This section focuses on addressing common issues related to specific cooling devices. Understanding the operational aspects of such equipment is crucial for maintaining optimal performance and ensuring longevity.

In the world of refrigeration technology, problems can arise unexpectedly. Identifying these challenges promptly can save time and resources. This guide aims to provide insights into troubleshooting procedures, empowering users to tackle minor issues effectively.

Moreover, having access to detailed instructions enhances one’s ability to manage and maintain essential devices. Clear guidelines facilitate a better understanding of the components involved and their functions, ultimately leading to improved efficiency and reliability.

When it comes to maintaining and fixing equipment, having the right set of instruments can significantly enhance the efficiency of the process. A well-equipped toolkit ensures that tasks can be performed smoothly and effectively, minimizing downtime and preventing further issues.

Basic Toolkit Essentials

Starting with a solid foundation, certain tools are indispensable for any technician. These items facilitate a variety of tasks, from assembly to troubleshooting. Below is a table outlining the fundamental tools required for effective servicing:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for fastening and unfastening screws of various sizes. |

| Wrench Set | Essential for gripping and turning nuts and bolts. |

| Pliers | Helpful for gripping, bending, and cutting wire. |

| Multimeter | Used for measuring voltage, current, and resistance. |

| Flashlight | Illuminates dark areas to aid in inspections. |

Advanced Tools for Specific Tasks

In addition to the basics, certain specialized instruments can be invaluable for more complex tasks. These tools may not be necessary for every situation but are crucial for specific types of maintenance or troubleshooting:

| Tool | Purpose |

|---|---|

| Pressure Gauge | Measures the pressure levels in the system. |

| Thermometer | Used for checking temperature settings and ensuring optimal performance. |

| Refrigerant Scale | Measures refrigerant levels accurately during service. |

| Vacuum Pump | Removes moisture and air from the system for better efficiency. |

Step-by-Step Troubleshooting Guide

When facing challenges with a cooling unit, it is essential to follow a systematic approach to identify and resolve issues effectively. This guide provides clear steps that assist in diagnosing common problems, ensuring a smoother operation and extending the life of the equipment.

Initial Assessment

Begin by observing the device for any unusual sounds, leaks, or error messages. Ensure that the power supply is stable and check the circuit breakers. Document any irregularities, as this information can be crucial for further analysis.

Component Inspection

Proceed to inspect key components, such as the condenser and evaporator. Look for signs of wear, damage, or obstructions. Cleaning any debris and ensuring proper airflow can often resolve many issues. Regular maintenance is vital for optimal functionality.

Identifying Faulty Components

Recognizing malfunctioning parts within an appliance can significantly enhance its longevity and performance. A systematic approach to troubleshooting ensures that the correct issues are addressed, minimizing unnecessary replacements and repairs.

Common Signs of Failure

Several indicators can suggest that a component is not functioning properly. Unusual noises, inconsistent performance, or leaks can signal potential problems. Paying close attention to these signs can aid in early detection and prevent further damage.

Testing and Verification

Utilizing testing tools such as multimeters can provide insights into the functionality of various parts. Testing voltage levels, resistance, and continuity can help pinpoint the specific areas that require attention. Verifying the integrity of components through these methods is essential for effective troubleshooting.

Maintaining Your Ice Machine

Regular upkeep of your freezing equipment is essential for optimal performance and longevity. By following a few simple practices, you can ensure that your unit operates efficiently, producing quality results and reducing the likelihood of future issues. Consistent attention to detail not only enhances the lifespan of the equipment but also promotes hygiene and safety in your establishment.

Daily Cleaning Tasks

Start each day by inspecting the interior and exterior of the unit. Wipe down surfaces with a mild detergent and a soft cloth to remove any residue or buildup. Ensure that drainage areas are clear and free from obstructions. This simple routine prevents contamination and maintains a sanitary environment for storage.

Periodic Maintenance Checks

Schedule thorough inspections at regular intervals to address any potential problems before they escalate. This includes checking electrical connections, ensuring adequate airflow, and examining water supply lines for leaks or blockages. Additionally, consider replacing filters as recommended by the manufacturer to maintain efficient operation. Keeping a log of these checks can help track performance over time and highlight any recurring issues.

Cleaning Procedures for Optimal Performance

Maintaining the cleanliness of your equipment is essential for ensuring it operates efficiently and effectively. Regular sanitation not only enhances performance but also extends the lifespan of the unit. This section outlines the necessary steps to achieve optimal cleanliness, which will promote reliable operation and minimize potential issues.

Step-by-Step Cleaning Process

Begin by turning off the unit and disconnecting it from the power supply. Remove any removable components and clean them with a mild detergent solution. Use a soft brush or cloth to reach into tight spaces, ensuring no debris is left behind. Rinse thoroughly and allow all parts to dry completely before reassembling.

Frequency and Maintenance Tips

For the best results, establish a regular cleaning schedule, ideally on a monthly basis or as specified by the manufacturer. Regular inspections for build-up or wear will help identify issues early. Keeping a log of cleaning dates and any maintenance performed can aid in tracking the unit’s condition over time.

Refrigerant and Its Role

The substance responsible for transferring heat within cooling systems plays a crucial part in maintaining optimal temperatures. Its effectiveness directly influences the efficiency and performance of the entire cooling process, ensuring that desired levels are achieved consistently.

How Refrigerants Work

In essence, the refrigerant circulates through various components, absorbing heat from the surrounding environment and releasing it elsewhere. This cycle of evaporation and condensation allows for effective heat exchange, which is vital for sustaining low temperatures in the desired area.

Importance of Proper Refrigerant Management

Proper handling and monitoring of this vital fluid are essential for the longevity of the system. Over time, leaks or improper levels can lead to diminished performance, increased energy consumption, and even environmental concerns. Regular maintenance and checks ensure that the refrigerant levels remain optimal, allowing for efficient operation and minimizing the risk of breakdowns.

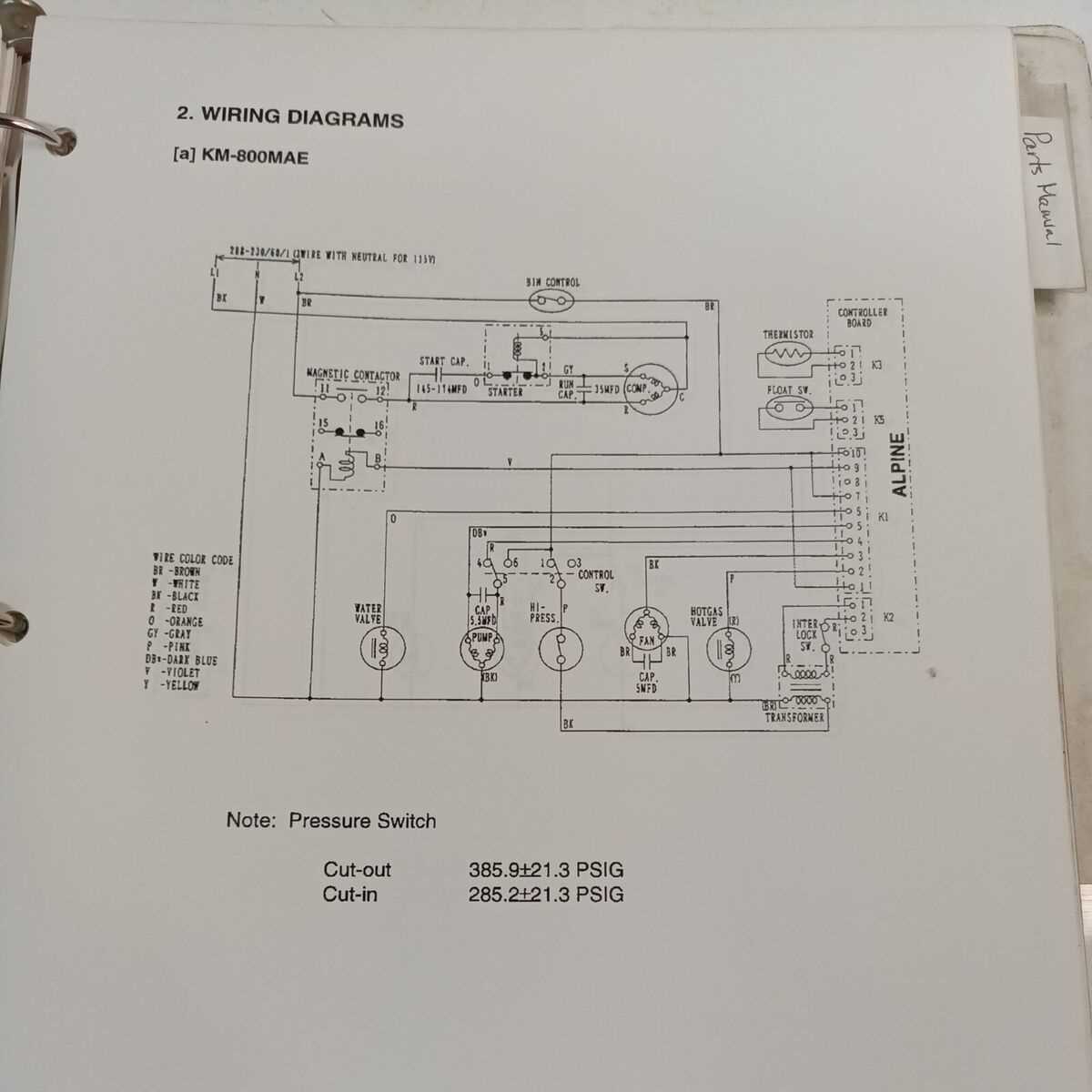

Electrical System Insights

This section delves into the intricacies of the power systems that facilitate the operation of cooling devices. Understanding the components and their interconnections is crucial for ensuring optimal performance and longevity of the unit.

At the core of these systems are several key elements that work in tandem to provide functionality. Each part plays a vital role, and any disruption can affect overall efficiency. Below is a summary of essential components and their functions:

| Component | Description |

|---|---|

| Power Supply | Converts electrical input into usable energy for the unit. |

| Control Board | Regulates the operations and coordinates signals between different parts. |

| Thermostat | Monitors temperature and adjusts operation to maintain desired levels. |

| Wiring Harness | Facilitates the connection between various electrical components. |

| Compressors | Circulate refrigerant and enable cooling by compressing gas. |

Regular inspection of these elements can prevent issues and enhance performance. Familiarity with each part helps in diagnosing problems quickly, allowing for effective solutions.

Replacing the Water Filter

Maintaining a clean and efficient water supply is essential for optimal performance. Over time, filters can become clogged with impurities, affecting the overall functionality. Regularly changing the filter ensures the system operates smoothly and prevents potential issues.

To begin the process, gather the necessary tools and a replacement filter compatible with your unit. It is advisable to turn off the water supply and unplug the device for safety. Next, locate the filter compartment, which is typically situated near the water inlet.

Once accessed, gently remove the old filter by twisting or pulling it out, depending on the design. Make sure to dispose of it properly. Before installing the new filter, inspect the compartment for any debris and clean it if necessary.

Insert the new filter firmly, ensuring it is secured in place. After installation, restore the water supply and plug the unit back in. Run a small amount of water through the system to clear any remaining air and check for leaks. Regular filter replacement is key to maintaining performance and ensuring the longevity of the equipment.

Safety Protocols During Repairs

Ensuring a secure environment while conducting maintenance tasks is paramount. Adhering to established guidelines helps prevent accidents and injuries, safeguarding both the technician and the equipment. Awareness of potential hazards and taking appropriate precautions can significantly enhance safety during servicing procedures.

Before commencing any work, it is essential to disconnect the power source to eliminate the risk of electrical shock. Additionally, using personal protective equipment such as gloves and goggles can further shield individuals from potential harm. Maintaining a clean workspace free of clutter is also crucial, as it reduces the likelihood of slips, trips, and falls.

When handling tools and components, follow the manufacturer’s instructions carefully. It is advisable to familiarize oneself with the equipment’s design and functionality to avoid unintended consequences. Regularly inspecting tools for wear and tear ensures that they remain in optimal condition, contributing to a safer working environment.

Lastly, staying informed about emergency procedures can be invaluable. In case of an accident, knowing how to respond swiftly can mitigate damage and promote a safe outcome. By prioritizing these protocols, technicians can effectively minimize risks while performing essential tasks.

When to Call a Professional

Knowing when to seek expert assistance can save time and prevent further complications. While some issues may seem minor and manageable, certain circumstances demand the attention of a skilled technician.

If you encounter persistent problems that do not resolve after basic troubleshooting, it is wise to consider professional help. Strange noises, leaking fluids, or unexpected shutdowns are signs that indicate the need for specialized knowledge. Additionally, if you notice a significant drop in performance or efficiency, it may be time to reach out to an expert.

Furthermore, if the device is under warranty, attempting to fix it yourself could void that protection. In such cases, contacting a certified technician ensures that any repairs are handled correctly and maintain the warranty coverage. Remember, prioritizing safety and efficiency is crucial, and sometimes calling in a professional is the best course of action.