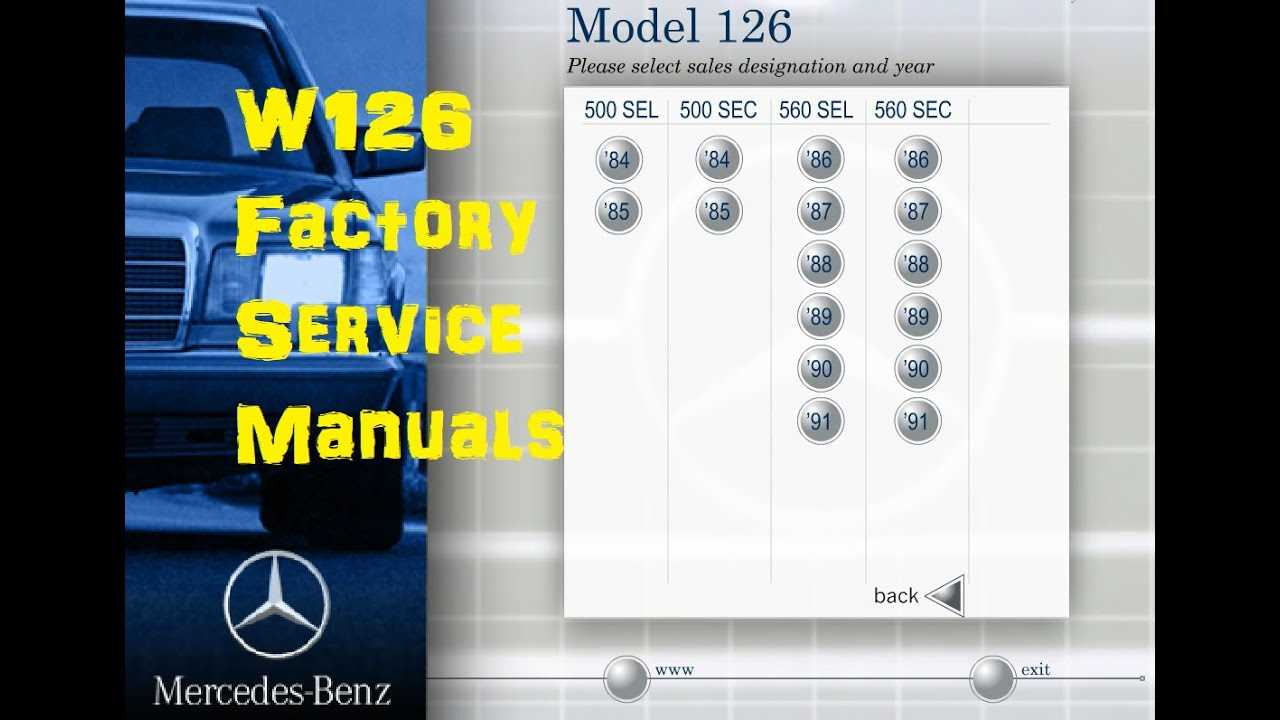

Maintaining a classic automobile requires a thorough understanding of its intricacies and components. This section provides insights into the essential practices for keeping your vehicle in optimal condition. With the right knowledge, you can ensure longevity and performance.

Familiarity with the vehicle’s systems is crucial for effective upkeep. From the engine and transmission to the electrical systems, knowing how each part functions allows for more informed decisions during servicing. Proper techniques can help in identifying potential issues before they escalate.

Additionally, understanding the tools and equipment necessary for maintenance can streamline the process. By being well-equipped, you can perform tasks with greater efficiency and confidence. This guide aims to empower enthusiasts and owners alike, ensuring that every aspect of their automobile receives the attention it deserves.

Electrical problems in vehicles can lead to significant inconveniences and affect overall performance. Identifying these issues early can save time and resources. Here are some frequent electrical concerns and their potential remedies.

Frequent Problems

- Battery Drain: A weak or faulty battery can lead to starting difficulties.

- Flickering Lights: This may indicate issues with the alternator or wiring connections.

- Malfunctioning Sensors: Faulty sensors can disrupt various systems, including safety features.

Possible Solutions

- Regularly check battery health and replace if necessary.

- Inspect all wiring connections for signs of wear or corrosion.

- Test the alternator output to ensure proper charging.

- Utilize diagnostic tools to identify sensor failures and replace as needed.

Suspension System Overview and Repair

The suspension system plays a crucial role in providing a smooth and comfortable ride. It absorbs shocks from the road, enhances vehicle stability, and ensures optimal tire contact with the surface. Understanding its components and maintenance needs is essential for preserving performance and safety.

- Components:

- Shock absorbers

- Struts

- Springs

- Control arms

- Stabilizer bars

- Common Issues:

- Worn-out shock absorbers leading to excessive bouncing

- Broken springs causing uneven ride height

- Faulty control arms resulting in steering misalignment

- Leaking struts affecting ride quality

- Maintenance Tips:

- Regularly inspect components for wear and damage

- Check alignment and balance to prevent uneven tire wear

- Replace worn parts promptly to maintain performance

- Keep the system clean to avoid corrosion and debris buildup

Addressing issues within the suspension system promptly can enhance vehicle handling, prolong component life, and improve overall safety on the road. Regular checks and maintenance are key to ensuring longevity and optimal performance.

Transmission Troubleshooting Guide

This section provides essential insights for diagnosing issues related to automatic shifting systems in vehicles. Understanding common symptoms can help in identifying the root causes of transmission malfunctions.

1. Identifying Symptoms

Begin by observing the vehicle’s behavior during operation. Look for signs such as delayed engagement, slipping gears, or unusual noises. Each of these indicators can point to different underlying problems.

2. Fluid Assessment

Check the transmission fluid level and condition. Low fluid can cause performance issues, while dirty or burnt fluid may indicate the need for a complete system flush. Always refer to the manufacturer’s specifications for the correct fluid type.

3. Electrical Components

Modern systems often rely on electronic controls. Inspect the wiring harnesses and connectors for wear or damage. Faulty sensors or solenoids can lead to improper shifting or failure to engage.

4. Conducting Tests

Perform diagnostic tests using a suitable scanner to retrieve error codes. These codes can provide valuable information about specific components that may be malfunctioning, aiding in efficient troubleshooting.

Brake System Inspection Techniques

Regular evaluation of the braking mechanism is crucial for ensuring vehicle safety and performance. Understanding various inspection methods allows for early detection of issues, enhancing reliability during operation.

| Inspection Method | Description |

|---|---|

| Visual Inspection | Check for visible wear on brake pads, discs, and lines. |

| Fluid Check | Assess brake fluid level and quality, ensuring it meets specifications. |

| Noise Assessment | Listen for unusual sounds during braking, indicating potential problems. |

| Brake Pedal Feel | Evaluate the responsiveness and firmness of the brake pedal. |

| Test Drive | Conduct a short drive to identify any irregularities in braking performance. |

Cooling System Efficiency Improvements

The optimization of the cooling system plays a crucial role in maintaining engine performance and longevity. Enhancements in this area can lead to better thermal management, reduced engine wear, and improved fuel efficiency. Implementing specific modifications can significantly contribute to the overall effectiveness of the cooling system.

Upgrading Components: Replacing outdated parts with high-performance alternatives can greatly increase the system’s capability. For instance, a more efficient radiator can enhance heat dissipation, while a high-capacity water pump ensures better circulation of coolant throughout the engine.

Regular Maintenance: Consistent inspection and maintenance of cooling system components are essential. Regularly checking for leaks, ensuring proper coolant levels, and flushing the system to remove debris can prevent overheating and maintain optimal function.

Thermostat Management: Installing a high-performance thermostat can help regulate engine temperature more effectively. This modification ensures that the engine reaches its ideal operating temperature quickly and maintains it, leading to improved efficiency.

Interior Repairs and Restoration Advice

Maintaining the interior of a classic vehicle is essential for preserving its charm and value. Addressing wear and tear while enhancing aesthetics can significantly improve the overall experience for both the driver and passengers.

Assessing Damage: Begin by thoroughly examining the interior components, including upholstery, dashboard, and trim. Identifying areas requiring attention will help prioritize repairs and ensure a comprehensive approach.

Upholstery Care: For fabric or leather surfaces, consider professional cleaning or repair services. If reupholstering, select materials that closely match the original to maintain authenticity.

Dashboard Restoration: Cracked or faded dashboards can detract from the vehicle’s appearance. Utilize specialized kits for restoring finishes or replacing damaged sections to restore a factory-like look.

Trim and Fittings: Inspect all interior trim and fittings for signs of deterioration. Replace broken pieces with original or high-quality aftermarket alternatives to ensure a cohesive look.

Overall, paying attention to the interior not only enhances comfort but also preserves the unique character of the vehicle.

Fuel System Components and Care

The fuel system is a critical aspect of any vehicle’s operation, ensuring efficient performance and reliability. Understanding its various elements and how to maintain them is essential for optimal functionality. Proper care of these components can prevent issues and enhance the overall lifespan of the system.

Key Components: The primary elements of the fuel system include the fuel tank, fuel pump, fuel filter, and fuel injectors. Each component plays a vital role in delivering the appropriate amount of fuel to the engine, enabling effective combustion and power generation.

Maintenance Practices: Regular inspection and maintenance of the fuel system components are crucial. Replacing the fuel filter at recommended intervals helps to keep the fuel clean and free from contaminants. Additionally, checking for leaks in the fuel lines and ensuring the pump operates efficiently are essential tasks that should not be overlooked.

Common Issues: Problems such as clogged fuel injectors or a malfunctioning pump can lead to poor performance or stalling. If any unusual symptoms arise, such as engine misfires or reduced power, it is important to address these issues promptly to avoid further complications.

By prioritizing the upkeep of the fuel system components, vehicle owners can ensure their engine operates smoothly and efficiently, ultimately enhancing driving experience and vehicle longevity.

Exhaust System Modifications and Repairs

Enhancing and maintaining the exhaust assembly is crucial for optimal vehicle performance. This section explores various approaches to upgrading and fixing components of the exhaust framework, ensuring better efficiency, sound quality, and longevity.

Common Upgrades and Enhancements

One of the most popular modifications involves replacing the factory-installed parts with high-performance alternatives. Upgrading to a stainless steel exhaust can improve durability and provide a more appealing sound profile. Additionally, installing a larger diameter system may increase exhaust flow, resulting in enhanced engine performance.

Maintenance and Troubleshooting

Regular inspections are essential to identify any signs of wear or damage within the exhaust structure. Common issues include rust, leaks, and loose connections. Addressing these problems promptly can prevent more extensive damage and costly repairs down the line. Utilizing quality seals and clamps during repairs ensures a reliable and effective exhaust system.

Bodywork and Paint Restoration Tips

Restoring the exterior of a classic automobile involves meticulous attention to detail and a clear understanding of techniques that can enhance its aesthetic appeal. The process not only revitalizes the vehicle’s appearance but also protects it from the elements, ensuring longevity and preserving its value.

Assessing Damage: Begin by thoroughly examining the body for dents, scratches, and rust. Identifying all imperfections early allows for a comprehensive plan of action.

Preparation: Proper surface preparation is crucial. Clean the areas to be worked on, removing dirt, grease, and old paint. Sanding the surface helps create a smooth foundation for new coatings.

Choosing Materials: Select high-quality fillers, primers, and paints. The right products contribute significantly to the final finish, ensuring durability and a professional look.

Application Techniques: Use even strokes when applying paint, maintaining a consistent distance from the surface to avoid runs or uneven coverage. Consider using a spray gun for a smoother application.

Final Touches: After the paint has dried, inspect for imperfections. Polishing the surface can enhance the shine and provide a protective layer, further extending the life of the finish.

By following these guidelines, enthusiasts can achieve outstanding results in restoring their vehicle’s bodywork and paint, enhancing its overall appeal and performance.

Preventative Maintenance for Longevity

Regular upkeep is essential for ensuring the durability and performance of any vehicle. Proactive care not only enhances the driving experience but also prolongs the lifespan of various components. Adhering to a consistent maintenance schedule can mitigate the risk of unforeseen repairs and optimize the overall functionality of the automobile.

Key Maintenance Practices

Implementing essential maintenance practices can significantly contribute to vehicle longevity. These practices encompass regular checks and replacements of crucial components, fluid changes, and ensuring the vehicle operates under optimal conditions.

Maintenance Schedule

| Service | Frequency | Details |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace engine oil and filter to ensure smooth operation. |

| Tire Rotation | Every 6,000 miles | Helps to maintain even tire wear and extends tire life. |

| Brake Inspection | Every 10,000 miles | Check pads, rotors, and fluid to ensure effective braking. |

| Fluid Levels Check | Monthly | Inspect coolant, brake fluid, and transmission fluid levels. |

| Battery Check | Every 12 months | Test battery health and clean terminals to avoid electrical issues. |

Tools Needed for DIY Repairs

For successful home maintenance projects, having the right equipment is essential. A well-equipped toolkit not only enhances efficiency but also ensures safety during the process. Below is a list of essential items that can facilitate various tasks.

- Basic Hand Tools:

- Wrenches (various sizes)

- Screwdrivers (flat and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Power Tools:

- Electric drill

- Impact wrench

- Angle grinder

- Jigsaw

- Measuring Instruments:

- Tape measure

- Caliper

- Torque wrench

- Safety Equipment:

- Safety goggles

- Work gloves

- Ear protection

Ensuring you have these tools at hand can greatly simplify maintenance and enhancement efforts, making each project more manageable and enjoyable.