Every creator knows the importance of keeping their tools in optimal condition. Ensuring your crafting device operates smoothly not only enhances performance but also extends its lifespan. Understanding the essential care and troubleshooting steps can make a significant difference in your crafting experience.

Within this section, you will discover a variety of techniques aimed at addressing common challenges and enhancing functionality. From basic upkeep to more involved procedures, the information provided will empower you to handle issues confidently, ensuring your equipment remains a reliable partner in your creative endeavors.

By equipping yourself with the right knowledge and skills, you can navigate potential obstacles with ease. This resource serves as a valuable companion, guiding you through effective practices and innovative solutions tailored to enhance your overall crafting journey.

Understanding Your Brother Sewing Machine

Grasping the essentials of your textile crafting device is crucial for optimal performance and longevity. Familiarity with its components and functionalities can significantly enhance your experience and efficiency, ensuring that you achieve your creative goals with ease.

Each unit comes equipped with various features designed to assist users in diverse projects. Knowing how to utilize these attributes effectively can transform your crafting sessions. Below is a table highlighting key elements typically found in these devices and their purposes:

| Component | Function |

|---|---|

| Needle | Pierces fabric to create stitches |

| Foot Pedal | Controls speed of operation |

| Thread Tension Dial | Adjusts tightness of thread for consistent stitching |

| Stitch Selector | Allows choice of different stitching patterns |

| Bobbins | Holds lower thread for stitching |

By understanding these essential elements, you can navigate your crafting tasks more effectively and enjoyably, leading to enhanced creativity and satisfaction in your projects.

Basic Troubleshooting for Common Issues

Addressing frequent challenges that may arise with your crafting apparatus can enhance your overall experience. Understanding fundamental solutions helps in identifying and resolving common problems, ensuring smooth functionality.

Identifying Stitching Problems

When stitches appear uneven or skip altogether, check the thread tension. Ensure that both upper and lower threads are threaded correctly. Additionally, inspect the needle for any damage and replace it if necessary. Regular maintenance, such as cleaning the bobbin area, can also prevent these issues.

Dealing with Jamming

If the device becomes stuck or jammed, start by turning it off and carefully removing any obstructing fabric. Examine the feed dogs for lint or debris that may hinder movement. Lubricating moving parts according to the manufacturer’s guidelines can also alleviate this common inconvenience.

Guide to Proper Machine Maintenance

Maintaining your device is crucial for ensuring its longevity and optimal performance. Regular attention to key components can prevent issues and enhance functionality, allowing for smoother operation and improved results. This section provides essential tips for preserving your equipment in excellent condition.

Regular Cleaning and Inspection

Routine cleaning and inspection are vital steps in upkeep. Dust and debris can accumulate, impacting performance. By consistently checking and cleaning critical parts, you can prevent potential malfunctions and maintain efficiency.

| Component | Maintenance Action | Frequency |

|---|---|---|

| Interior | Remove dust and lint | After every use |

| Needle | Replace if damaged | As needed |

| Bobbin case | Clean and oil | Weekly |

Proper Storage Techniques

How you store your device can significantly affect its lifespan. Protecting it from dust and environmental factors is essential. Utilize appropriate covers and ensure it is placed in a stable environment to avoid damage.

Essential Tools for Sewing Machine Repair

When it comes to maintaining and fixing fabric crafting equipment, having the right instruments at your disposal is crucial. A well-equipped toolkit can make all the difference in efficiently addressing various issues that may arise. From basic to advanced tools, understanding their purpose can significantly enhance the troubleshooting process.

First and foremost, a set of screwdrivers in various sizes is indispensable. These will help in accessing different parts of the apparatus, allowing for thorough inspections and adjustments. It’s advisable to have both flathead and Phillips types to accommodate various screw designs.

Additionally, a pair of precision pliers can be beneficial for gripping small components or wires that might need repositioning. Their fine tips enable users to reach tight spots, making them an essential addition to any toolkit.

For cleaning, a small brush and lint-free cloth are necessary. These items help remove dust and debris from intricate areas, ensuring smooth functionality. A vacuum attachment can also assist in this process, especially for hard-to-reach corners.

Finally, having a reliable manual or guidebook that outlines common issues and solutions can serve as a valuable reference. This resource can provide insights into troubleshooting techniques and best practices for upkeep, ensuring the longevity of your equipment.

Identifying Signs of Wear and Tear

Recognizing the early indications of deterioration in a textile crafting device is crucial for maintaining its performance and longevity. By paying attention to specific symptoms, users can address issues before they escalate into more significant problems.

Common Indicators

- Unusual Noises: Listen for any grinding, clanking, or rattling sounds during operation.

- Irregular Stitch Quality: Look for uneven stitching, skipped stitches, or thread breakage.

- Difficulty in Functioning: Notice if the device struggles to feed fabric or if the controls are unresponsive.

- Visible Wear: Inspect for frayed cables, worn-out components, or rust spots.

Routine Checks

- Regularly clean and lubricate moving parts to prevent buildup.

- Examine thread tension settings to ensure consistent results.

- Keep an eye on needle condition; replace when bent or dull.

- Ensure that the device is correctly calibrated for optimal performance.

Replacing Broken or Damaged Parts

Maintaining optimal performance often requires addressing issues related to worn or compromised components. Identifying the specific parts that need attention is essential for restoring functionality and ensuring longevity. This section outlines key steps for effectively replacing damaged elements to keep your device operating smoothly.

Identifying Faulty Components

Before proceeding with any replacements, it is crucial to assess which parts are causing issues. Signs of malfunction may include unusual noises, failure to operate, or visible wear. Take time to inspect each component thoroughly to pinpoint the source of the problem.

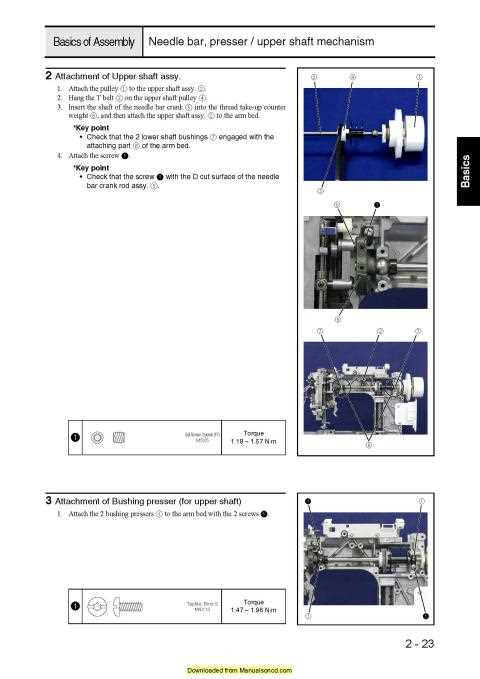

Steps for Replacement

Once you have identified the faulty parts, follow these steps for a successful replacement:

- Gather Tools: Ensure you have the necessary tools, such as screwdrivers, pliers, and replacement components ready.

- Follow Instructions: Refer to guidelines specific to the components you are replacing to avoid any mishaps.

- Secure Connections: After replacing the part, check that all connections are secure and properly aligned.

By following these steps, you can effectively address issues related to compromised components, ensuring your device continues to perform at its best.

How to Clean and Oil Components

Maintaining optimal functionality requires regular attention to essential parts, ensuring they operate smoothly and efficiently. This process not only enhances performance but also extends the lifespan of the equipment. Here’s a straightforward guide on how to effectively clean and lubricate key elements.

Start by gathering the necessary tools and materials. You will need a soft cloth, a small brush, suitable lubricant, and a vacuum cleaner. Follow these steps to ensure thorough care:

| Step | Action | Details |

|---|---|---|

| 1 | Unplug the device | Always disconnect from the power source for safety before starting any maintenance. |

| 2 | Remove dust and debris | Use a vacuum cleaner and a soft brush to eliminate any accumulated particles around the components. |

| 3 | Wipe surfaces | With a soft cloth, gently clean all accessible areas to remove grease and grime. |

| 4 | Apply lubricant | Use an appropriate oil on moving parts to reduce friction and ensure smooth operation. |

| 5 | Reassemble | Once everything is clean and lubricated, carefully put back any parts that were removed. |

Regular maintenance not only ensures efficiency but also prevents potential issues, keeping your equipment in top condition for years to come.

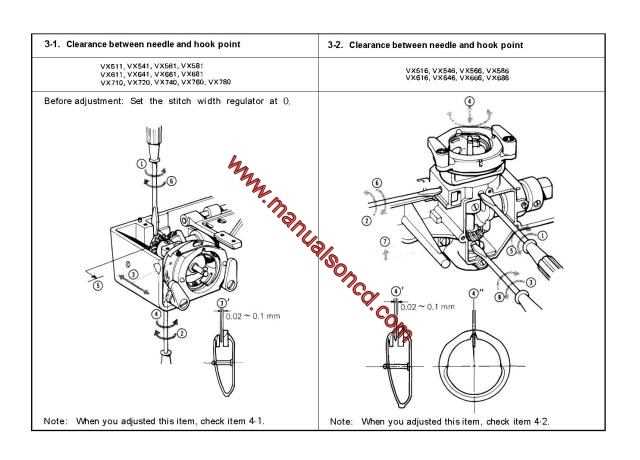

Adjusting Stitch Settings for Optimal Use

Fine-tuning stitch parameters is essential for achieving the best results in fabric manipulation. By adjusting various settings, users can enhance the quality of their work, ensuring that the finished product meets their expectations. This process involves understanding different factors that influence the stitching process and making necessary modifications accordingly.

Here is a table that outlines common adjustments and their effects:

| Adjustment Type | Description | Impact on Output |

|---|---|---|

| Tension | Modifies the tightness of the thread | Affects stitch appearance and durability |

| Length | Controls the distance between stitches | Influences the fabric’s gather and stretch |

| Width | Affects the breadth of the stitch | Determines the style and finish of the seams |

| Type | Selects the stitch pattern | Enhances decorative aspects and functionality |

Experimenting with these settings allows users to tailor their approach to different fabrics and project requirements, leading to improved outcomes and satisfaction in the crafting process.

Resolving Tension Problems Effectively

Achieving the perfect balance of thread tension is crucial for producing high-quality stitches. When issues arise, it can lead to frustrating results and compromise your projects. Understanding the underlying factors that contribute to these inconsistencies is essential for effective resolution.

- Check Thread Quality: Ensure that you are using the right type and weight of thread for your fabric. Poor quality or unsuitable thread can lead to tension discrepancies.

- Examine the Needles: Using the correct needle size and type is vital. Dull or damaged needles can affect how the thread interacts with the fabric.

- Adjust Tension Settings: Most devices have adjustable tension settings. Experiment with these to find the optimal balance for your specific materials.

In addition to these steps, regular maintenance and cleaning can help prevent tension-related issues. Dust and debris can accumulate and affect the performance of the threading system.

- Clean the Thread Path: Periodically inspect and clean the threading channels to ensure smooth operation.

- Consult the Guidelines: Always refer to the manufacturer’s recommendations for thread and needle compatibility, as well as suggested tension settings.

By systematically addressing these areas, you can effectively resolve tension problems and enhance the overall quality of your creations.

Fixing Needle and Threading Issues

When working with textile equipment, encountering problems with the needle and threading can be frustrating. Addressing these common issues is essential for achieving smooth operation and maintaining optimal performance.

Here are some typical problems and their solutions:

- Needle Misalignment: Ensure the needle is properly inserted and aligned. A crooked needle can lead to skipping stitches or damaging fabric.

- Incorrect Threading: Verify that the threading follows the correct path. Refer to the threading diagram, if available, to ensure all guides are properly utilized.

- Thread Tension Problems: Adjust the tension settings if stitches appear too tight or too loose. A balanced tension is crucial for uniform stitches.

- Needle Selection: Choose the appropriate needle type for the fabric being used. Using a needle designed for heavier materials on lightweight fabrics can cause issues.

By following these guidelines, you can effectively troubleshoot and resolve common needle and threading challenges, enhancing the overall experience with your textile equipment.

Electrical Safety Tips for Repairs

Ensuring safety during maintenance tasks involving electrical devices is crucial. Adhering to proper guidelines can help prevent accidents and injuries. Here are some essential practices to follow when engaging in such activities.

- Disconnect Power: Always unplug the device before beginning any work to eliminate the risk of electric shock.

- Use Insulated Tools: Utilize tools with insulated handles to provide an extra layer of protection against electrical currents.

- Check for Damage: Inspect cords and plugs for any signs of wear or damage before use. Replace any faulty components immediately.

- Work in a Dry Area: Ensure that your workspace is dry and free from moisture, as water increases the risk of electrical hazards.

- Avoid Overloading Circuits: Do not plug multiple devices into a single outlet, as this can lead to overheating and potential fires.

Following these precautions can significantly reduce the chances of accidents, making your maintenance tasks safer and more efficient.