Ensuring the longevity and optimal performance of an automobile requires a thorough understanding of its components and systems. This section delves into essential procedures and troubleshooting techniques that can enhance the reliability of your vehicle. By familiarizing yourself with the intricacies of maintenance, you empower yourself to address common issues effectively.

Throughout this guide, you will encounter detailed insights on various aspects of automotive care. Whether it’s addressing minor repairs or conducting routine checks, the information presented here aims to equip you with the knowledge necessary for successful vehicle management. Each step is designed to provide clarity and promote confidence in handling your car’s upkeep.

From understanding specific components to implementing maintenance strategies, this resource serves as a valuable tool for both novice and experienced car enthusiasts. By following the outlined procedures, you can ensure that your vehicle remains in prime condition, contributing to a smoother and safer driving experience. Your journey towards effective vehicle maintenance begins here.

Essential Tools for C230 Maintenance

Maintaining your vehicle requires a selection of essential instruments that facilitate various tasks. Proper tools not only enhance efficiency but also ensure that procedures are executed correctly, safeguarding the integrity of the automobile. Whether you are performing routine checks or more involved repairs, having the right equipment is crucial for optimal performance.

Basic Hand Tools: A fundamental toolkit should include wrenches, screwdrivers, and pliers. These items are vital for loosening and tightening fasteners, enabling access to different components for inspection and maintenance.

Diagnostic Equipment: Modern vehicles often come equipped with complex systems that require specialized diagnostic tools. An OBD-II scanner can provide valuable insights into the vehicle’s performance and help identify issues that may not be apparent through visual inspections.

Fluid Management Tools: For tasks involving oil changes or fluid top-ups, tools such as fluid pumps and drain pans are essential. These tools simplify the process and help avoid messes, making maintenance tasks more manageable.

Safety Equipment: Personal safety should never be overlooked. Gloves, goggles, and masks are necessary when working on your automobile to protect against harmful substances and debris.

Investing in these key instruments will contribute significantly to the longevity and reliability of your vehicle. Regular maintenance becomes a seamless process when equipped with the appropriate tools, ensuring that your automobile remains in prime condition.

Understanding the C230 Engine Layout

The configuration of an engine plays a crucial role in its overall performance and efficiency. By examining the arrangement of components and their functions, one can gain valuable insights into how the powertrain operates. This section delves into the structural design and key elements of the engine system, providing a comprehensive overview.

Key Components

The engine comprises several critical parts that work in harmony to ensure optimal performance. Below is a summary of these essential elements:

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders and crankshaft. |

| Cylinder Head | Caps the top of the cylinders, containing valves and spark plugs. |

| Intake Manifold | Distributes air-fuel mixture to the cylinders. |

| Exhaust Manifold | Channels exhaust gases away from the cylinders. |

| Crankshaft | Converts linear motion from pistons into rotational motion. |

Layout Overview

The engine’s arrangement is designed to maximize power output while maintaining efficiency. The placement of components is strategically engineered to enhance airflow and reduce friction, which are vital for improving performance. Understanding this layout is essential for diagnosing issues and optimizing maintenance procedures.

Common Issues with the C230 Model

This section explores frequent challenges encountered by owners of this luxury vehicle, highlighting areas that may require attention over time. Understanding these common problems can aid in maintaining optimal performance and longevity.

Electrical System Failures

One of the notable concerns involves the electrical system, which can manifest in various ways:

- Battery drain issues, often linked to faulty wiring or components.

- Malfunctions in the central locking system, leading to difficulties in securing the vehicle.

- Dashboard warning lights activating unexpectedly, indicating potential underlying issues.

Engine Performance Problems

Another area of focus is the engine, where certain symptoms may arise:

- Inconsistent idling, which can be caused by issues with sensors or fuel delivery.

- Overheating, often attributed to coolant leaks or thermostat failures.

- Unusual noises, signaling possible mechanical wear or component failure.

Step-by-Step Oil Change Procedure

Regular maintenance of your vehicle’s engine is crucial for optimal performance and longevity. One essential task in this maintenance routine is changing the lubricant. This process helps ensure that the engine runs smoothly by removing contaminants and providing necessary protection to the internal components.

Gathering Necessary Tools and Materials

Before starting, collect all required items. You will need fresh lubricant, an appropriate filter, an oil catch pan, a funnel, and basic tools like a wrench and an oil filter removal tool. Having everything at hand will make the process more efficient.

Executing the Oil Change

Begin by warming up the engine for a few minutes to thin the lubricant, allowing it to drain more easily. Turn off the engine and ensure the vehicle is on a level surface. Position the oil catch pan under the oil pan and remove the drain plug to let the old lubricant flow out completely. Once drained, replace the drain plug securely. Next, remove the old filter and install the new one, applying a bit of new lubricant to the rubber seal to ensure a tight fit. Finally, pour the new lubricant into the engine using the funnel, checking the level with the dipstick. Start the engine and let it run for a moment, checking for any leaks before disposing of the old lubricant responsibly.

Replacing the C230 Brake Pads

Changing the braking components is essential for ensuring optimal performance and safety in your vehicle. This process involves removing the worn-out pads and installing new ones, which can significantly enhance stopping power and responsiveness.

Before starting the replacement, gather the necessary tools and materials:

- New brake pads

- Jack and jack stands

- Wrench set

- Brake cleaner

- Torque wrench

- Gloves and safety glasses

Follow these steps to complete the pad replacement:

- Lift the vehicle using the jack and secure it with jack stands.

- Remove the wheel to access the braking assembly.

- Locate the caliper and unscrew the bolts holding it in place.

- Carefully slide the caliper off the rotor and support it using a hanger or bungee cord to avoid stress on the brake line.

- Take out the old pads from the caliper bracket.

- Clean the caliper and rotor surfaces with brake cleaner to remove any dust or debris.

- Install the new pads into the caliper bracket, ensuring they are positioned correctly.

- Reattach the caliper over the new pads and tighten the bolts to the specified torque setting.

- Reinstall the wheel and lower the vehicle back to the ground.

After completing the installation, it is advisable to pump the brake pedal a few times to seat the new pads before driving. Regular checks and maintenance of the braking system can prevent potential issues and enhance safety on the road.

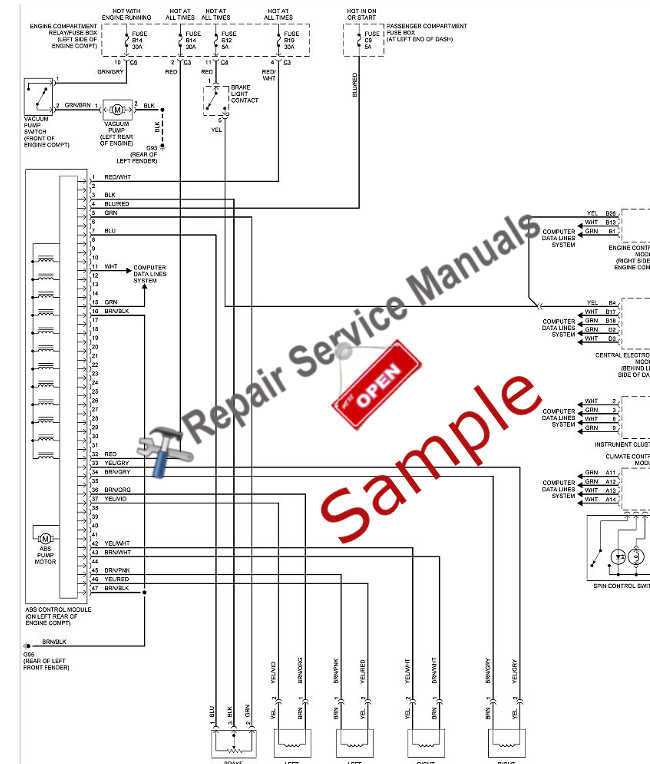

How to Troubleshoot Electrical Problems

Tackling electrical issues can often seem daunting, but a systematic approach can simplify the process. By understanding how different components interact, you can identify and resolve common faults without professional assistance.

1. Initial Assessment

Begin by conducting a visual inspection of the electrical system. Look for obvious signs of wear, such as frayed wires or loose connections. Check fuses and relays to ensure they are functioning properly. If you find any damaged parts, replace them before proceeding.

2. Use Diagnostic Tools

Employ diagnostic tools like multimeters to measure voltage and continuity. This can help pinpoint where the issue lies. For instance, checking voltage levels at various points in the circuit will indicate whether power is reaching the intended components. If a component isn’t receiving power, trace the circuit back to locate the fault.

Maintaining the Cooling System

The cooling system plays a crucial role in preventing the engine from overheating and ensuring optimal performance. Regular maintenance of this system is essential to extend the lifespan of the engine and avoid costly repairs. Properly functioning components help regulate temperature and promote efficiency.

Key components of the cooling system include the radiator, water pump, thermostat, and coolant. Regular checks and replacements are vital to maintain their effectiveness. The following table outlines essential maintenance tasks and their recommended intervals:

| Maintenance Task | Recommended Interval |

|---|---|

| Inspect coolant level | Every month |

| Flush and replace coolant | Every 2 years |

| Check for leaks | Every 6 months |

| Inspect radiator and hoses | Every 6 months |

By following these maintenance guidelines, you can ensure that the cooling system operates efficiently, providing reliable performance and preventing overheating issues. Regular attention to this system is key to a smooth driving experience.

Inspecting and Replacing Belts

Maintaining optimal performance in your vehicle involves regular checks of essential components, including the drive belts. These components play a crucial role in transferring power from the engine to various accessories. Regular inspection helps identify wear and tear, ensuring reliable operation and preventing potential breakdowns.

To begin the inspection, visually examine each belt for signs of fraying, cracking, or glazing. Use your fingers to feel for any irregularities in the surface texture. If a belt appears excessively worn or damaged, it is advisable to replace it promptly. Pay attention to the tension as well; a belt that is too loose or too tight can lead to performance issues.

When replacing a belt, ensure that you select the correct size and type for your specific engine configuration. Follow the manufacturer’s guidelines for installation to guarantee proper alignment and tension. After installation, run the engine briefly and listen for any unusual noises, which could indicate that adjustments are necessary.

Guidelines for Transmission Service

Proper maintenance and care of the transmission system are crucial for ensuring smooth operation and longevity of the vehicle. This section provides essential recommendations to help maintain optimal performance and prevent common issues that may arise over time.

Regular Fluid Checks: Monitoring transmission fluid levels is vital. Low fluid can lead to overheating and potential damage. Ensure to check levels regularly and replace the fluid as per the manufacturer’s schedule.

Inspect for Leaks: Regularly examine the transmission for signs of fluid leaks. Early detection of leaks can prevent more significant issues and costly repairs down the line.

Filter Replacement: Changing the transmission filter periodically is essential. A clogged filter can restrict fluid flow, leading to inefficient operation and increased wear on components.

Driving Habits: Adopt smooth driving techniques. Abrupt acceleration and hard braking can strain the transmission and lead to premature wear. Aim for gradual changes in speed whenever possible.

Diagnostic Checks: Utilize diagnostic tools to monitor transmission performance. If any unusual noises or shifting issues occur, it’s crucial to investigate immediately to avoid further damage.

Performing Routine Tire Checks

Regular inspection of your vehicle’s tires is essential for maintaining safety and enhancing performance. Ensuring that tires are in optimal condition can prevent accidents and improve fuel efficiency. This process involves checking for proper inflation, tread depth, and any visible signs of wear or damage.

Begin by verifying tire pressure with a reliable gauge. Insufficient air can lead to poor handling and increased wear, while over-inflation may cause a harsh ride and susceptibility to punctures. Next, assess tread depth using the penny test or a tread depth gauge. Adequate tread is crucial for traction, especially in adverse weather conditions. Finally, inspect the tires for cracks, bulges, or foreign objects that may compromise their integrity.

By performing these routine checks, you can extend the life of your tires and ensure a safer driving experience.