In this guide, you’ll find essential insights into keeping specialized landscaping machinery in top condition. Consistent care and understanding of the machine’s components can extend its lifespan, ensure reliable performance, and reduce downtime. This section provides a thorough look at how to approach upkeep with a focus on efficiency and durability.

Maintenance Tips for Longevity: By familiarizing yourself with the regular checks and adjustments needed, you’ll be better prepared to handle routine service tasks with ease. From adjusting essential parts to understanding optimal operating conditions, these tips help maintain high functionality.

Troubleshooting and Common Challenges: Learn how to address typical issues that may arise, from minor wear to more complex situations. This section explores practical solutions, empowering you to address and prevent potential challenges efficiently, saving both time and resources in the long run.

Wright Stander Repair Manual

This section provides a comprehensive guide to maintaining and troubleshooting key mechanical issues for standing mowers, focusing on optimal performance and longevity. Here, you will find useful insights to identify and resolve common functional challenges, ensuring smooth operation and minimal downtime.

Common Mechanical Checks

Regular inspections can prevent major issues and help you avoid costly repairs. Ensure to check these components frequently to keep your machine running efficiently:

- Engine Oil: Monitor and change oil based on usage frequency to prevent overheating and maintain engine health.

- Blades: Sharpen and balance periodically for efficient and precise cutting.

- Belt Condition: Look for wear or damage on belts to avoid slippage and ensure proper power transmission.

- Air Filter: Clean or replace regularly to maintain engine airflow and reduce dust buildup.

Troubleshooting Frequent Issues

If you encounter recurring issues, consider the following troubleshooting steps for effective solutions:

- Starting Problems: Check the fuel level, spark plug condition, and battery charge to ensure the machine powers up reliably.

- Vibrations: Inspect blade alignment and wheel balance to reduce shaking and ensure steady operation.

Key Components Overview

This section provides an in-depth look at the primary elements essential for the optimal performance and reliability of a riding mower. Understanding these components and their roles is crucial for ensuring smooth operation and preventing unexpected downtime.

Engine and Transmission

The engine powers the entire unit, and its efficient functioning directly impacts performance. The transmission, on the other hand, translates this power into movement, ensuring smooth transitions and control. Proper maintenance of both is necessary for overall efficiency.

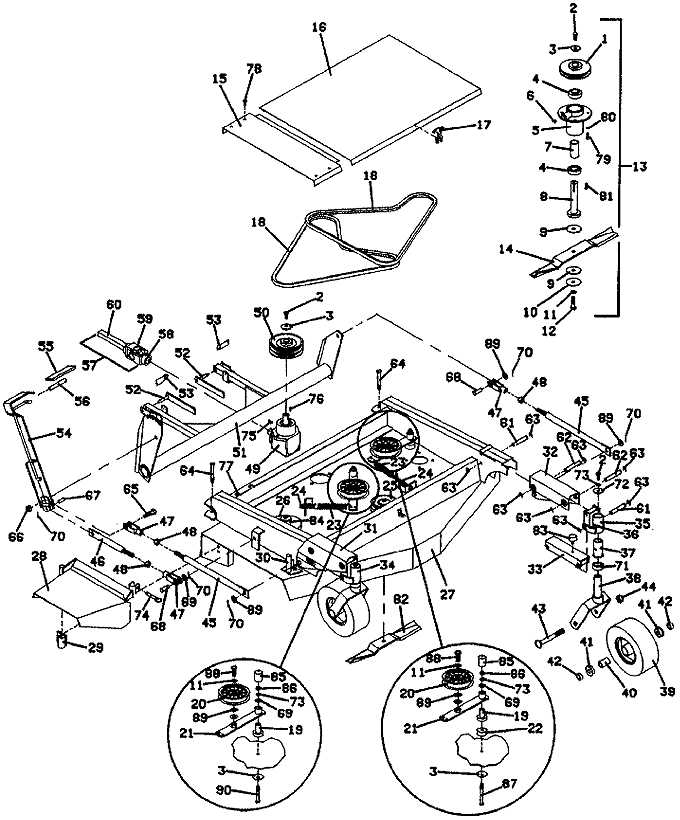

Cutting Deck Assembly

The cutting deck is responsible for the actual grass-cutting process, housing the blades and enabling height adjustments. This assembly needs regular inspection to maintain blade sharpness and alignment for precise cutting.

- Blades: Sharp and balanced blades are essential for a clean cut and preventing turf damage.

- Deck Shell: Provides a housing that protects and supports the blades, ensuring safety and stability.

- Height Adjusters: Allow the operator to set the preferred cutting height, adapting to various terrains and grass types.

Familiarizing oneself with these key components enables a more thorough understanding of mower functionality and aids in timely maintenance and troubleshooting.

Routine Maintenance Essentials

Regular upkeep ensures equipment remains dependable and operates at peak performance. Consistent care minimizes unexpected issues and prolongs the lifespan of essential components. By adhering to a structured maintenance schedule, operators can prevent common mechanical problems and maintain efficiency.

Key elements of routine maintenance include frequent checks on oil levels, filters, and belts. Clean filters contribute to optimal airflow, while well-lubricated parts prevent wear. Monitoring these parts regularly helps in identifying early signs of wear or damage before they become costly repairs.

In addition, tire inspections are crucial, as correct pressure ensures stable movement and reduces strain on other components. Tightening bolts and inspecting electrical connections can also prevent vibrations and malfunctions. Such attention to detail ensures consistent functionality and enhances overall safety during operation.

Following these essential practices fosters durability and reliability, ensuring equipment is always ready for use. A proactive approach to maintenance saves time and expense, reducing the risk of prolonged downtimes and costly overhauls.

Engine Troubleshooting Guide

In this section, we explore methods for diagnosing common engine issues, helping to identify and address typical causes of engine malfunctions. Following a structured approach can make it easier to detect problems early and ensure smooth operation.

Signs of Common Engine Issues

Engine problems often manifest through specific symptoms. Pay attention to unusual noises, unexpected vibrations, or issues such as starting difficulties. Recognizing these indicators early can prevent further complications.

Initial Inspection Steps

Begin troubleshooting by inspecting basic components. Check the fuel levels and filter conditions, ensuring that both are clean and in good working order. Additionally, confirm that the spark plugs are functional and correctly aligned, as misalignment can lead to ignition problems.

Battery and Electrical Connections

Engine performance can be hindered by poor electrical connections. Ensure the battery terminals are clean and firmly connected. Examine all electrical wiring for any signs of wear, as faulty connections can disrupt engine functionality.

Fuel System Maintenance

Hydraulic System Checks

Regular inspection of the hydraulic system is crucial to ensure efficient performance and to prevent unexpected malfunctions. This process involves examining fluid levels, checking for any signs of wear, and assessing the general condition of components such as hoses and connections.

Inspecting Fluid Levels

Hydraulic fluid levels should be checked periodically to maintain optimal functionality. Low fluid levels can lead to reduced efficiency and potential damage to the system. Use the recommended fluid type and ensure that levels are kept within specified limits.

Assessing Hoses and Connections

Hoses and connectors should be carefully inspected for any signs of leaks, wear, or damage. Over time, these parts can deteriorate, which may lead to fluid loss and reduced pressure. Replace any worn-out or cracked hoses immediately to keep the system running smoothly.

Electrical Fault Solutions

When dealing with electrical issues in mobility devices, it’s essential to identify and resolve the underlying problems effectively. Common challenges may arise from faulty connections, damaged components, or improper settings. This section outlines various strategies to troubleshoot and rectify these electrical faults, ensuring optimal performance and safety.

Begin by inspecting the power source. Ensure that batteries are fully charged and connections are secure. Loose or corroded terminals can lead to power loss, resulting in malfunction. If the device fails to start, consider testing the battery voltage with a multimeter to confirm its integrity.

If issues persist after checking the power supply, examine the wiring harness for signs of wear or damage. Frayed wires can cause short circuits, leading to erratic behavior or complete failure. Replacing damaged wires promptly can restore functionality.

In cases where components such as switches or motors are involved, it’s crucial to verify their operation. Testing switches for continuity can reveal faults that prevent the system from functioning correctly. Similarly, motors may require inspection for signs of overheating or blockage.

Additionally, software or control system errors can contribute to electrical malfunctions. Resetting the device or updating firmware may resolve these issues. If the problem remains, consult technical specifications for further diagnostics.

Blade Adjustment Techniques

Properly adjusting the cutting components is crucial for achieving optimal performance and a clean finish. This process ensures that the blades operate at their best, providing an even cut while extending the lifespan of the equipment.

Here are some effective techniques for adjusting the cutting edges:

- Height Adjustment: Ensure the blades are set to the correct height for the type of grass or terrain being mowed. This can typically be adjusted through levers or knobs.

- Leveling the Blades: Check that the blades are level relative to the ground. Uneven blades can lead to an inconsistent cut and may require adjustments at the mounting points.

- Tightening Bolts: Regularly inspect and tighten the bolts that secure the blades to prevent any wobbling or misalignment during operation.

- Sharpening the Blades: Keep the cutting edges sharp for better performance. Dull blades can tear the grass rather than cut it cleanly, requiring more frequent adjustments.

By regularly performing these adjustments, users can ensure that the cutting mechanism functions efficiently, leading to a well-maintained lawn and enhanced machine longevity.

Deck Height Calibration

Proper adjustment of the deck height is essential for optimal performance and efficiency. This process ensures that the cutting mechanism operates at the appropriate distance from the ground, allowing for an even cut and preventing damage to the turf. Accurate calibration not only improves the quality of the cut but also prolongs the lifespan of the equipment.

To achieve precise deck height settings, start by identifying the desired height based on the type of grass and the specific conditions of the lawn. It’s crucial to use a reliable measuring tool to verify the height accurately. Begin the adjustment by loosening the necessary bolts or knobs on the deck and raising or lowering it as needed. Once the height is set, retighten the hardware securely to maintain stability during operation.

Regular checks are advised to ensure that the deck height remains consistent over time, especially after heavy use or maintenance. Performing these calibrations will contribute to a healthier lawn and enhance the overall functionality of the machinery.

Replacing Worn Out Parts

Over time, certain components in equipment may become ineffective or damaged due to regular use. Recognizing the need for replacements is crucial for maintaining optimal functionality and ensuring safety during operation. This section will guide you through the process of identifying and substituting these essential parts effectively.

When it comes to replacing parts, the following steps should be considered:

| Step | Description |

|---|---|

| 1 | Assess the condition of each component regularly to determine if a replacement is necessary. |

| 2 | Gather the required tools and replacement items before beginning the substitution process. |

| 3 | Follow manufacturer guidelines for removing the old parts, ensuring safety measures are in place. |

| 4 | Install the new components carefully, verifying that they are compatible and secure. |

| 5 | Test the equipment post-replacement to confirm that it operates correctly and efficiently. |

Fuel System Cleaning Tips

Maintaining a clean fuel system is essential for optimal engine performance and longevity. Regular cleaning helps to remove deposits and contaminants that can hinder fuel flow and affect combustion efficiency. Here are some effective strategies to ensure your fuel system remains in top condition.

- Use Quality Fuel: Always choose high-quality fuel from reputable sources to minimize the introduction of impurities.

- Regular Fuel Filter Replacement: Change the fuel filter according to the manufacturer’s recommendations to keep contaminants from entering the fuel system.

- Fuel Additives: Consider using fuel system cleaners that are compatible with your engine. These products can help dissolve carbon buildup and prevent clogs.

- Inspect Fuel Lines: Regularly check fuel lines for signs of wear or damage. Replace any that show cracks or leaks to prevent contamination.

- Clean Injectors: Utilize injector cleaning kits to remove deposits from fuel injectors. This can significantly improve fuel atomization and performance.

By implementing these practices, you can enhance the efficiency and reliability of your engine, ensuring it operates smoothly and effectively over time.

Seasonal Maintenance Checklist

Regular upkeep of your equipment is crucial to ensure optimal performance and longevity. By following a structured maintenance schedule throughout the year, you can prevent potential issues and enhance the efficiency of your machinery. This checklist serves as a guide for essential tasks to be performed in each season.

Spring Maintenance Tasks

- Inspect all components for wear and tear.

- Clean and lubricate moving parts to reduce friction.

- Check hydraulic systems for leaks and proper fluid levels.

- Test safety features to ensure they are functioning correctly.

Fall Maintenance Tasks

- Remove debris and clean the exterior surfaces thoroughly.

- Examine electrical connections and replace any frayed wires.

- Inspect tires for proper inflation and tread wear.

- Store the equipment in a dry, sheltered area to protect it from harsh weather.

By adhering to this seasonal checklist, you can maintain your equipment in peak condition, ensuring reliability and performance throughout its lifespan.

Storage Preparation Guidelines

Properly preparing equipment for storage is essential to ensure longevity and optimal performance when it is put back into use. This process involves several key steps to protect the equipment from environmental factors and wear during periods of inactivity.

Cleaning and Maintenance

Before storing the equipment, it is crucial to clean and perform necessary maintenance. Follow these steps:

- Remove any dirt, debris, or residue from surfaces.

- Inspect all parts for wear or damage and replace if necessary.

- Lubricate moving components to prevent rust and corrosion.

Storage Environment

Choosing the right environment for storage can significantly affect the condition of the equipment. Consider the following factors:

- Store in a cool, dry place to prevent moisture buildup.

- Avoid direct sunlight to minimize fading and heat damage.

- Ensure proper ventilation to prevent the accumulation of harmful gases.