When it comes to the upkeep of off-road vehicles, having a thorough resource at your disposal is essential for both enthusiasts and casual users alike. Proper maintenance ensures longevity, enhances performance, and prevents minor issues from escalating into significant problems. This section will equip you with the necessary knowledge to tackle various challenges that may arise, providing you with step-by-step guidance for effective management.

Understanding the intricacies of your vehicle’s systems is crucial for any owner. From engine diagnostics to electrical concerns, this guide will offer invaluable insights into the common hurdles faced by operators. By familiarizing yourself with essential procedures and best practices, you can approach each task with confidence and precision.

Whether you’re dealing with routine checks or unexpected malfunctions, having a reliable reference can make all the difference. With clear instructions and practical tips, you’ll be able to maintain your vehicle in optimal condition, ensuring it remains ready for any adventure that lies ahead. Embrace the journey of vehicle maintenance and empower yourself with the skills needed for effective troubleshooting.

Understanding the Polaris Ranger 700

This section aims to provide a comprehensive overview of a versatile all-terrain vehicle known for its robust performance and adaptability in various environments. Designed for utility and recreation, this model has garnered a loyal following among enthusiasts and professionals alike, making it an essential part of outdoor adventures and work-related tasks.

Key Features

Equipped with a powerful engine and advanced suspension system, this vehicle excels in both off-road conditions and on smoother terrains. Its spacious cargo capacity and user-friendly controls enhance usability, ensuring that operators can navigate through challenging landscapes with ease.

Specifications Overview

| Feature | Details |

|---|---|

| Engine Type | Single-cylinder, liquid-cooled |

| Horsepower | Approximately 40 HP |

| Transmission | Automatic, CVT |

| Ground Clearance | 11 inches |

| Payload Capacity | 1,500 lbs |

By understanding these fundamental aspects, users can fully appreciate the capabilities and applications of this all-terrain vehicle, making informed decisions for maintenance and enhancement. Proper knowledge allows for optimal usage, ensuring longevity and performance in diverse situations.

Common Issues with Polaris Ranger 700

When operating an off-road utility vehicle, owners may encounter several recurring challenges that can affect performance and safety. Recognizing these common problems is crucial for effective troubleshooting and maintenance, ensuring a smooth and reliable riding experience.

Electrical Problems

One of the frequent issues faced involves the electrical system. Problems can range from battery drainage to malfunctioning lights. Understanding the underlying causes helps in timely diagnosis and resolution.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Battery Drain | Vehicle won’t start, dim lights | Check connections, replace battery |

| Faulty Lights | Headlights not functioning | Inspect bulbs and wiring |

Engine Performance Issues

Another area of concern is engine performance. Owners might notice a lack of power or unusual noises. Identifying these signs early can prevent more severe complications down the road.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Poor Acceleration | Slow response, stalling | Check fuel filter, clean injectors |

| Unusual Noises | Knocking or grinding sounds | Inspect engine components |

Essential Tools for Repairs

When it comes to maintaining your vehicle, having the right set of instruments is crucial for effective troubleshooting and restoration. Properly selected tools can make the difference between a smooth process and a frustrating experience. Below is a list of fundamental instruments that every owner should consider for their maintenance tasks.

- Wrenches: A variety of sizes, including adjustable and socket types, are essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips options are necessary for dealing with different types of screws.

- Pliers: Needle-nose and standard pliers assist in gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage from overtightening.

- Jack and Stands: Used for lifting the vehicle safely to access the underside for inspections or replacements.

In addition to the basic tools, consider having specialized equipment for more advanced tasks:

- Diagnostic Tools: These devices help identify issues by reading error codes and analyzing performance.

- Oil Filter Wrench: A must-have for changing the oil and ensuring the filter is properly secured.

- Cleaning Supplies: Brushes and solvents are essential for maintaining cleanliness and preventing dirt buildup.

- Replacement Parts: Keeping a stock of commonly used components can expedite the repair process.

Equipped with these essential instruments, you can tackle a variety of maintenance tasks efficiently, ensuring your vehicle remains in top condition.

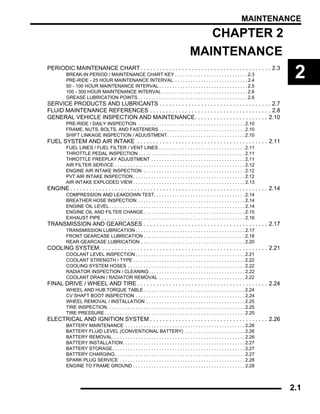

Step-by-Step Maintenance Procedures

Regular upkeep of your all-terrain vehicle is essential for optimal performance and longevity. This section outlines a series of detailed procedures to ensure your machine remains in peak condition. By following these guidelines, you can prevent common issues and enhance your riding experience.

1. Pre-Ride Inspection

Before each outing, conduct a thorough inspection to identify any potential problems. This can help you catch issues early and avoid breakdowns on the trail.

- Check fluid levels: Ensure that oil, coolant, and brake fluids are at appropriate levels.

- Inspect tires: Look for signs of wear, proper inflation, and adequate tread depth.

- Examine brakes: Test both front and rear brakes for responsiveness and wear.

- Assess lights: Ensure that headlights, taillights, and indicators are functioning properly.

- Look for leaks: Inspect underneath the vehicle for any fluid leaks.

2. Routine Maintenance Tasks

Performing regular maintenance tasks will help prolong the life of your vehicle and keep it running smoothly.

- Change the oil and filter every 50 hours of operation or as specified in the user guidelines.

- Clean or replace the air filter to ensure optimal airflow and engine performance.

- Lubricate all moving parts, including suspension components and joints, to reduce wear.

- Inspect and tighten all fasteners to prevent rattling or losing components during use.

- Check battery connections and clean any corrosion to ensure reliable starts.

Following these maintenance procedures will help you maintain the efficiency and reliability of your vehicle, allowing you to enjoy every ride with peace of mind.

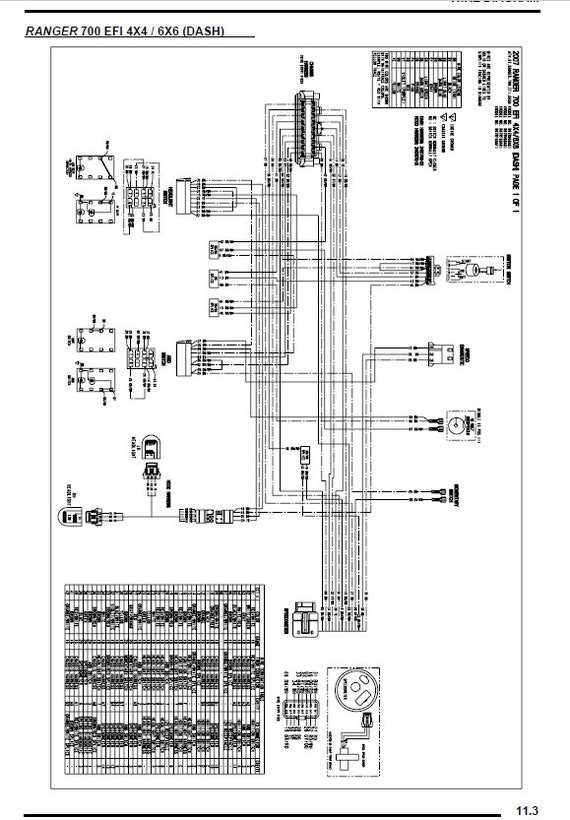

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues within the electrical framework of your vehicle. By following a systematic method, you can identify and resolve common problems that may hinder performance or functionality.

Common Symptoms and Initial Checks

Begin by observing any unusual behavior, such as flickering lights or failure to start. These signs may indicate underlying electrical faults. Check the battery connections for corrosion or looseness, as poor contact can lead to insufficient power supply. Ensure that fuses are intact and functioning, as a blown fuse can disrupt circuits.

Advanced Diagnostics

If initial checks do not reveal the issue, consider using a multimeter to assess voltage levels at various points in the system. Start with the battery and proceed through the wiring harness, inspecting for breaks or shorts. Pay close attention to grounding points, as poor grounds can cause a range of electrical problems. Always follow safety precautions when handling electrical components to prevent injury or further damage.

Engine Overhaul Techniques Explained

Revitalizing an engine can breathe new life into a vehicle, ensuring optimal performance and longevity. This process involves several critical steps, each designed to enhance the functionality of the power unit. Understanding these techniques can help maintain efficiency and reliability in various applications.

Here are key techniques to consider during an engine overhaul:

- Disassembly: Carefully taking apart the engine components to assess their condition.

- Inspection: Checking parts for wear, damage, or signs of failure to determine what needs replacement.

- Cleaning: Removing dirt, carbon buildup, and old oil from components to ensure optimal performance.

- Machining: Precision work on surfaces like the cylinder head and block to restore proper dimensions.

- Component Replacement: Installing new gaskets, bearings, and seals to prevent leaks and ensure tight fits.

- Reassembly: Meticulously putting the engine back together, adhering to torque specifications for bolts and fasteners.

- Testing: Conducting thorough checks after reassembly to verify that the engine operates correctly.

Each of these stages plays a vital role in achieving a successful overhaul. By following these established practices, one can ensure that the engine performs at its best for years to come.

Transmission Repair and Replacement Tips

Maintaining and fixing the power transfer system of your vehicle is crucial for ensuring optimal performance and longevity. Proper understanding of the components involved can help you identify issues early and tackle repairs or replacements effectively. This section provides essential guidelines for managing common problems associated with the drivetrain.

Diagnosis is the first step in addressing any issues. Listen for unusual sounds such as grinding or whining, and pay attention to any irregularities in shifting or responsiveness. Conduct a thorough inspection to check for fluid leaks or signs of wear.

When it comes to fluid maintenance, always use the recommended type and viscosity. Regularly check levels and replace fluids as needed to prevent overheating and excessive wear. Ensure that seals and gaskets are in good condition to avoid leaks that can compromise the system’s efficiency.

If you find yourself needing to replace components, consider using high-quality parts that match the specifications of your system. This ensures compatibility and reliability. When disassembling, keep track of all components and their arrangement to facilitate reassembly.

Lastly, consult reliable sources for step-by-step guides and tips from experienced technicians. Joining community forums can also provide valuable insights and support from fellow enthusiasts. Staying informed and proactive will contribute significantly to the smooth operation of your vehicle’s power transfer system.

Suspension System Maintenance Advice

Regular upkeep of the suspension framework is vital for ensuring optimal performance and longevity of your off-road vehicle. This system plays a crucial role in providing stability, comfort, and control, making it essential to follow proper maintenance practices. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance the overall riding experience.

Inspection Checklist

Performing periodic inspections can help identify wear and tear before they escalate into significant problems. Here’s a simple checklist to guide your assessment:

| Component | What to Check | Frequency |

|---|---|---|

| Shocks | Look for leaks and inspect for damage. | Every 100 miles |

| Springs | Check for rust, cracks, or deformation. | Every 500 miles |

| Control Arms | Examine bushings and ball joints for wear. | Every 300 miles |

| Alignment | Ensure proper alignment for optimal handling. | Every 1000 miles |

Maintenance Tips

To prolong the life of the suspension components, consider the following maintenance practices:

- Regularly clean the undercarriage to remove dirt and debris that may accumulate.

- Apply protective coatings to metal parts to prevent corrosion.

- Ensure that all fasteners are tightened to manufacturer specifications.

- Replace worn parts immediately to maintain safety and performance.

Preventive Measures for Longevity

Ensuring the extended life of your off-road vehicle requires diligent care and attention. By implementing a few essential practices, you can significantly reduce wear and tear, enhancing performance and reliability over time.

- Regular Maintenance: Schedule routine checks to inspect vital components, including the engine, transmission, and suspension systems.

- Fluid Changes: Change engine oil, coolant, and other essential fluids at recommended intervals to prevent overheating and mechanical issues.

- Tire Care: Monitor tire pressure and tread wear, and rotate tires regularly to ensure even distribution of wear.

- Cleaning: Regularly clean the exterior and undercarriage to remove dirt and debris that can cause corrosion and damage.

- Battery Maintenance: Check battery connections and clean terminals to avoid electrical failures.

In addition to these practices, consider keeping detailed records of all maintenance tasks performed. This documentation can assist in identifying patterns and areas that may require extra attention, ultimately contributing to the longevity of your vehicle.

- Inspect the brakes frequently for wear and responsiveness.

- Store the vehicle in a sheltered environment to protect it from harsh weather conditions.

- Follow manufacturer guidelines for optimal care and servicing.

By adopting these preventive measures, you not only enhance the lifespan of your vehicle but also ensure a safer and more enjoyable riding experience.

Finding Genuine Replacement Parts

Ensuring the longevity and optimal performance of your all-terrain vehicle hinges on sourcing authentic components. Using original parts not only guarantees compatibility but also enhances safety and reliability during operation. This section aims to guide you in identifying and acquiring the right pieces for your machinery.

Importance of Authentic Components

Using genuine parts is crucial for maintaining the integrity of your vehicle. Counterfeit or generic substitutes may save money initially but can lead to more significant issues over time. Original components are designed specifically for your model, ensuring proper fit and function.

Where to Find Genuine Parts

Several avenues exist for procuring authentic components. Below are some recommended sources:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers offer a wide range of genuine parts with the assurance of quality and reliability. |

| Manufacturer’s Website | Online platforms often provide a catalog of parts specific to your model, along with direct purchasing options. |

| Reputable Aftermarket Suppliers | Some aftermarket companies specialize in high-quality replacements, ensuring compatibility and durability. |

By choosing authentic parts from trusted sources, you can significantly enhance your vehicle’s performance and extend its lifespan.

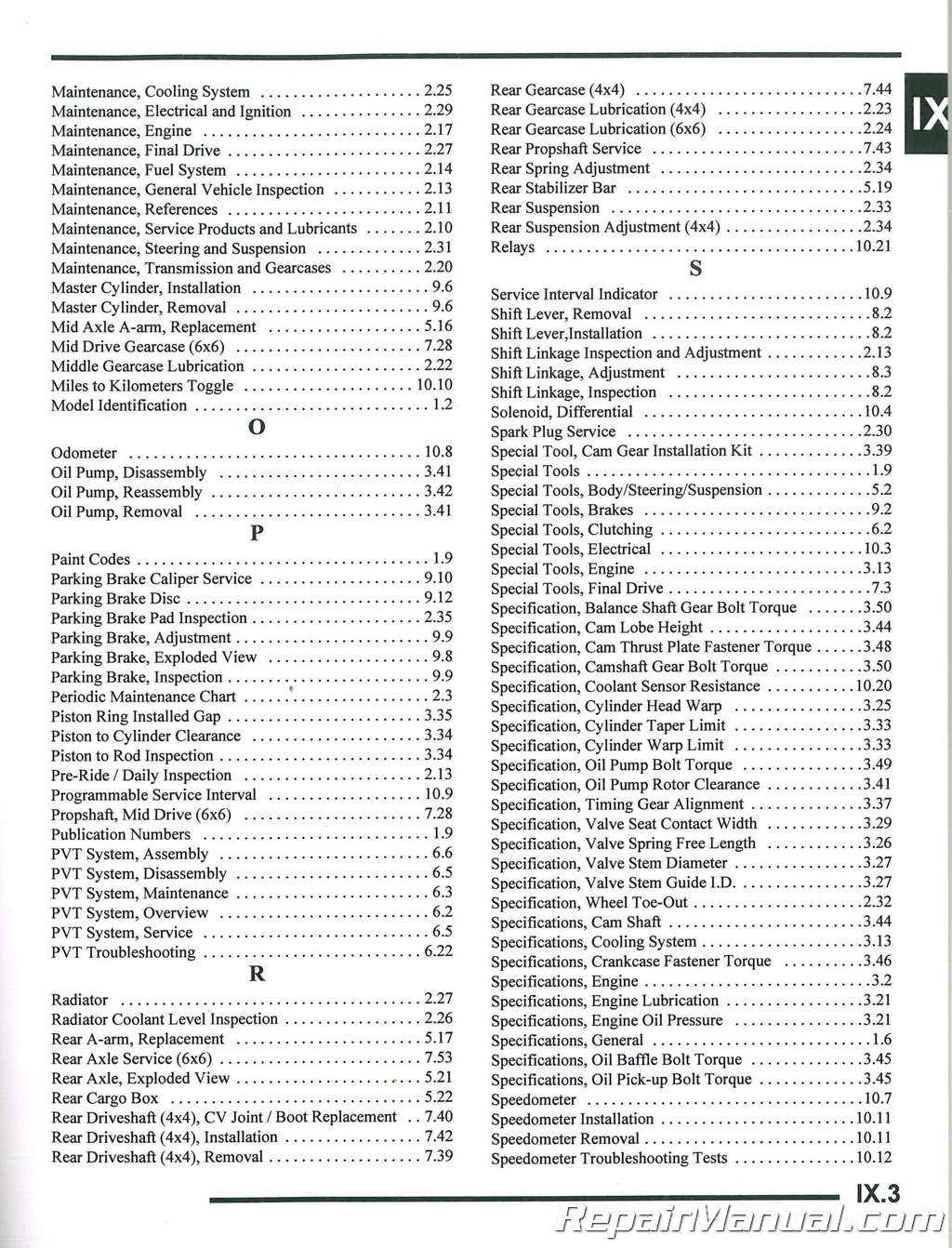

Where to Access Repair Manuals

Finding comprehensive guides for vehicle maintenance and troubleshooting can significantly enhance your ability to handle various mechanical issues. Whether you are a seasoned technician or a novice enthusiast, having the right resources at your fingertips is essential for efficient and effective work. Here are some avenues to explore when seeking detailed documentation.

Online Resources

The internet is a treasure trove of information, with numerous websites dedicated to automotive repair. Official manufacturer websites often provide downloadable documents and manuals for specific models. Additionally, forums and communities centered around vehicle enthusiasts can be invaluable for sharing insights, tips, and unofficial guides. Websites like eBay or specialized retailers also offer printed and digital versions for purchase.

Local Dealerships and Shops

Your local dealership is another reliable source for obtaining technical literature. They can provide access to proprietary information and updates specific to your vehicle’s make and model. Moreover, independent repair shops may also have collections of manuals and resources they can share, especially if they have experience with your specific vehicle type.