This section aims to provide essential insights into the upkeep and servicing of a popular two-wheeled vehicle. By understanding the mechanics and features, users can ensure optimal performance and longevity.

Familiarity with the various components and systems is crucial for effective management. Detailed instructions and guidance will facilitate the identification of common issues and the application of appropriate solutions.

Whether you’re an enthusiast or a casual user, having access to systematic advice enhances the overall experience. Equip yourself with the knowledge necessary to tackle challenges and maintain functionality.

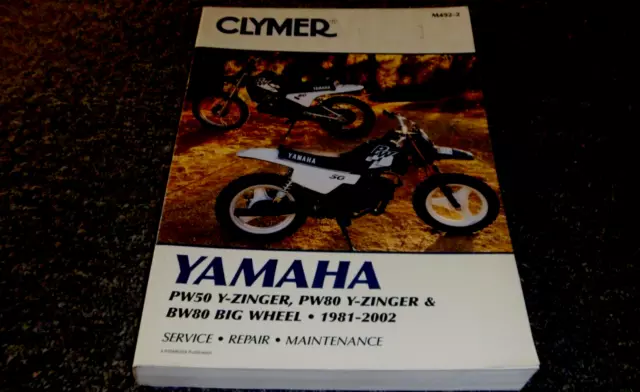

Understanding the Yamaha PW50

This section delves into the essential components and mechanisms of a popular small motorcycle designed for beginners. By exploring its design and functionality, we can gain insights into how to maintain and enhance performance effectively.

Key aspects to consider include:

- Engine Specifications: Understanding the power unit’s features and how they impact overall performance.

- Transmission System: Examining the gear setup and how it influences speed and handling.

- Chassis Design: Assessing the structural elements that contribute to stability and rider comfort.

- Electrical Components: Identifying the critical wiring and battery systems that ensure proper operation.

For enthusiasts and newcomers alike, familiarizing oneself with these elements is vital for effective upkeep and troubleshooting. Each aspect plays a crucial role in delivering a smooth riding experience and maximizing the longevity of the vehicle.

Common Issues with the PW50

When it comes to maintaining small two-wheeled vehicles, certain challenges frequently arise. Understanding these common problems can help owners address issues promptly and keep their machines in optimal condition. Below are some typical concerns that may affect performance and reliability.

Engine Performance Problems

One prevalent issue is engine performance degradation. This can manifest as difficulty starting or irregular idling. Factors contributing to this may include clogged fuel filters, dirty air filters, or improper fuel mixture. Regular maintenance and inspections are crucial to ensure smooth operation.

Electrical System Malfunctions

Another frequent concern relates to the electrical system. Components such as the ignition system may fail, leading to starting difficulties. Additionally, battery-related issues can hinder performance. Checking connections and ensuring the battery is in good condition can mitigate these problems.

Tools Needed for Repairs

Proper maintenance and fixing of any mechanical device require a specific set of instruments. Having the right tools at hand can greatly enhance the efficiency of the process and ensure that tasks are completed with precision. Below is a list of essential items that will assist in addressing common issues and performing regular upkeep.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For various types of screws, essential for disassembly. |

| Socket Set | Provides versatility in fastening tasks. |

| Plier Set | Useful for gripping and bending materials. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Multimeter | For electrical diagnostics and troubleshooting. |

| Cleaning Supplies | For maintaining cleanliness and functionality of parts. |

Step-by-Step Maintenance Guide

Proper upkeep of your two-wheeled vehicle is essential for ensuring its longevity and optimal performance. This guide provides a systematic approach to routine checks and essential tasks that every owner should perform regularly. By following these steps, you can enhance the reliability and efficiency of your machine.

Essential Tools and Supplies

Before starting the maintenance process, gather the necessary tools and materials. This preparation will facilitate a smooth and efficient maintenance session.

| Tool/Supply | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Adjusting various components |

| Oil | Lubricating moving parts |

| Air Filter | Replacing for better airflow |

| Spark Plug | Checking and replacing for optimal ignition |

Maintenance Steps

Follow these steps for thorough maintenance:

- Check and change the engine oil regularly to ensure smooth operation.

- Inspect the air filter and clean or replace it as necessary to maintain airflow.

- Examine the brake system for wear and adjust or replace components as needed.

- Inspect tires for proper inflation and tread wear, replacing them when necessary.

- Check the battery terminals for corrosion and ensure a secure connection.

Engine Troubleshooting Techniques

Identifying issues within a power unit requires a systematic approach that helps isolate the problem effectively. By employing specific techniques, one can enhance the diagnostic process and ensure that repairs are both efficient and accurate.

The following table outlines common symptoms, possible causes, and recommended solutions for troubleshooting engine issues:

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|

| Hard to start | Weak battery or faulty starter | Check battery charge and connections; replace if necessary. |

| Excessive smoke | Oil leaking into the combustion chamber | Inspect gaskets and seals; replace any damaged components. |

| Unusual noises | Worn or damaged internal components | Perform a thorough inspection of the engine; consider professional assistance. |

| Loss of power | Clogged fuel filter or air intake | Replace or clean filters and ensure proper airflow. |

Implementing these troubleshooting techniques can significantly aid in diagnosing and resolving common issues that arise within the engine, ultimately leading to improved performance and longevity.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of a vehicle is crucial for ensuring optimal performance and longevity. This process involves a systematic approach to identifying and resolving malfunctions that can impact the overall functionality of the machine.

Common Symptoms of Electrical Issues

- Difficulty starting the engine

- Inconsistent lighting or flickering lights

- Unresponsive electrical components

- Frequent blown fuses

Diagnostic Steps

- Visual Inspection: Examine wiring for signs of wear, damage, or corrosion.

- Test the Battery: Use a multimeter to check voltage and ensure it meets specifications.

- Inspect Fuses: Check for blown fuses and replace them if necessary.

- Evaluate Components: Test switches, relays, and other electrical parts for proper operation.

- Monitor Voltage Levels: Ensure that the voltage at various points in the system is within acceptable ranges.

By following these diagnostic procedures, one can effectively troubleshoot and rectify electrical concerns, ensuring the machinery operates reliably and efficiently.

Brake and Suspension Adjustments

Proper adjustment of braking and suspension systems is crucial for optimal performance and safety. Ensuring that these components are finely tuned not only enhances the riding experience but also contributes to the longevity of the vehicle. This section will guide you through the essential steps to achieve the right settings for both brakes and suspension.

Start by inspecting the brake system for any wear and tear. Adjust the brake lever to ensure it engages smoothly and provides sufficient stopping power. If necessary, replace worn-out pads or shoes, and ensure that the cables or hydraulic lines are functioning correctly. Regular maintenance of the braking components is vital for effective operation.

Next, focus on the suspension settings. Check the alignment and overall condition of the forks and shocks. Adjust the preload and damping settings according to the rider’s weight and riding style. A well-tuned suspension can significantly improve handling and stability, allowing for a more enjoyable ride on various terrains.

Lastly, always test the adjustments in a safe environment before heading out on the road. Fine-tuning these systems will not only enhance performance but also ensure a safer riding experience.

Carburetor Cleaning and Tuning

Maintaining optimal performance of a small engine requires regular attention to its fuel delivery system, particularly the carburetor. This component is crucial for mixing air and fuel in the right proportions, ensuring efficient combustion. Proper cleaning and tuning can enhance engine responsiveness and prolong its lifespan.

Steps for Cleaning the Carburetor

To effectively clean the fuel delivery system, follow these steps:

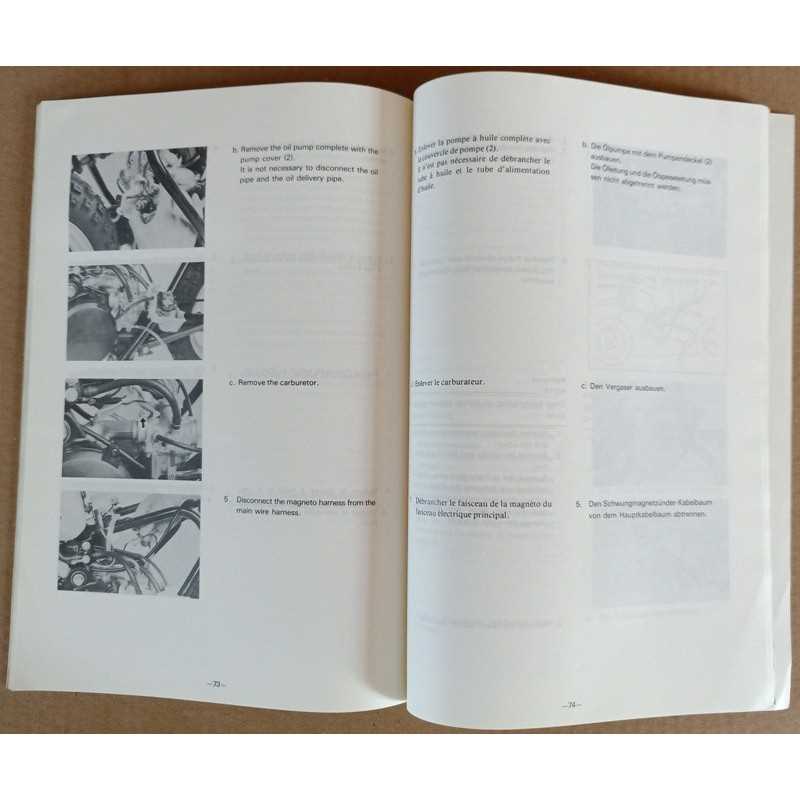

- Gather Necessary Tools: Ensure you have a cleaning solution, screwdriver set, and brushes.

- Remove the Carburetor: Carefully detach it from the engine, taking note of the connections.

- Disassemble the Unit: Take apart the carburetor to access all internal components.

- Clean the Parts: Use a specialized cleaner to remove any buildup and debris. Pay special attention to jets and passages.

- Inspect Components: Look for wear or damage and replace parts if necessary.

- Reassemble the Carburetor: Carefully put all components back together, ensuring proper alignment.

- Reattach to Engine: Securely reconnect the carburetor to the engine, ensuring no leaks.

Tuning the Carburetor

After cleaning, tuning the system is essential for optimal performance. Consider the following adjustments:

- Idle Speed: Adjust the idle screw to achieve a stable running speed when the engine is warm.

- A/F Mixture: Fine-tune the air-fuel mixture for smooth acceleration and reduced emissions.

- Throttle Response: Test the throttle to ensure it reacts promptly without hesitation.

- Final Check: After adjustments, perform a test run to ensure the engine operates smoothly and efficiently.

Chain and Sprocket Maintenance

Proper upkeep of the drive system is essential for optimal performance and longevity. Regular attention to the chain and sprockets can prevent wear and ensure smooth operation, enhancing the overall efficiency of the vehicle.

Inspection and Adjustment

Begin by checking the chain for signs of wear or damage. Look for any kinks, rust, or excessive looseness. If the chain appears too loose, it should be adjusted according to the manufacturer’s specifications. Maintaining the correct tension is crucial to avoid premature wear of both the chain and the sprockets.

Lubrication

Regular lubrication of the chain is vital to reduce friction and wear. Use an appropriate lubricant designed for chains, applying it evenly along the length of the chain while ensuring that excess is wiped away. This practice will help maintain the integrity of both the chain and the sprockets, providing a smoother and more reliable ride.

Bodywork and Frame Inspection

Thorough examination of the external structure and support system is crucial for ensuring the longevity and performance of any vehicle. Proper assessment can help identify any damage, misalignment, or wear that may affect functionality and safety. Regular checks are essential to maintain integrity and prevent further issues.

Visual Assessment

Begin by visually inspecting the outer casing for any signs of cracks, dents, or corrosion. Look for areas where the paint may be chipped or flaking, as this can indicate underlying problems. Pay close attention to joints and seams, ensuring they are secure and free from any separation.

Structural Integrity

Next, assess the frame for straightness and stability. Use a level or straight edge to determine if the frame is aligned properly. Check all mounting points and connections to ensure they are tight and free from rust or damage. Address any issues promptly to maintain optimal performance and safety.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for both the technician and the equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries during the process. It is essential to create a secure working environment and be aware of potential hazards that may arise.

Personal Protective Equipment

Using appropriate personal protective gear is a fundamental step. Items such as gloves, goggles, and masks should be worn to safeguard against chemical exposure, debris, and other harmful elements. Ensuring that all safety equipment is in good condition enhances protection during the task.

Work Environment Considerations

Maintaining a clean and organized workspace is vital. Remove any unnecessary tools and materials from the area to minimize the risk of accidents. Additionally, ensure proper ventilation when working with hazardous substances. Keep flammable materials away from the work zone to prevent fire hazards.

Upgrades for Improved Performance

Enhancing the functionality of your two-wheeled vehicle can lead to a more exhilarating ride and increased efficiency. Various modifications can be implemented to achieve better acceleration, handling, and overall performance. Below are some popular upgrades that enthusiasts often consider.

| Upgrade | Description | Benefits |

|---|---|---|

| Performance Exhaust | Replacing the stock exhaust system with a high-flow option can reduce back pressure. | Increased horsepower and a more aggressive sound. |

| Rejetting the Carburetor | Adjusting the fuel mixture to optimize combustion after other upgrades. | Better throttle response and improved fuel efficiency. |

| Upgraded Air Filter | Installing a high-performance air filter for enhanced airflow. | Improved engine breathing, resulting in better power output. |

| Adjustable Suspension | Upgrading to adjustable forks and shocks for personalized ride quality. | Enhanced stability and comfort during rides. |

Where to Find Replacement Parts

Finding suitable components for your vehicle is essential for maintaining its performance and longevity. Numerous sources can provide the necessary items, ensuring that your machine remains in optimal condition.

Here are some reliable options to consider:

- Authorized Dealers: Visiting official dealerships guarantees access to original equipment manufacturer (OEM) parts that meet the exact specifications.

- Online Retailers: Websites dedicated to parts sales often stock a wide range of items, making it convenient to compare prices and availability.

- Local Auto Shops: Many automotive parts suppliers offer a variety of components. Engaging with local businesses can also provide personalized service and advice.

- Second-hand Markets: Platforms such as online marketplaces or salvage yards may have used parts at reduced prices. Be sure to verify their condition before purchase.

- Specialty Stores: Shops focusing on specific brands or types of vehicles can be excellent resources for hard-to-find components.

Always ensure to check compatibility and quality before making a purchase to avoid future issues. Keeping a list of required parts can also streamline the search process, allowing for a more efficient procurement experience.