In the world of outdoor machinery, understanding how to maintain and troubleshoot your devices is essential for ensuring optimal performance and longevity. This section aims to provide you with comprehensive insights into caring for your equipment, helping you tackle common issues effectively.

Every machine requires attention to detail, and knowing the fundamentals of upkeep can save you time and money. By following practical advice and expert suggestions, you can enhance the functionality of your tools, keeping them in top condition for any task.

Whether you’re dealing with routine maintenance or addressing unexpected challenges, having the right knowledge is key. This guide serves as a valuable resource, empowering you to manage your equipment with confidence and ease.

This section provides an overview of a specific chainsaw model, focusing on its features, applications, and general characteristics. Understanding these elements is essential for effective maintenance and troubleshooting.

- General Description

- Specifications and Features

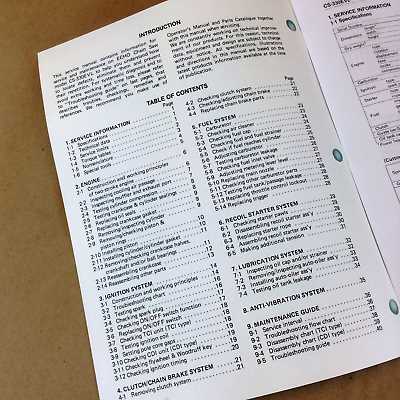

- Common Uses

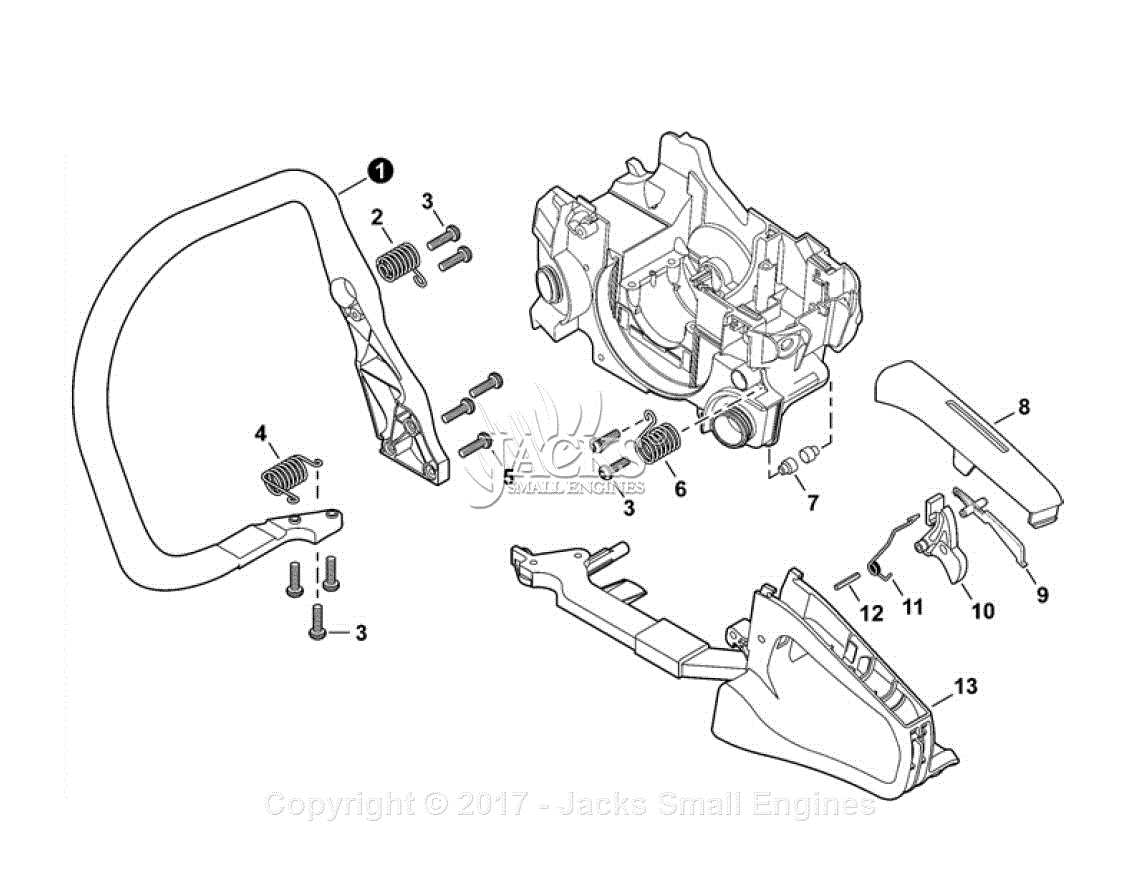

- Assembly Instructions

- Safety Precautions

- Operating Guidelines

- Maintenance Tips

- Troubleshooting Common Issues

- Replacement Parts Overview

- Storage Recommendations

- Frequently Asked Questions

- Conclusion

Each heading will delve into specific aspects, providing detailed insights and practical advice for users seeking to enhance their understanding and skills related to this chainsaw model.

Common Issues and Solutions

Understanding and addressing frequent malfunctions can extend the life of your tool and improve its performance. This section provides guidance on recognizing typical signs of wear and implementing straightforward adjustments or fixes to keep the equipment functioning smoothly.

Engine Won’t Start

One common issue involves the engine failing to start, often due to fuel or spark-related concerns. Ensure the fuel is fresh and at the correct mixture ratio, as old or improperly mixed fuel can impede ignition. Additionally, check the spark plug for wear and clean or replace it as needed to maintain optimal performance.

Reduced Power or Stalling

Another frequent problem is a noticeable drop in power or sudden stalling during use. This may be caused by a clogged air filter or a dirty carburetor. Regularly clean or replace the air filter, and consider inspecting the carburetor, as dirt buildup can hinder airflow, leading to inconsistent performance.

Chain Issues

Over time, the chain may become dull or loose, impacting cutting efficiency. Regularly check the chain for sharpness, and adjust the tension to ensure safe and efficient operation. Sharpen or replace the chain as necessary, following safety guidelin

Tools Required for Repair

To ensure efficient and safe maintenance, having the right set of tools at hand is essential. Proper preparation with well-suited instruments allows for smooth work, enhances accuracy, and reduces the risk of errors. This section outlines the key tools needed for handling tasks with ease.

| Tool | Purpose | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screwdriver Set | Useful for loosening and tightening various screws, helping to access internal parts efficiently. | ||||||||||||||||||||||||||||||||

| Wrench | Essential for securing bolts and nuts, providing stability during maintenance tasks. | ||||||||||||||||||||||||||||||||

| Allen Keys | Used for handling hexagonal screws, allowing precise adjustments in compact spaces. | ||||||||||||||||||||||||||||||||

| Cleaning Brush | Ideal for removing dirt and debris from small components, helping to maintain cleanliness and function. | ||||||||||||||||||||||||||||||||

| Pliers | Assists in gripping, twisting, and holding small parts, making component handling more manageable.

Step-by-Step Disassembly ProcessThis section provides a structured guide for safely taking apart the equipment, focusing on ensuring a smooth and effective dismantling. Following these steps carefully will allow for efficient inspection or maintenance without causing unnecessary damage to the components. Step 1: Prepare Your Workspace Before beginning, set up a clean, organized area with all required tools within reach. This setup minimizes the chance of losing small parts and enhances safety during the process. Step 2: Remove External Attachments Carefully disconnect any external parts or covers that may be obstructing access to the internal sections. Be sure to use gentle force to avoid damaging clips or fasteners. Step 3: Access Internal Components Once external parts are removed, locate and unscrew any visible fasteners holding the main structure together. Keep track of screws and bolts, as some may differ in size and function. Step 4: Separate the Core Assemblies With the primary casing open, identify the main components and begin carefully disconnecting each from its housing. Pay attention to wires or hoses, and disconnect these as necessary, using caution to avoid tearing or stretching them. Replacing the Fuel System ComponentsMaintaining the fuel system is essential for ensuring optimal engine performance and longevity. Over time, certain parts of the fuel system may wear out or become clogged, affecting overall functionality. This section provides a step-by-step approach to replacing these components, which can help restore efficiency and prevent future issues.

|