Keeping a home tidy and fresh often requires reliable tools. Over time, these helpful devices can experience a few functional challenges, making it essential to understand effective maintenance strategies. This section provides clear steps and insights to help keep your equipment running smoothly, contributing to a cleaner and more comfortable living space.

Regular upkeep not only extends the lifespan of your device but also enhances its efficiency. Small adjustments and routine care can prevent the need for more extensive repairs down the line. Here, you’ll find practical advice and troubleshooting tips to address common issues, ensuring that your cleaning helper performs at its best.

Whether you’re dealing with minor malfunctions or aiming to improve overall performance, this guide offers straightforward solutions. From simple adjustments to essential component checks, every step is designed to empower you in maintaining your essential home cleaning appliance without unnecessary hassle.

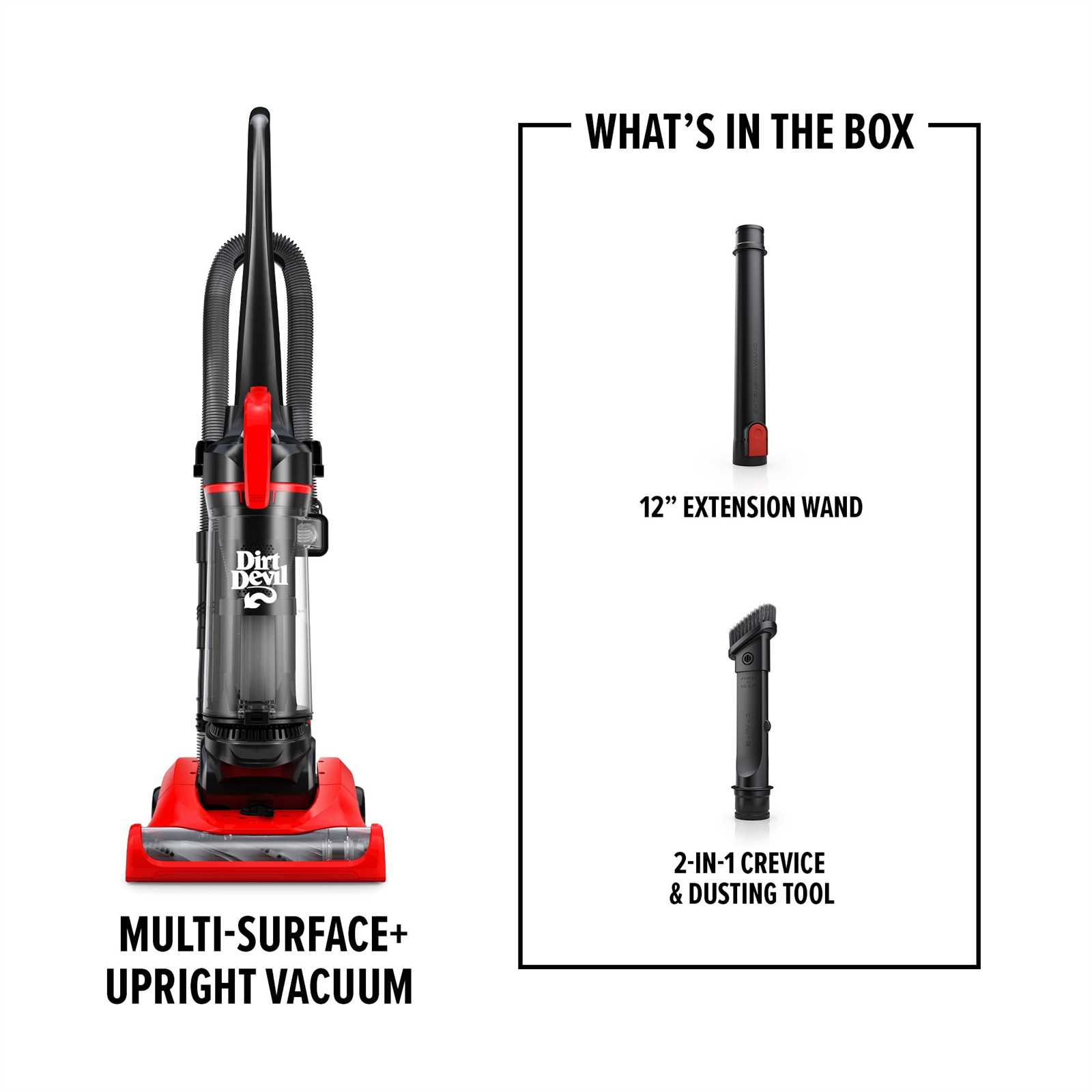

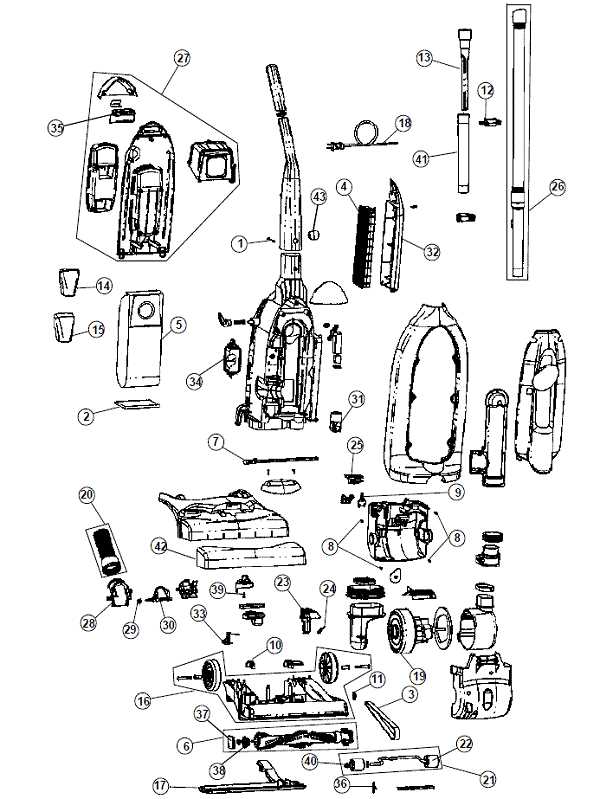

Understanding Dirt Devil Vacuum Components

To maintain optimal performance, it is essential to understand the various parts and mechanisms within a household cleaning device. Each component plays a crucial role in ensuring efficient operation, contributing to the overall effectiveness of the cleaning tool.

Primary Internal Mechanisms

The internal setup of a cleaning appliance generally includes a motor, filtration system, and collection chamber. The motor generates the power needed to create the suction force, while the filtration system ensures that dirt and dust particles are trapped securely, maintaining indoor air quality. The collection chamber holds the debris, which can be easily emptied for regular upkeep.

Exterior and Attachment Elements

Externally, components such as the power switch, handle, and brush attachments are essential for ease of use and functionality. Adjustable brushes or nozzles help target different surfaces, allowing users to reach both open and narrow spaces effectively. Regular inspection of these external elements ensures better control and maneuverability during operation.

Common Issues with Dirt Devil Vacuums

Many household floor-cleaning devices can encounter a range of common issues over time. Understanding these typical problems can help identify solutions quickly, keeping your device running smoothly without interruptions.

One frequent challenge is the loss of suction power, often caused by blockages in the airways or clogged filters. Checking these areas and cleaning them regularly can restore proper function.

Another issue users might face is unusual noise during operation. This can stem from lodged debris or worn-down parts inside the device. Routine maintenance and part replacement as necessary help in minimizing noise and maintaining performance.

Sometimes, there may be problems with the device’s movement across certain surfaces. Inspecting the brush roll for tangles or damage and ensuring that wheels are free from obstructions can improve maneuverability.

Finally, power-related difficulties, such as inconsistent operation or sudden shutdowns, might signal electrical or battery concerns. Verifying connections and battery life periodically can prevent these malfunctions.

Steps to Diagnose Vacuum Problems

Identifying the root cause of issues in a home cleaning device can be straightforward if approached methodically. By following a series of steps, common problems can be pinpointed, enabling an informed decision on further actions.

- Check for Obstructions

Look for any visible blockages in the air passageways, such as hoses, filters, or nozzles. Clogs are often the primary cause of reduced performance, so ensure that pathways are clear.

- Inspect the Filtration System

Over time, filters can accumulate dirt, reducing efficiency. Take out and examine filters, ensuring they are clean or replaced according to the recommended schedule.

- Test Suction Power

After verifying that the device is free of blockages, switch it on and test the suction. A significant drop in strength could indicate an internal issue that may require professional attention.

- Examine Moving Parts

Look over parts such as belts and brushes, as they are prone to wear and may affect cleaning efficiency. Replacing or adjusting these components may resolve persistent issues.

Replacing the Vacuum Belt

The belt is a crucial part of any cleaning equipment, connecting the motor to the brush roll to ensure efficient floor care. Over time, belts can wear out, resulting in decreased performance. Here’s a simple guide to replacing it effectively.

- Unplug the device to ensure safety.

- Locate the bottom cover on the base; remove any screws holding it in place.

- Carefully remove the cover to access the belt and brush roll area.

- Slide the brush roll out and gently remove the worn belt from both the motor shaft and brush roll.

- Align the new belt with the motor shaft, then loop it around the brush roll.

- Position the brush roll back into place, ensuring the belt has a secure fit.

- Replace the bottom cover, secure it with screws, and test the device.

Regular belt replacement can significantly improve cleaning results and prolong the machine’s service life.

Cleaning the Vacuum Filter Effectively

Maintaining a clean filter is essential for ensuring efficient performance and prolonging the lifespan of your appliance. Regular upkeep prevents blockages that can reduce airflow, thus enhancing the overall operation of your equipment.

Step-by-Step Guide to Filter Cleaning

Start by removing the filter from its compartment, taking care to follow the device’s instructions. Rinse the filter gently with warm water to remove accumulated dust and particles. Avoid harsh chemicals, as they may damage the filter material. Let it air dry completely before reattaching it, ensuring it is free of moisture to prevent mildew or odor buildup.

Tips for Maintaining Optimal Filter Condition

For best results, clean the filter every few uses, especially if the device is used frequently or in dusty areas. If the filter becomes heavily worn or damaged, replace it promptly to maintain effective operation. Periodic maintenance will help the appliance function smoothly, providing consistent performance for a longer period.

Fixing Suction Problems

When an appliance loses its ability to effectively draw in debris, it can lead to subpar cleaning performance. Identifying and addressing the underlying issues is essential to restore functionality. Various factors may contribute to this problem, and understanding these can simplify the troubleshooting process.

Common causes of inadequate suction include:

- Clogs: Obstructions in the hose, filters, or brush can restrict airflow.

- Filter Issues: Dirty or worn filters can hinder performance.

- Seal Failures: Leaks in the unit’s seals may lead to air loss.

- Brush Roll Problems: A malfunctioning brush can reduce effectiveness.

To address suction issues, consider the following steps:

- Inspect Hoses: Check for blockages and clear any debris.

- Replace Filters: Clean or replace filters as necessary to ensure optimal airflow.

- Examine Seals: Look for any signs of wear or damage and replace seals if needed.

- Check Brush Roll: Ensure the brush roll is functioning correctly and free of hair or tangles.

Regular maintenance and prompt attention to these areas can help keep the appliance running smoothly and enhance its efficiency.

Removing Clogs from the Hose

Ensuring the proper functioning of your cleaning device often involves addressing blockages within the hose. Over time, debris can accumulate, leading to reduced performance and efficiency. Understanding how to effectively clear these obstructions can enhance the overall cleaning experience.

To begin, disconnect the hose from the main unit, ensuring that any power source is turned off. Inspect the hose visually for any noticeable blockages. If a clog is visible, gently maneuver the hose to dislodge the debris. In cases where the blockage is deeper, using a long, flexible object, like a broom handle, can help push through stubborn materials.

If physical methods do not yield results, consider utilizing a mixture of warm water and mild detergent. Pour this solution into the hose, allowing it to sit for a few minutes before rinsing thoroughly with clean water. This approach can help break down any remaining residue. Always ensure the hose is completely dry before reattaching it to the main device.

Repairing the Power Cord

Addressing issues with the electrical cord is essential for ensuring optimal functionality of your cleaning device. A faulty cord can lead to interruptions during operation and potential safety hazards. This section outlines key steps and considerations for restoring the integrity of the power cord.

First, ensure that the device is unplugged before any examination or modification of the cord. Inspect the entire length of the cord for visible signs of damage, such as fraying or cuts. If the cord appears compromised, replacement may be necessary. For minor issues, a proper repair technique can extend its lifespan.

Step Description 1 Unplug the device to avoid electrical shock. 2 Inspect the cord thoroughly for any signs of wear or damage. 3 If the cord is damaged, carefully cut away the affected section. 4 Strip the insulation from the ends of the cord using appropriate tools. 5 Twist the corresponding wires together and secure them with electrical tape. 6 Wrap the repaired section with additional insulation to ensure safety. Following these steps can help restore functionality to the cord, ensuring a safe and efficient operation of the appliance. Always prioritize safety and consult a professional if uncertain about any repair processes.

Motor Troubleshooting for Dirt Devil

This section provides guidance on diagnosing and resolving issues related to the motor unit of your cleaning device. Understanding common problems can help you maintain optimal performance and extend the life of the equipment.

Below are some typical symptoms along with possible causes and solutions:

Symptom Possible Cause Solution No power Faulty power cord or connection Check and replace the power cord if damaged; ensure secure connections. Overheating Clogged filters or debris Inspect and clean the filters and remove any blockages. Unusual noise Worn bearings or motor issues Examine the motor for wear; lubricate or replace as necessary. Low suction power Full dust container Empty the dust container and clean any filters. By following these guidelines, you can effectively troubleshoot motor-related issues and ensure your cleaning appliance operates smoothly.

Brush Roller Maintenance Guide

Proper upkeep of the brush roller is essential for ensuring optimal performance and longevity. Regular maintenance prevents dust and debris buildup, which can hinder efficiency and lead to more significant issues over time.

- Regular Inspection: Check the brush roller frequently for wear and tear. Look for any frayed bristles or signs of damage.

- Cleaning: Remove hair, fibers, and debris that may have accumulated around the brush. Use scissors or a tool to cut through any tangled material carefully.

- Lubrication: Apply a small amount of lubricant to the ends of the brush roller to ensure smooth rotation. Avoid excess, as it can attract more dirt.

- Replacement: If the bristles are excessively worn or the roller is damaged, consider replacing it. Follow the manufacturer’s guidelines for suitable replacement parts.

By following these maintenance steps, you can enhance the functionality and lifespan of the brush roller, ensuring consistent performance in cleaning tasks.

Resetting Overheating Safeguards

When a cleaning device experiences excessive heat, it often activates built-in protective features to prevent damage. These safeguards are crucial for maintaining the longevity and functionality of the appliance. Understanding how to reset these mechanisms can help restore normal operation and ensure effective performance.

Identifying Overheating Signs

Common indicators of overheating include unusual smells, a decrease in suction power, or the device shutting off unexpectedly. If you notice any of these symptoms, it is essential to allow the machine to cool down before proceeding with the reset.

Steps to Reset the Device

To initiate the reset process, first unplug the appliance from the power source. Wait for at least 30 minutes to allow it to cool completely. After this period, plug the unit back in and turn it on. If the overheating safeguard remains activated, check for blockages in filters or hoses, as these can contribute to overheating.

Regular Maintenance is vital for preventing overheating issues. Cleaning filters and ensuring proper airflow can significantly reduce the risk of encountering this problem in the future.

Choosing Replacement Parts

When it comes to maintaining the efficiency of your cleaning device, selecting the right components is essential. Using quality parts ensures optimal performance and longevity, minimizing future issues.

Start by identifying the specific elements that need replacement. This may include filters, belts, or brushes. Check compatibility with your device model, as using non-matching parts can lead to malfunction or damage.

Researching options is crucial. Look for reputable brands that offer durable components. Consider customer reviews and ratings to gauge the reliability of the parts.

Moreover, it’s beneficial to compare prices across various suppliers. Sometimes, you can find the same part at a better price, allowing for cost-effective maintenance without sacrificing quality.

Lastly, when making a purchase, ensure that the parts come with a warranty. This provides added security, knowing that you can seek a replacement if the part fails prematurely.

Essential Tools for Vacuum Repairs

Having the right equipment is crucial when addressing issues in cleaning devices. A well-equipped toolkit allows for efficient troubleshooting and maintenance, ensuring optimal performance of these appliances. Below are key instruments that can assist in restoring functionality.

Basic Hand Tools

Standard hand tools are fundamental for any maintenance task. A screwdriver set with various heads enables easy access to different screws. Pliers and wrenches are also necessary for handling components securely. These tools facilitate straightforward disassembly and reassembly processes.

Specialized Instruments

In addition to standard tools, specialized instruments can enhance repair efficiency. A multimeter helps diagnose electrical issues, while a brush for debris removal ensures thorough cleaning of internal parts. Furthermore, a flashlight can illuminate dark areas, allowing for better visibility during inspections.