Understanding the intricacies of heavy equipment is essential for ensuring optimal performance and longevity. This section delves into the vital aspects of maintaining a specific type of construction machinery known for its versatility and efficiency. Proper care and troubleshooting can significantly enhance the lifespan and functionality of this powerful tool.

In this guide, you will discover comprehensive insights into the various components and systems that require attention. Emphasis is placed on systematic approaches to address common issues, ensuring that operators can tackle challenges effectively. With a focus on practical knowledge and step-by-step instructions, this resource aims to empower users in their maintenance endeavors.

Whether you are a seasoned professional or a novice in the field, the information provided here will assist you in mastering the upkeep of your machinery. By adhering to the guidelines and recommendations, you can achieve reliable performance and minimize downtime, ultimately leading to increased productivity on the job site.

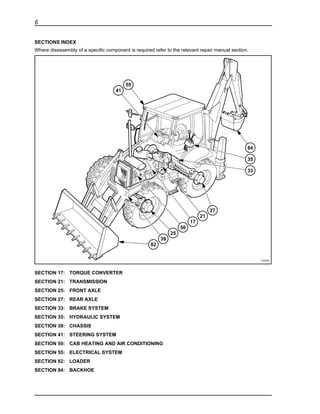

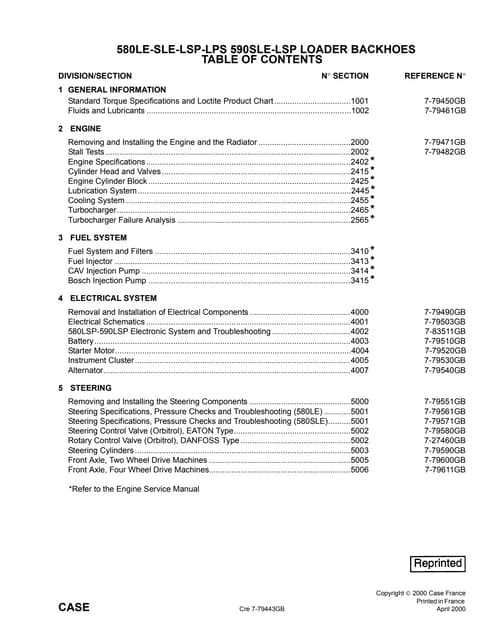

Overview of Case 580 Backhoe

This section provides a comprehensive look at a versatile construction machine known for its efficiency and reliability in various tasks. Its design combines the functionality of digging, lifting, and loading, making it an essential tool for contractors and landscapers alike. Understanding its features and capabilities can help operators maximize productivity and ensure optimal performance.

Key Features

This machine boasts several attributes that enhance its usability. With a powerful engine and advanced hydraulic systems, it offers impressive digging depth and lifting capacity. Additionally, its ergonomic controls facilitate ease of operation, allowing users to navigate tight spaces with precision.

Applications

Commonly utilized in construction, agriculture, and landscaping, this heavy equipment performs a variety of functions. It excels in tasks such as trenching, material handling, and site preparation. Its adaptability to different attachments further expands its range of applications, making it a valuable asset on any job site.

Common Issues with Backhoe Performance

When operating heavy machinery, various factors can affect overall efficiency and functionality. Identifying and addressing these concerns is crucial for optimal operation and longevity of the equipment.

- Hydraulic Problems: Insufficient fluid levels or leaks can lead to reduced lifting capacity and sluggish movements.

- Engine Performance: Issues such as overheating or irregular idling may stem from poor maintenance, affecting power output.

- Transmission Issues: Difficulty in shifting gears or slipping can hinder performance and may require immediate attention.

- Electrical Failures: Faulty wiring or dead batteries can disrupt control systems, leading to erratic operations.

- Wear and Tear: Components such as tires and buckets may experience significant degradation, impacting maneuverability and digging efficiency.

By monitoring these common issues, operators can ensure smoother functionality and extend the lifespan of their machinery.

Tools Required for Repairs

To effectively address maintenance tasks and troubleshooting, having the right equipment is essential. The following tools will facilitate the process and ensure optimal performance during the restoration of heavy machinery.

- Wrenches: A variety of sizes, including adjustable and socket types, are crucial for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing various components.

- Pliers: These are helpful for gripping and manipulating small parts.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Impact Driver: Useful for removing stubborn screws and bolts that are difficult to loosen.

In addition to these basic tools, other specialized equipment may be required based on specific tasks:

- Diagnostic Tools: Essential for identifying issues within the machinery.

- Hydraulic Jack: Necessary for safely lifting heavy components during the process.

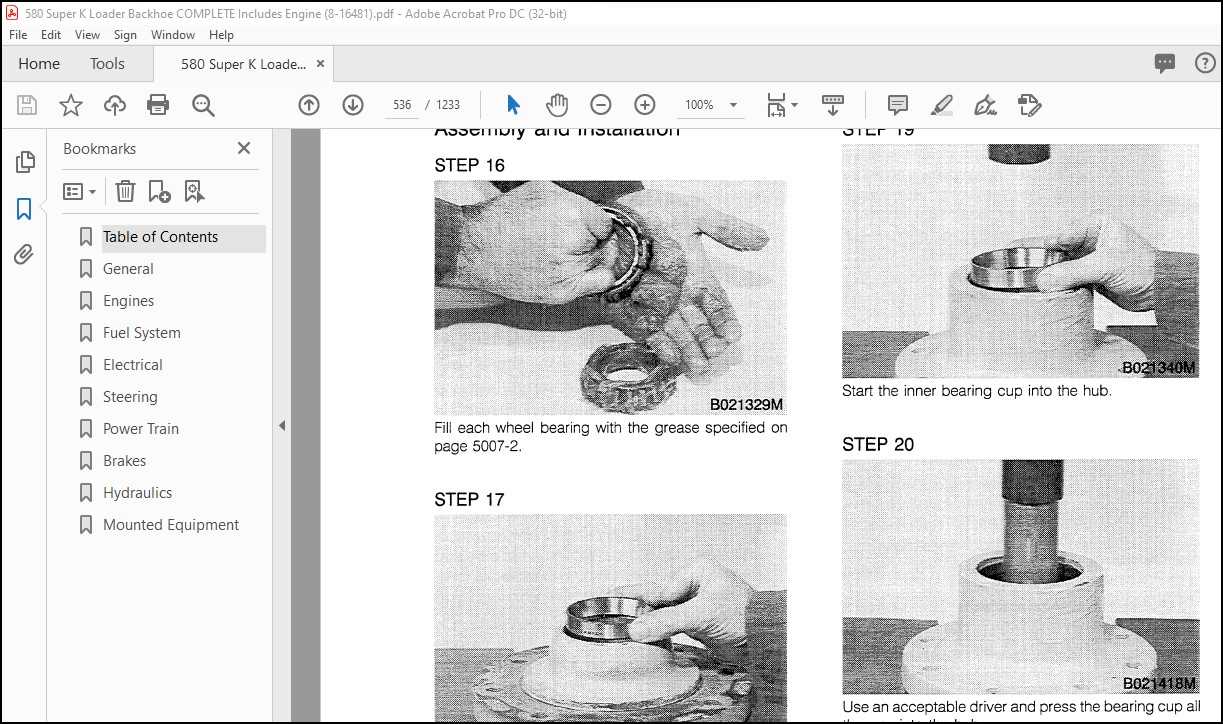

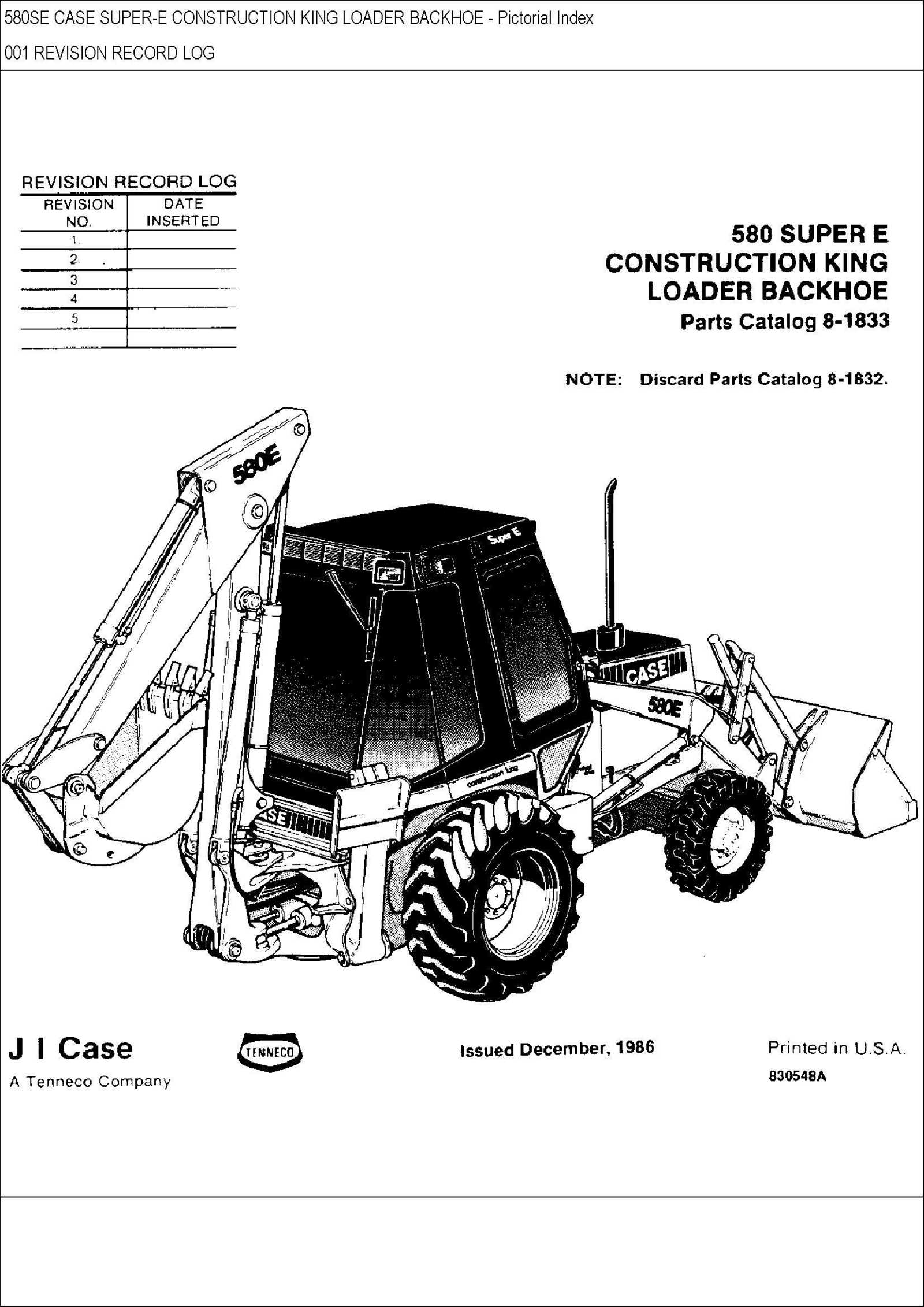

- Shop Manual: While not a tool, having access to an instructional guide is beneficial for understanding procedures and specifications.

Gathering these tools in advance will streamline the process, making it easier to complete the tasks efficiently and effectively.

Step-by-Step Troubleshooting Guide

This guide provides a structured approach to diagnosing and resolving common issues encountered with heavy machinery. By following these systematic steps, users can effectively identify problems and apply the necessary solutions.

Initial Assessment

- Check for visible signs of damage or wear.

- Inspect fluid levels, including oil, hydraulic fluid, and coolant.

- Listen for unusual sounds when operating the equipment.

- Verify that all safety mechanisms are functioning properly.

Systematic Diagnostics

- Start with the electrical system:

- Test battery voltage and connections.

- Inspect fuses and circuit breakers for faults.

- Examine the hydraulic system:

- Look for leaks in hoses and connections.

- Check pump operation and pressure levels.

- Evaluate the engine:

- Monitor temperature and pressure gauges.

- Inspect filters for blockages.

By carefully following these steps, operators can efficiently troubleshoot and resolve issues, ensuring optimal performance of the equipment.

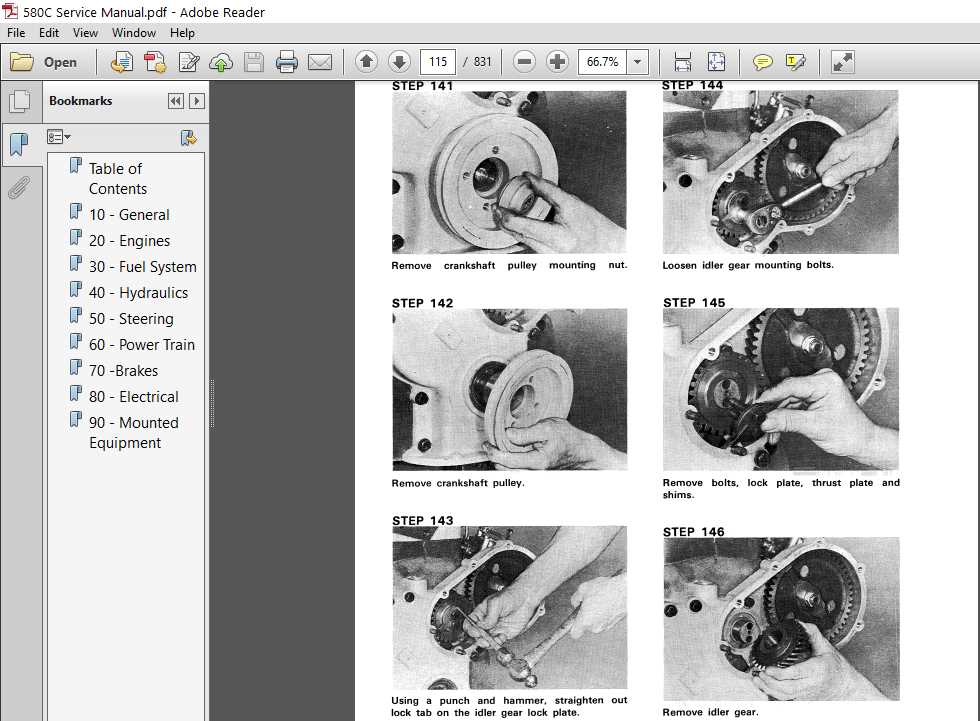

Engine Maintenance Procedures Explained

Proper upkeep of the engine is essential for ensuring optimal performance and longevity of any heavy machinery. Regular maintenance tasks not only enhance efficiency but also prevent costly breakdowns and repairs. This section outlines key procedures that should be regularly performed to keep the engine in peak condition.

- Oil Changes: Regularly replacing the engine oil is crucial for reducing friction and preventing wear. It’s advisable to check the oil level frequently and replace it as per the manufacturer’s recommendations.

- Filter Replacements: The oil filter and air filter play significant roles in maintaining engine cleanliness. Regular inspection and replacement of these filters help to prevent contaminants from entering the engine.

- Cooling System Maintenance: Ensuring the cooling system is functioning properly is vital for preventing overheating. Regularly check coolant levels, inspect hoses, and clean the radiator to promote efficient cooling.

Following these maintenance steps can lead to better fuel efficiency, increased power, and a prolonged lifespan of the engine. Additionally, documenting all maintenance activities helps to track performance and identify potential issues early on.

Hydraulic System Diagnostics and Repair

The functionality of hydraulic systems is crucial for the effective operation of heavy machinery. Diagnosing issues within these systems requires a systematic approach to identify malfunctions and ensure optimal performance. This section outlines key methods for assessing hydraulic components, along with strategies for addressing common problems.

Identifying Common Issues

Hydraulic systems can experience a variety of issues, such as leaks, pressure drops, or erratic operation. Symptoms may include unusual noises, sluggish movement, or failure to respond to controls. Conducting a thorough inspection of hoses, fittings, and cylinders is essential to pinpoint the source of the problem. Utilize pressure gauges to monitor system performance and confirm the integrity of the hydraulic circuit.

Corrective Actions

Once the issue is identified, taking appropriate measures is vital for restoring functionality. Replacing worn or damaged components, such as seals and hoses, can significantly improve system performance. Additionally, ensuring proper fluid levels and quality is essential for preventing future malfunctions. Regular maintenance checks and timely repairs will extend the lifespan of the hydraulic system and enhance overall efficiency.

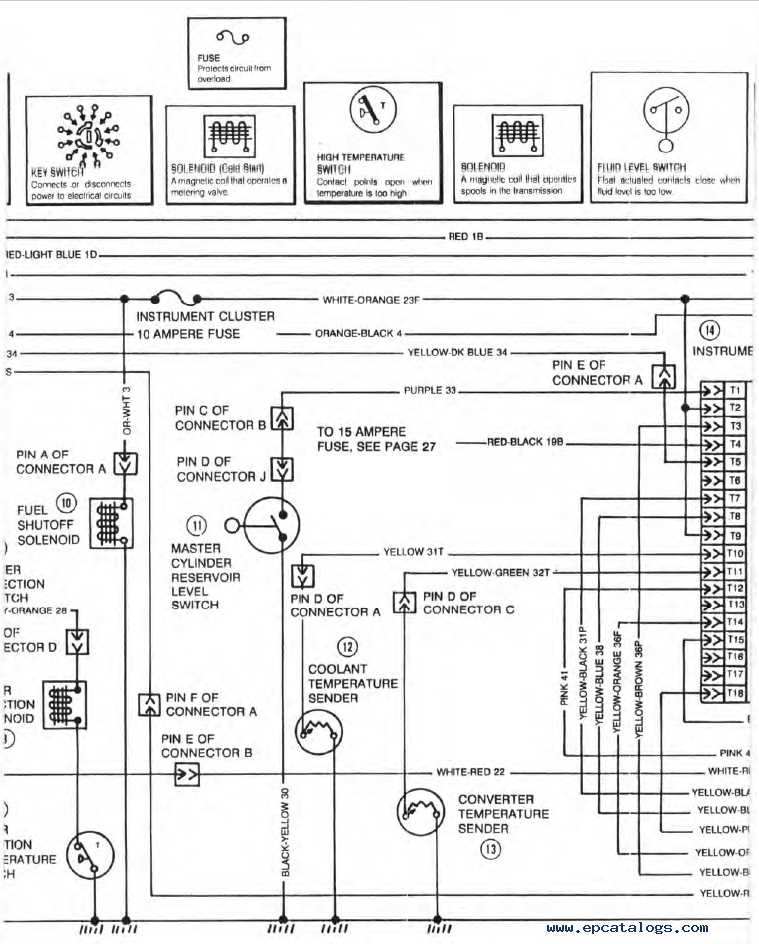

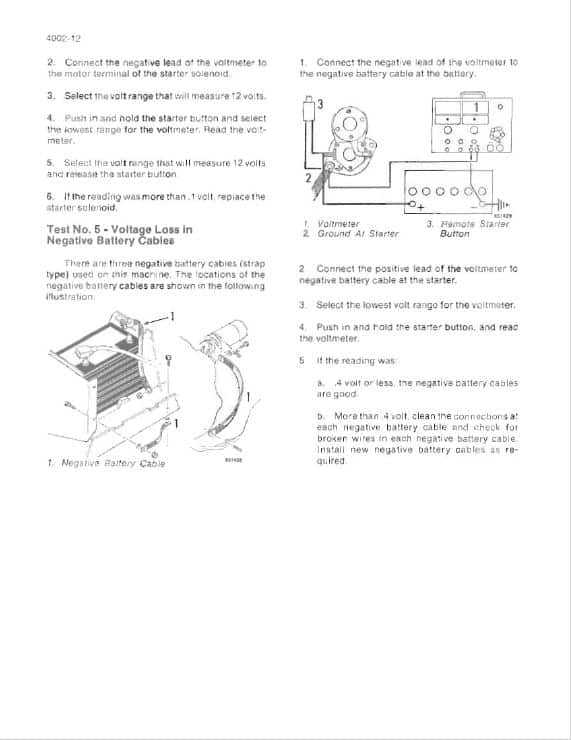

Electrical Components and Wiring Insights

This section delves into the intricate network of electrical elements and connections that are vital for the seamless operation of heavy machinery. Understanding these components not only enhances functionality but also aids in effective troubleshooting and maintenance.

Wiring Schematics play a crucial role in mapping out the flow of electrical current throughout the system. They provide a visual representation, making it easier to identify and rectify issues that may arise.

In addition, the quality of connectors and terminals significantly influences the reliability of electrical systems. Choosing the right materials ensures that connections remain secure and resistant to wear over time.

Power Distribution is another key aspect to consider. It involves the management of how electricity is supplied to various components, ensuring that each part receives adequate power to function optimally. Proper distribution reduces the risk of overloads and enhances overall efficiency.

Regular inspection of fuses and relays is essential for maintaining system integrity. These components serve as protective measures, preventing electrical failures that could lead to costly repairs.

Finally, a thorough understanding of grounding techniques is vital for minimizing electrical interference and ensuring safety during operation. Adequate grounding helps in protecting both the machinery and the operator from potential hazards.

Transmission Issues and Solutions

When operating heavy machinery, one may encounter various challenges related to the transmission system. These complications can arise from multiple sources, affecting the overall performance and efficiency of the equipment. Understanding common problems and their remedies is essential for maintaining optimal functionality.

Common Symptoms

Several indicators may suggest transmission difficulties. These include unusual noises, slipping gears, and delayed response when shifting. Operators should be vigilant for warning signs to prevent further damage.

Possible Causes

Issues can stem from a range of factors, such as low fluid levels, contaminated fluid, or worn components. Regular checks of fluid quality and levels can help identify potential problems before they escalate.

Effective Solutions

To address these challenges, first, ensure that the fluid is at the appropriate level and free of contaminants. If contamination is present, a complete fluid change may be necessary. For mechanical wear, inspecting and replacing worn parts will help restore proper functionality. Additionally, regular maintenance schedules can mitigate future issues.

Conclusion

Staying proactive with routine inspections and addressing issues promptly can significantly enhance the longevity and reliability of the transmission system. By understanding the common problems and implementing effective solutions, operators can ensure their machinery remains in optimal working condition.

Safety Precautions During Repairs

When performing maintenance on heavy machinery, ensuring a secure working environment is crucial. Adhering to safety protocols can prevent accidents and injuries, ensuring a smooth and efficient process.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and steel-toed boots.

- Keep the workspace clean and free from clutter to minimize trip hazards.

- Ensure all tools and equipment are in good condition and suitable for the tasks at hand.

Working with Machinery

- Before starting any maintenance, disconnect the power source to prevent accidental activation.

- Use proper lifting techniques and equipment when handling heavy components.

- Be aware of your surroundings and keep bystanders at a safe distance.

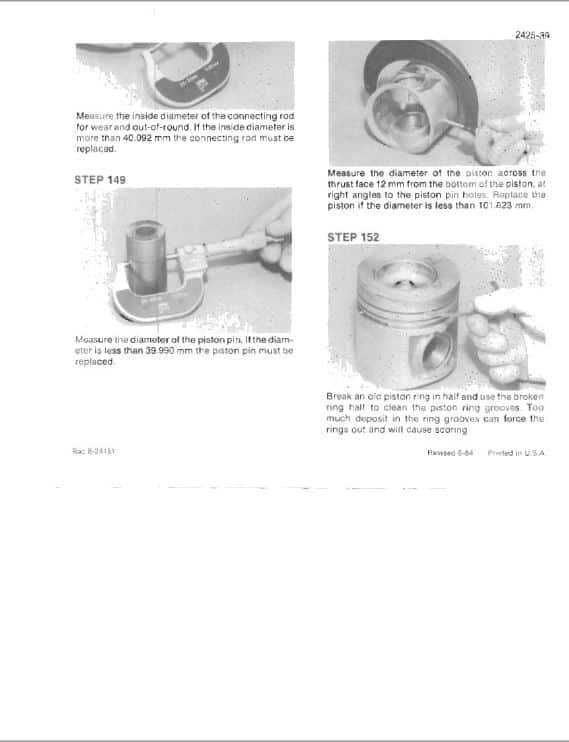

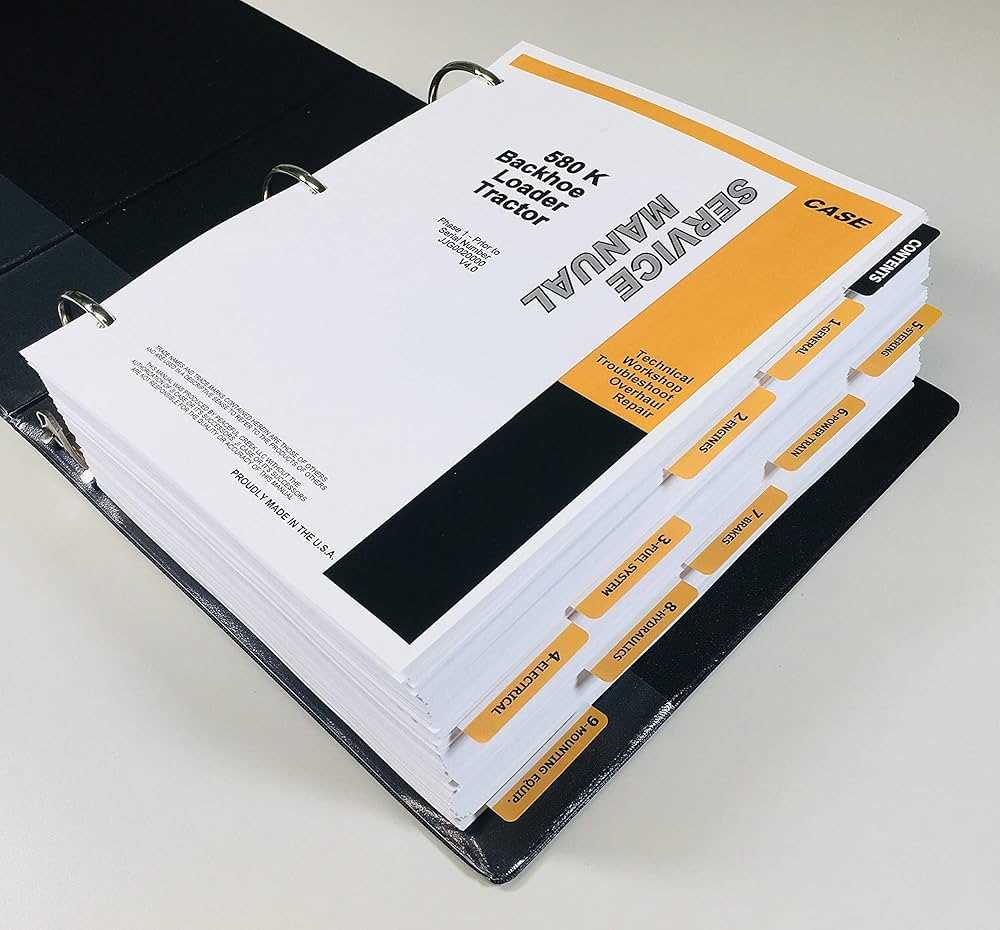

Parts Replacement and Specifications

This section outlines the essential considerations for substituting components in heavy machinery. Understanding the specifications and compatible parts is crucial for maintaining optimal performance and longevity.

Common Components for Replacement

- Hydraulic Cylinders

- Transmission Filters

- Fuel Injectors

- Engine Oil Filters

- Battery

Specifications to Consider

- Compatibility: Ensure that the new part matches the specifications of the original component.

- Quality: Opt for parts from reputable manufacturers to guarantee reliability.

- Performance: Consider the performance ratings of the replacement parts to ensure they meet operational standards.

- Warranty: Check for warranties that provide coverage for defects or premature failures.

By adhering to these guidelines, operators can effectively manage parts replacement, thereby enhancing the operational efficiency and lifespan of their equipment.

Maintenance Schedule for Optimal Operation

To ensure peak performance and longevity of your equipment, adhering to a systematic maintenance plan is crucial. Regular upkeep not only enhances efficiency but also minimizes unexpected breakdowns, ultimately leading to cost savings and increased productivity.

Daily Checks

Before commencing daily tasks, perform routine inspections to identify potential issues. Check fluid levels, inspect hoses and connections for leaks, and ensure that all safety features are operational. Address any irregularities immediately to prevent further complications.

Weekly and Monthly Maintenance

Conduct more comprehensive assessments on a weekly and monthly basis. This includes changing filters, greasing fittings, and examining the undercarriage for wear. Implementing these practices helps maintain optimal functionality and extends the lifespan of the machinery.

Regular maintenance is essential for achieving maximum efficiency and reliability. By following a well-structured schedule, operators can ensure that their equipment remains in top condition, ready to tackle any challenge.

Resources for Further Learning

Expanding your knowledge about construction machinery can significantly enhance your skills and understanding of equipment maintenance. There are numerous resources available that provide valuable information and insights into the operation and upkeep of heavy machinery.

- Online Forums: Engaging with communities of enthusiasts and professionals can offer practical tips and troubleshooting advice.

- Manufacturer Websites: Official sites often provide detailed specifications, FAQs, and technical bulletins related to various models.

- YouTube Channels: Visual tutorials can be particularly helpful in demonstrating repair techniques and maintenance procedures.

- Trade Publications: Subscribing to industry magazines can keep you updated on the latest innovations and best practices in machinery management.

- Books and E-books: Look for literature focused on machinery operation and maintenance, which can serve as excellent reference materials.

- Workshops and Training Programs: Participating in hands-on training can deepen your understanding and skills in equipment operation.

By utilizing these resources, you can build a comprehensive knowledge base that will serve you well in your endeavors with heavy equipment.