Owning a high-performance vehicle comes with the responsibility of ensuring it remains in optimal condition. Understanding the intricacies of its components is essential for both longevity and peak performance. This section aims to provide comprehensive insights into the care and upkeep of your prized automobile.

Regular upkeep not only enhances the driving experience but also prevents minor issues from escalating into significant problems. By familiarizing yourself with the essential aspects of your vehicle, you can tackle common challenges with confidence and precision.

Whether you are a seasoned enthusiast or a new owner, this guide will equip you with the ultimate knowledge necessary for effective maintenance. From routine checks to advanced troubleshooting techniques, the information provided here is designed to empower you on your journey to automotive excellence.

Overview of Mercedes SLK 230

This section provides a comprehensive insight into a specific model from a renowned automotive manufacturer, focusing on its design, performance, and features. The vehicle is celebrated for its elegant aesthetics, remarkable engineering, and driving dynamics, making it a favored choice among enthusiasts.

Design plays a crucial role in the appeal of this model. Its sleek silhouette and dynamic lines capture attention, embodying a sporty yet sophisticated character. The interior is equally impressive, offering a blend of luxury and practicality, with high-quality materials and user-friendly technology.

In terms of performance, this vehicle stands out due to its powerful engine, delivering an exhilarating driving experience. The handling is precise, allowing for confident navigation through various terrains. Additionally, the car features advanced safety systems that enhance both protection and peace of mind while on the road.

Overall, this model represents a harmonious balance of style, performance, and technology, appealing to those who seek both excitement and comfort in their driving experience.

Common Issues with SLK 230

When it comes to this particular model, several prevalent challenges may arise over time. Understanding these common problems can help owners anticipate potential repairs and maintain optimal performance.

Engine Performance: A frequent concern is related to engine performance, including rough idling or unexpected stalling. Regular checks of ignition components and fuel delivery systems can often mitigate these issues.

Electrical Failures: Electrical systems can sometimes exhibit malfunctions, such as failing windows or lights. It’s essential to inspect fuses and wiring to ensure everything is functioning correctly.

Cooling System: Overheating can be a significant problem, often due to coolant leaks or a malfunctioning thermostat. Keeping an eye on coolant levels and inspecting hoses can prevent serious damage.

Suspension Wear: Suspension components may wear out, leading to a less comfortable ride. Regularly checking shock absorbers and bushings can help maintain a smooth driving experience.

Transmission Issues: Some owners report transmission-related concerns, such as slipping or delayed shifting. Ensuring regular fluid changes can contribute to a healthier transmission system.

Essential Tools for Repairs

When it comes to maintaining your vehicle, having the right set of instruments is crucial. A well-equipped toolkit not only streamlines the process but also enhances the quality of work performed. This section outlines the fundamental devices that every automotive enthusiast should consider for effective maintenance and troubleshooting.

Basic Hand Tools

Start with a collection of essential hand tools, including wrenches, sockets, and screwdrivers. These instruments are vital for loosening and tightening various components. A comprehensive ratchet and socket set can save time, while an assortment of screwdrivers in different sizes ensures compatibility with various fasteners.

Diagnostic Equipment

In addition to manual tools, having access to diagnostic devices is increasingly important. A reliable OBD-II scanner helps identify issues by reading error codes from the vehicle’s computer. This information can guide you in troubleshooting, making it easier to pinpoint the root of the problem and apply appropriate solutions.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your vehicle. Regular upkeep is essential to prevent potential issues and enhance driving experience. Following a structured maintenance routine will help you identify problems early and keep your car running smoothly.

1. Check Fluid Levels: Begin by examining essential fluids such as engine oil, coolant, brake fluid, and transmission fluid. Low levels can lead to significant mechanical failures.

2. Inspect Filters: Regularly inspect and replace air and oil filters. Clean filters contribute to better engine efficiency and air quality within the cabin.

3. Tire Care: Monitor tire pressure and tread depth regularly. Properly inflated and well-maintained tires enhance safety and improve fuel efficiency.

4. Brake System Evaluation: Assess brake pads and discs for wear. Ensure that the braking system is functioning correctly to maintain safety on the road.

5. Battery Maintenance: Check battery terminals for corrosion and ensure a secure connection. Regular battery tests can prevent unexpected breakdowns.

6. Light Functionality: Regularly test all exterior and interior lights. Replacing burnt-out bulbs promptly ensures visibility and compliance with safety regulations.

7. Wiper Blades Replacement: Inspect wiper blades for wear and replace them as needed. Clear visibility during adverse weather conditions is critical for safe driving.

8. Scheduled Inspections: Adhere to the manufacturer’s recommendations for scheduled services. Routine inspections can catch issues before they escalate, saving time and money.

9. Keep Records: Maintain a log of all maintenance activities performed. Documenting services can help track the vehicle’s history and plan future upkeep.

By following these steps diligently, you can ensure your vehicle remains reliable and efficient for years to come.

Engine Troubleshooting Techniques

Diagnosing issues in an engine requires a systematic approach to identify and rectify malfunctions. By following a set of established techniques, one can effectively narrow down the causes of performance problems, unusual noises, or irregular behavior.

Here are some essential techniques to consider when troubleshooting engine issues:

- Visual Inspection:

- Check for leaks under the vehicle.

- Inspect hoses and belts for wear or damage.

- Examine electrical connections for corrosion or looseness.

- Listen for Unusual Noises:

- Identify knocking, rattling, or whining sounds that may indicate specific issues.

- Pay attention to changes in noise when accelerating or decelerating.

- Monitor Performance:

- Assess acceleration and power output.

- Observe fuel efficiency for any sudden changes.

- Check Warning Lights:

- Investigate dashboard indicators that may signify problems.

- Use a diagnostic scanner to retrieve trouble codes.

- Conduct Tests:

- Perform compression tests to evaluate cylinder health.

- Test spark plugs and ignition components for functionality.

- Analyze fuel pressure to ensure proper delivery.

By utilizing these strategies, one can gain insights into the root causes of engine malfunctions and proceed with appropriate corrective actions.

Replacing the Timing Belt

Replacing the timing belt is a crucial maintenance task that ensures the smooth operation of the engine. This component plays a vital role in synchronizing the movement of various engine parts, preventing potential damage and maintaining optimal performance.

Before starting the replacement process, gather the necessary tools and materials, including a new belt, tensioner, and any applicable gaskets. It’s essential to work in a clean environment to avoid contamination of engine components.

Step-by-step Procedure:

1. Disconnect the Battery: Begin by disconnecting the negative terminal of the battery to ensure safety during the procedure.

2. Remove Engine Covers: Take off any engine covers or accessories obstructing access to the timing belt. This may include the air intake and various hoses.

3. Align Timing Marks: Rotate the crankshaft to align the timing marks on the sprockets and engine casing. This step is critical to ensure proper installation of the new belt.

4. Remove the Old Belt: Carefully release the tension on the old belt and remove it from the sprockets. Inspect other components, such as the tensioner and water pump, for signs of wear.

5. Install the New Belt: Position the new timing belt according to the alignment marks. Ensure it is seated correctly on all sprockets.

6. Adjust Tension: Reapply tension using the tensioner. Double-check the alignment of the timing marks to avoid potential issues.

7. Reassemble Components: Replace any covers and reconnect hoses removed earlier. Ensure all connections are secure.

8. Reconnect the Battery: Finally, reconnect the negative terminal of the battery and start the engine to check for proper operation.

Regular inspection and timely replacement of this essential component can prevent significant engine problems and extend the lifespan of your vehicle.

Suspension System Inspection

The suspension system plays a crucial role in ensuring vehicle stability, comfort, and handling. Regular examination of this system is essential for identifying potential issues before they escalate into significant problems. Proper maintenance not only enhances performance but also contributes to safety on the road.

Key Components to Inspect

| Component | Inspection Criteria | Common Issues |

|---|---|---|

| Shock Absorbers | Check for leaks and proper damping. | Loss of fluid, reduced effectiveness. |

| Springs | Inspect for cracks and sagging. | Weakness, uneven ride height. |

| Control Arms | Look for wear in bushings and joints. | Excessive play, noise during turns. |

| Ball Joints | Examine for wear and mobility. | Looseness, knocking sounds. |

Inspection Process

Start with a visual assessment, checking for any obvious signs of damage or wear. Next, perform a bounce test by pushing down on the vehicle’s corners to evaluate the shock absorbers’ response. Finally, utilize specialized tools to measure alignment and suspension geometry for precise adjustments.

Brake System Maintenance Tips

Proper upkeep of the braking system is crucial for ensuring safe driving experiences. Regular checks and timely interventions can prevent issues that may compromise performance and reliability. This guide outlines essential practices to maintain optimal function and longevity of your vehicle’s braking components.

Regular Inspections

Conducting frequent examinations of brake pads, rotors, and fluid levels is essential. Look for signs of wear, such as uneven pad thickness or scoring on the rotors. Additionally, ensure that the brake fluid is at the recommended level and free from contamination. Regular inspections can catch potential problems early, saving time and resources.

Timely Replacement

Replacing worn-out components is vital to maintaining effective braking performance. Brake pads should be changed according to manufacturer recommendations or when they show significant wear. Additionally, if you notice unusual noises, vibrations, or a decrease in responsiveness, it may be time to assess and replace affected parts. Ignoring these signs can lead to more severe issues down the line.

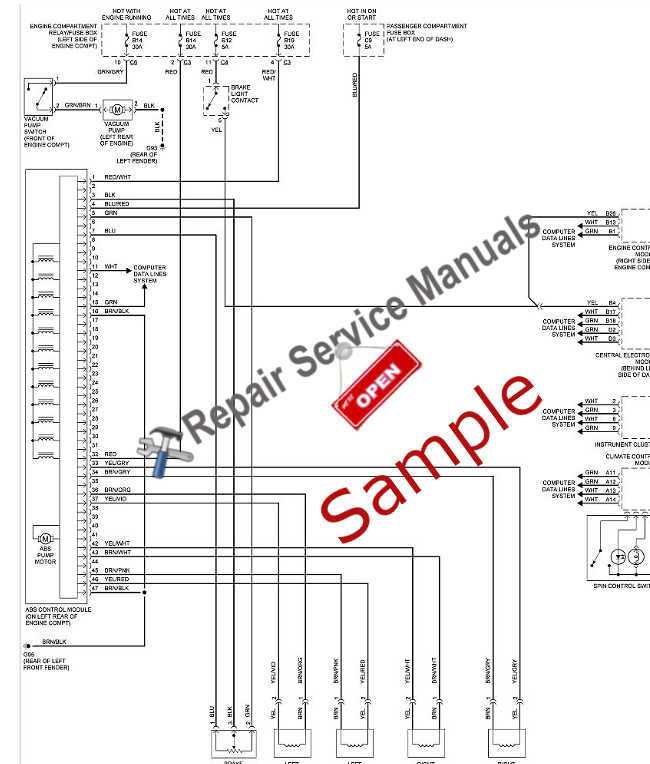

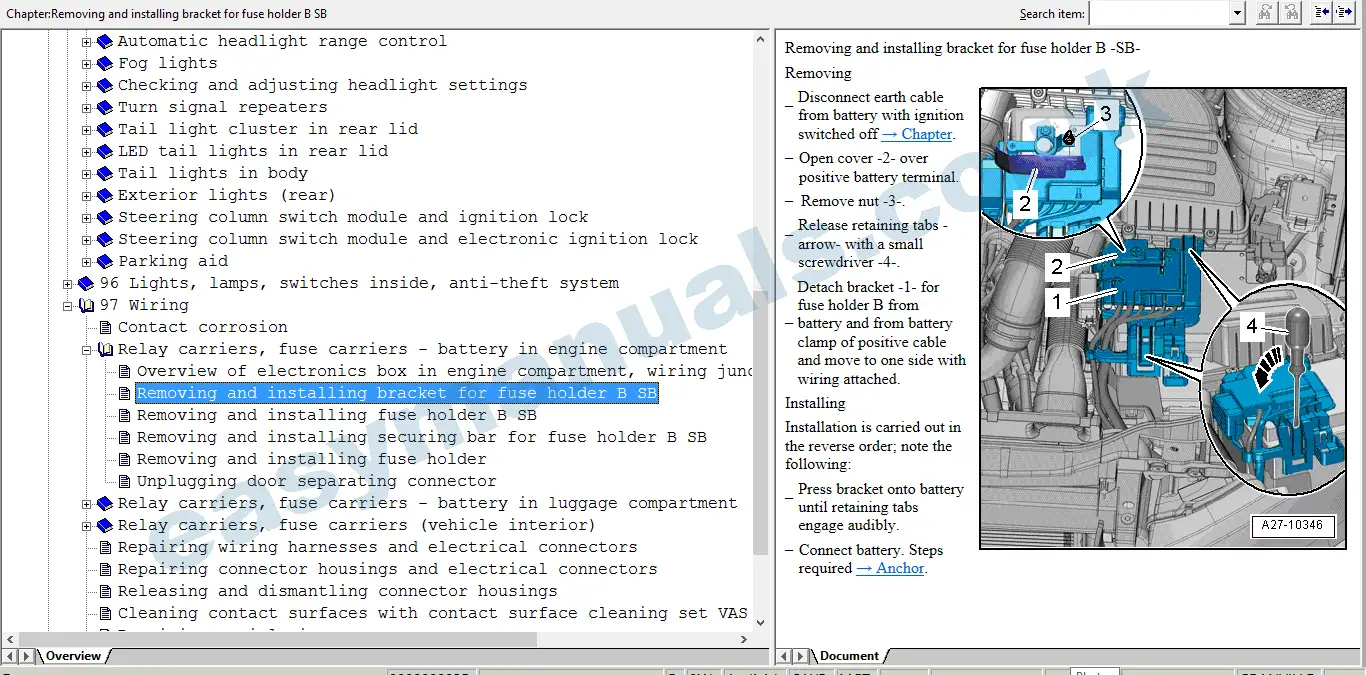

Electrical System Diagnostics

Diagnosing the electrical system is crucial for ensuring optimal performance and reliability of any vehicle. A thorough examination of the wiring, circuits, and components helps identify issues that could lead to malfunctions or inefficiencies. Proper diagnostic procedures not only assist in pinpointing faults but also in maintaining the overall health of the automotive electrical architecture.

Common Issues to Look For

Several problems can arise within the electrical framework. Dead batteries, faulty alternators, and corroded connections are frequent culprits. Additionally, issues with fuses and relays can lead to unexpected electrical failures. Regular checks and monitoring can prevent these issues from escalating and causing significant damage.

Diagnostic Tools and Techniques

Utilizing the right tools is essential for effective troubleshooting. Multimeters, scan tools, and oscilloscopes are invaluable for measuring voltage, current, and resistance. Moreover, understanding wiring diagrams and flowcharts can greatly enhance the diagnostic process. By systematically testing each component, technicians can isolate and resolve problems efficiently.

Bodywork Repair Procedures

This section outlines essential techniques for restoring the external structure of vehicles. Proper attention to detail during the process can ensure longevity and aesthetic appeal. Familiarizing oneself with the procedures is vital for achieving high-quality results and maintaining the vehicle’s value.

Common Damage Types

| Damage Type | Description |

|---|---|

| Dents | Shallow impressions caused by impacts from objects. |

| Scratches | Surface abrasions that penetrate the paint layer. |

| Rust | Corrosion resulting from moisture exposure and lack of protection. |

Repair Techniques

Addressing the various types of damage requires specific methods. For dents, using a heat source followed by gentle pressure can effectively restore the original shape. Scratches may be treated with polishing compounds or touch-up paint, depending on severity. Rust should be meticulously sanded down to bare metal, treated with anti-corrosion agents, and repainted to prevent further deterioration.

Fluid Replacement Guidelines

Maintaining the proper levels and quality of various fluids is essential for ensuring optimal performance and longevity of your vehicle. Regular fluid replacement helps prevent wear and tear, enhances efficiency, and contributes to overall safety on the road.

1. Engine Oil: It is crucial to change the engine oil at regular intervals, as old oil can lose its lubricating properties and lead to engine damage. Check the manufacturer’s recommendations for specific mileage or time intervals.

2. Coolant: Over time, coolant can become contaminated and lose its effectiveness. Replace the coolant according to the schedule provided in the vehicle’s specifications, ensuring the engine remains at a safe operating temperature.

3. Brake Fluid: Brake fluid absorbs moisture, which can reduce braking efficiency. It is advisable to replace it every couple of years to maintain optimal braking performance and safety.

4. Transmission Fluid: The transmission fluid should be checked regularly for color and consistency. Follow the guidelines for replacement to ensure smooth shifting and prolong the life of the transmission.

5. Power Steering Fluid: If you notice any issues with steering responsiveness, check the power steering fluid level. Replace it if it appears dark or contaminated to maintain steering performance.

6. Differential Fluid: This fluid should be changed according to the manufacturer’s recommendations, as it plays a vital role in the performance of the drivetrain.

In summary, adhering to a fluid replacement schedule not only promotes a well-functioning vehicle but also enhances safety and driving experience. Always consult the relevant guidelines to determine the appropriate fluids and intervals for replacement.