Proper upkeep of your trimming device is essential for ensuring optimal performance and longevity. Understanding the components and functions of this equipment will allow you to troubleshoot issues effectively and maintain its efficiency. Regular attention to your tools not only enhances their functionality but also saves time and effort in the long run.

In this section, we will explore various strategies for addressing common problems associated with your cutting tool. From identifying unusual sounds to understanding power issues, having a solid grasp of the workings of your device will empower you to tackle challenges head-on. With a few tips and techniques, you can enhance your skills and keep your equipment in peak condition.

Engaging with maintenance practices will also lead to a deeper appreciation of your tool’s design and capabilities. By taking the time to familiarize yourself with the necessary procedures, you will ensure that your trimmer remains a reliable partner in your gardening tasks. Let’s dive into the essentials that will help you manage your device effectively.

Common Weed Eater Issues

Maintaining a trimming device is essential for optimal performance, but several common problems can hinder its efficiency. Understanding these issues can help users address them swiftly, ensuring a smooth operation and prolonged lifespan.

1. Difficulty Starting: One of the most frequent complaints is the inability to start the machine. This can stem from fuel-related issues, such as stale fuel or improper mixing of oil and gasoline. Additionally, a clogged air filter can restrict airflow, making ignition challenging.

2. Uneven Cutting: When the device fails to cut evenly, it can lead to an unsightly appearance of the lawn. This issue may arise from a dull cutting line or incorrect line length, which prevents effective trimming.

3. Excessive Vibration: High levels of vibration during operation can indicate that components are loose or worn. Ensuring that all screws and bolts are tightly secured can alleviate this problem.

4. Overheating: Machines can overheat due to prolonged use without breaks or insufficient airflow. Regular pauses and ensuring that air vents are clear can help prevent this issue.

5. Fuel Leaks: If fuel is leaking, it poses both a safety risk and a performance issue. This problem often arises from damaged fuel lines or loose connections, necessitating immediate attention.

Addressing these common concerns promptly can enhance the effectiveness of the device and prevent more significant issues down the line.

Essential Tools for Repairs

When it comes to maintaining and restoring outdoor power equipment, having the right instruments at your disposal is crucial. Proper tools not only streamline the process but also enhance the efficiency and effectiveness of the task at hand. Here, we outline the key implements that will assist in tackling common issues encountered with these machines.

Basic Hand Tools

Every enthusiast should have a set of fundamental hand tools. These instruments are indispensable for various tasks, ranging from adjustments to replacements.

| Tool | Function |

|---|---|

| Screwdriver Set | For tightening and loosening screws. |

| Socket Wrench | Ideal for removing and securing bolts. |

| Plier Set | Useful for gripping and bending components. |

Specialized Equipment

In addition to basic tools, certain specialized equipment may be required for specific tasks. These tools can make complex procedures much simpler.

| Tool | Function |

|---|---|

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Feeler Gauge | Measures gaps or clearance between parts. |

| Fuel Line Wrench | Facilitates the removal and installation of fuel lines. |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues associated with your outdoor maintenance equipment. By following these detailed steps, you can effectively diagnose problems and implement solutions to restore optimal performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Fuel tank empty, spark plug faulty, or clogged air filter | Refill fuel, check and replace spark plug, clean or replace air filter |

| Uneven Cutting | Blades dull, incorrect height setting, or obstruction | Sharpen or replace blades, adjust height setting, remove debris |

| Excessive Vibration | Loose components, damaged blades, or unbalanced load | Tighten all screws and bolts, inspect and replace damaged blades, redistribute weight |

| Overheating | Poor ventilation, low oil level, or excessive use | Ensure proper airflow, check and refill oil, take breaks during operation |

| Stalling During Use | Clogged fuel line, insufficient power supply, or dirty spark plug | Clear fuel line, ensure adequate power source, clean or replace spark plug |

By systematically addressing these potential problems, you can enhance the functionality and lifespan of your equipment. Regular maintenance and timely interventions are key to avoiding future complications.

Replacing the Trimmer Line

Maintaining optimal performance of your trimming device requires periodic replacement of the cutting line. This task is straightforward and can significantly enhance the efficiency of your tool. In this section, we’ll guide you through the steps to successfully change the line, ensuring a clean and effective cut.

Necessary Tools and Materials

- New cutting line (appropriate thickness)

- Scissors or line cutter

- Protective gloves

- Safety goggles

Step-by-Step Instructions

- Ensure the device is powered off and disconnected from any power source.

- Locate the spool housing and remove it according to the manufacturer’s guidelines.

- Carefully remove any remaining line from the spool.

- Cut a length of new line, typically around 10-15 feet, depending on the spool size.

- Insert one end of the line into the designated hole on the spool and wind it evenly in the direction indicated on the spool.

- Leave enough line to extend beyond the spool and secure it in place.

- Reassemble the spool housing, ensuring everything is locked into position.

- Reconnect the power source and perform a test run to check functionality.

By following these steps, you can efficiently maintain your trimming equipment, ensuring it remains effective for all your gardening tasks.

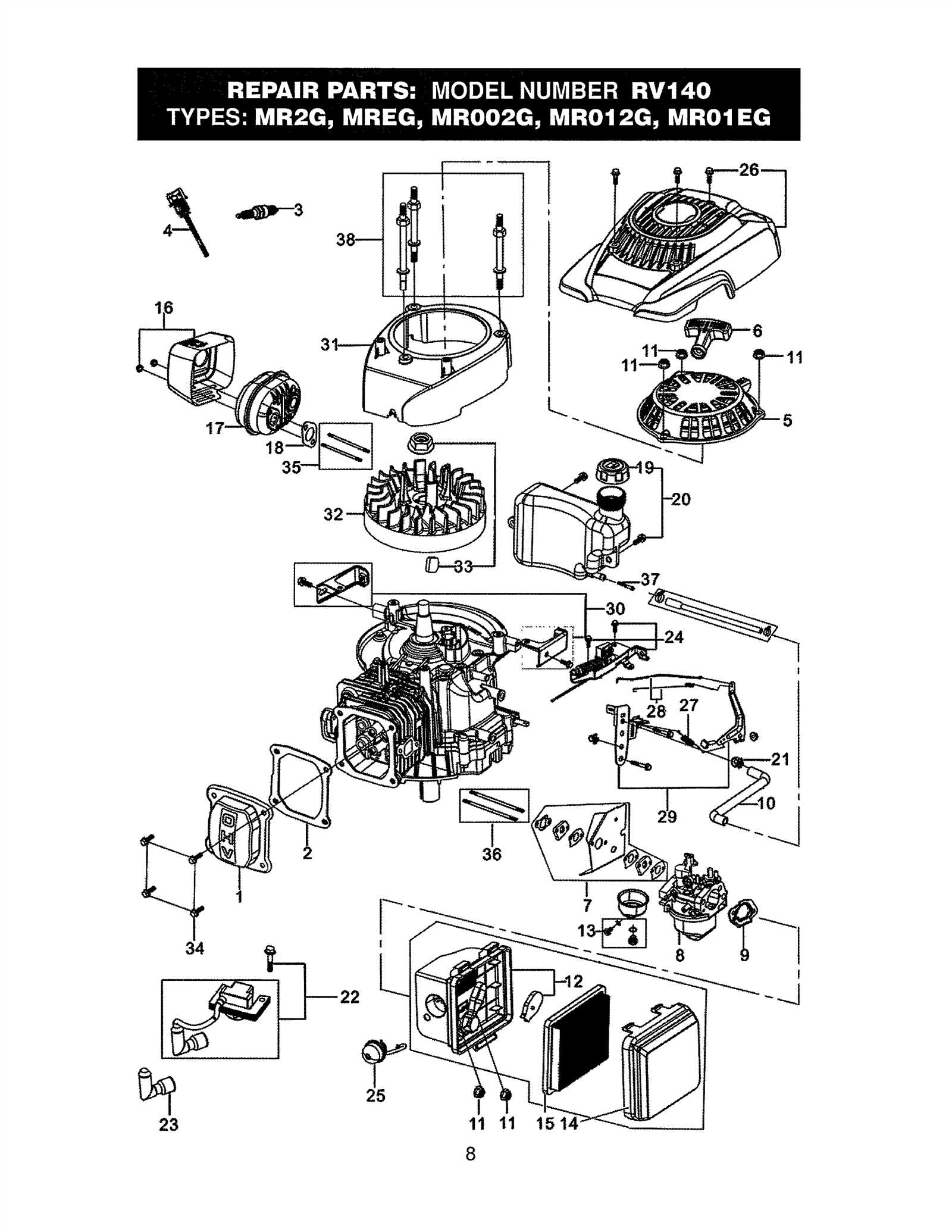

How to Clean the Engine

Maintaining the internal components of your equipment is essential for optimal performance and longevity. Regular cleaning can prevent buildup that may hinder operation and efficiency. Follow these steps to ensure your engine remains in top condition.

-

Gather Necessary Tools:

- Soft brush

- Compressed air canister

- Cleaning solution

- Cloth or rag

- Protective gloves

-

Prepare the Equipment:

- Ensure the engine is turned off and cool to the touch.

- Disconnect the spark plug to prevent accidental ignition.

-

Remove Debris:

- Use the soft brush to remove dirt and debris from the surface.

- Focus on air intakes and cooling fins for better airflow.

-

Apply Cleaning Solution:

- Spray a suitable cleaning solution on greasy areas.

- Let it sit for a few minutes to loosen grime.

-

Scrub and Wipe Down:

- Use a cloth or rag to scrub areas with built-up residue.

- Wipe down all surfaces thoroughly to remove cleaning solution.

-

Use Compressed Air:

- Utilize the compressed air canister to blow out any remaining dust or debris.

- Be cautious around sensitive components to avoid damage.

-

Reassemble and Test:

- Reconnect the spark plug once everything is clean and dry.

- Start the engine to ensure proper functionality.

Regularly cleaning your engine not only enhances performance but also extends the lifespan of your equipment. Follow these steps diligently for best results.

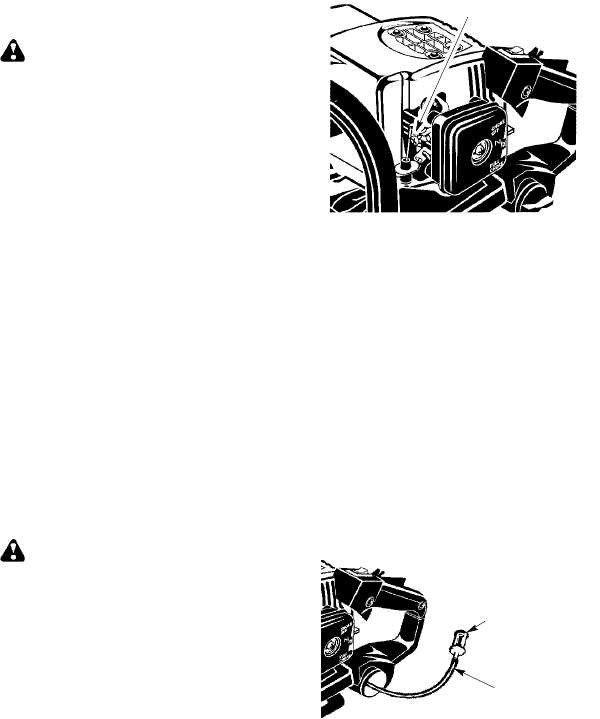

Identifying Electrical Problems

Electrical issues can manifest in various ways, affecting the overall performance of the device. Recognizing these problems early can prevent further complications and ensure efficient functionality.

Symptoms of electrical malfunctions often include inconsistent operation, unexpected shutdowns, or failure to start. These signs indicate that there may be underlying issues that need to be addressed.

To diagnose electrical concerns, begin by checking connections for any signs of wear or damage. Loose or corroded terminals can disrupt the flow of electricity, leading to performance problems. Additionally, testing the battery and wiring for continuity can help pinpoint faults in the system.

Using a multimeter can provide valuable insights into the device’s electrical components. By measuring voltage and resistance, you can identify whether the components are functioning within the manufacturer’s specifications. If readings fall outside acceptable ranges, further investigation is necessary.

Finally, consult the product documentation for specific troubleshooting guidelines related to electrical systems. This can offer detailed information on the particular model, aiding in identifying and resolving issues effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your outdoor equipment. Implementing a few simple practices can significantly enhance performance and reliability over time. This section will provide you with valuable insights to ensure your tools remain in optimal condition for years to come.

Routine Cleaning

Cleaning your equipment after each use helps prevent the buildup of debris and contaminants. Use a soft brush or cloth to remove grass clippings and dirt from the exterior and any moving parts. Pay special attention to air vents and filters to ensure proper airflow, which is crucial for engine efficiency.

Regular Inspections

Conducting frequent inspections can identify potential issues before they escalate. Check for wear and tear on cords, blades, and other components. Replace any damaged parts promptly to maintain optimal functionality. Additionally, ensure that all screws and fittings are tight to avoid unnecessary vibrations during operation.

Adjusting the Carburetor Settings

Fine-tuning the fuel delivery system is essential for optimal engine performance. Proper adjustments can enhance efficiency and ensure smooth operation, allowing the machine to function effectively during use.

Begin by identifying the adjustment screws, typically labeled for easy recognition. Each screw plays a vital role in regulating air and fuel mixture. Turn the low-speed screw clockwise to enrich the mixture, while counterclockwise will lean it out. For the high-speed screw, the same principles apply, but adjustments are made while the engine is running at full throttle.

After initial adjustments, it is crucial to test the equipment under load. Observe how the engine responds. If it sputters or stalls, further fine-tuning may be necessary. Always refer to the manufacturer’s specifications to maintain optimal settings.

Regular maintenance and periodic adjustments are key to prolonging the lifespan of the machinery. Keeping the fuel delivery system well-tuned ensures reliability and enhances overall performance, making your tasks more efficient.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor power tools, it is essential to prioritize safety to prevent injuries and ensure a smooth process. Proper precautions can minimize risks and protect both the individual and the equipment.

First and foremost, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. This gear safeguards against potential hazards such as sharp edges and flying debris.

Additionally, ensure that the tool is completely powered down and disconnected from any energy sources before beginning any work. This step is crucial to avoid accidental starts that could lead to serious injuries.

Keep your work area clean and organized to reduce the likelihood of slips or falls. A clutter-free space allows for better focus and minimizes distractions during the task at hand.

Furthermore, familiarize yourself with the specific features and components of the equipment. Understanding its design can aid in identifying potential hazards and troubleshooting effectively.

Lastly, always have a first aid kit readily accessible. In case of an accident, prompt access to medical supplies can make a significant difference in outcomes.

Resources for Additional Help

When facing challenges with your outdoor equipment, having access to reliable resources can greatly enhance your troubleshooting experience. Whether you’re seeking guidance on common issues or looking for specialized assistance, various platforms can provide the information you need to resolve problems effectively.

Online Forums and Communities

Engaging with online forums dedicated to gardening and lawn care can be invaluable. These communities often consist of experienced users who share their insights and solutions. Platforms like Reddit or specific gardening websites can offer practical advice and personal anecdotes that might resonate with your situation. Don’t hesitate to ask questions; the collective knowledge can be a powerful tool.

Manufacturer Support and Documentation

Visiting the official website of your equipment’s manufacturer is another excellent approach. Many manufacturers provide user manuals, troubleshooting guides, and FAQs that can help you navigate through various issues. Additionally, customer support services can assist you directly with any technical questions you might have, ensuring that you receive tailored advice.