This section offers an in-depth overview of the essential processes involved in the upkeep and restoration of a specific type of power tool, ensuring it operates efficiently and safely. Understanding the intricacies of these machines is crucial for both novice and experienced users alike.

Regular maintenance can significantly extend the lifespan of the equipment, preventing common issues that may arise during use. This guide provides detailed instructions and tips to troubleshoot potential problems, enabling users to confidently handle their tools.

By following the outlined steps, one can enhance the performance and reliability of the device. Whether addressing minor adjustments or more significant challenges, this resource aims to empower individuals to take charge of their machinery.

Understanding the Stihl MS250 Model

This section delves into the essential characteristics and features of a popular power tool designed for cutting and trimming tasks. It highlights the aspects that make this model a favored choice among users, including its performance, ease of use, and durability. Understanding these features can enhance the user experience and ensure optimal operation.

With its powerful engine and ergonomic design, this equipment stands out in the market. The engine’s specifications contribute to its efficiency, allowing for extended use without significant fatigue. Moreover, the compact structure facilitates maneuverability, making it suitable for various applications, from home gardening to professional landscaping.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine providing robust cutting capability. |

| Weight | Lightweight design for enhanced portability. |

| Fuel Efficiency | Designed for optimal fuel consumption, extending operation time. |

| Ease of Start | Equipped with technology for straightforward starting procedures. |

| Safety Features | Integrated safety mechanisms to protect the user during operation. |

By familiarizing oneself with these attributes, users can maximize the performance and lifespan of their equipment, ensuring that it remains a reliable partner for all cutting tasks.

Common Issues with MS250 Chainsaw

Every tool may encounter specific challenges over time, leading to decreased performance or operational failures. Understanding these frequent problems can help users identify and address them swiftly, ensuring efficient use of their equipment.

Fuel-Related Problems

One prevalent issue involves the fuel system. Users may notice difficulty starting or erratic idling, often caused by stale fuel or improper fuel mixtures. Regularly replacing old fuel and ensuring the correct oil-to-gas ratio can significantly mitigate these issues.

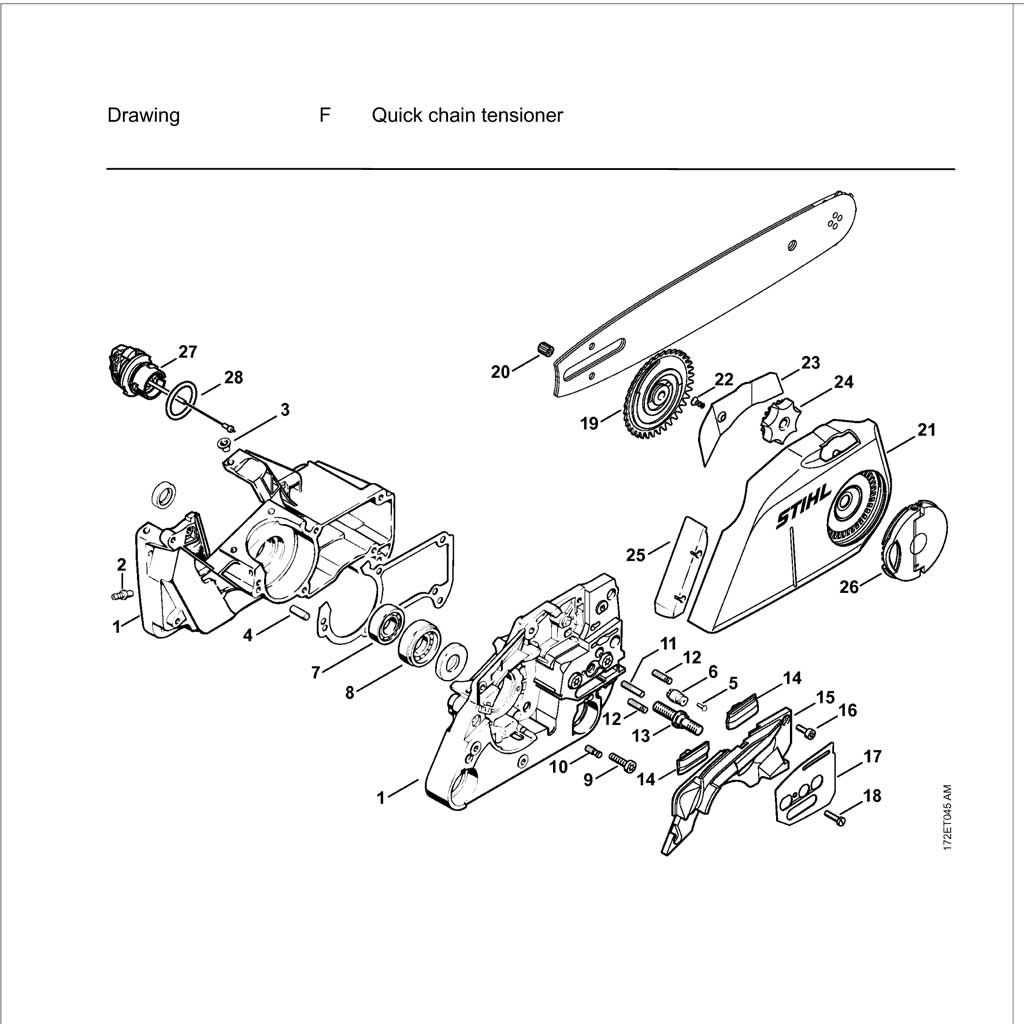

Chain Tension and Lubrication

Another common concern is related to the chain and bar. Insufficient lubrication can lead to overheating, causing the chain to stretch or wear prematurely. It’s crucial to regularly check the oil level and adjust the chain tension to maintain optimal performance and prolong the lifespan of the cutting components.

Essential Tools for Repairs

When it comes to maintaining outdoor power equipment, having the right instruments at your disposal is crucial. This section will guide you through the essential implements that ensure efficient service and troubleshooting, making your tasks smoother and more effective.

Basic Hand Tools

Start with a solid set of hand tools, which form the backbone of any maintenance kit. Wrenches, screwdrivers, and pliers are indispensable for loosening and tightening various components. A reliable torque wrench is also recommended to apply precise force, ensuring parts are secured to manufacturer specifications.

Specialized Equipment

In addition to standard tools, consider incorporating specialized devices for more complex tasks. A chain brake tool is vital for servicing cutting mechanisms, while a fuel line removal tool facilitates easier access to fuel components. Having a spark plug wrench ensures quick maintenance of the ignition system, keeping your equipment in optimal condition.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your equipment remains in optimal working condition. Regular upkeep not only enhances performance but also extends the lifespan of your tool. Following these systematic steps will help you maintain efficiency and reliability.

-

Inspect the Components:

- Examine the cutting chain for wear and damage.

- Check the air filter for dirt and debris.

- Ensure the spark plug is clean and properly gapped.

-

Clean the Exterior:

- Wipe down the outer casing to remove dirt and grime.

- Use a brush to clean any stubborn residue.

-

Lubricate Moving Parts:

- Apply lubricant to the chain and bar.

- Ensure all pivot points are properly greased.

-

Replace Worn Components:

- Change the cutting chain if it shows signs of excessive wear.

- Replace the air filter if it appears clogged.

-

Test Functionality:

- Start the machine to ensure it runs smoothly.

- Check for any unusual noises or vibrations.

By adhering to this maintenance routine, you can ensure that your equipment operates at peak efficiency, providing reliable performance for years to come.

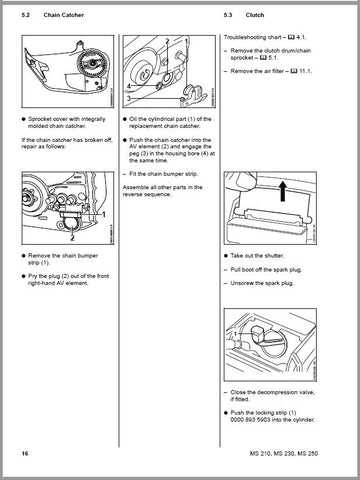

How to Replace the Chain

Changing the cutting link on your device is an essential maintenance task that ensures optimal performance and safety. This process not only enhances cutting efficiency but also prolongs the lifespan of your tool. Here, we will guide you through the necessary steps to complete this task successfully.

Preparation Steps

Before you begin, ensure you have the appropriate replacement link that matches the specifications of your device. Gather the required tools, including a wrench and a file, for a smooth procedure. Make sure the equipment is switched off and completely cooled down to prevent any accidents during the process.

Removing the Old Chain

Start by loosening the tensioning mechanism to release the existing cutting link. Carefully detach the guide bar, noting the orientation for reassembly. Gently slide off the worn-out chain, ensuring that all components are accessible for inspection and cleaning. Once removed, check for any debris or damage on the guide bar and sprocket, cleaning as necessary.

Once the old chain is removed and the area is prepared, you can proceed with installing the new cutting link by reversing the removal steps.

Adjusting the Carburetor Settings

Proper calibration of the fuel delivery system is essential for optimal performance and efficiency of your outdoor power equipment. Fine-tuning these settings can significantly enhance engine responsiveness and reduce emissions. This process involves adjusting the air-fuel mixture to ensure the engine operates smoothly under various conditions.

Understanding the Components

Before making any adjustments, it’s crucial to familiarize yourself with the main components involved in the air-fuel mixture control. Typically, there are two main screws that govern the mixture and idle speed. These components play a vital role in achieving the desired performance levels.

Adjustment Procedure

Follow these steps to effectively adjust the settings:

| Step | Action |

|---|---|

| 1 | Start the engine and allow it to warm up for a few minutes. |

| 2 | Locate the adjustment screws, typically marked as H (high) and L (low). |

| 3 | Turn the H screw clockwise to increase the fuel flow or counterclockwise to decrease it. |

| 4 | Adjust the L screw similarly for low-speed performance. |

| 5 | Test the engine under load to ensure smooth operation. |

Make small adjustments and observe the changes in performance. It may take a few tries to achieve the perfect balance for your equipment.

Cleaning the Air Filter

Regular maintenance of the air filtration system is essential for optimal engine performance. Keeping this component clean ensures proper airflow, enhances combustion efficiency, and prolongs the life of the equipment.

Steps for Cleaning

Start by removing the filter from its housing. Gently tap it against a hard surface to dislodge any loose debris. For a more thorough clean, use compressed air to blow out any stubborn particles. If the filter is excessively dirty, it may be necessary to wash it with soap and water, then allow it to dry completely before reinstallation.

Reinstallation and Maintenance Tips

After cleaning, carefully reinsert the air filtration element into its compartment, ensuring it fits snugly. Regularly check the filter for dirt accumulation, especially after extensive use, and clean it as needed to maintain performance. A well-maintained air filter can significantly improve the reliability and efficiency of your equipment.

Safety Precautions During Repairs

When undertaking maintenance on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and ensure a secure working environment.

First, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear helps shield against potential hazards, including sharp components and flying debris. Additionally, ensure your workspace is clean and organized, minimizing the chance of slips or falls.

Before beginning any task, disconnect the power source to avoid unintended operation. Familiarize yourself with the equipment’s layout and mechanisms, as understanding how parts interact is crucial for safe handling. If using tools, make sure they are in good condition and suitable for the job at hand.

Lastly, if you encounter unfamiliar issues, seek guidance from experienced individuals or consult reliable resources. Taking these precautions can enhance safety and lead to more effective maintenance practices.

Identifying Electrical Problems

Understanding the common electrical issues in your equipment is crucial for maintaining optimal performance. Electrical malfunctions can manifest in various forms, such as failure to start, erratic operation, or sudden shutoffs. Recognizing the symptoms early can save time and prevent further complications.

Begin by inspecting the power supply. Ensure that connections are secure and that the source is functioning correctly. Loose or corroded terminals can lead to inconsistent power delivery. Additionally, check the wiring for any visible signs of wear or damage, as frayed wires may cause shorts or interruptions in power.

Next, assess the ignition system. A faulty spark plug can prevent the engine from starting or lead to poor performance. Examine the spark plug for wear or deposits and replace it if necessary. Ensure that the ignition coil is providing adequate voltage; a multimeter can help in measuring output.

Finally, evaluate any electronic components that control various functions of the equipment. Problems with sensors or control modules can affect performance significantly. Testing these components for continuity and functionality will help pinpoint any underlying issues. Regular maintenance and thorough inspections can prevent electrical problems from escalating.

Troubleshooting Engine Performance

Ensuring optimal engine functionality is crucial for the reliable operation of any power tool. When performance issues arise, identifying the root causes is essential for restoring efficiency. This section explores common problems and their potential solutions to help maintain peak performance.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Poor Starting | Engine fails to start or takes multiple attempts | Check fuel quality, inspect the spark plug, and verify the ignition system. |

| Loss of Power | Unresponsive throttle or sluggish acceleration | Examine the air filter, clean the carburetor, and adjust the fuel mixture. |

| Excessive Smoke | Visible smoke during operation | Inspect the oil levels, check for oil leaks, and evaluate the fuel ratio. |

| Unusual Noises | Grinding, knocking, or rattling sounds | Inspect the muffler, check for loose components, and ensure proper lubrication. |

Addressing these issues promptly can significantly improve the overall performance of the equipment. Regular maintenance and careful observation of symptoms will aid in early detection and resolution of potential problems.

Finding Replacement Parts Online

Locating suitable components for maintenance or repair tasks can be a straightforward process when utilizing online resources. The internet offers a wide array of options, making it easier to find the necessary items to keep your equipment in optimal condition.

To effectively search for parts, consider the following strategies:

- Official Websites: Many manufacturers provide a list of compatible parts on their official sites, ensuring you find quality replacements.

- Authorized Dealers: Look for certified sellers who specialize in specific brands, as they often carry genuine items and provide expert assistance.

- Online Marketplaces: Platforms such as eBay and Amazon can be useful for sourcing both new and used components. Always check seller ratings and reviews.

- Forums and Community Groups: Engaging with enthusiasts on dedicated forums can lead to valuable recommendations for trusted suppliers and specific parts.

- Local Repair Shops: Some local establishments may have online ordering options and can help source what you need if it’s not readily available.

When searching, it’s crucial to have the model number and specifications at hand. This information helps in identifying the correct parts and ensures compatibility with your equipment.

Lastly, always compare prices across different sources. This will help you secure the best deals while ensuring quality and authenticity in your purchases.