Ensuring the longevity and optimal performance of large vehicles requires a comprehensive understanding of their intricate systems. This section aims to equip users with essential knowledge, enabling them to address common issues effectively.

Detailed insights into various components are crucial for anyone involved in the upkeep of such machines. By familiarizing oneself with operational intricacies, one can significantly enhance functionality and reduce downtime.

Additionally, this guide offers practical solutions and troubleshooting techniques, empowering users to tackle challenges confidently. With the right information at hand, maintaining these robust machines becomes a manageable task.

Understanding Volvo Truck Repair Manuals

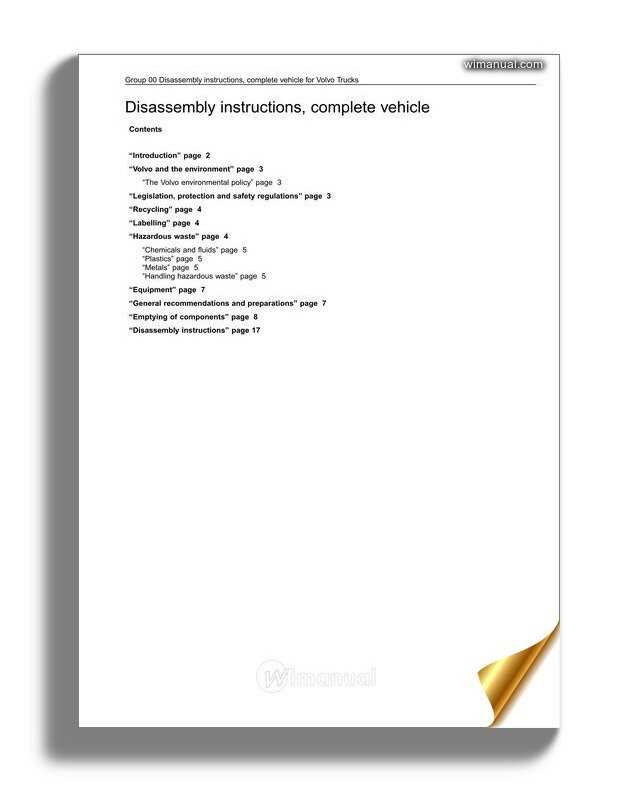

This section explores the importance of comprehensive guides designed for the maintenance and service of heavy-duty vehicles. Such documents are essential for technicians and enthusiasts alike, providing detailed instructions to ensure proper functionality and longevity of the machinery.

Key Components of Service Guides

These resources typically include schematics, diagnostic procedures, and troubleshooting tips. Understanding each section is crucial for effective maintenance, as it empowers users to identify issues quickly and implement solutions without unnecessary delays.

The Role of Accurate Documentation

Accurate documentation enhances safety and efficiency during servicing tasks. Clear illustrations and step-by-step processes foster a better understanding of complex systems, allowing for informed decisions in the repair process. Adhering to these guidelines not only aids in restoring optimal performance but also contributes to the overall reliability of the vehicle.

Common Issues with Volvo Trucks

When operating heavy-duty vehicles, various challenges may arise that affect performance and reliability. Understanding these frequent problems can help owners and operators prepare for maintenance and troubleshooting, ensuring smoother operations.

Engine Performance Troubles

One of the most prevalent issues involves the engine’s efficiency. Drivers may notice reduced power, unusual noises, or irregular idling. These symptoms can indicate problems with fuel delivery, air intake systems, or even exhaust blockages that require immediate attention to prevent further damage.

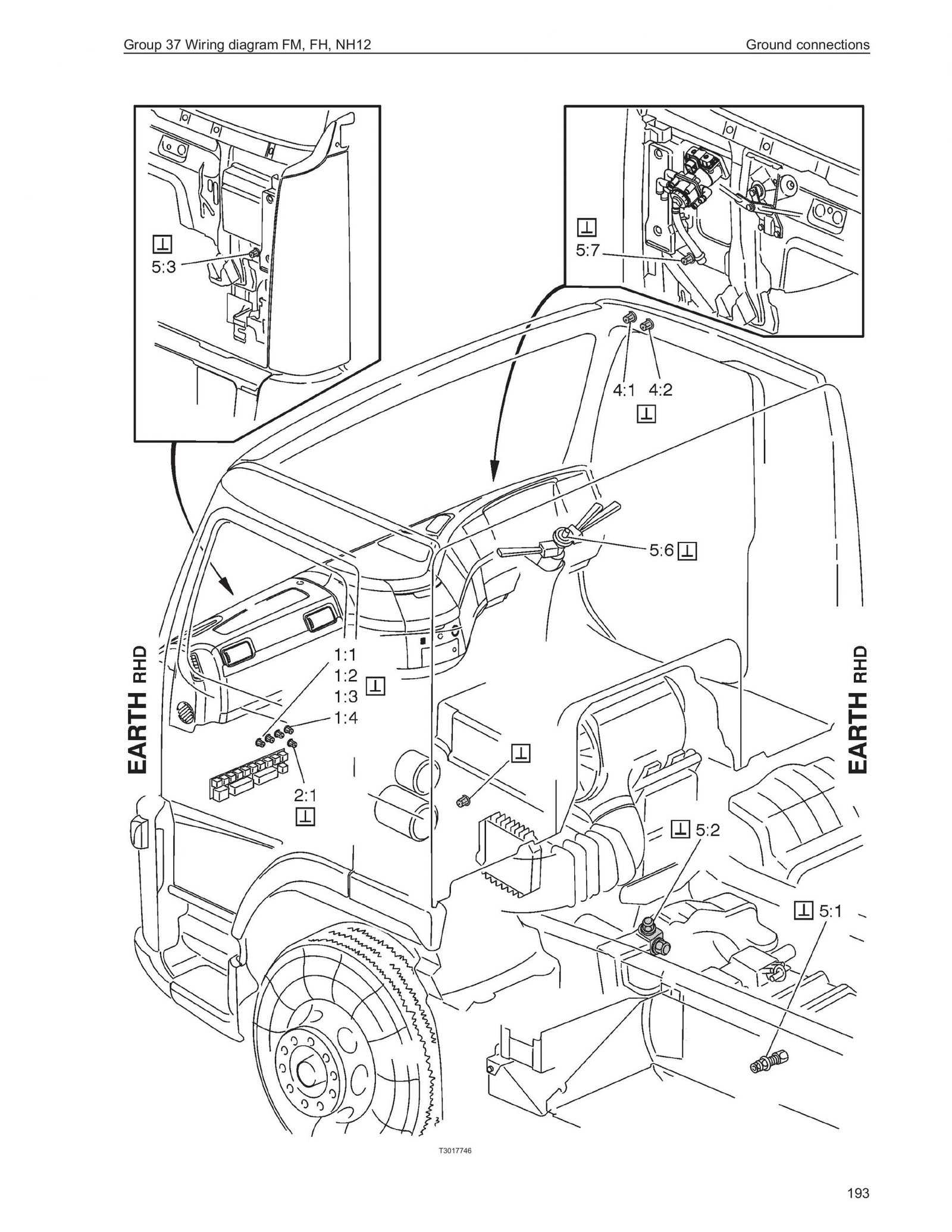

Electrical System Failures

Another common concern relates to the vehicle’s electrical components. Faulty wiring, dead batteries, or malfunctioning sensors can lead to a host of problems, including starting difficulties or dashboard warning lights. Regular inspections of the electrical system can mitigate these issues and enhance the overall reliability of the vehicle.

Essential Tools for Truck Maintenance

Proper upkeep of heavy vehicles is crucial for ensuring their longevity and optimal performance. Having the right equipment can make a significant difference in efficiency and effectiveness during service tasks. Here are some indispensable implements that every mechanic should have at their disposal.

Wrenches and Sockets: A comprehensive set of wrenches and sockets is fundamental for loosening and tightening various fasteners. These tools come in different sizes and types, allowing for versatility in handling numerous components.

Diagnostic Equipment: Modern machinery often requires electronic diagnostics to identify issues. A quality diagnostic tool can provide insights into the vehicle’s systems, enabling timely interventions before minor problems escalate.

Safety Gear: Ensuring personal safety is paramount when working on large machinery. Items such as gloves, goggles, and steel-toed boots protect the technician from potential hazards during maintenance activities.

Fluid Management Tools: Efficient fluid changes are essential for maintaining optimal functioning. Tools like oil extractors, funnels, and containers facilitate clean and straightforward fluid management.

Air Compressor: An air compressor is vital for various tasks, from inflating tires to powering pneumatic tools. This equipment enhances productivity and streamlines many maintenance processes.

Jack and Stands: Lifting heavy vehicles safely requires robust jacks and stands. These tools ensure stability while accessing critical undercarriage components, providing a safe working environment.

Investing in these essential tools can enhance maintenance quality and efficiency, ultimately contributing to the reliable operation of heavy machinery.

Step-by-Step Repair Procedures

This section provides detailed instructions for addressing common issues encountered during vehicle maintenance. By following these systematic guidelines, operators can efficiently diagnose and resolve problems, ensuring optimal performance.

Preparation for Maintenance

Before beginning any work, gather all necessary tools and materials. Ensure the vehicle is parked on a level surface and that the engine is turned off. For safety, wear appropriate personal protective equipment such as gloves and goggles.

Diagnostic Approach

Start by assessing the symptoms. Conduct a visual inspection to identify any apparent damage or irregularities. Record any error codes if the vehicle is equipped with a diagnostic system. This information will guide further investigation.

Follow the specific steps outlined for each task, ensuring all connections and components are correctly handled. Regular adherence to these procedures enhances reliability and longevity.

Safety Tips During Repairs

When working on vehicles, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, making the maintenance process more efficient and secure. This section outlines essential guidelines to follow while conducting mechanical work.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) to safeguard against potential hazards. This includes gloves, safety glasses, and sturdy footwear. High-visibility clothing can also be beneficial, especially in low-light conditions, to ensure you are seen by others.

Workspace Organization

A tidy workspace significantly reduces the risk of accidents. Keep tools organized and within reach to prevent unnecessary movement. Make sure the area is well-lit and free from clutter. Additionally, ensure that all hazardous materials are stored correctly and clearly labeled.

Preventive Maintenance Guidelines

Effective upkeep is essential for ensuring the longevity and reliability of any vehicle. Establishing a systematic approach to routine checks and care can help identify potential issues before they escalate, ultimately enhancing performance and safety.

Routine Inspections

Conducting regular examinations of key components is vital. This includes assessing fluid levels, checking tire conditions, and evaluating brake performance. Regularly scheduled assessments help detect wear and tear, allowing for timely interventions that prevent more significant problems.

Fluid Management

Maintaining optimal fluid levels is crucial for smooth operation. Regularly changing oils, coolants, and other essential fluids ensures that the engine and other systems function effectively. Adhering to the recommended service intervals for fluid replacement can significantly extend the life of various parts.

Electrical Systems Troubleshooting

This section provides a comprehensive overview of diagnosing issues related to electrical systems in heavy-duty vehicles. Understanding the fundamental principles of electricity and common symptoms of faults can significantly aid in effective problem resolution.

When faced with electrical malfunctions, it is essential to follow a systematic approach:

- Identify Symptoms:

- Intermittent power loss

- Non-functioning accessories

- Unusual warning lights on the dashboard

- Inspect Components:

- Check the battery condition and connections

- Examine fuses for any signs of damage

- Assess wiring for frays or corrosion

- Use Diagnostic Tools:

- Multimeter for voltage and continuity tests

- Scan tools for retrieving fault codes

- Oscilloscope for waveform analysis

- Test and Replace:

- Perform tests on suspect components

- Replace faulty parts as needed

- Ensure all connections are secure and insulated

Following this structured approach can help in accurately pinpointing and rectifying electrical system issues, leading to improved functionality and reliability.

Engine Components and Care

The functionality and longevity of any vehicle largely depend on the quality and condition of its power unit. Understanding the various elements that constitute the engine, as well as how to maintain them effectively, is crucial for optimal performance. This section will delve into the essential parts of the power unit and provide insights into their proper upkeep.

Key Engine Parts

Modern power units consist of several critical components, including the cylinder head, pistons, and crankshaft. Each of these parts plays a significant role in the overall operation of the engine. The cylinder head is responsible for housing the intake and exhaust valves, while the pistons facilitate the combustion process by moving up and down within the cylinders. The crankshaft converts linear motion into rotational motion, powering the vehicle’s drivetrain.

Maintenance Practices

Regular care is essential to ensure the engine runs smoothly. Routine checks should include monitoring oil levels, inspecting belts for wear, and replacing filters as needed. Additionally, keeping the cooling system in optimal condition prevents overheating, which can lead to severe damage. Implementing these maintenance practices will extend the life of the power unit and enhance its efficiency.

Transmission System Insights

The transmission system plays a crucial role in the overall functionality of heavy-duty vehicles, facilitating the transfer of power from the engine to the wheels. Understanding its components and operation is essential for maintaining optimal performance and ensuring smooth driving experiences.

Key Components

The primary elements of a transmission system include the gearbox, clutches, and associated linkages. Each part works in harmony to provide various gear ratios, allowing for effective acceleration and deceleration under different conditions. A well-maintained gearbox ensures seamless shifting, contributing to the vehicle’s efficiency.

Common Issues

Over time, wear and tear can lead to common problems such as slipping gears, delayed engagement, or unusual noises. Regular inspections and timely interventions can mitigate these issues, extending the lifespan of the system and enhancing reliability.

Maintenance Tips

To keep the transmission system in top shape, it is vital to check fluid levels regularly, replace filters, and follow recommended service intervals. Utilizing quality lubricants tailored for specific systems can also make a significant difference in performance and longevity.

Conclusion

Comprehending the intricacies of the transmission system not only aids in troubleshooting but also empowers operators to make informed decisions regarding maintenance and care. A proactive approach can lead to improved efficiency and a more enjoyable driving experience.

Bodywork and Interior Repairs

This section focuses on the maintenance and restoration of the outer and inner elements of vehicles. Addressing cosmetic and structural issues is essential for both aesthetics and functionality. Proper attention to these areas ensures longevity and enhances overall performance.

Common Exterior Issues

- Dents and scratches

- Rust and corrosion

- Panel misalignment

Interior Damage Solutions

- Assessing upholstery wear and tear

- Replacing or repairing damaged panels

- Addressing electrical component failures

Regular inspections and timely interventions can significantly improve both appearance and usability, making these tasks vital for any vehicle owner.

Using Diagnostic Software Effectively

Utilizing diagnostic applications can significantly enhance the troubleshooting process, providing insights into vehicle performance and identifying underlying issues. These tools allow technicians to access critical data, enabling them to make informed decisions during maintenance procedures.

Understanding the Interface: Familiarizing oneself with the software interface is essential. Navigating through various menus and options can streamline the diagnostic process, allowing for quicker access to vital information.

Interpreting Data: Analyzing the information provided by the diagnostic tool is crucial. Interpreting error codes and system readings accurately can lead to more effective problem-solving and prevent unnecessary repairs.

Regular Updates: Keeping the software up to date ensures access to the latest features and improvements. Regular updates can enhance compatibility with new systems and enhance overall functionality.

Training and Resources: Investing time in training can improve proficiency in using diagnostic applications. Online resources, manuals, and forums can provide valuable insights and tips for maximizing the tool’s effectiveness.

Finding Genuine Volvo Parts

Ensuring the longevity and performance of your vehicle relies heavily on the quality of components used during maintenance and replacement. Identifying authentic parts is crucial for optimal operation and reliability. Here are several strategies to assist you in locating original components:

- Authorized Dealers: Visit certified retailers that specialize in original equipment. They can provide access to a full range of components designed specifically for your model.

- Manufacturer’s Website: Check the official site for guidance on genuine parts and where to purchase them. This resource often includes valuable information about compatibility.

- Parts Catalogs: Utilize detailed catalogs that list original components. These can be found online or at authorized service centers.

- Community Forums: Engage with online communities where enthusiasts and professionals share their experiences. They can provide recommendations and insights on where to find authentic items.

- Part Numbers: Always verify the part number. Cross-referencing ensures that you are acquiring the correct component for your vehicle.

By following these guidelines, you can confidently source authentic components that will maintain the integrity and performance of your vehicle.

Resources for Further Learning

Expanding your knowledge in the field of automotive maintenance and troubleshooting can significantly enhance your skills and understanding. Various resources are available to help individuals delve deeper into essential concepts, techniques, and best practices related to vehicle servicing and diagnostics.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Interactive courses that cover various aspects of vehicle maintenance and repair. | Coursera |

| Webinars | Live sessions hosted by industry experts, focusing on advanced techniques and new technologies. | WebinarJam |

| Technical Journals | Publications that provide in-depth research articles and case studies in the automotive sector. | Automotive Engineering |

| Forums | Online communities where professionals share experiences, advice, and solutions. | Automotive Forums |

| YouTube Channels | Video tutorials that demonstrate practical techniques and troubleshooting steps. | YouTube |