity.

- Engine Difficulties:

- Difficulty starting due to fuel delivery issues.

- Overheating from inadequate cooling system maintenance.

- Unusual noises indicating potential internal damage.

- Transmission Problems:

- Shifting difficulties caused by worn gears or linkage issues.

- Fluid leaks that may affect overall operation.

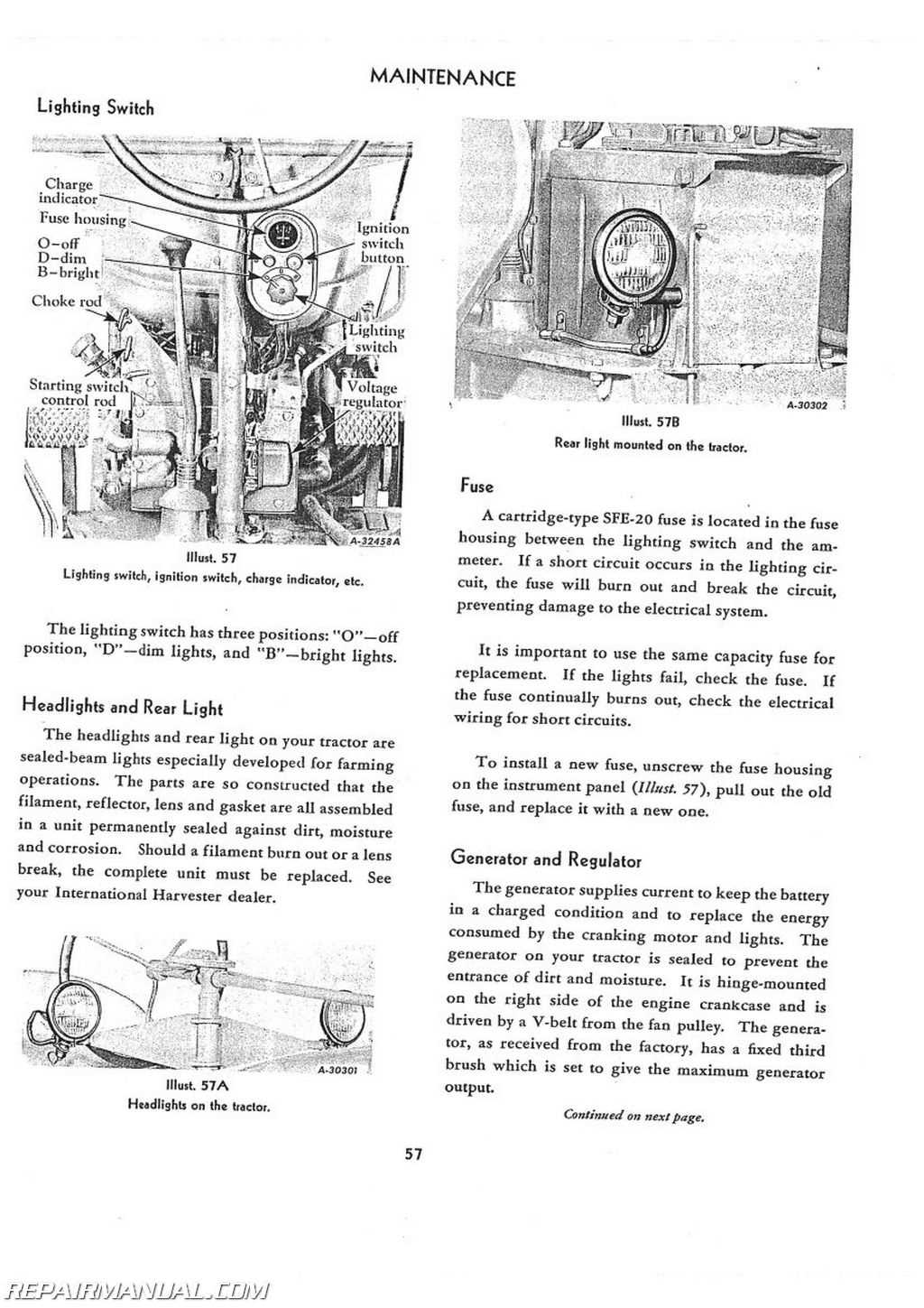

- Electrical Failures:

- Battery drainage due to faulty connections or corroded terminals.

- Inconsistent lighting or signaling from aged wiring.

- Hydraulic System Malfunctions:

- Inadequate lifting power from worn seals or low fluid levels.

- Leaks that compromise efficiency and safety.

- Wear and Tear:

- Degraded tires affecting traction and stability.

- Corrosion on metal components due to exposure to elements.

Addressing these issues promptly can prevent further complications, ensuring the machine remains a reliable asset in agricultural tasks.

Essential Tools for Tractor Repairs

When it comes to maintaining and fixing agricultural machinery, having the right instruments is crucial. A well-equipped toolkit not only enhances efficiency but also ensures safety during the maintenance process. Understanding which tools are indispensable can make all the difference in keeping equipment in optimal working condition.

Basic Hand Tools

- Wrenches: An assortment of sizes is necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are essential for various fastening tasks.

- Pliers: Useful for gripping, twisting, and cutting wire or other materials.

- Hammers: A claw hammer or a rubber mallet can help with assembling or disassembling parts.

Specialized Equipment

- Socket Set: Ideal for working with fasteners that are difficult to reach with standard wrenches.

- Diagnostic Tools: These devices help in identifying issues by reading error codes and monitoring performance.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Lift Jacks: Essential for elevating machinery safely during maintenance tasks.

Investing in high-quality tools not only improves the longevity of the equipment but also enhances the overall effectiveness of maintenance efforts. Being prepared with the right gear can save time and reduce the risk of injury, making any task more manageable.

Step-by-Step Maintenance Guide

This guide provides a systematic approach to ensuring optimal performance and longevity of your equipment. By following these essential procedures, you can enhance functionality and prevent potential issues that may arise from neglect. Regular upkeep is key to maintaining reliability and efficiency.

1. Routine Inspections

2. Lubrication and Fluid Changes

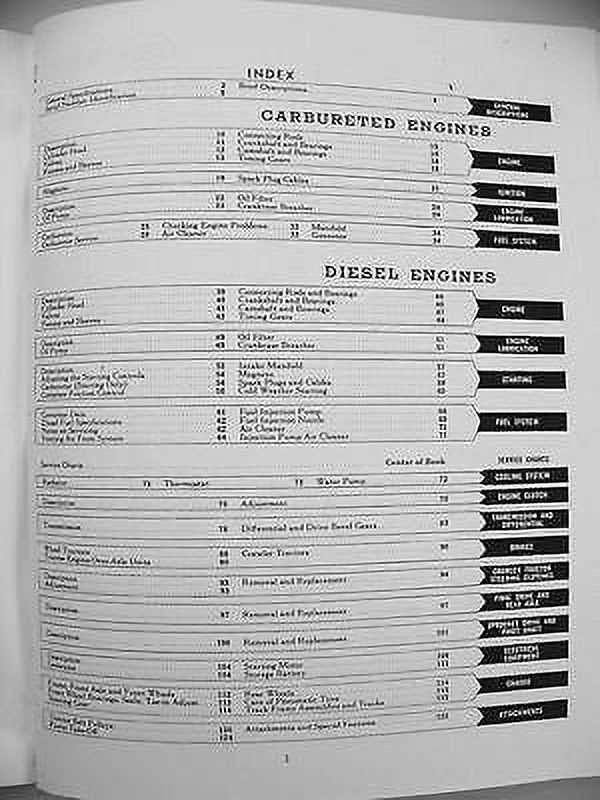

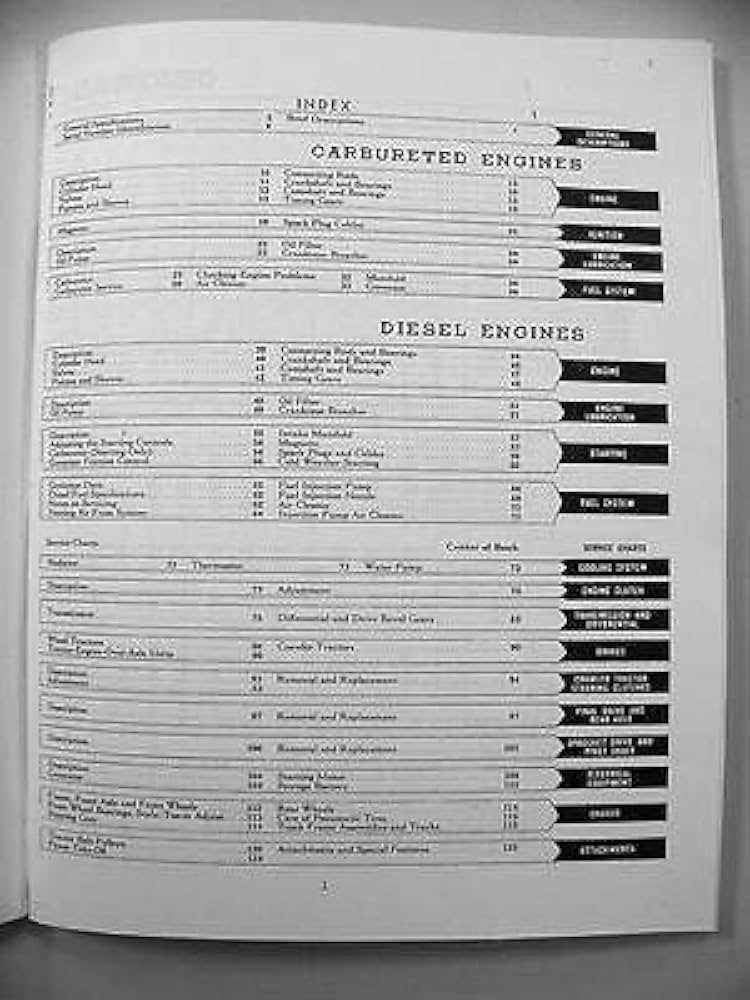

Engine Troubleshooting Techniques

Diagnosing issues within a power unit can be a complex process, requiring a systematic approach to identify underlying problems. Employing effective techniques can help streamline this task, ensuring that you address the root cause of any malfunctions rather than just the symptoms. This section will explore essential methods and tools that can assist in identifying engine-related challenges.

Common Indicators of Issues

Understanding the common signs of engine distress is crucial. Unusual noises, decreased performance, and irregular emissions are all red flags that warrant further investigation. Listening for abnormal sounds, observing fluctuations in operation, and checking fluid levels can provide significant clues. Additionally, any warning lights on the dashboard should never be ignored, as they may indicate specific system failures.

Diagnostic Procedures

Once symptoms have been noted, a thorough examination is necessary. Start by conducting a visual inspection, looking for leaks, cracks, or loose connections. Utilizing diagnostic tools such as compression testers and multimeters can yield valuable information about engine health. Testing each component individually allows for pinpointing faults more effectively. Always document your findings to track progress and identify patterns that may emerge over time.

Hydraulic System Repair Insights

Understanding the intricacies of fluid-powered mechanisms is crucial for maintaining optimal performance in agricultural machinery. This section delves into common issues and solutions related to hydraulic systems, enabling users to enhance efficiency and extend the lifespan of their equipment.

Common Issues in Hydraulic Systems

- Fluid Leaks: One of the most prevalent problems, often resulting from worn seals or damaged hoses.

- Pressure Loss: Insufficient pressure can hinder performance, typically caused by blocked filters or faulty pumps.

- Overheating: Excessive heat can lead to fluid breakdown and component wear, often due to prolonged operation or low fluid levels.

Maintenance Tips

- Regular Inspections: Routinely check hoses, connections, and fluid levels to identify potential issues early.

- Fluid Replacement: Use high-quality hydraulic fluid and replace it according to the manufacturer’s recommendations.

- System Flushing: Periodically flush the system to remove contaminants that can cause wear and inefficiency.

By following these insights, users can effectively troubleshoot and maintain their fluid systems, ensuring reliable operation in demanding agricultural environments.

Electrical System Diagnostics Made Easy

Understanding and troubleshooting the electrical components of your equipment can seem daunting. However, with a systematic approach and the right tools, diagnosing issues can be straightforward. This section outlines essential steps and common practices to help identify and resolve electrical problems effectively.

The key to successful diagnostics lies in recognizing symptoms and utilizing appropriate techniques. Start by familiarizing yourself with the basic layout of the electrical system, including the battery, wiring, and key components. This knowledge will aid in pinpointing potential faults.

| Common Symptoms | Possible Causes | Suggested Actions |

|---|---|---|

| Failure to Start | Dead Battery, Faulty Starter | Check battery charge, inspect starter connections |

| Dim Lights | Weak Battery, Bad Alternator | Test battery voltage, examine alternator output |

| Frequent Blown Fuses | Short Circuit, Overloaded Circuit | Inspect wiring for damage, reduce load |

| Intermittent Electrical Issues | Loose Connections, Corroded Terminals | Check and tighten connections, clean terminals |

By systematically following these steps and utilizing the table for guidance, you can streamline the diagnostic process and efficiently address electrical challenges. Remember to always prioritize safety and consult additional resources when necessary.

Transmission and Clutch Adjustments

Proper calibration of the gear shifting system and engagement mechanism is essential for optimal performance. This section covers the necessary steps to ensure seamless operation and longevity of these components.

- Check the fluid levels regularly to maintain hydraulic efficiency.

- Inspect the linkage for wear or misalignment that could hinder operation.

- Adjust the clutch pedal free play to ensure responsive engagement.

Follow these procedures to enhance functionality and reduce wear:

- Begin with a visual inspection of the transmission and clutch components.

- Test the engagement by pressing the clutch pedal and shifting through gears.

- Make adjustments as needed based on the manufacturer’s specifications.

Regular attention to these adjustments will result in smoother transitions and improved overall efficiency.

Restoration Tips for Vintage Tractors

Reviving classic agricultural machinery can be a rewarding endeavor that connects enthusiasts with history. Whether you are breathing life into a long-forgotten piece of equipment or enhancing its original charm, there are several strategies to consider that can streamline the process and yield satisfying results.

Assessing Condition and Planning

Before diving into the restoration project, thoroughly evaluate the state of the machine. Look for signs of wear, rust, or any structural damage. Create a detailed plan that outlines which components need attention. This will not only help prioritize tasks but also keep the project organized. Documentation of the original specifications can guide your efforts in maintaining authenticity.

Gathering Resources and Parts

Locating the right components is crucial for a successful rejuvenation. Search for reputable suppliers or online forums where fellow enthusiasts share leads on hard-to-find parts. Consider upcycling components from similar machines, which can save time and costs. Investing in quality materials during this phase can prevent future issues and enhance the overall longevity of your revived piece.

Parts Replacement: What You Need

Ensuring optimal performance of your machinery often requires timely component swaps. This section outlines essential considerations for effectively managing the replacement process. Having the right information and resources at your fingertips can significantly streamline this task.

Identification of Parts is the first step. Familiarize yourself with the specific components that may need replacement over time. Regular inspections will help you spot wear and tear early, allowing for proactive measures.

Next, sourcing the right components is crucial. Always choose high-quality, compatible pieces to maintain efficiency and safety. Research various suppliers and compare their offerings to ensure you get the best options available.

Tools Required for the replacement process should not be overlooked. Having the correct tools on hand can make the job easier and more efficient. Ensure you have basic tools like wrenches, sockets, and screwdrivers, as well as any specialized equipment needed for specific parts.

Lastly, following guidelines for installation is key to achieving successful outcomes. Review the manufacturer’s specifications and recommended procedures to avoid common pitfalls and ensure everything fits and functions as intended.

By paying attention to these aspects, you can enhance the longevity and performance of your equipment, ultimately leading to better productivity and reliability.

Safety Practices for Tractor Repairs

Ensuring a secure working environment is paramount when addressing maintenance tasks on heavy machinery. Proper safety measures not only protect the individual performing the work but also safeguard the equipment and surroundings. Following established protocols can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, goggles, and sturdy footwear. This equipment serves as a barrier against potential hazards, such as sharp objects or flying debris. Additionally, consider using hearing protection if you are working near loud machinery.

Workspace Organization

A tidy workspace can greatly enhance safety. Keep tools and materials organized to prevent tripping hazards. Ensure that the area is well-lit and free from obstructions. Regularly inspect the equipment for any potential issues before beginning any maintenance tasks to avoid unexpected complications.

By adhering to these fundamental safety practices, individuals can create a safer and more efficient working environment while maintaining machinery.

Finding Reliable Repair Resources Online

In today’s digital age, locating trustworthy information for equipment maintenance has become essential for enthusiasts and professionals alike. With a plethora of online sources, it’s crucial to discern which platforms offer credible guidance and useful insights. This section explores effective strategies to identify and utilize dependable resources to ensure your machinery operates smoothly.

Evaluating Source Credibility

When searching for information, consider the origin of the content. Look for websites that are well-known within the community or affiliated with reputable organizations. Reviews and ratings from other users can provide valuable insight into the reliability of the material. Furthermore, check for author credentials; expertise in the field often correlates with the quality of information provided.

Utilizing Community Forums and Groups

Engaging with online communities can be an invaluable resource. Forums and social media groups dedicated to machinery enthusiasts frequently share firsthand experiences and practical advice. By participating in discussions, you can gain unique perspectives and solutions tailored to specific challenges. Remember to evaluate the feedback from multiple users to form a well-rounded understanding.